Electronic helical accelerator

An accelerator and helical technology, applied in the field of electron helical accelerators, can solve the problems of low beam power and can not meet the needs of material irradiation, and achieve the effect of reducing the space occupied, high radio frequency utilization efficiency, and good use economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

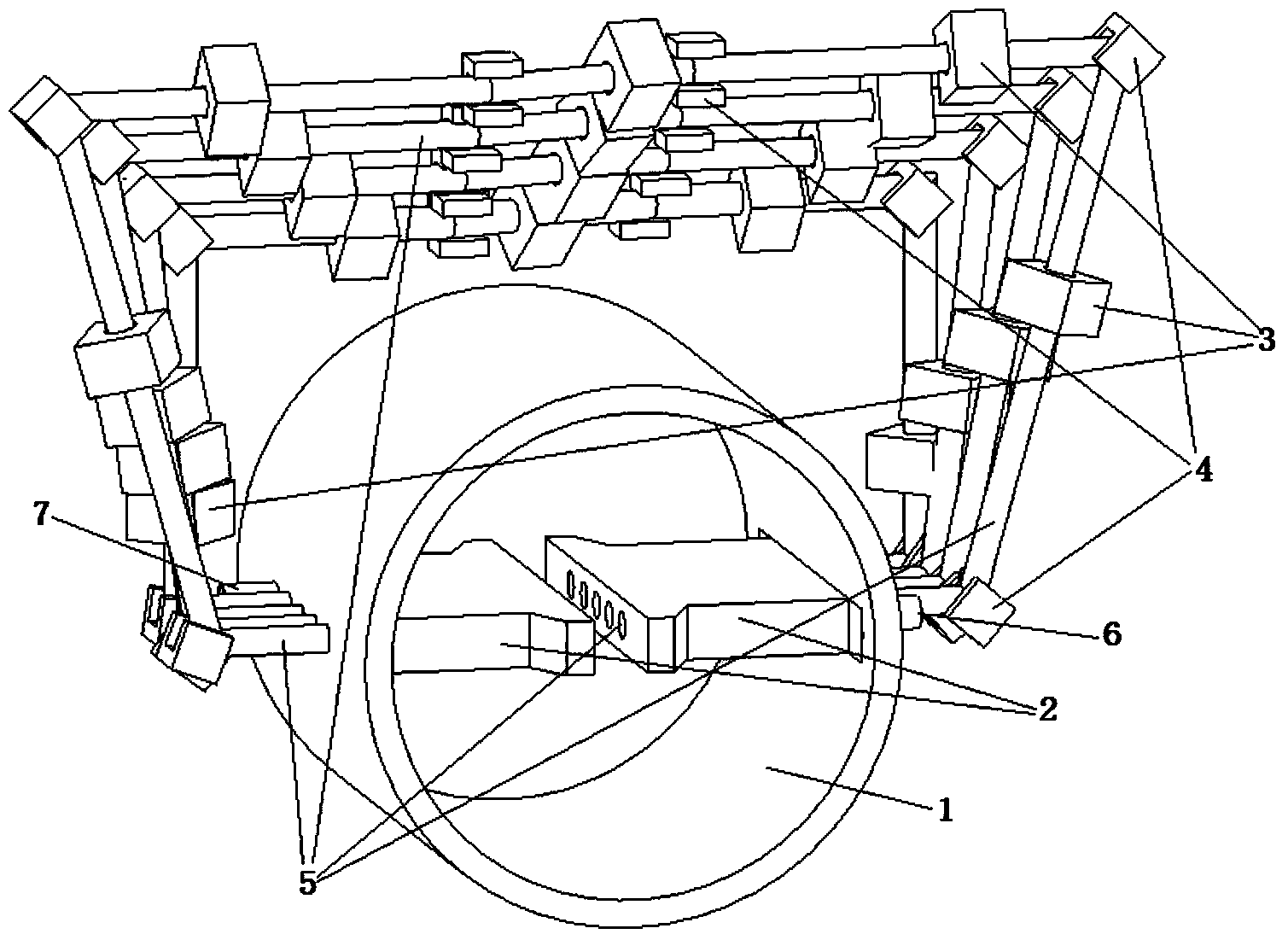

[0023] An electron spiral accelerator, such as figure 1 As shown, the electron spiral accelerator includes a radio frequency resonant cavity 1, a pair of ridge electrodes 2, a quadrupole magnet 3, a deflection magnet 4, a beam movement channel 5, a channel entrance 6, and a channel exit 7. The working frequency band of its radio frequency power source is is 100MHz, and the shape of the radio frequency resonant cavity 1 is a cylindrical cavity;

[0024] The electron spiral accelerator also includes a gate-controlled electron gun, the grid voltage waveform of which is a sine wave, and the working frequency is the same as that of the radio frequency power source;

[0025] The beam movement tunnel 5 includes a beam deflection tunnel and a ridge electrode beam tunnel. The beam deflection tunnel passes through the radio frequency resonant cavity 1 housing and communicates with the ridge electrode beam tunnel. The spatial structure of the beam movement tunnel 5 It is a spring-type t...

