Low-heat-loss diesel engine combustor structure

A diesel engine and combustion chamber technology, which is applied to combustion engines, mechanical equipment, engine components, etc., can solve the problems of large heat load and heat transfer loss in the combustion chamber, and achieve the goal of improving fuel utilization, improving combustion efficiency, and reducing heat loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

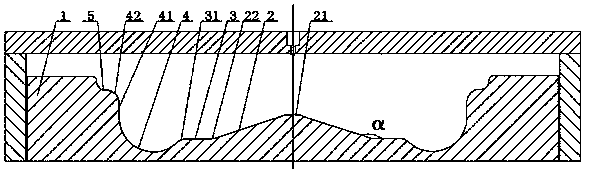

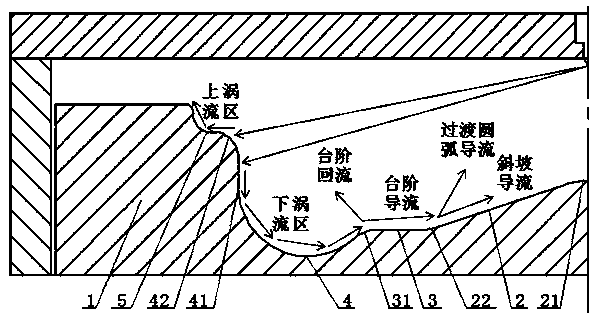

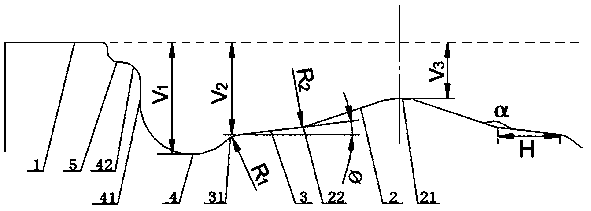

[0048] A low heat loss diesel engine combustion chamber, comprising a cylinder piston 1, the top of the cylinder piston 1 is coaxially provided with a slope guide cone 2 and a lower swirl groove 4; the lower swirl groove 4 and the slope guide cone 2 There is a diversion step surface 3 between them, and the angle α between the diversion step surface 3 and the slope diversion cone surface 2 is 120°-165°; between the lower vortex groove 4 and the top surface of the cylinder piston 1 The maximum distance is V1, the maximum distance between the guide step surface 3 and the top surface of the cylinder piston 1 is V2, the minimum distance between the spherical crown boss 21 and the top surface of the cylinder piston 1 is V3, V1 and The ratio between V2 is 1.05-1.5, and the ratio between V2 and V3 is 1.3-2.5; the projection width H of the guide step surface 3 on the top surface of the cylinder piston 1 is 1mm-6mm; the slope guide The conical surface 2 is connected to the inner circumf...

Embodiment 2

[0050] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0051] The included angle ø between the diversion step surface 3 and the top surface of the cylinder piston 1 is 0°-30°; the inner arc surface of the first diversion arc 22 is tangent to the slope diversion cone surface 2, so The outer arc surface of the first diversion arc 22 is tangent to the diversion step 3, and the radius R2 of the circle where the section of the first diversion arc 22 is located is 1mm-6mm; the inner arc of the second diversion arc 31 The surface is tangent to the diversion step 3, the outer arc surface of the second diversion arc 31 is tangent to the inner arc surface of the lower vortex groove 4, and the radius R1 of the circle where the section of the second diversion arc 31 is located is 1mm -6mm.

Embodiment 3

[0053] Embodiment 3 is basically the same as Embodiment 2, and its difference is:

[0054] The guide step surface 3 is parallel to the top surface of the cylinder piston 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com