Image processing method for processing image of plug in type stove camera

An image processing and plug-in technology, applied in furnaces, furnace components, image communication, etc., can solve problems such as failure of window valves and mechanical focusing devices, complicated movement and protection devices, and inability to perform maintenance and repairs, etc., to achieve Good protection effect, small shape and small aperture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

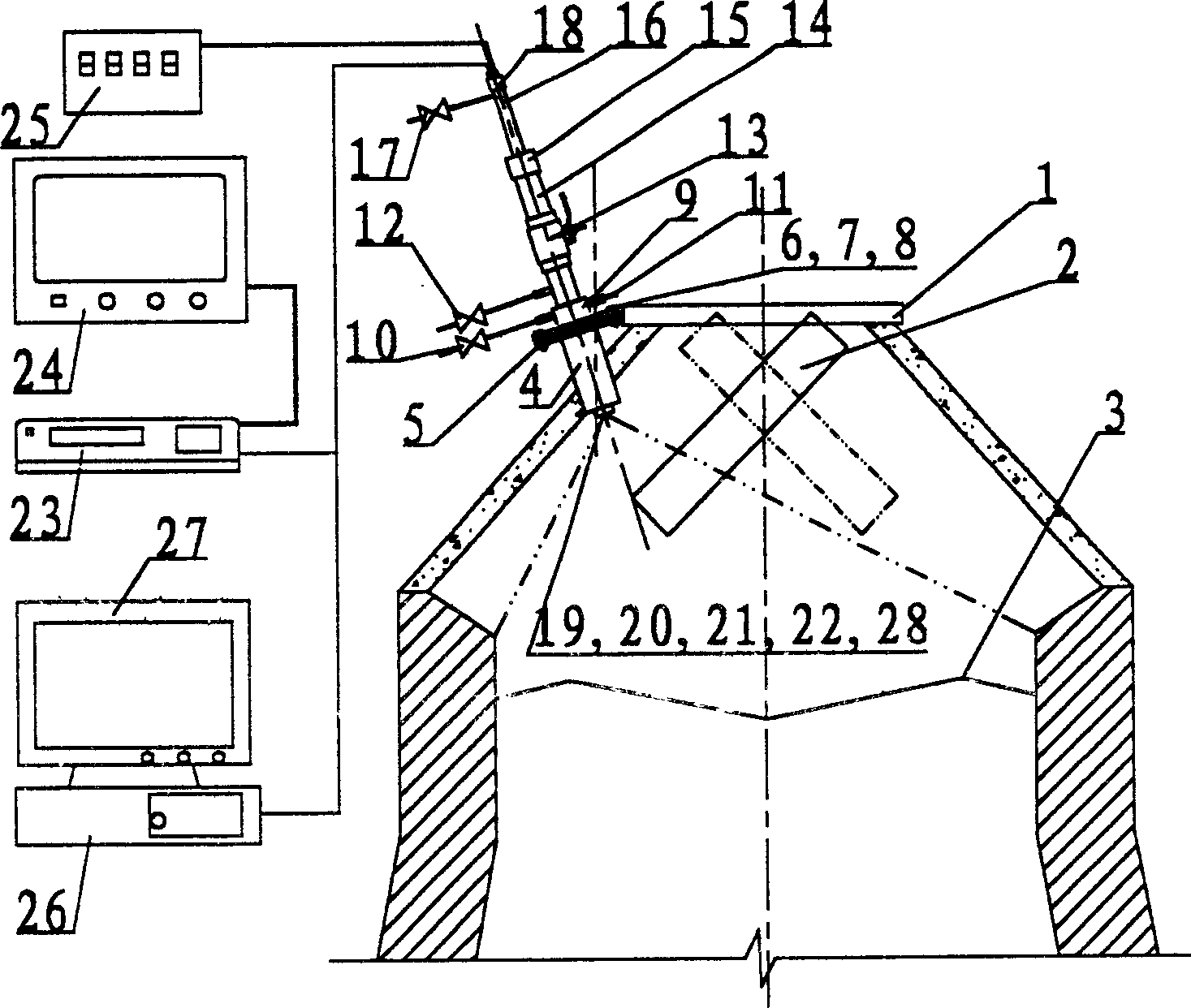

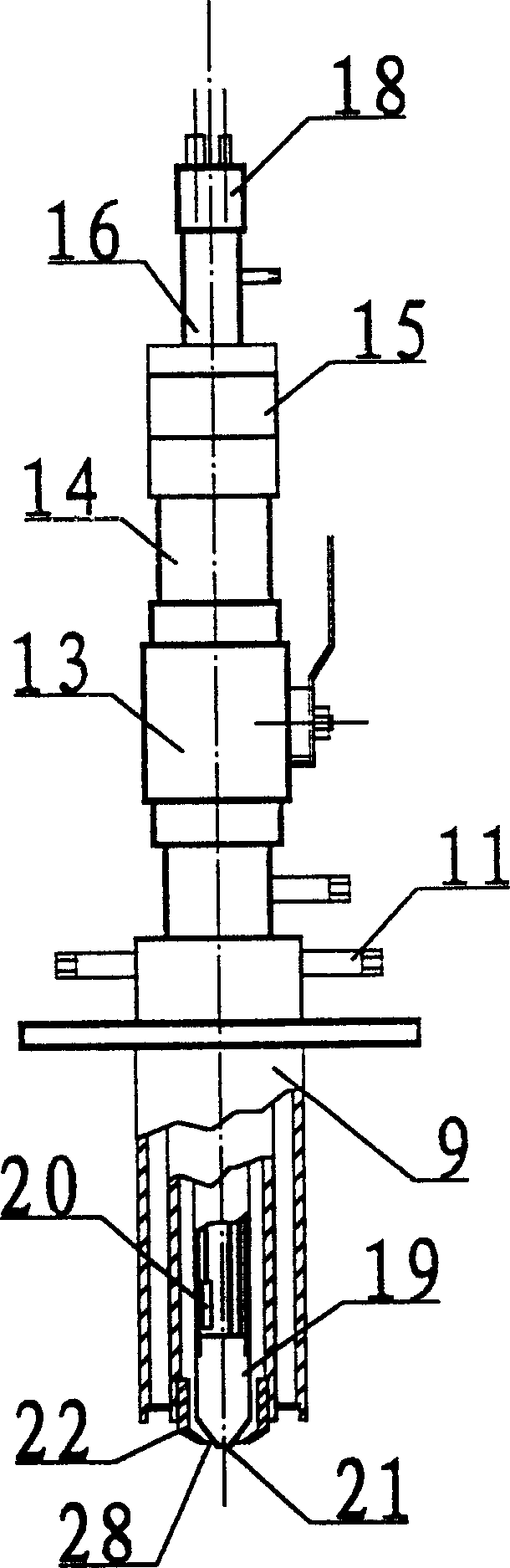

[0009] Holes are drilled at appropriate parts of the top furnace shell of the blast furnace 1, and the flange short pipe 4 is welded. The tubular cooler 9 is inserted into the furnace through the gasket 5 and the flanged short tube 4, and the cooler is installed and tightened with bolts 6, washers 7 and nuts 8 to ensure tightness. Water is supplied to the tube cooler 9 from the valve 10, and the water is discharged from the drain port 11 to ensure the cooling effect. Pass the protective gas (nitrogen or clean gas) into the blast furnace from the valve 12, and continuously purge the peep hole 21 through the purge ring gap 28 between the purge ring 22 and the camera 19. Special camera 19 and temperature measuring element 20 are installed at the front end of camera gun 16, inserted into cooler front end by sealing sleeve 15, connecting pipe 14 and valve 13, and protective gas (nitrogen or clean coal gas) passes in the camera barrel from valve 17 , Blow into the furnace from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com