Embodiment 2

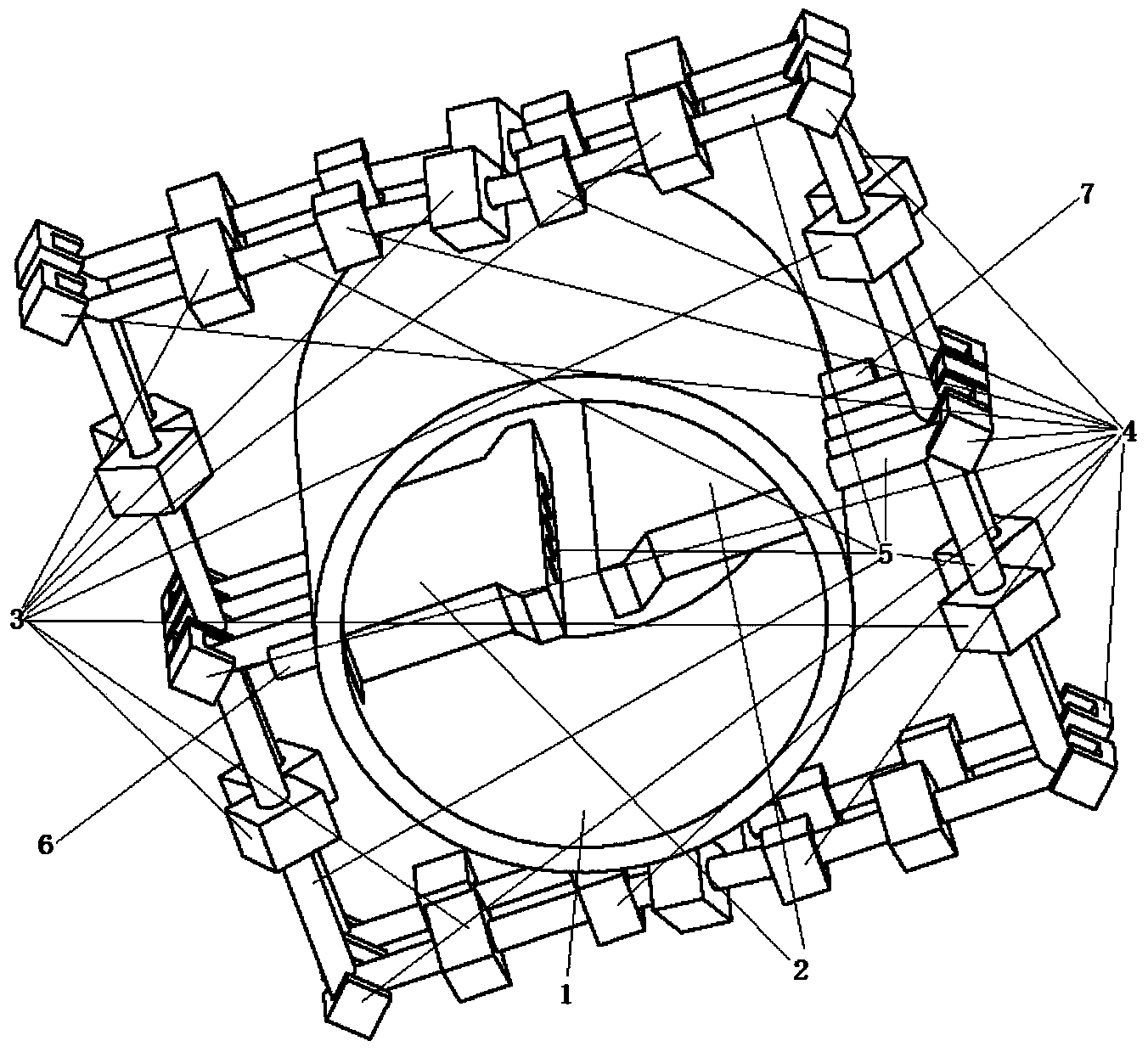

[0029] An electron spiral accelerator, such as figure 2 As shown, the electron spiral accelerator includes a radio frequency resonant cavity 1, a pair of ridge electrodes 2, a quadrupole magnet 3, a deflection magnet 4, a beam movement channel 5, a channel entrance 6, and a channel exit 7. The working frequency band of its radio frequency power source is is 100MHz, and the shape of the radio frequency resonant cavity 1 is a cylindrical cavity;

[0030] The electron spiral accelerator also includes a gate-controlled electron gun, the grid voltage waveform of which is a sine wave, and the working frequency is the same as that of the radio frequency power source;

[0031] The beam movement tunnel 5 includes a beam deflection tunnel and a ridge electrode beam tunnel. The beam deflection tunnel passes through the radio frequency resonant cavity 1 housing and communicates with the ridge electrode beam tunnel. The spatial structure of the beam movement tunnel 5 It is an 8-shaped th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com