Color layered artist clay and its production

A production process and clay technology, which is applied in the field of melaleuca process clay materials to achieve the effects of bright color, not easy to break, and easy to prepare

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

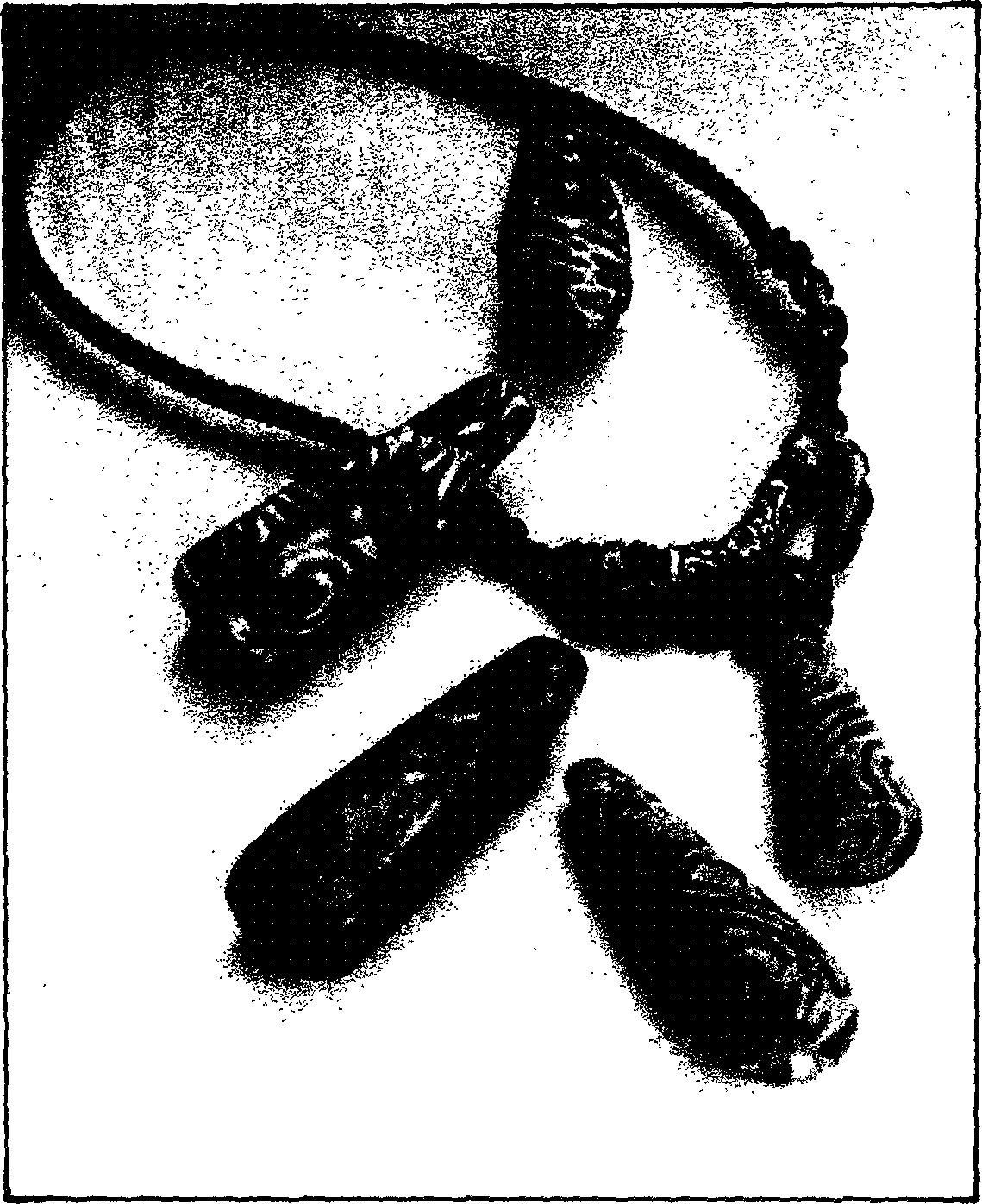

[0011] The formula ratio of the new clay material is selected as:

[0012] PVC powder resin: 45; dioctyl ester: 17; plastic: 4; calcium carbonate: 34.

[0013] Toner powder imported from the UK is used as a color additive, and with different colors, it is molded into cone-shaped beads, round beads and other colored beads of different shapes as required, and holes for threading rope are reserved, and then put into an electric heating box and baked at 130°C Bake for less than 30 minutes. After drying and hardening, they become brightly colored pottery beads, which are then threaded with ropes to become a string of beautiful, unique and personalized hanging ornaments.

Embodiment 2

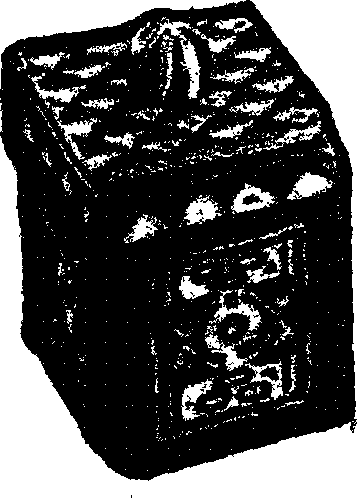

[0015] The formula ratio of the new clay material is selected as:

[0016] PVC powder resin: 43; dioctyl ester: 20; plastic: 2; calcium carbonate: 35.

[0017] With different colors, according to your own creative design, shape it into a storage box, and then put it in an electric oven and bake it at 140°C for less than 30 minutes. After drying and hardening, it becomes a colorful and unique ceramic storage box. Beautiful and generous, it can be used for both storage and decoration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com