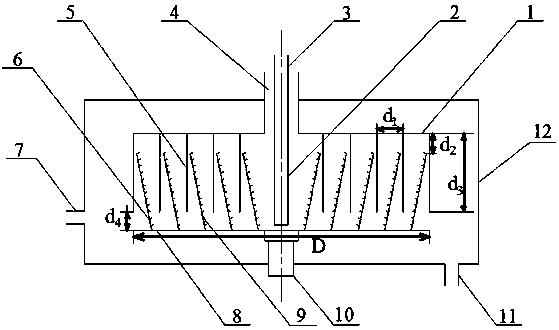

Compound baffled rotating bed mass transfer and reaction equipment

A technology of reaction equipment and rotating bed, which is applied in chemical methods, chemical/physical/physical-chemical mobile reactors, feeding devices, etc. for reacting liquid and gas medium, which can solve the problems of low mass transfer efficiency and gas interface problems. Without rapid update, uneven distribution of gas and liquid, etc., to achieve the effect of improving operation stability, increasing the area of gas-liquid interface, and improving uneven distribution of gas and liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

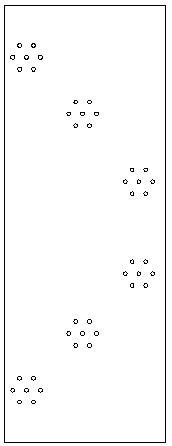

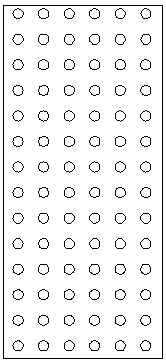

[0031] Embodiment 1: the device of the present invention is applied to 2000mg / m 3 Hydrogen sulfide absorption process. The structural parameters of the device in the experiment are: θ=45 o 、d 1 =1 / 10D, d 2 =1 / 7d 1 、d 3 =3d 1 、d 4 =1 / 7d 1 , puncture hole diameter 1.5mm, puncture hole spacing 2mm, circular small hole diameter 1mm, puncture hole spacing 2.5mm, liquid distributor pore diameter 0.45mm; operating parameters: liquid-gas ratio 10L / m 3 , under the conditions of rotating bed speed of 1000r / min, soda ash content of 12g / L, PDS content of 15mg / L, and temperature of 30°C, the average removal rate of hydrogen sulfide is 96.4%.

Embodiment 2

[0032] Embodiment 2: apply the device of the present invention to 2000mg / m 3 Hydrogen sulfide absorption process. The structural parameters of the device in the experiment are: θ=60 o 、d 1 =1 / 12D, d 2 =1 / 6d 1 、d 3 =2.4d 1 、d 4 =1 / 5d 1 , puncture hole diameter 1mm, puncture hole spacing 2.5mm, circular small hole diameter 1.5mm, puncture hole spacing 2mm, liquid distributor pore diameter 0.4mm; operating parameters: liquid-gas ratio 10L / m 3, the rotating bed speed is 1000r / min, the content of soda ash is 12g / L, the content of PDS is 15mg / L, and the temperature is 30℃, the average removal rate of hydrogen sulfide is 98.7%.

Embodiment 3

[0033] Embodiment 3: the device of the present invention is applied to 2000mg / m 3 Hydrogen sulfide absorption process. The structural parameters of the device in the experiment are: θ=75 o 、d 1 =1 / 11D, d 2 =1 / 8d 1 、d 3 =2.7d 1 、d 4 =1 / 6d 1 , puncture hole diameter 2mm, puncture hole spacing 1.5mm, circular small hole diameter 2mm, puncture hole spacing 1.5mm, liquid distributor pore diameter 0.5mm; operating parameters: liquid-gas ratio 10L / m 3 , the rotating bed speed is 1000r / min, the content of soda ash is 12g / L, the content of PDS is 15mg / L, and the temperature is 30℃, the average removal rate of hydrogen sulfide is 95.3%.

[0034] Under the same operating parameters, it is applied to the 2000mg / m 3 The comparison of hydrogen sulfide absorption process is shown in the table below.

[0035] experiment

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com