Treatment method of laterite-nickel ore

A lateritic nickel ore and treatment method technology, applied in the field of metallurgy, can solve problems such as high equipment requirements, complex treatment process, and serious environmental pollution, and achieve the effects of improving comprehensive treatment efficiency, avoiding environmental pollution, and improving comprehensive benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

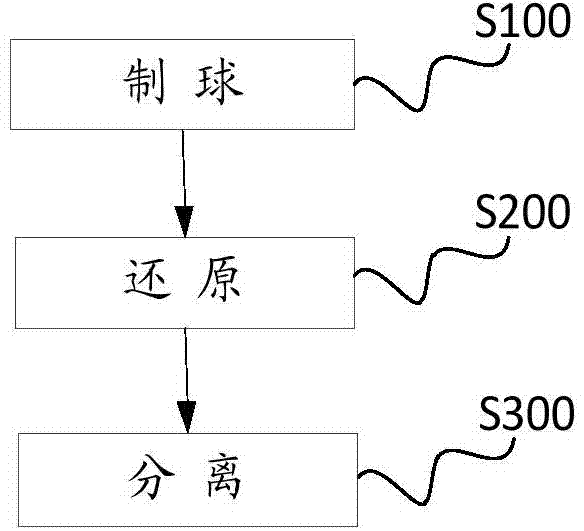

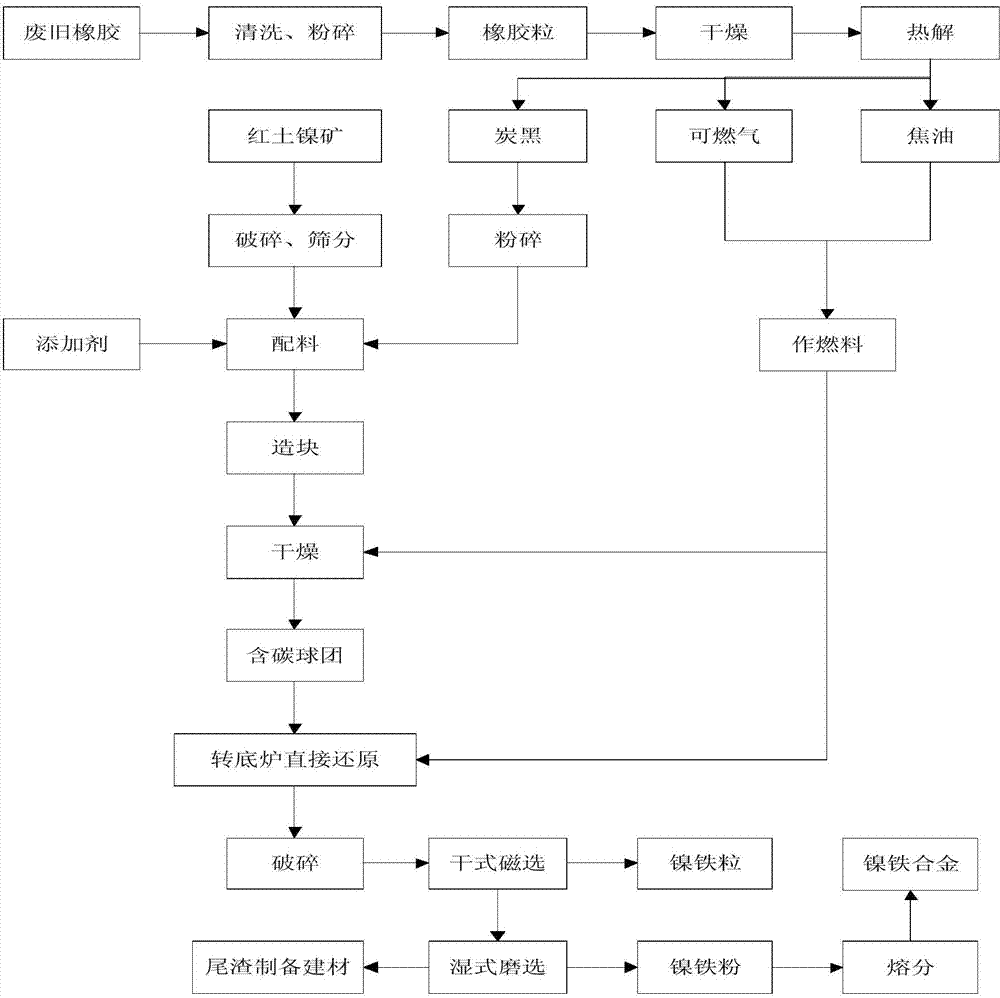

Method used

Image

Examples

Embodiment 1

[0074] A laterite nickel ore with a nickel grade of 1.31% by weight and a total iron content of 23.75% by weight is used. According to the ratio of laterite nickel ore: carbon black: additive = 100:12:10, after mixing evenly, use a double-roller high-pressure briquetting machine to make agglomerates, and distribute the dried carbon-containing pellets into the rotary hearth furnace through the distribution device , the carbon-containing pellets are reduced in a regenerative rotary hearth furnace, the reduction temperature is 1500°C, and the reduction time is 60 minutes. The metallized pellets discharged from the discharge port are crushed and dry-type magnetic separation to obtain the nickel grade of nickel-iron particles. It is 14.16% by weight. At the same time, in order to improve the recovery rate of nickel, the tailings were subjected to wet grinding and separation in an electric furnace, and the nickel grade of the obtained nickel-iron alloy was 8.33% by weight. The tota...

Embodiment 2

[0076] A laterite nickel ore with a nickel grade of 0.72% by weight and a total iron content of 41.93% by weight is used. According to the proportion of laterite nickel ore: carbon black: additive = 100:26:17, after mixing evenly, use a double-roller high-pressure briquetting machine to make agglomerates, and distribute the dried carbon-containing pellets into the rotary hearth furnace through the distribution device , the carbon-containing pellets are reduced in a regenerative rotary hearth furnace, the reduction temperature is 1450°C, and the reduction time is 45 minutes. The metallized pellets discharged from the discharge port are crushed and dry-type magnetic separation to obtain the nickel grade of nickel-iron particles. It is 4.11% by weight. At the same time, in order to improve the recovery rate of nickel, the tailings were subjected to wet grinding and then melted in a non-electric furnace. The nickel grade of the nickel-iron alloy obtained by melting was 6.07% by we...

Embodiment 3

[0078] A laterite nickel ore with a nickel grade of 1.71% by weight and a total iron content of 11.62% by weight is used. According to the proportion of laterite nickel ore: carbon black: additive = 100:5:20, after mixing evenly, use a double-roller high-pressure briquetting machine to make agglomerates, and distribute the dried carbon-containing pellets into the rotary hearth furnace through the distribution device , the carbon-containing pellets are reduced in a regenerative rotary hearth furnace, the reduction temperature is 1550°C, and the reduction time is 105min. The metallized pellets discharged from the discharge port are crushed and dry-type magnetic separation to obtain the nickel grade of nickel-iron particles. It is 30.47% by weight. At the same time, in order to improve the recovery rate of nickel, the tailings were subjected to wet grinding and then melted in a non-electric furnace. The nickel grade of the nickel-iron alloy obtained by melting was 16.58% by weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com