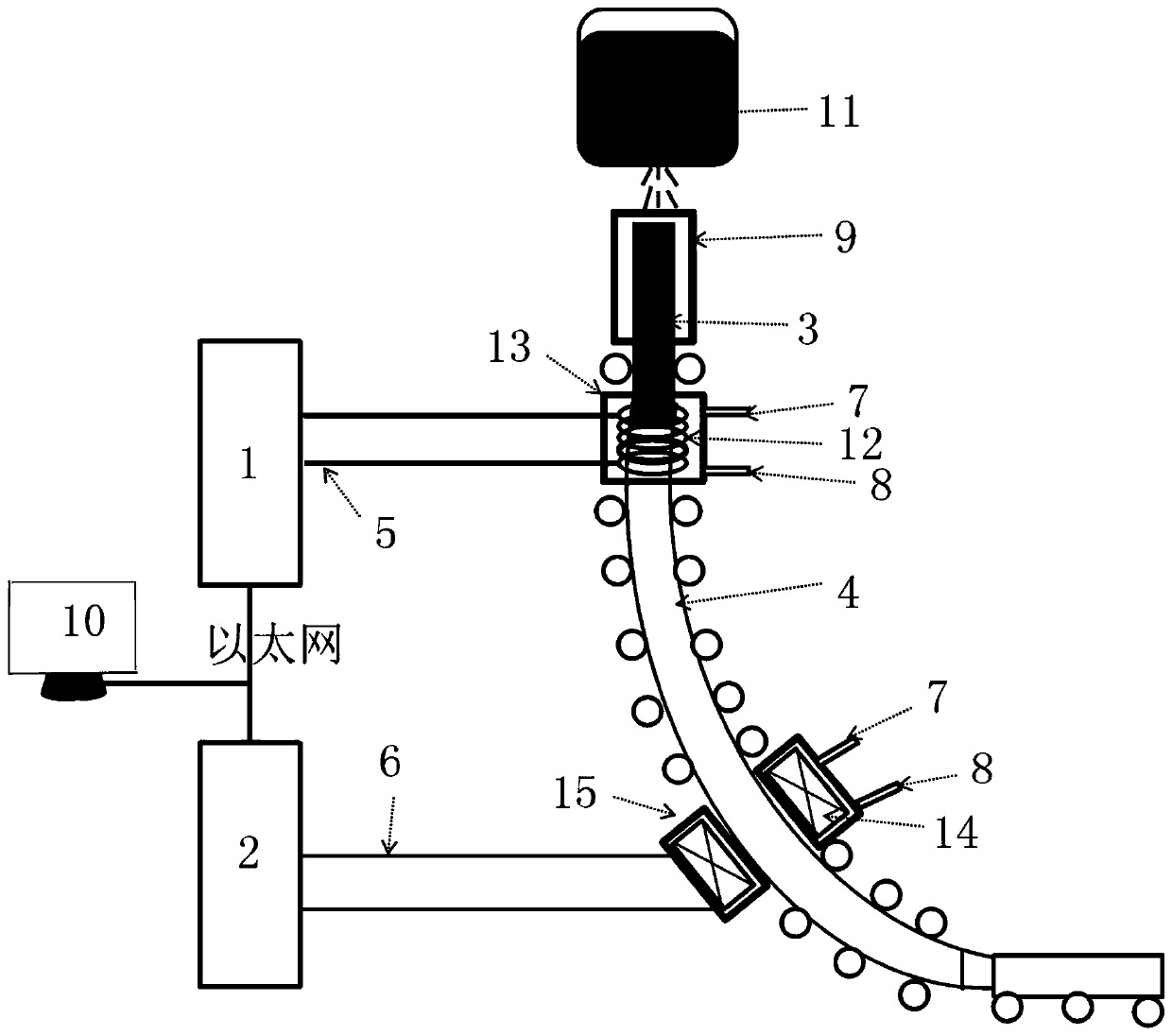

Continuously cast blank homogenization device and method

A technology for homogenizing and continuous casting slabs, which is applied in the field of continuous casting slab homogenization devices, which can solve the problem of the difficulty in determining the solidification end position of the continuous casting slab, the shrinkage of the continuous casting slab center, and the inability to accurately control the amount of reduction and other problems, to achieve the effect of low equipment price, elimination of central shrinkage cavity, and high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

