Method and system for processing waste liquid

A technology for waste liquid and alkali treatment, which is applied in combustion methods, chemical instruments and methods, and neutralized water/sewage treatment. The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Material: waste liquid from an amino acid production plant.

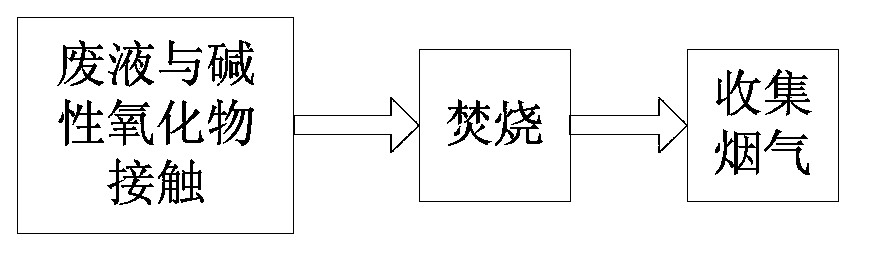

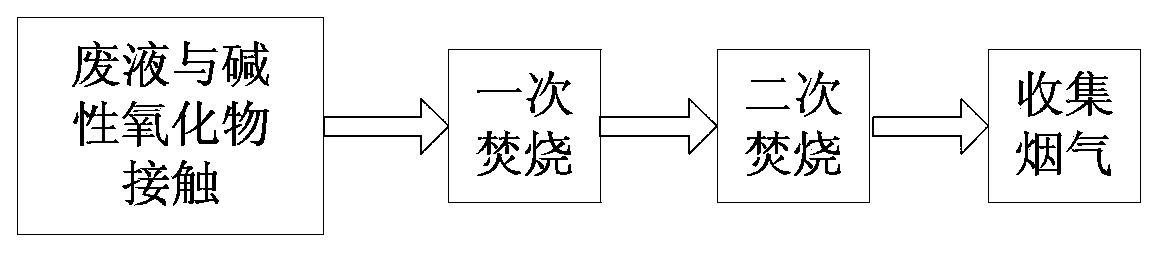

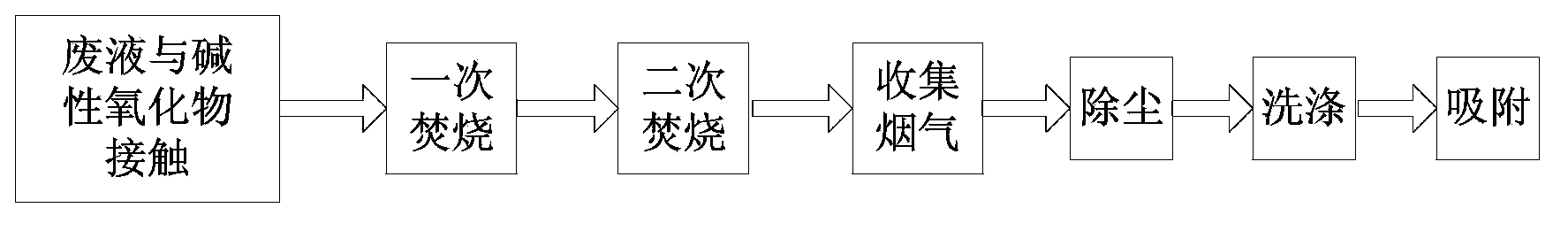

[0058] refer to figure 1 , the main steps are as follows:

[0059] 1) Mix calcium oxide at a feeding speed of 1895kg / h and waste liquid at a flow rate of 29.167t / h in a powder-liquid jet mixer, and stir evenly. The salt in the waste liquid and calcium oxide react as follows:

[0060] CaO+H 2 O+(NH 4 ) 2 SO 4 =CaSO 4 2H 2 O+2NH 3 ↑,

[0061] Collect the precipitate and supernatant, release the NH 3 It enters the ammonia buffer storage tank through the collection pipe, and then enters the spray scrubber through the fan, and uses water for circular washing to absorb ammonia;

[0062] 2) Mix the sediment with coal with a softening point greater than 1100 degrees Celsius at a weight ratio of 7.5:1, and then incinerate in a rotary kiln for 60 to 70 minutes at an incineration temperature of 850 degrees Celsius and a pressure of -1 mbar to obtain salt and untreated coal. fuel;

[0063]3) Incinerate the un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com