Touch display substrate and touch display device

A technology for touch display substrates and touch display devices, which is applied to static indicators, instruments, calculations, etc., can solve the problems of uneven distribution of touch electrode lines and poor display uniformity of touch display devices, and achieve improved display performance. Uniformity, improve the effect of uneven distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

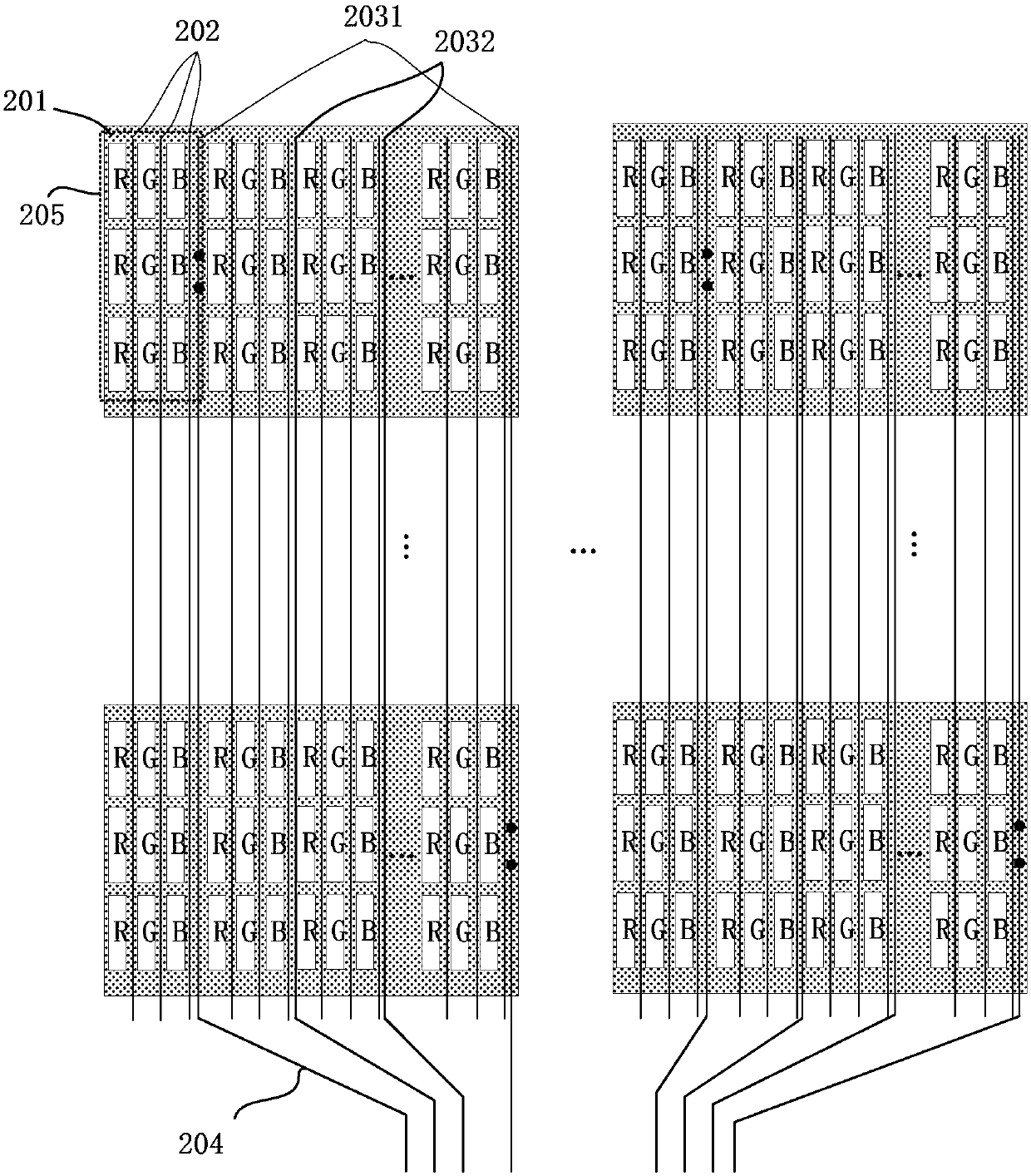

[0043] Please refer to figure 1 , figure 1 It is a schematic diagram of a touch display substrate according to Embodiment 1 of the present invention. The touch display substrate includes a base substrate (not shown in the figure), and the base substrate includes a display area and a lead area. A touch electrode 201, a plurality of wires, a plurality of data lines 202, and a plurality of pixel units.

[0044] The wiring and the data wiring 202 are arranged in the same layer and material in parallel, and each of the touch electrodes 201 is provided with a plurality of wiring in the orthographic projection area of the base substrate, and each of the touch electrodes 201 is provided with a plurality of wiring The multiple wires corresponding to the electrodes 201 include a touch electrode wire 2031 for connecting to the touch electrode 201 and multiple auxiliary wires 2032 not connected to the touch electrode 201 . A plurality of lead wires 204 are arranged in the lead wire ar...

