Patents

Literature

103 results about "Polymer clay" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymer clay is a type of hardenable modeling clay based on the polymer polyvinyl chloride (PVC). It typically contains no clay minerals, but like mineral clay a liquid is added to dry particles until it achieves gel-like working properties, and similarly, the part is put into an oven to harden, hence its colloquial designation as clay. Polymer clay is generally used for making arts and craft items, and is also used in commercial applications to make decorative parts. Art made from polymer clay can now be found in major museums.

Method of producing an exfoliated polymer-clay nanocomposite through solid-state shear pulverization

A method of producing a polymer-clay nanocomposite comprises providing a supply of polymer-clay mixture, exfoliating the mixture through solid-state shear pulverization in the presence of cooling sufficient to maintain the extruded mixture in the solid state during the pulverization, and discharging the resulting exfoliated mixture. The invention is also directed to a method of producing a polymer hybrid nanocomposite, wherein a component is dispersed throughout a polymer matrix by solid-state shear pulverization of a polymer mixed with the second component.

Owner:NORTHWESTERN UNIV

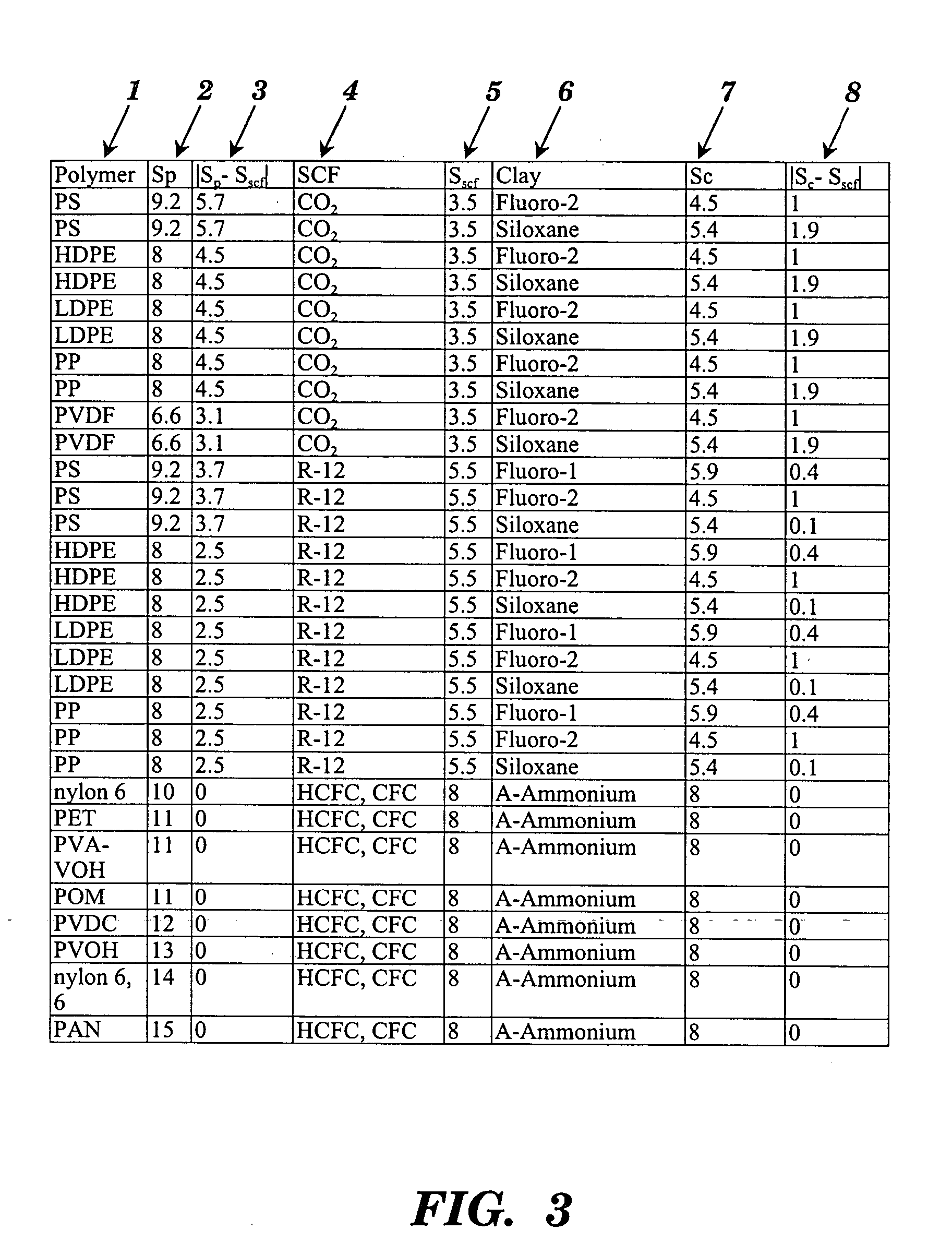

Production of polymer nanocomposites using supercritical fluids

InactiveUS20050131126A1Maximum and efficient dispersionMaterial nanotechnologyBulk chemical productionSolubilityPolymer nanocomposite

