Composite baffling revolving bed mass transfer and reaction device

A technology of reaction equipment and rotating bed, which is applied in chemical methods for reacting liquid and gaseous media, chemical/physical/physicochemical mobile reactors, feeding devices, etc., can solve the problem of low mass transfer efficiency and poor gas phase interface No problems such as rapid update, uneven gas-liquid distribution, etc., to achieve the effect of improving operational stability, increasing the area of the gas-liquid interface, and improving the uneven distribution of gas-liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

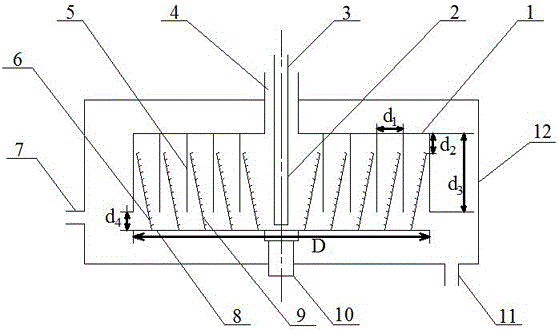

[0031] Embodiment 1: the device of the present invention is applied to 2000mg / m 3 Hydrogen sulfide absorption process. The structural parameters of the device in the experiment are: θ=45 o 、d 1 =1 / 10D, d 2 =1 / 7d 1 、d 3 =3d 1 、d 4 =1 / 7d 1 , puncture hole diameter 1.5mm, puncture hole spacing 2mm, circular small hole diameter 1mm, puncture hole spacing 2.5mm, liquid distributor pore diameter 0.45mm; operating parameters: liquid-gas ratio 10L / m 3 , under the conditions of rotating bed speed of 1000r / min, soda ash content of 12g / L, PDS content of 15mg / L, and temperature of 30°C, the average removal rate of hydrogen sulfide is 96.4%.

Embodiment 2

[0032] Embodiment 2: apply the device of the present invention to 2000mg / m 3Hydrogen sulfide absorption process. The structural parameters of the device in the experiment are: θ=60 o 、d 1 =1 / 12D, d 2 =1 / 6d 1 、d 3 =2.4d 1 、d 4 =1 / 5d 1 , puncture hole diameter 1mm, puncture hole spacing 2.5mm, circular small hole diameter 1.5mm, puncture hole spacing 2mm, liquid distributor pore diameter 0.4mm; operating parameters are: liquid-gas ratio 10L / m 3 , the rotating bed speed is 1000r / min, the content of soda ash is 12g / L, the content of PDS is 15mg / L, and the temperature is 30℃, the average removal rate of hydrogen sulfide is 98.7%.

Embodiment 3

[0033] Embodiment 3: the device of the present invention is applied to 2000mg / m 3 Hydrogen sulfide absorption process. The structural parameters of the device in the experiment are: θ=75 o 、d 1 =1 / 11D, d 2 =1 / 8d 1 、d 3 =2.7d 1 、d 4 =1 / 6d 1 , puncture hole diameter 2mm, puncture hole spacing 1.5mm, circular small hole diameter 2mm, puncture hole spacing 1.5mm, liquid distributor pore diameter 0.5mm; operating parameters: liquid-gas ratio 10L / m 3 , the rotating bed speed is 1000r / min, the content of soda ash is 12g / L, the content of PDS is 15mg / L, and the temperature is 30℃, the average removal rate of hydrogen sulfide is 95.3%.

[0034] Under the same operating parameters, it is applied to the 2000mg / m 3 The comparison of hydrogen sulfide absorption process is shown in the table below.

[0035] experiment Experiment 1 Experiment 2 Experiment 3 literature Average removal rate of hydrogen sulfide 96.40% 98.70% 95.30% 92.40%

[0036] It ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com