Elevation-type oil-gas-water three-phase separator with high water ratio

A technology of three-phase separator and high water content, which is applied in the direction of liquid separation, separation method, liquid degassing, etc., to achieve the effect of reducing the probability of outflow, occupying a small area and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

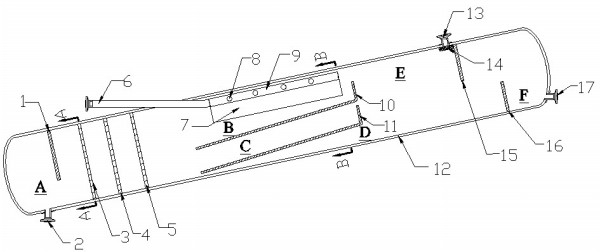

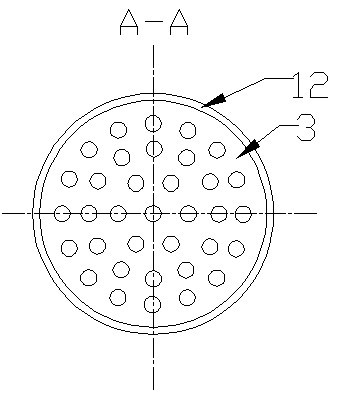

[0024] Such as figure 1 Shown: This device includes weir plate 1, drain port 2, No. 1 orifice plate 3, No. 2 orifice plate 4, No. 3 orifice plate 5, mixture inlet pipe 6, choke tube 7, liquid distribution pipe outlet hole 8. Liquid distribution pipe 9, No. 1 baffle 10, No. 2 baffle 11, tank body 12, exhaust port 13, wire mesh trap 14, air weir plate 15, oil weir plate 16, oil discharge port 17.

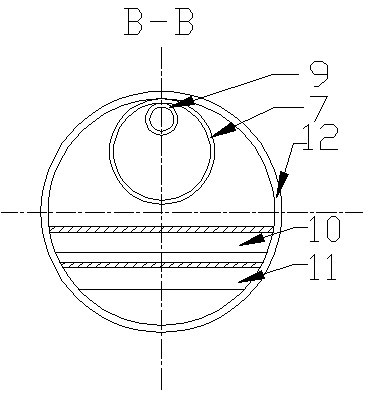

[0025] The mixture liquid inlet pipe 6 is placed horizontally, and the right end is connected with the liquid distribution pipe 9 . The liquid distribution pipe 9 and the tank body 12 are placed horizontally, and the discharge holes 8 are evenly and symmetrically spaced on both sides along the pipe direction, and the choke tube 7 is installed on the outside. tangency (eg image 3 As shown), two baffles 10 and 11 parallel to each other are installed under the choke tube 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com