A method and system of forming a polymer nanocomposite. A layered clay and polymer are selected wherein |Sp−Sscf|>|Sc−Sscf| and |Sc−Sscf|≦2.0 (cal / cm3)0.5 are satisfied. Sp, Sc, and Sscf is a solubility parameter of the polymer, clay, and a supercritical fluid (SCF), respectively. The polymer and clay are mixed to form a polymer-clay mixture. The polymer-clay mixture is melted to form a polymer-clay melt. The polymer-clay melt is initially contacted with the SCF while the SCF is subject to an initial pressure exceeding the critical pressure of the SCF and to a temperature exceeding the critical temperature of the SCF. The polymer-clay melt is further contacted with the SCF while the SCF is at a lower pressure below the critical pressure of the SCF to exfoliate the clay to form the nanocomposite having the exfoliated clay being substantially dispersed throughout the polymer of the polymer-clay.

Owner:RENESSELAER POLYTECHNIC INST

Production of polymer nanocomposites using peroxides

InactiveUS20060066012A1Maximum and efficient dispersionMaterial nanotechnologyMixer accessoriesPolymer sciencePolymer nanocomposite

A method and system for forming a polymer nanocomposite. A peroxide-degradable polymer, a clay, and a peroxide are mixed to form a polymer-clay-peroxide mixture. The polymer-clay-peroxide mixture is then heated forming a polymer-clay-peroxide melt containing peroxide radicals. The result is a degradation of the peroxide-degradable polymer within the melt to form smaller molecular weight polymer chains using the peroxide radicals and a diffusion of said polymer chains into the clay within the melt so as to exfoliate the clay to form the polymer nanocomposite having exfoliated clay being randomly dispersed throughout the polymer nanocomposite.

Owner:YANG KUMIN +2

Preparation method of low molecular weight clay stabilizer

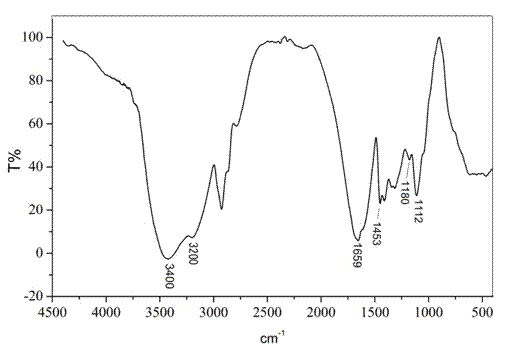

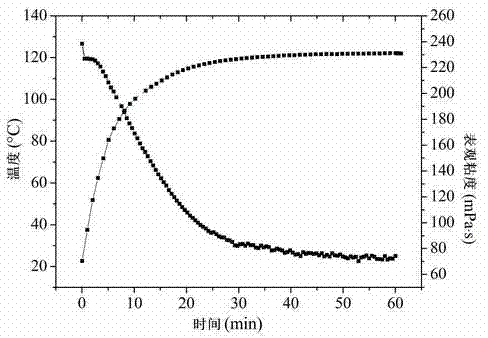

The invention belongs to the technical field of oil production engineering, and provides a preparation method of a low molecular weight polymer clay stabilizer. The clay stabilizer is prepared from raw materials of carbon-containing ammonium salt and 2-acrylamido-2-methyl propane sulfonic acid (AMPS) in the presence of an initiator in an aqueous solution through polymerization. The number average molecular weight of the polymer is less than 50000. The sulfonic acid group is introduced into the polymer stabilizer, so as to increase the water solubility and high temperature performance of the polymer. The stabilizer can form multiple point adsorption with a plurality of clay particles in the water; after adsorption, a layer of protective film is formed on the surface of clay particles to prevent expansion and migration of clay particles; and the stabilizer has the high temperature resistance performance reaching more than 120 DEG C.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of producing exfoliated polymer-clay nanocomposite and polymer-clay nanocomposite produced therefrom

Owner:NORTHWESTERN UNIV

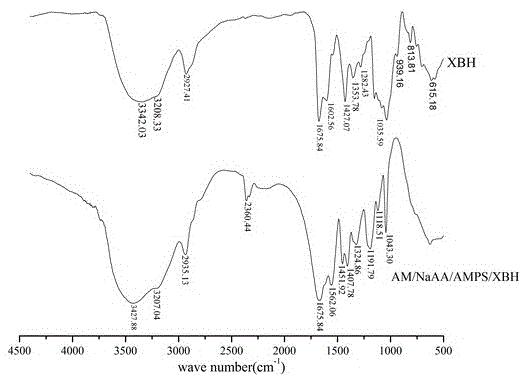

Polymer clay stabilizer containing Beta-cyclodextrin structure and synthesis method thereof

InactiveCN102618237AWith parcel landfill functionGood water solubilityDrilling compositionSolubilityPolymer science

