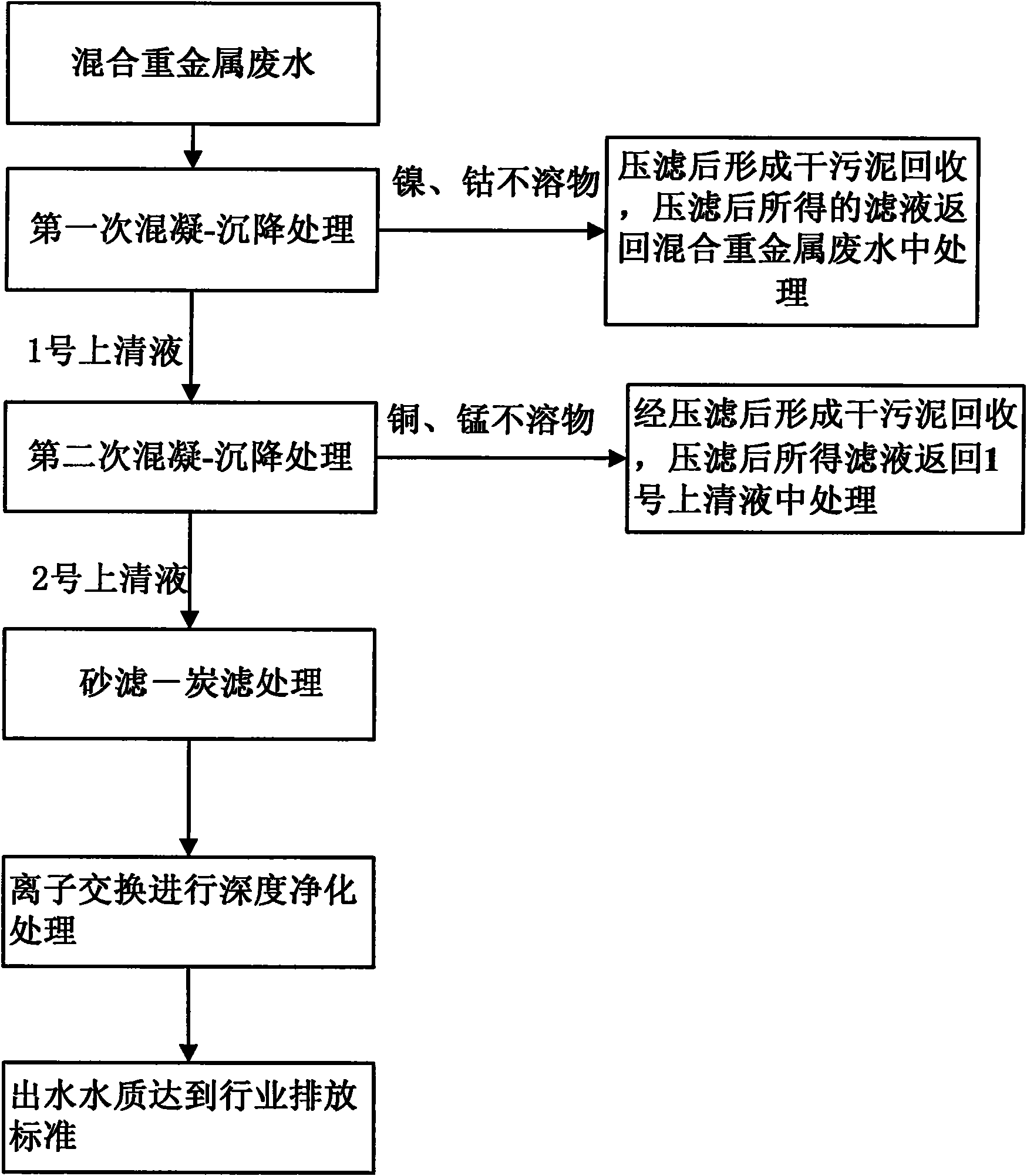

Treatment method of nickel-cobalt-manganese wastewater generated in waste and old battery treatment process

A treatment process and waste battery technology, applied in chemical instruments and methods, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as waste of water resources, secondary pollution, easy blockage of membrane pores, etc. To achieve the effect of reasonable process flow, high metal recovery rate and good working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In the raw nickel-cobalt-manganese wastewater: PH≈6.5, total nickel 493.98mg / L, total cobalt 115.79mg / L, total manganese 1000mg / L, total copper 5000mg / L, and total iron 1.14mg / L.

