Metal smelting method

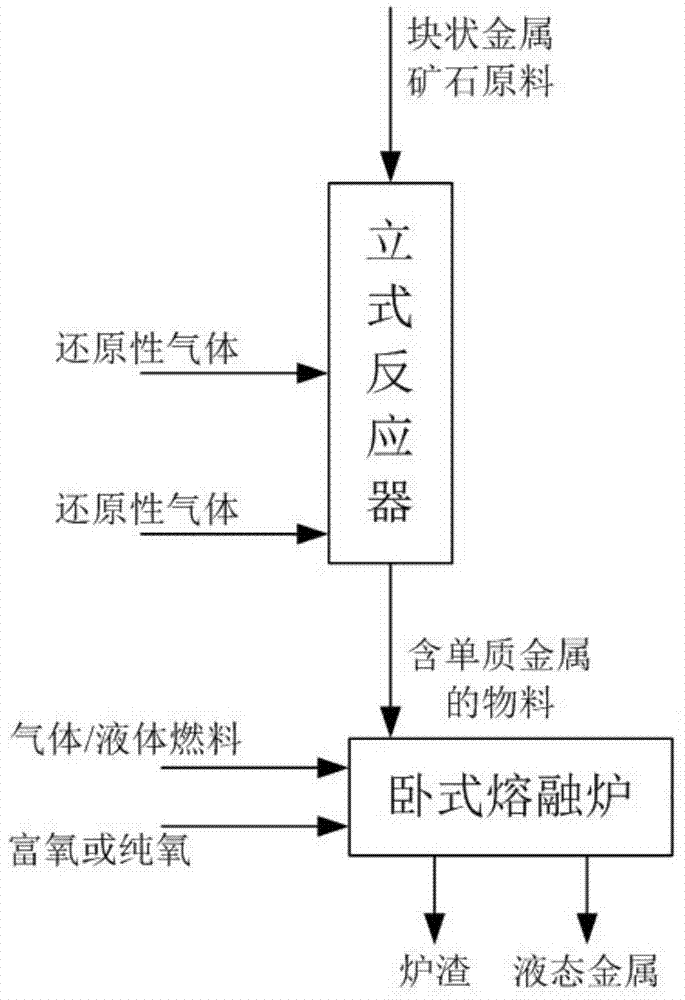

A metal smelting and metal technology, applied in the field of metal smelting, can solve the problems of heavy process burden, large amount of slag, lower metal grade, etc., and achieve the effects of improving work efficiency, high metal recovery rate, and promoting reduction reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Crush the refractory ore raw material to 10-20mm, put it into a vertical reactor through a hopper, and reduce it at 0.15MPa and 900-950°C for 3-4 hours. The reducing gas enters from the middle of the vertical reactor, and the H in the reducing gas 2 +CO≥85%. After reduction, the product containing elemental metallic iron at ~700°C is sent to the melting furnace for melting and separation of metal and slag (melting). The fuel of the melting furnace has a calorific value higher than 750kcal / m 3 , less than 4500kcal / m 3 The mixed gas, the combustion gas is air. The dust-laden flue gas in the melting furnace passes through the high-temperature dust collector to remove large particles of dust and then enters the heat storage body for heat exchange. After heat exchange, the flue gas below 200 °C enters the bag filter for fine dust removal and is discharged from the chimney. The heat is used to preheat the mixture of gas and air. The temperature of the melting furnace is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com