The invention relates to a polymer clay stabilizer containing Beta-cyclodextrin structure and a synthesis method thereof, wherein the polymer clay stabilizer is used for restraining clay hydration swelling of an oil well. The technical scheme is as follows: the polymer clay stabilizer comprises the following materials and monomers in percentage by mass: 35-54.8% of acrylamide AM, 15-25% of sodium acrylate NaAA, 8-20% of 2-acryloyl-methyl-propyl sulfonate AMPS, and 0.2% of 2-O (propenyloxy-2-hydroxy-propyl)-Beta-cyclodextrin XBH; 0.02g of XBH and 2g of AMPS are added into a flask, and then 5.48g AM, 1.915g of AA and 0.585 g of NaOH are added into the flask, so a water solution with the monomer mass percentage concentration of 20% is prepared, and nitrogen is introduced into the water solution for 20 min; (NH4)2S2O8 solution and NaHSO3 solution are then added into the water solution while nitrogen is continuously introduced into the water solution for 10-20 min, and reaction is carried out at the temperature of 35 DEG C for 4-12 hours; and finally, the reacted solution is subjected to washing with absolute ethyl alcohol, smashing and drying to obtain AM / NaAA / AMPS / XBH quaternary polymer. The polymer clay stabilizer has good water solubility, viscosifying capacity, temperature resistance, salt resistance, anti-shearing capacity and clay-swelling restraining capacity, and reaches the swelling prevention rate of 84.37% towards sodium-montmorillonite.

Owner:SOUTHWEST PETROLEUM UNIV

Clay antiswelling agent for petroleum extraction and preparation method thereof

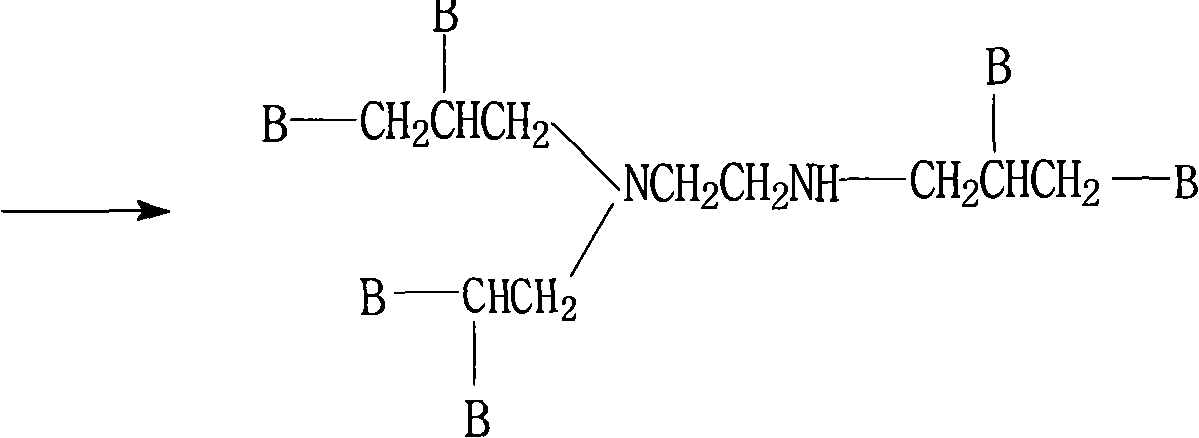

ActiveCN101921366ATo overcome the shortcomings of poor anti-expansion effectOvercoming osmotic injuriesDrilling compositionPotassium persulfateNitrogen gas