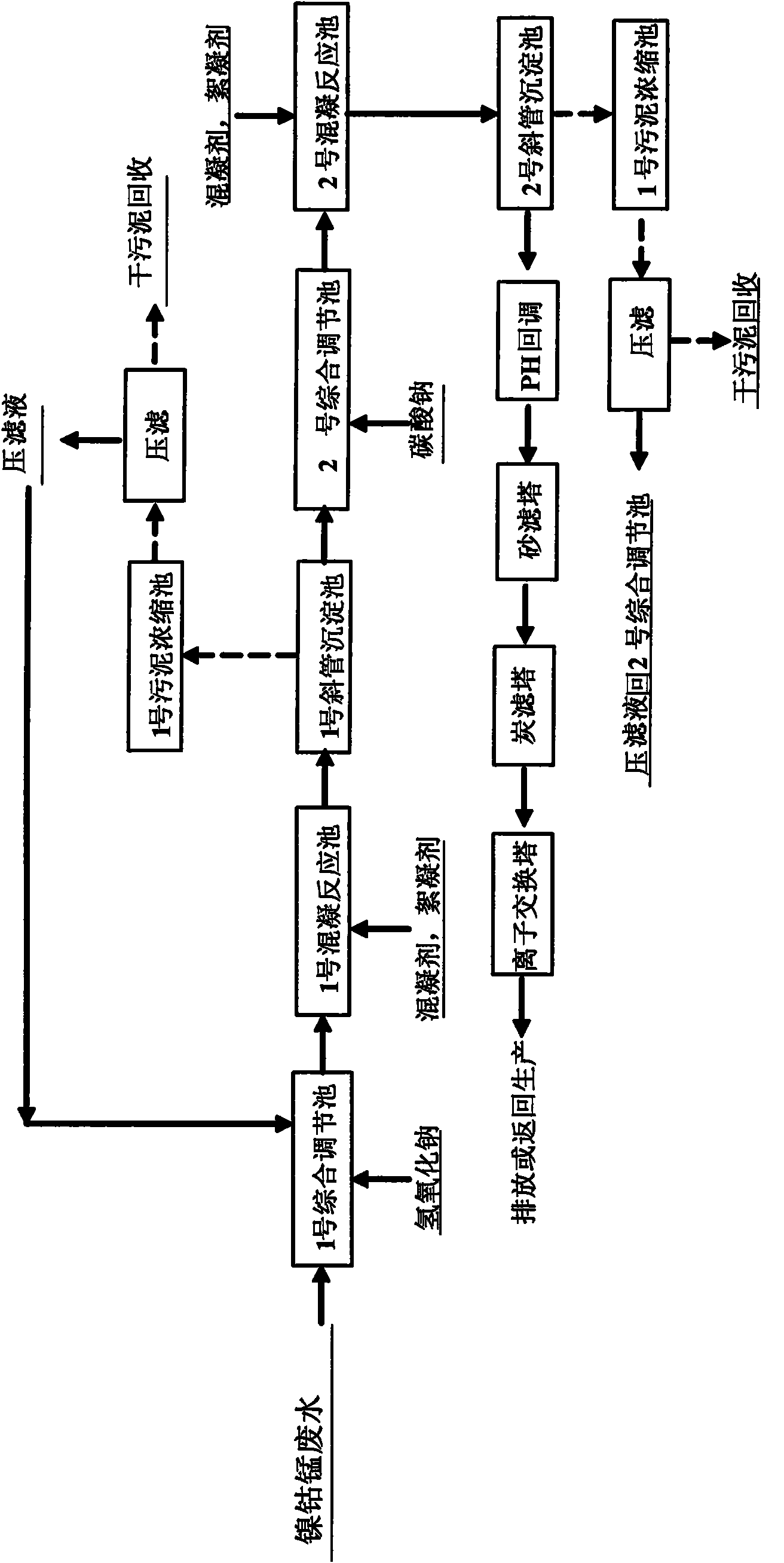

[0047] The treatment method of the nickel-cobalt-manganese wastewater produced in the waste battery treatment process comprises the following steps of continuous execution:

[0048] (1) Nickel-cobalt-manganese wastewater is subjected to step-by-step coagulation-sedimentation pretreatment: add saturated sodium hydroxide solution to adjust the pH value of the wastewater to 9.5, and after blowing and stirring for 0.5h, the wastewater is introduced into the coagulation reaction tank, and an appropriate mixing agent is added. Coagulant, add 500g polyaluminum chloride and 600g polyacrylamide to each cubic meter of nickel-cobalt-manganese waste water, blow and stir for 0.5h, and then pump the turbid solution into the inclined tube sedimentation tank for sedimentation and separation to obtain No. 1 T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com