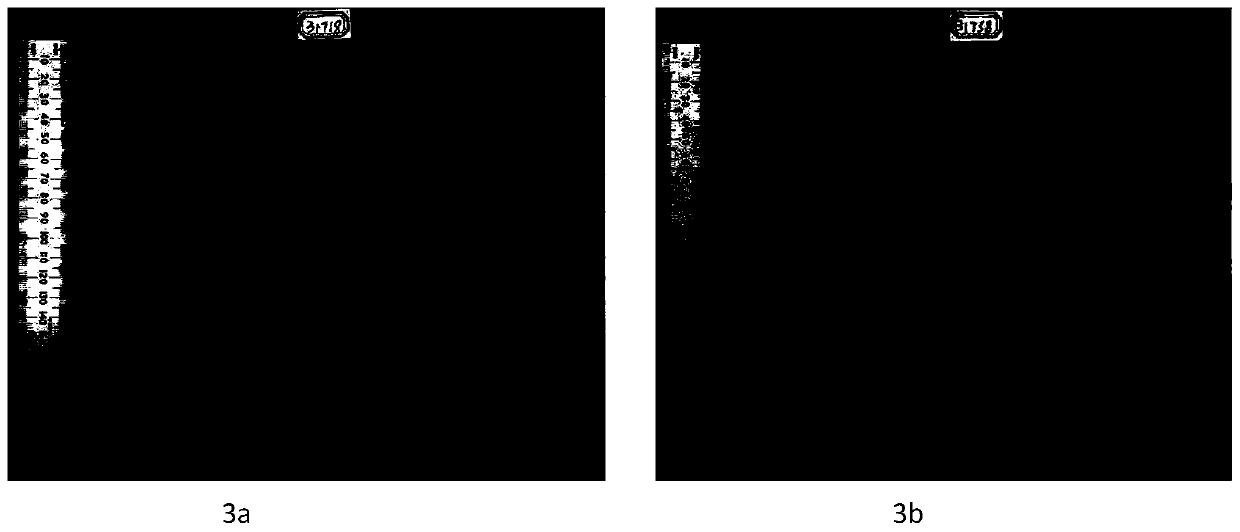

Embodiment 1

[0047] The experimental process is as follows: the experiment was carried out on the Zhongtian No. 1 continuous casting machine. The casting machine is one machine with five strands. The section size of the continuous casting billet is 220mm × 260mm. The harmonic magnetic field coil is a single-layer spring coil with 15 turns, which is installed 0.5m below the mold. The continuous harmonic magnetic field coil is a motor coil fixed around the encapsulation shell, and is installed 5m below the pulsed harmonic magnetic field coil. Flow 1 is a comparative experiment without any treatment, and flow 5 is treated by a combination of pulsed harmonic magnetic field and continuous harmonic magnetic field. Pulse harmonic magnetic field power parameters: pulse harmonic voltage 450V, duty cycle 21%, frequency 29Hz, no-load coil center magnetic field strength 5800 Gauss; continuous harmonic magnetic field power parameters: harmonic voltage 350V, no-load coil center magnetic field strength 34...

Embodiment 2

[0051] The experimental process is as follows: the experiment was carried out on the Zhongtian No. 1 continuous casting machine. The casting machine is one machine with five strands. The section size of the continuous casting billet is 220mm × 260mm. The harmonic magnetic field coil is a single-layer spring coil with 15 turns, which is installed 0.5m below the mold. The continuous harmonic magnetic field coil is a motor coil fixed around the encapsulation shell, and is installed 5m below the pulsed harmonic magnetic field coil. Flow 1 is a comparative experiment without any treatment, and flow 5 is treated by a combination of pulsed harmonic magnetic field and continuous harmonic magnetic field. Pulse harmonic magnetic field power parameters: pulse harmonic voltage 400V, duty cycle 21%, frequency 22Hz, no-load coil center magnetic field strength 4900 Gauss; continuous harmonic magnetic field power parameters: harmonic voltage 280V, no-load coil center magnetic field strength 28...

Embodiment 3

[0055] The experimental process is as follows: the experiment was carried out on the Zhongtian No. 1 continuous casting machine. The casting machine is one machine with five strands. The cross-sectional size of the continuous casting billet is 220mm × 260mm. 25℃, the pulse harmonic magnetic field coil is a single-layer spring coil, the number of turns is 18, and it is installed 1.3m below the mold. The continuous harmonic magnetic field coil is a motor coil fixed around the package shell, and is installed in the pulse harmonic magnetic field coil. 4.5m below. Flow 1 is a comparative experiment without any treatment, and flow 5 is treated by a combination of pulsed harmonic magnetic field and continuous harmonic magnetic field. Pulse harmonic magnetic field power parameters: pulse harmonic voltage 450V, duty cycle 21%, frequency 33Hz, no-load coil center magnetic field strength 6000 Gauss; continuous harmonic magnetic field power parameters: harmonic voltage 370V, no-load coil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com