Efficient desulfurized seawater quality restoration method and system

A technology for desulfurizing seawater and restoring water quality, which is applied in seawater treatment, chemical instruments and methods, oxidized water/sewage treatment, etc., and can solve the problems of high energy consumption and large footprint of the aeration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

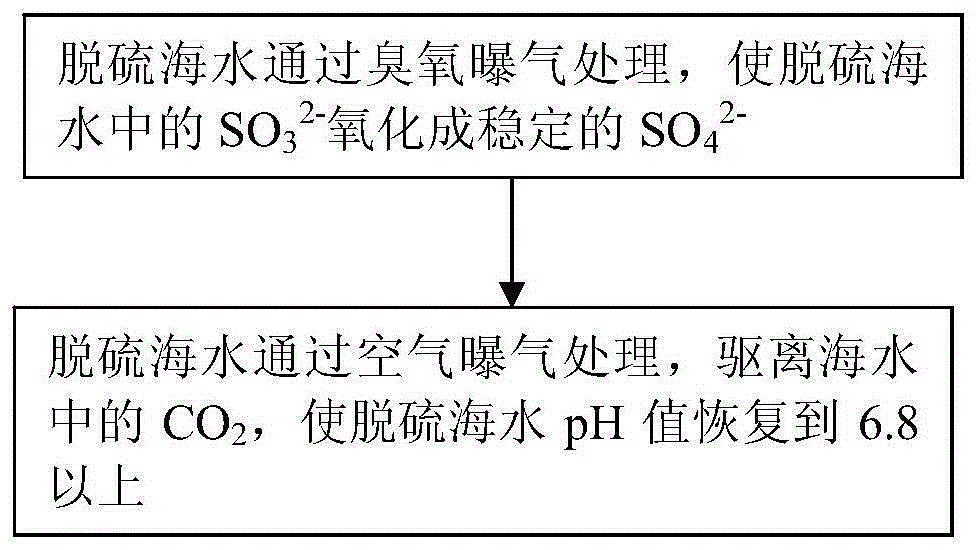

Method used

Image

Examples

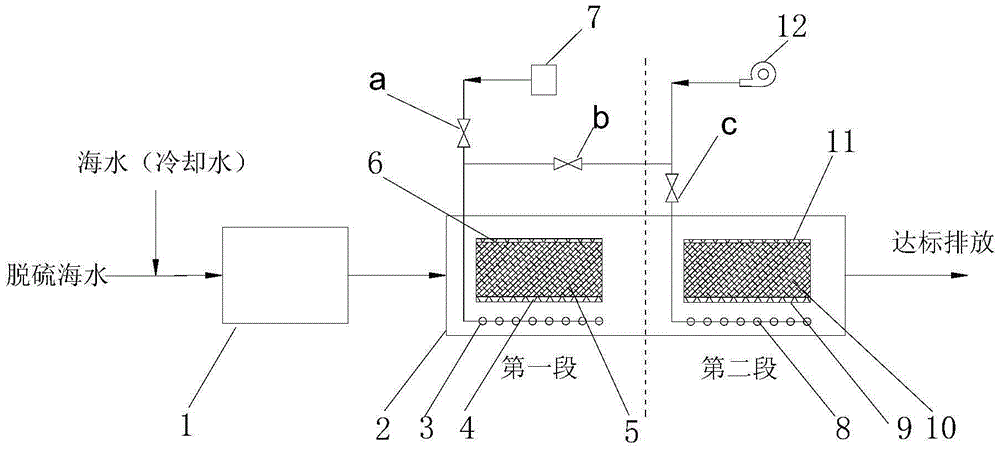

Embodiment 1

[0035] Desulfurization seawater flow rate is 20000m 3 / h, using traditional technology, the ratio of air to sea water is 2:1, the hydraulic retention time in the aeration tank is 400s, and the area of the aeration tank is about 2000m 2 and adopt the method and system of the present invention, the molar mass ratio of S (Ⅳ) in ozone and seawater is 2:1, the air and seawater air-water ratio is 5:1, and the hydraulic retention time in the aeration tank is 200s, and the aeration tank accounts for The land is about 1000m2.

Embodiment 2

[0037] Desulfurization seawater flow rate is 20000m 3 / h, using traditional technology, the ratio of air to sea water is 2:1, the hydraulic retention time in the aeration tank is 400s, and the area of the aeration tank is about 2000m 2 and adopt the method and system of the present invention, the molar mass ratio of S (Ⅳ) in ozone and seawater is 5:1, the air and seawater air-water ratio is 10:1, and the hydraulic retention time in the aeration tank is 150s, and the aeration tank accounts for The land is about 800m2.

Embodiment 3

[0039] Desulfurization seawater flow rate is 20000m 3 / h, using traditional technology, the ratio of air to sea water is 2:1, the hydraulic retention time in the aeration tank is 400s, and the area of the aeration tank is about 2000m 2 and adopt the method and system of the present invention, the molar mass ratio of S (Ⅳ) in ozone and seawater is 8:1, the air and seawater air-water ratio is 15:1, and the hydraulic retention time in the aeration tank is 100s, and the aeration tank accounts for The land is about 500m2.

[0040] In addition, an ozone aerator backwashing system is also set up in the present invention. Since the ozone consumption is relatively small and the aeration intensity is low, the aerator may be blocked after long-term operation. In the present invention, the valve can be used to switch , realize the purging and cleaning process of the ozone aerator with high-pressure air, and avoid setting up additional cleaning equipment. After running for a period of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com