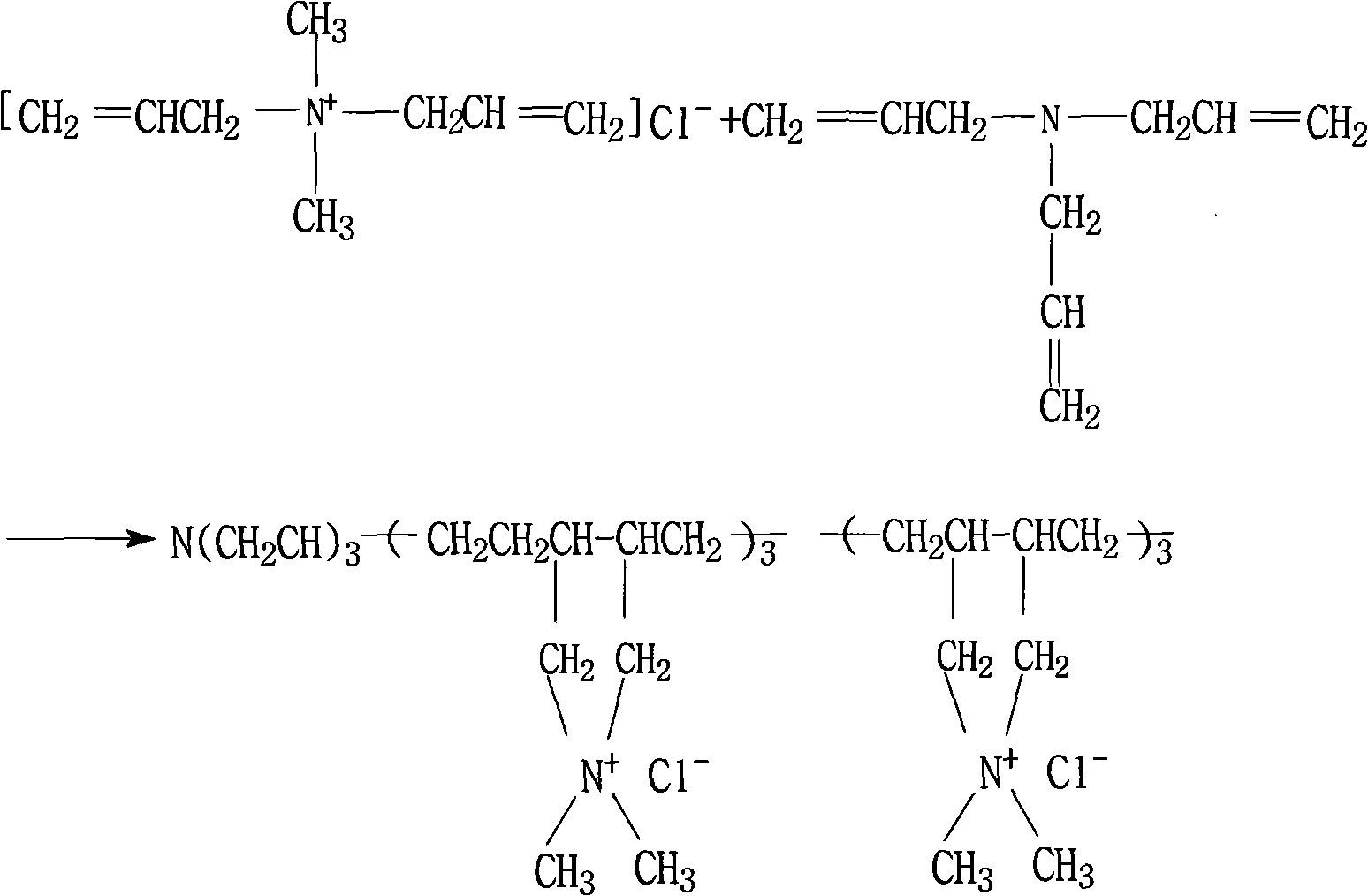

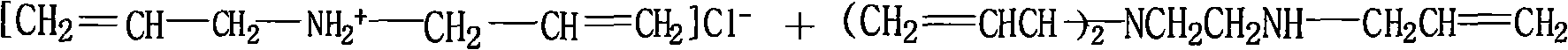

The invention relates to a clay antiswelling agent for petroleum extraction and a preparation method thereof. The preparation method comprises the following steps of: dissolving 50-90 percent of diallyl ammonium chloride monomer and 10-50 percent of triallylamine monomer into distilled water according to mass proportion, wherein the total mass proportion concentration of the two monomers is 20-80 percent; adding into a reactor; charging nitrogen; adding initiator at 65-85 DEG C, wherein the initiator is ammonium persulfate, potassium persulfate or hydrogen peroxide; and reacting for 4-6 hours to obtain a polymer clay antiswelling agent for petroleum extraction, which has the molecular structure that three branch chains contain organic cations. The antiswelling agent has high inhibiting performance on clay, durable antiswelling effect, water scouring resistance and no damage to the stratum and can be used for water injection, acidification and well control fluid.

Owner:PETROCHINA CO LTD

Method of producing exfoliated polymer-clay nanocomposite and polymer-clay nanocomposite produced therefrom

