Box-type automatic sintering device

An automatic sintering, box-type technology, applied in the furnace type, furnace, lighting and heating equipment, etc., can solve the problems of high labor intensity, increase air convection, heat loss, etc., achieve a high degree of automation, prevent flying everywhere, and sinter quality. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

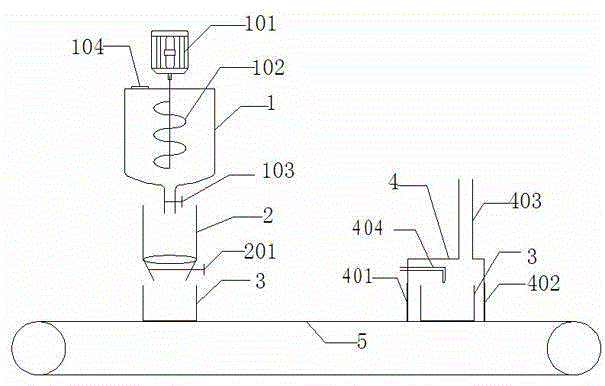

[0016] Add dust, powdered mineral powder and binder into the batching kettle 1 from the feed port 104 according to the proportion, start the motor 101, drive the rotation of the screw agitator 102, mix the materials evenly, open the valve 103 at the bottom of the batching kettle, and Put the mixed material into the mixture storage tank 2, and prepare the next batch of materials in the vacated batching kettle 1; open the blanking baffle plate 201 at the bottom of the mixture storage tank 2, and put the empty sintering material placed under the mixture storage tank 2 The box 3 is filled with materials, the feed port 401 is opened, the motor drives the transmission of the conveyor belt 5, and the sintering box 3 filled with materials is transported to the sintering chamber 4, the doors 401 and 402 of the sintering chamber 4 are closed, and the igniter is activated. Coal gas is used as fuel, the ejected flame ignites the materials in the sintering box 3, sinters under the set sinte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com