Embodiment 2

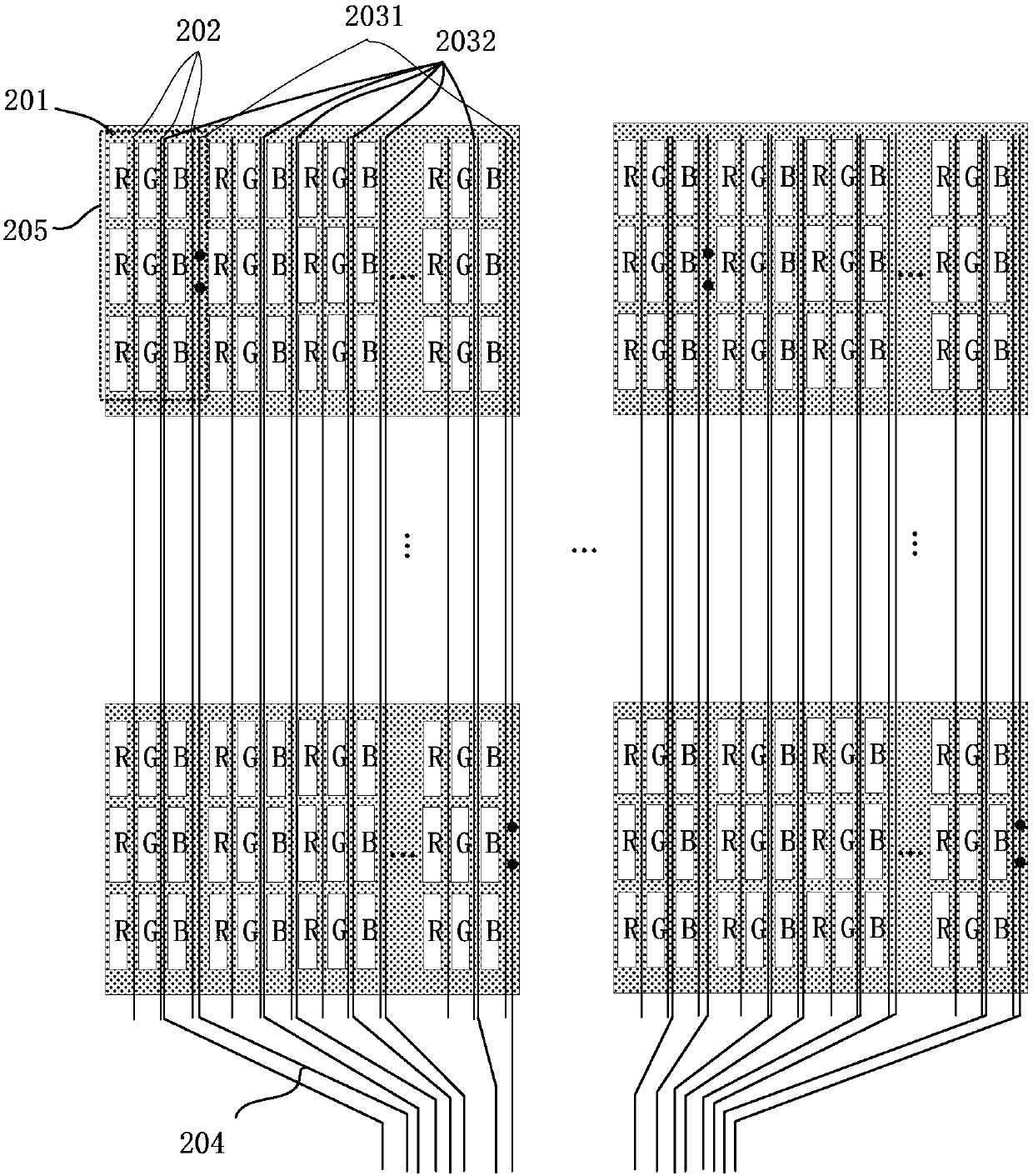

[0048] Please refer to figure 2 , figure 2 It is a schematic diagram of a touch display substrate according to Embodiment 2 of the present invention. The touch display substrate includes a base substrate (not shown in the figure), and the base substrate includes a display area and a lead area. A touch electrode 201, a plurality of wires, a plurality of data lines 202 and a plurality of pixel units.

[0049] The wiring and the data wiring 202 are arranged in the same layer and material in parallel, and each of the touch electrodes 201 is provided with a plurality of wiring in the orthographic projection area of the base substrate, and each of the touch electrodes 201 is provided with a plurality of wiring The multiple wires corresponding to the electrodes 201 include a touch electrode wire 2031 for connecting with the corresponding touch electrode 201 and multiple auxiliary wires 2032 not connected with the touch electrode. A plurality of lead wires 204 are arranged in th...