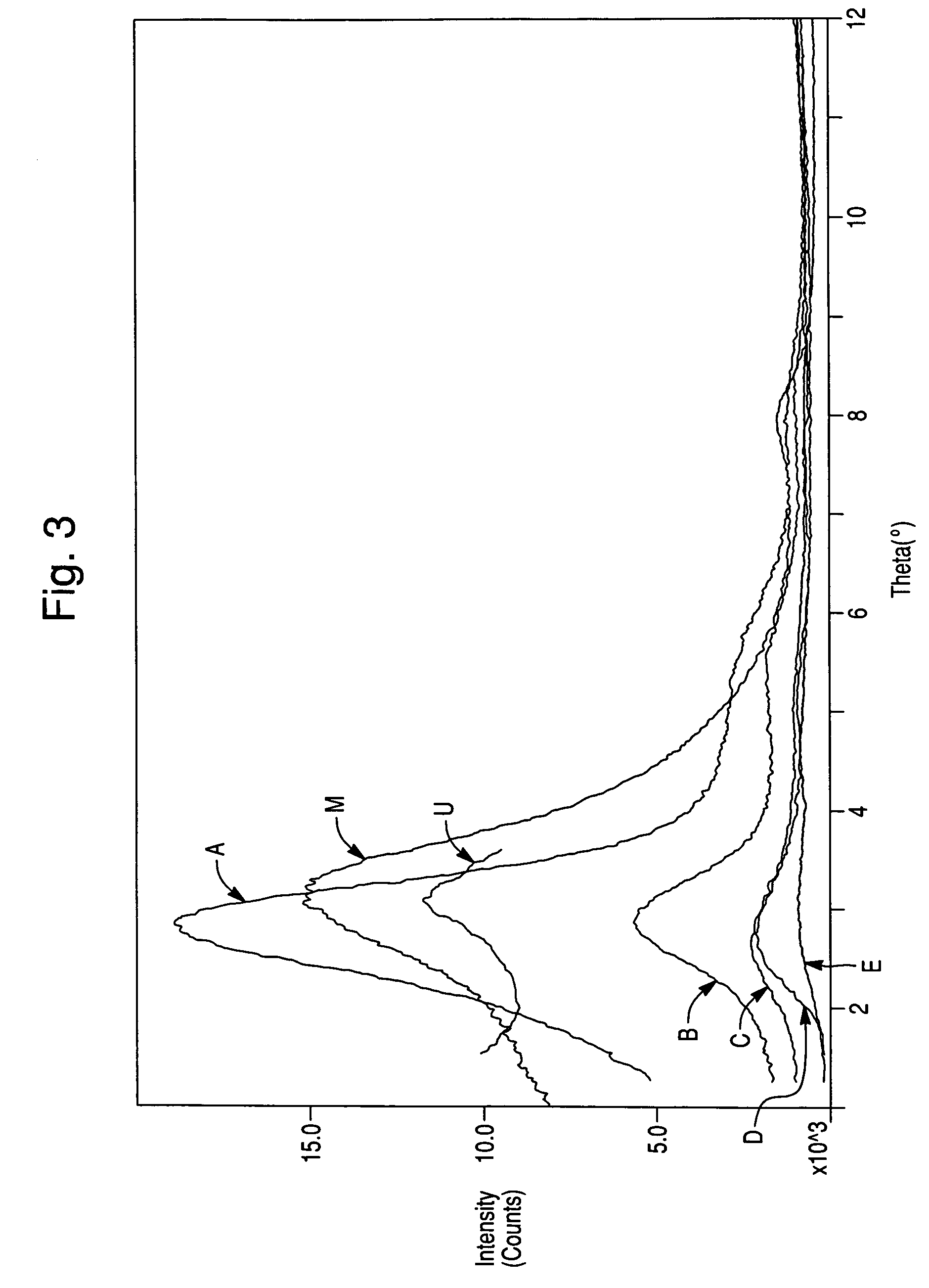

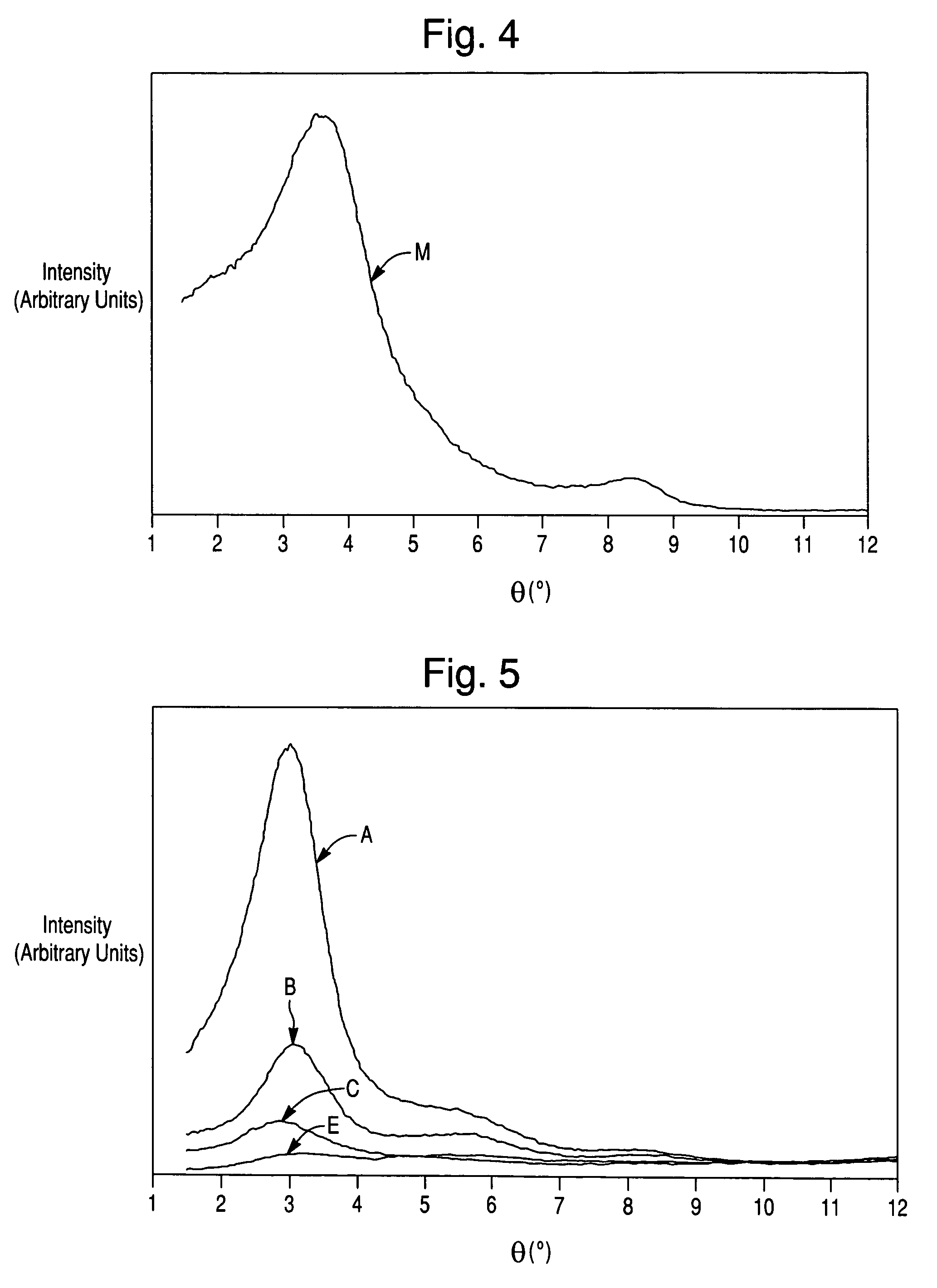

