Diesel engine

A technology of diesel engine and timing mechanism, applied in engine components, combustion engine, engine control and other directions, can solve problems such as poor fuel consumption, large amount of black smoke, incomplete combustion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Next, embodiments of the invention will be described.

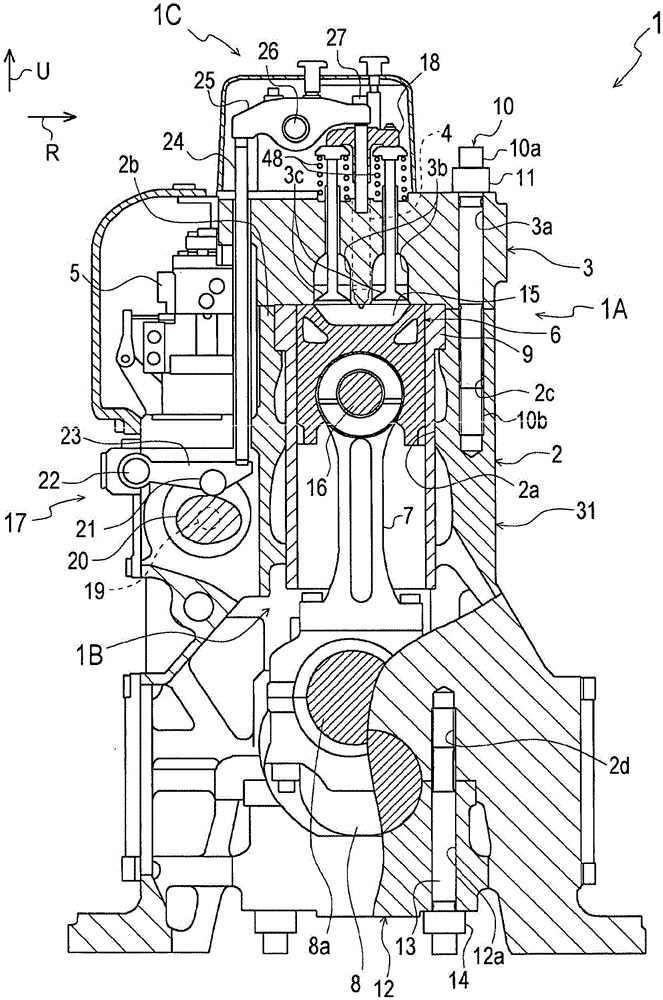

[0039] Additionally, the figure 1 The direction indicated by the arrow U of 2 is taken as the upper side of the diesel engine 1, and the direction indicated by the arrow R is taken as the right side of the diesel engine 1, and the positions and directions of the various components described below will be described.

[0040] First, use figure 1 The overall structure of the diesel engine 1 according to the present invention will be described. In addition, in the diesel engine 1 , since the configurations of the respective cylinders are substantially the same, only one of the cylinders will be described.

[0041] The diesel engine 1 is composed of the following parts: the engine main body 1A such as the cylinder 31 constituted by the cylinder block 2 and the cylinder head 3; and the fuel injection nozzle 4, the fuel injection pump 5, and the intake and exhaust valve drive section 1C.

[0042] In the engine main bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com