Garbage hazard-free comprehensive treatment equipment

A comprehensive treatment and harmless technology, applied in chemical instruments and methods, solid separation, separation of solids from solids by air flow, etc. , to achieve the effect of various types of recycling, advanced production technology and high recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

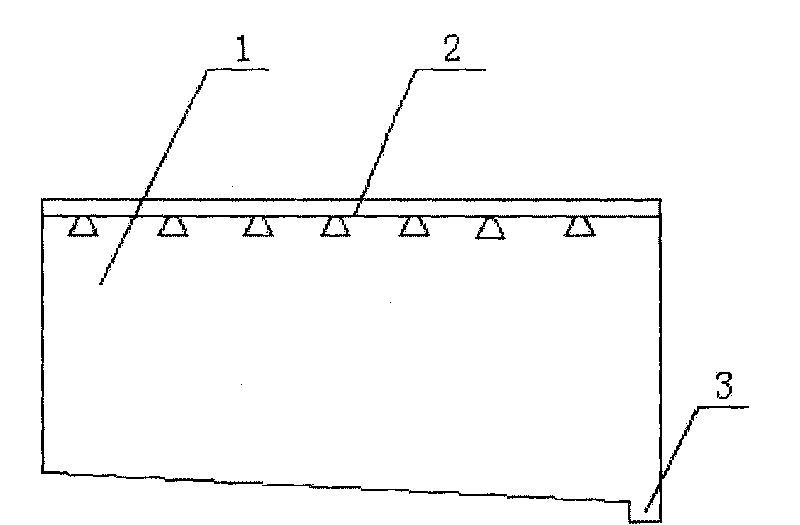

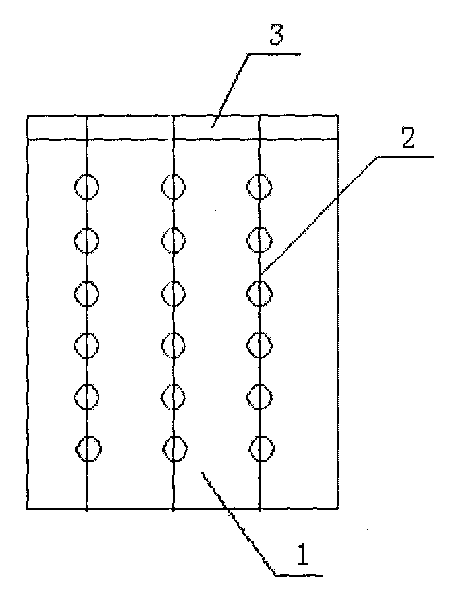

[0020] Such as figure 1 and figure 2 As shown, the fermentation bin 1 is a sealed bin with a transparent design on the top (not shown), and a sprinkler system 2 is installed on the upper part. The fermentation bin 1 can accommodate 300-800 tons of garbage according to the demand, and the bottom surface of the fermentation bin 1 is an inclined plane. Set, the inclination angle is about 3~8 °, and the lower end is provided with drainage ditch 3.

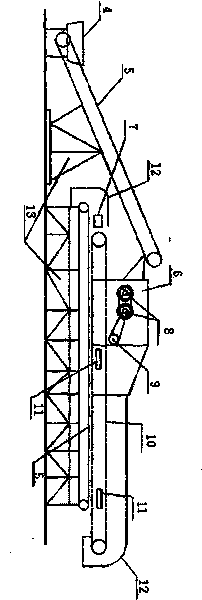

[0021] Such as image 3 As shown, the hopper 4 is arranged above one end of the belt conveyor 5-1, the other end of the belt conveyor 5-1 is connected to the m-type rotary sorter 6, and the chain screening conveyor belt 10 is arranged below, and the chain screening conveyor belt 10 Wind separation machine 11 is set outside the side cover 12 of the side, and a belt conveyor 5-2 is arranged below the chain type screening conveyor belt 10, and the transmission direction of the belt conveyor 5-2 is opposite to that of the chain type scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com