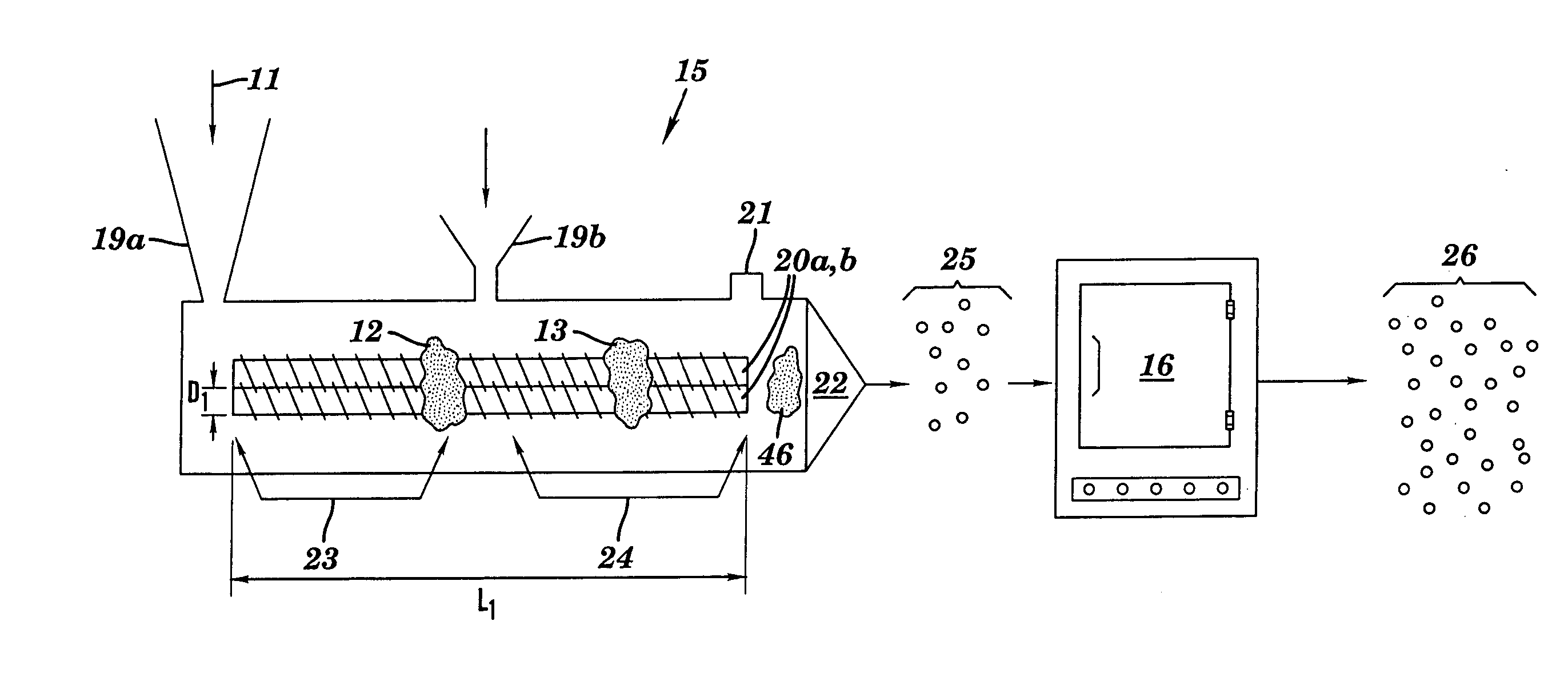