Embodiment 3

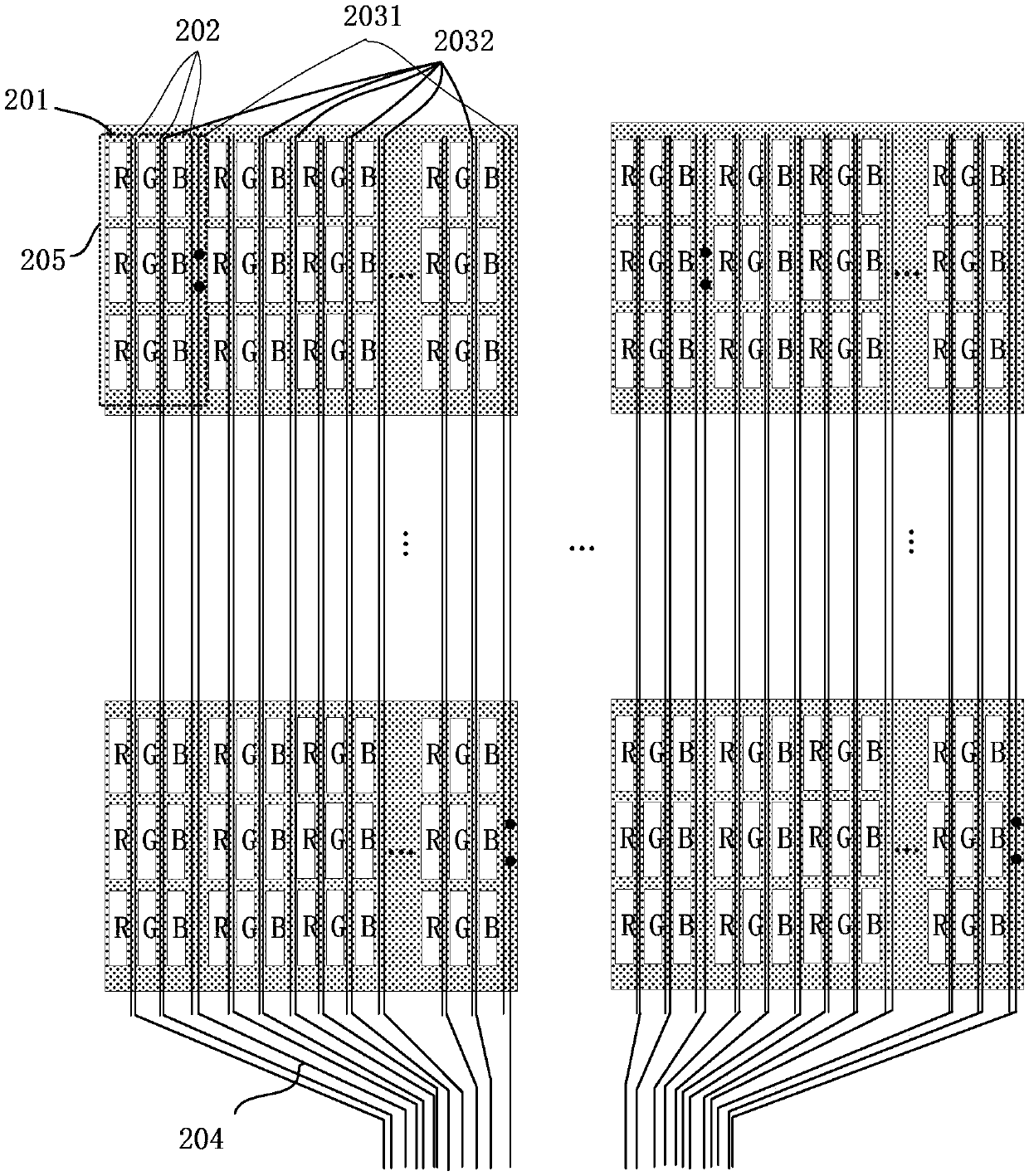

[0053] Please refer to image 3 , image 3 It is a schematic diagram of a touch display substrate according to Embodiment 3 of the present invention. The touch display substrate includes a base substrate (not shown in the figure), and the base substrate includes a display area and a lead area. A touch electrode 201, a plurality of wires, a plurality of data lines 202 and a plurality of pixel units.

[0054] The wiring and the data wiring 202 are arranged in the same layer and in parallel, and each of the touch electrodes 201 is provided with a plurality of wiring in the orthographic projection area of the base substrate, and each of the touch electrodes 201 The corresponding multiple wires include a touch electrode wire 2031 for connecting with the corresponding touch electrode 201 and multiple auxiliary wires 2032 not connected with the touch electrode. A plurality of lead wires 204 are arranged in the lead wire area, and the wires are connected to the lead wires 204 in o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com