Device and method for lowering comprehensive power unit consumption of air separation unit

A technology of air separation equipment and unit consumption, applied in lighting and heating equipment, liquefaction, solidification and other directions, can solve the problems of different design parameters and operating parameters, low system operating efficiency, etc., to achieve the effect of less energy consumption and increased medium gas volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with specific embodiments. It should be understood that the following examples are only used to illustrate the present invention but not to limit the scope of the present invention. Those skilled in the art to which the present invention belongs can make various modifications or supplements to the described specific embodiments or replace them in similar ways, but they will not deviate from the spirit of the present invention or go beyond the definition of the appended claims range.

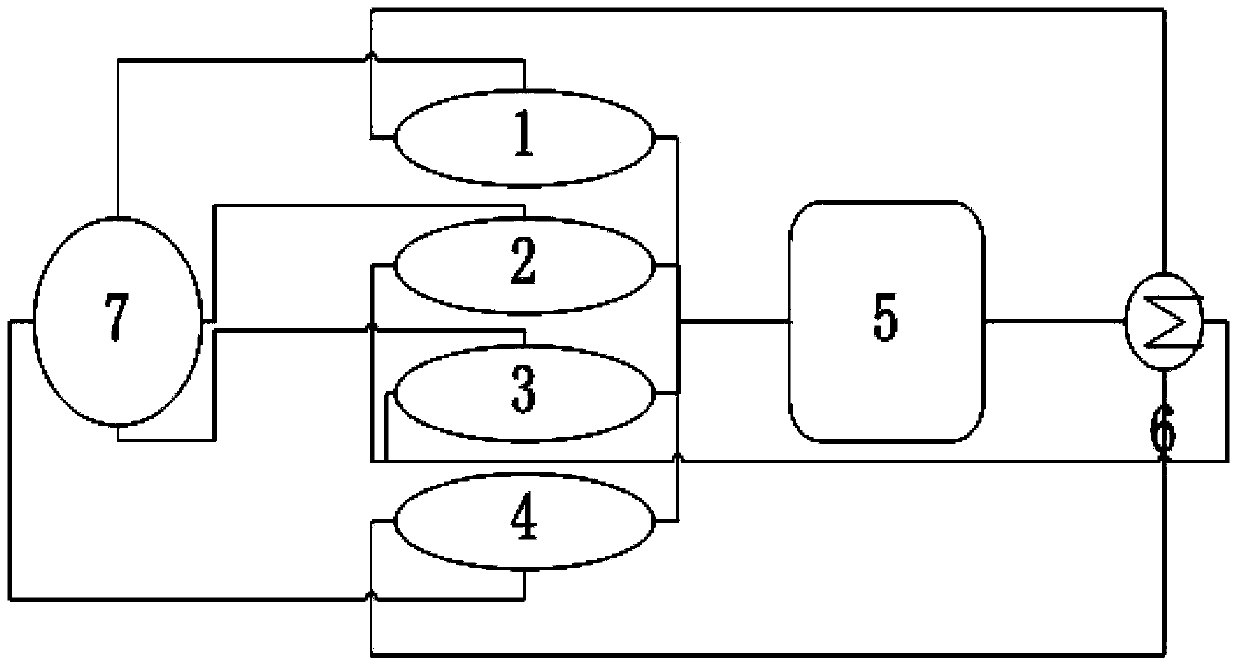

[0030] The device for reducing the comprehensive power consumption of the air separation plant includes an air compressor 1, an oxygen compressor 2, a nitrogen compressor 3 and a booster 4; it also includes a waste heat recovery device 5 capable of preparing chilled water through vapor compression; the waste heat recovery device 5 are respectively connected to the heat exchange jackets of air compressor 1, oxyg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com