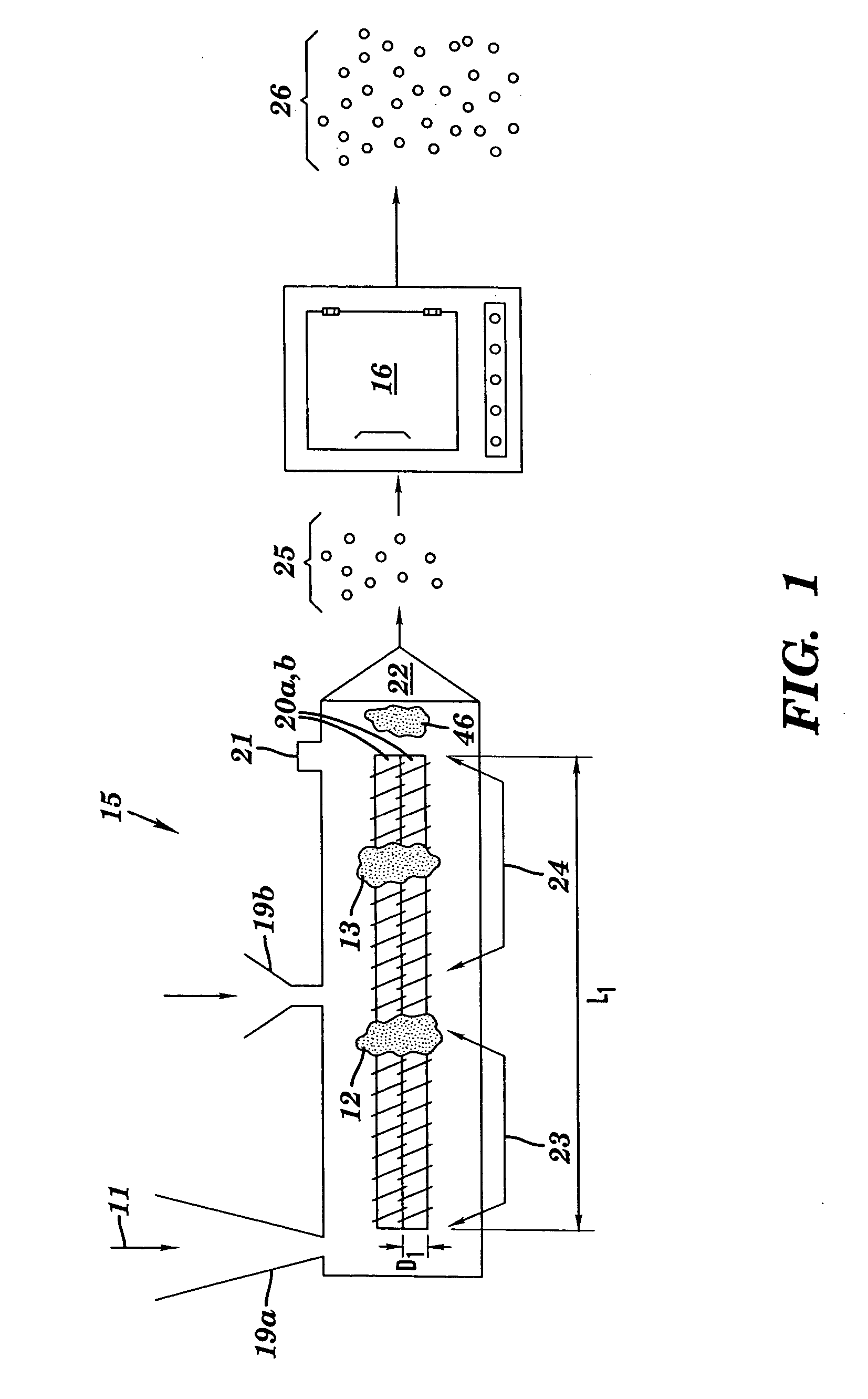

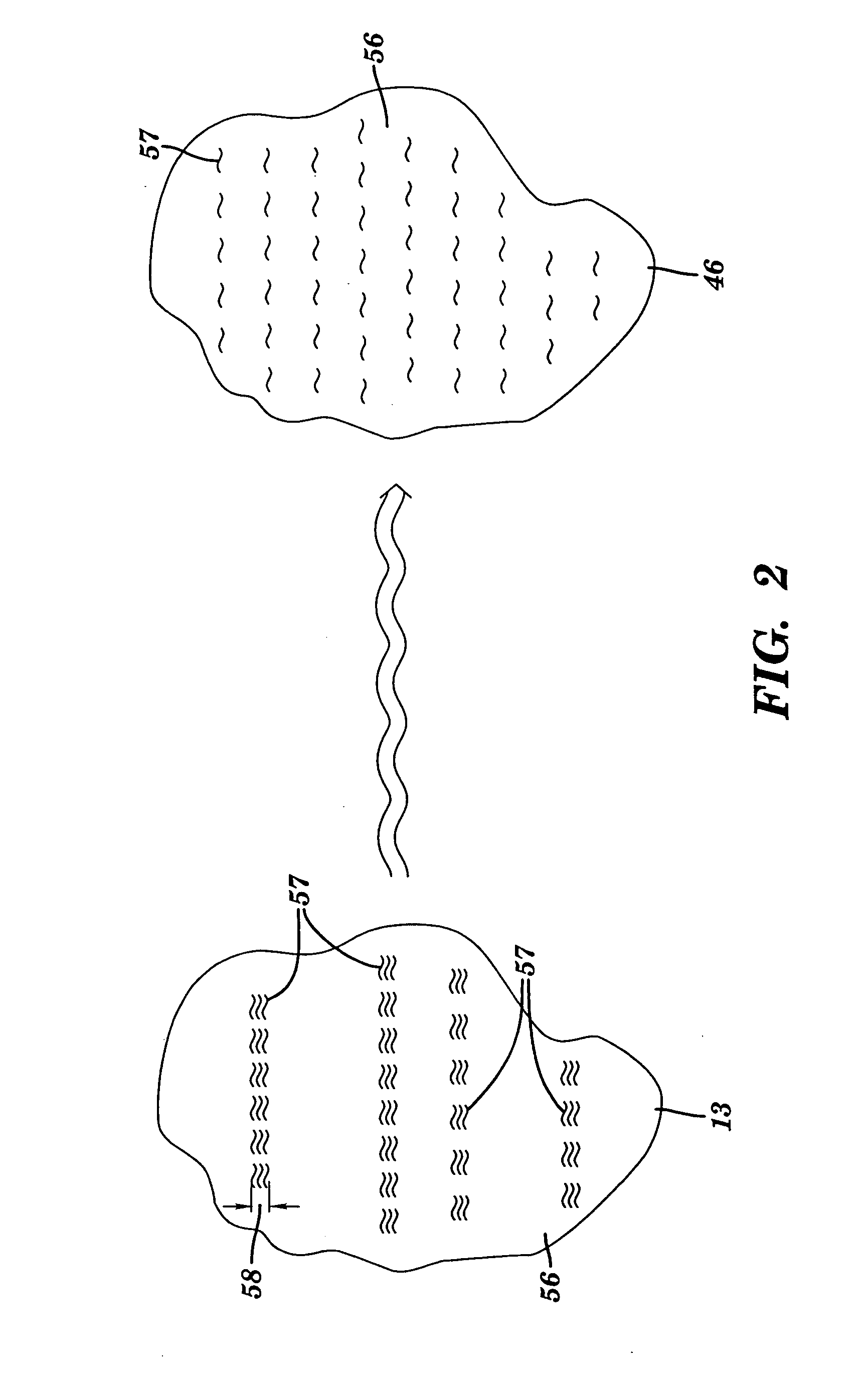

