Tubular device and method for producing cold water by means of indirect evaporation and direct evaporation

An evaporative cooler, an indirect technology, applied in direct contact heat exchangers, water shower coolers, lighting and heating equipment, etc., can solve the problems of poor cold water effect, waste of energy, low air utilization rate, etc., and achieve refrigeration performance Improvement, reduction of usage costs, and equipment simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

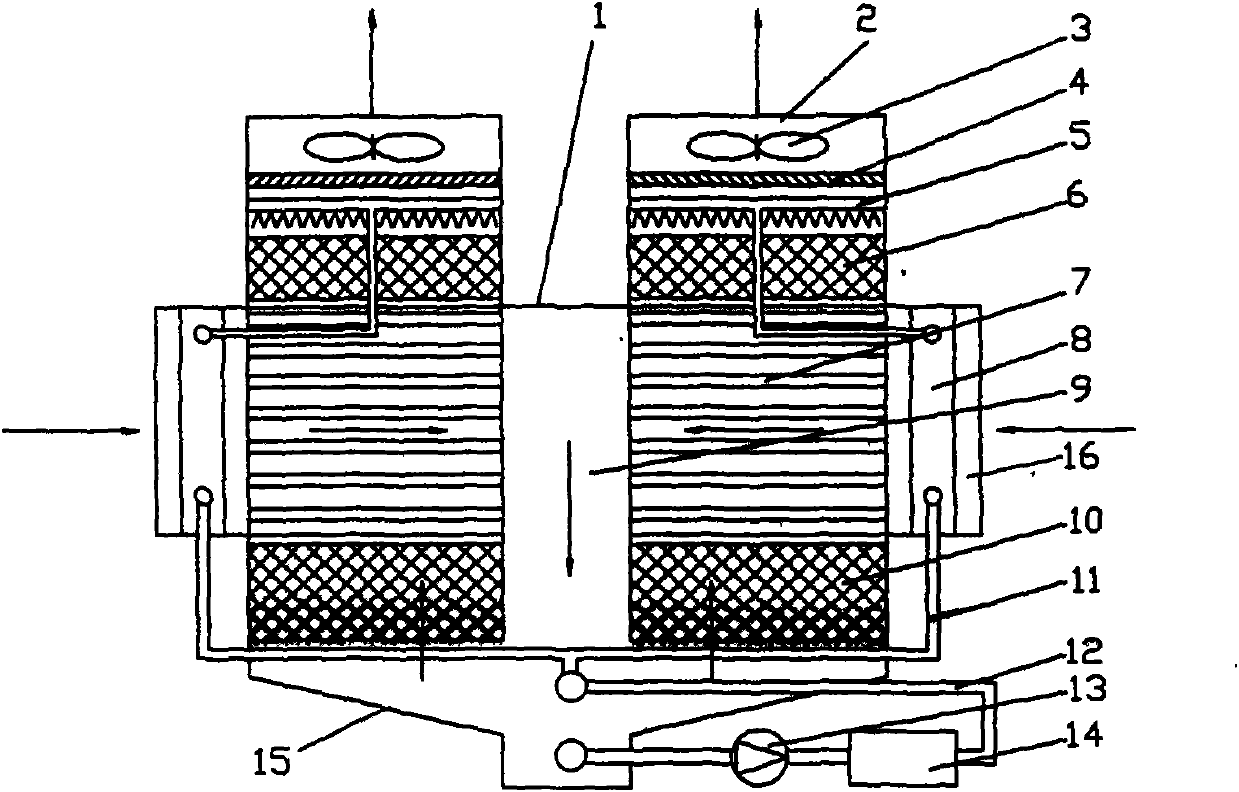

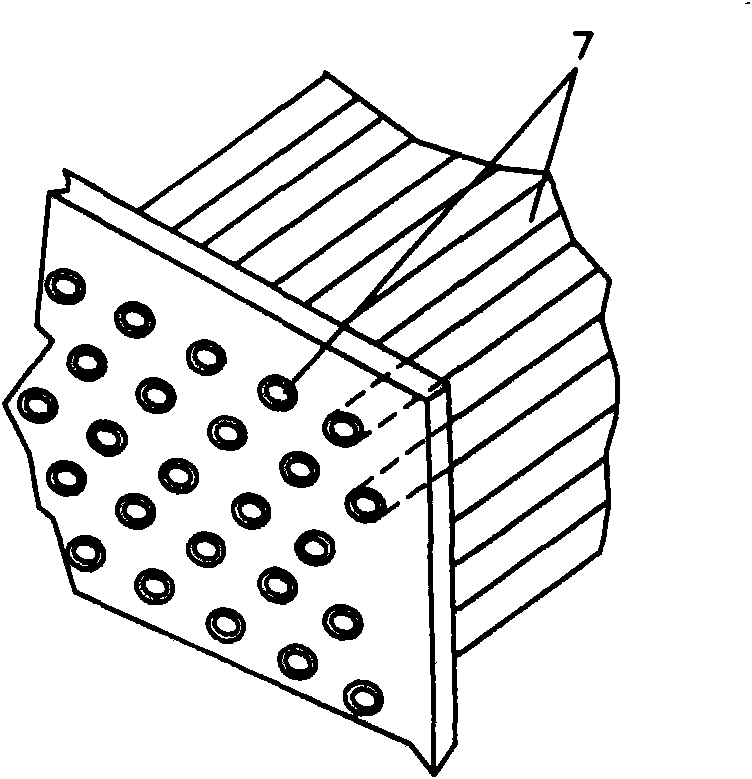

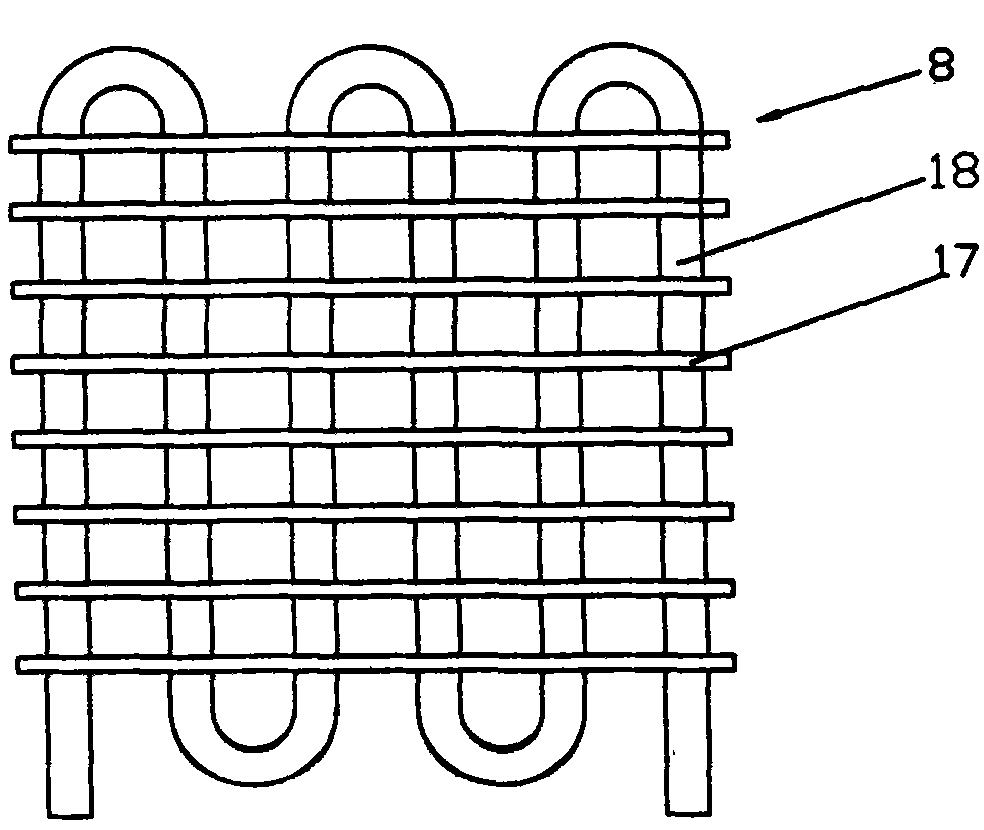

[0018] like figure 1 Shown, said device of the present invention mainly is made of surface cooler 8, tubular indirect heat exchanger 7, two direct evaporative coolers 6,10 and spray pipe 5, return pipe 12, circulating water pump 13 up and down. Among them, the surface cooler 8 is arranged at the air inlet 16 on the outside of the housing 11, and the tube-type indirect heat exchanger 7 is arranged opposite to the air inlet 16 in the axial direction of the tube, and on the tube-type indirect heat exchanger 7 and The upper direct evaporative cooler 6 and the lower direct evaporative cooler 10 are respectively arranged below, and the upper part of the upper direct evaporative cooler 6 is sequentially provided with a spray pipe 5 , a water retaining plate 4 and an exhaust fan 3 from bottom to top. The upper part of the surface cooler 8 communicates with the spray pipe 5 through a pipeline, and the lower part of the surface cooler 8 communicates with the user 14 through a return pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com