Laterite gas gas reduction apparatus

A technology of laterite nickel ore and equipment, which is applied in the field of laterite ore gas-based reduction to achieve the effects of protecting the ecological environment, reducing production costs and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

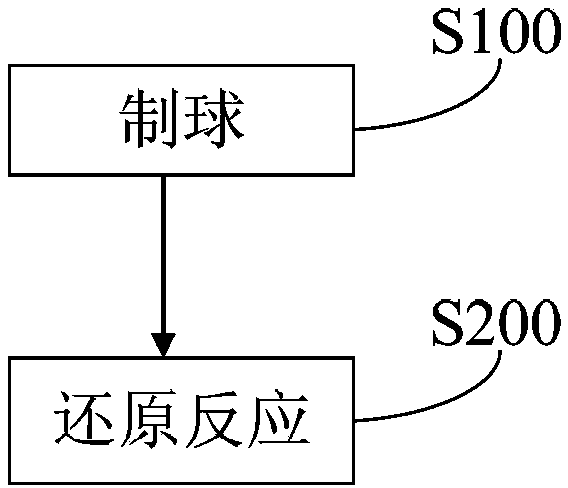

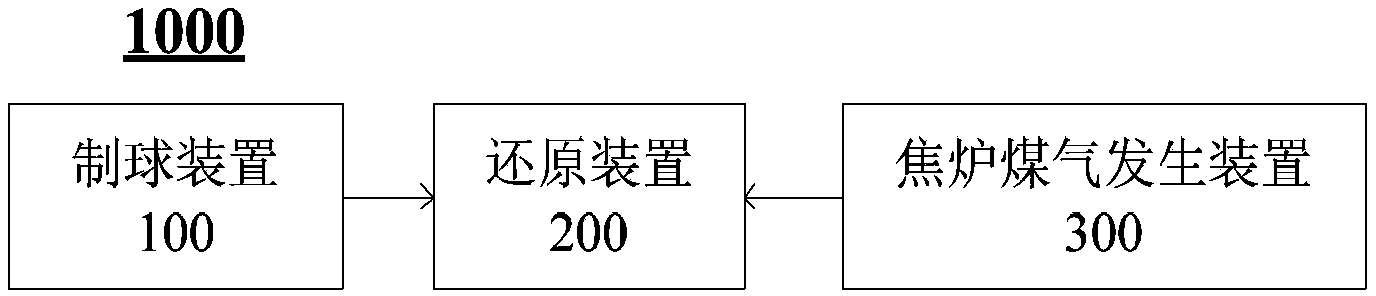

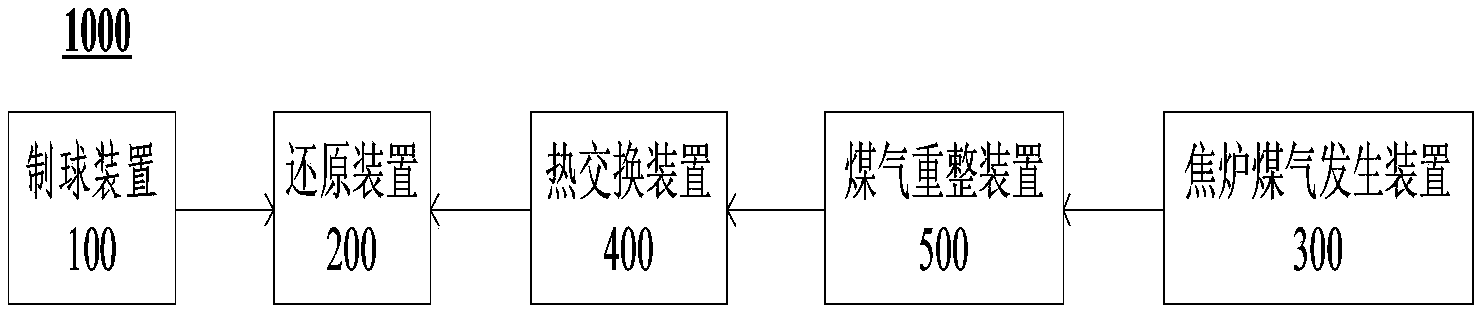

Method used

Image

Examples

Embodiment 1

[0061] The composition will be NiO1.4%, Fe 2 o 3 65.2%, SiO 2 16.5%, Al 2 o 3 4.2%, CaO2.2%, MgO3.3%, Cr 2 o 3 2% and H 2 O5.5% limonite-type laterite and lignite with fixed carbon content of 60% and water were made into pellets at a ratio of 100:3:5, and dried in a belt dryer at 300 degrees Celsius . The raw coke oven gas and the dried pellets are separated by 700m 3 The / t pellets are supplied to the reduction shaft furnace, and the reduction reaction is carried out at the reduction heat equilibrium temperature of 1000 degrees Celsius.

[0062] After inspection, the Ni metal conversion rate of the obtained product is 85%, and the Fe metallization rate is 80%.

Embodiment 2

[0064] The composition will be NiO1.4%, Fe 2 o 3 65.2%, SiO 2 16.5%, Al 2 o 3 4.2%, CaO2.2%, MgO3.3%, Cr 2 o 3 2% and H 2 O5.5% limonite-type laterite, binder, lignite with fixed carbon content of 60%, and water were made into pellets at a ratio of 100:3:1.5:5, and were placed in a belt conveyor at a temperature of 400 degrees Celsius. Dry in a dryer. The raw coke oven gas and the dried pellets are separated by 700m 3 The / t pellets are supplied to the reduction shaft furnace, and the reduction reaction is carried out at the reduction heat equilibrium temperature of 1000 degrees Celsius.

[0065] After inspection, the Ni metal conversion rate of the obtained product is 87%, and the Fe metallization rate is 82%.

Embodiment 3

[0067] The composition will be Ni2%, Fe14%, SiO 2 48.5%, Al 2 o 3 1.5%, CaO0.8%, MgO25%, Cr 2 o 3 1% and H 2 O5.2% humus-type laterite ore, lignite with fixed carbon content of 60%, regulator and water are made into pellets at a ratio of 100:2:5:5, and are placed in a belt dryer at a temperature of 400 degrees Celsius to dry in. Combine coke oven waste gas and dried pellets at a distance of 500m 3 / t The pellets are supplied to the reduction shaft furnace, and the reduction reaction is carried out at the reduction heat equilibrium temperature of 1100 degrees Celsius.

[0068] After inspection, the Ni metal conversion rate of the obtained product is 90%, and the Fe metallization rate is 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com