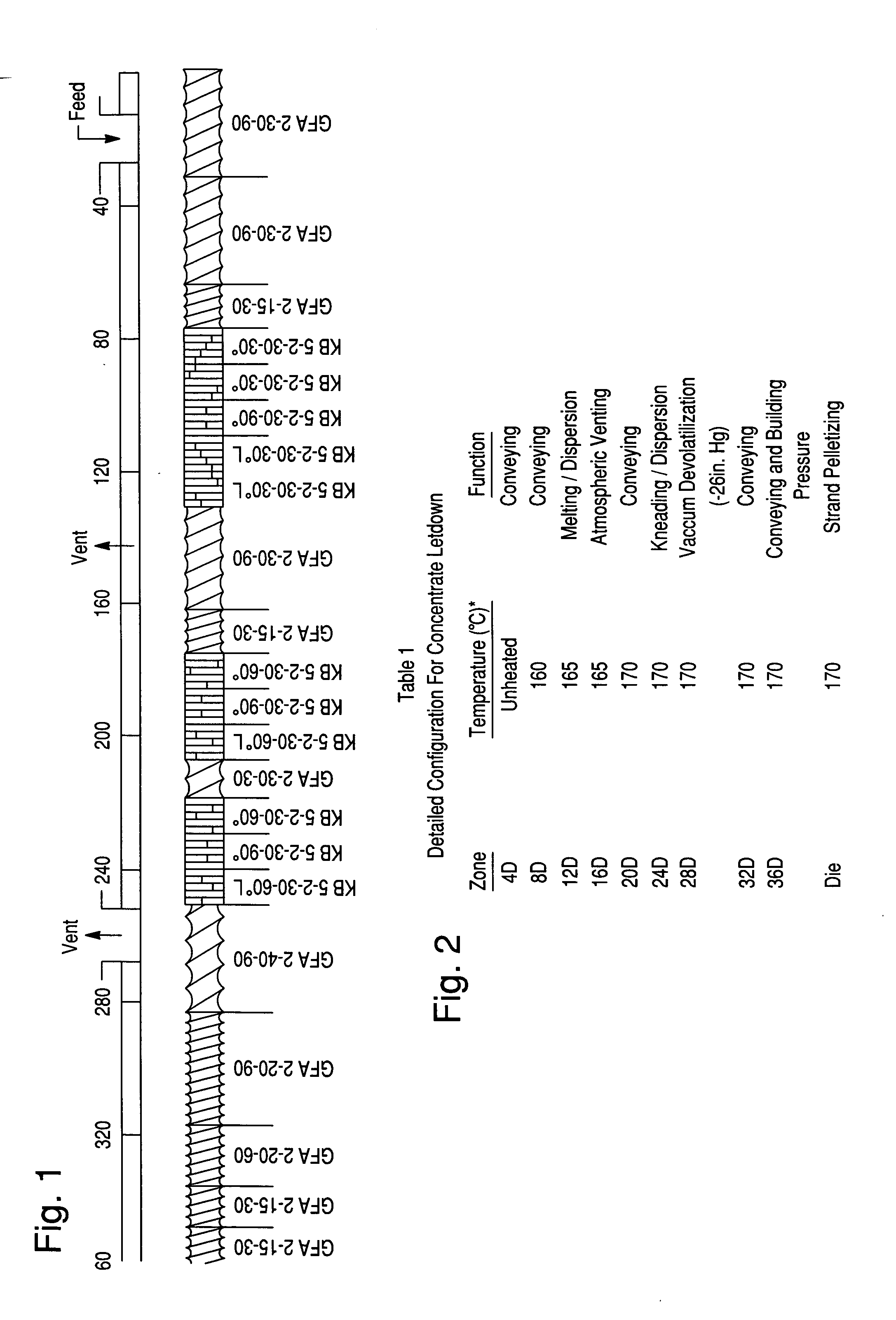

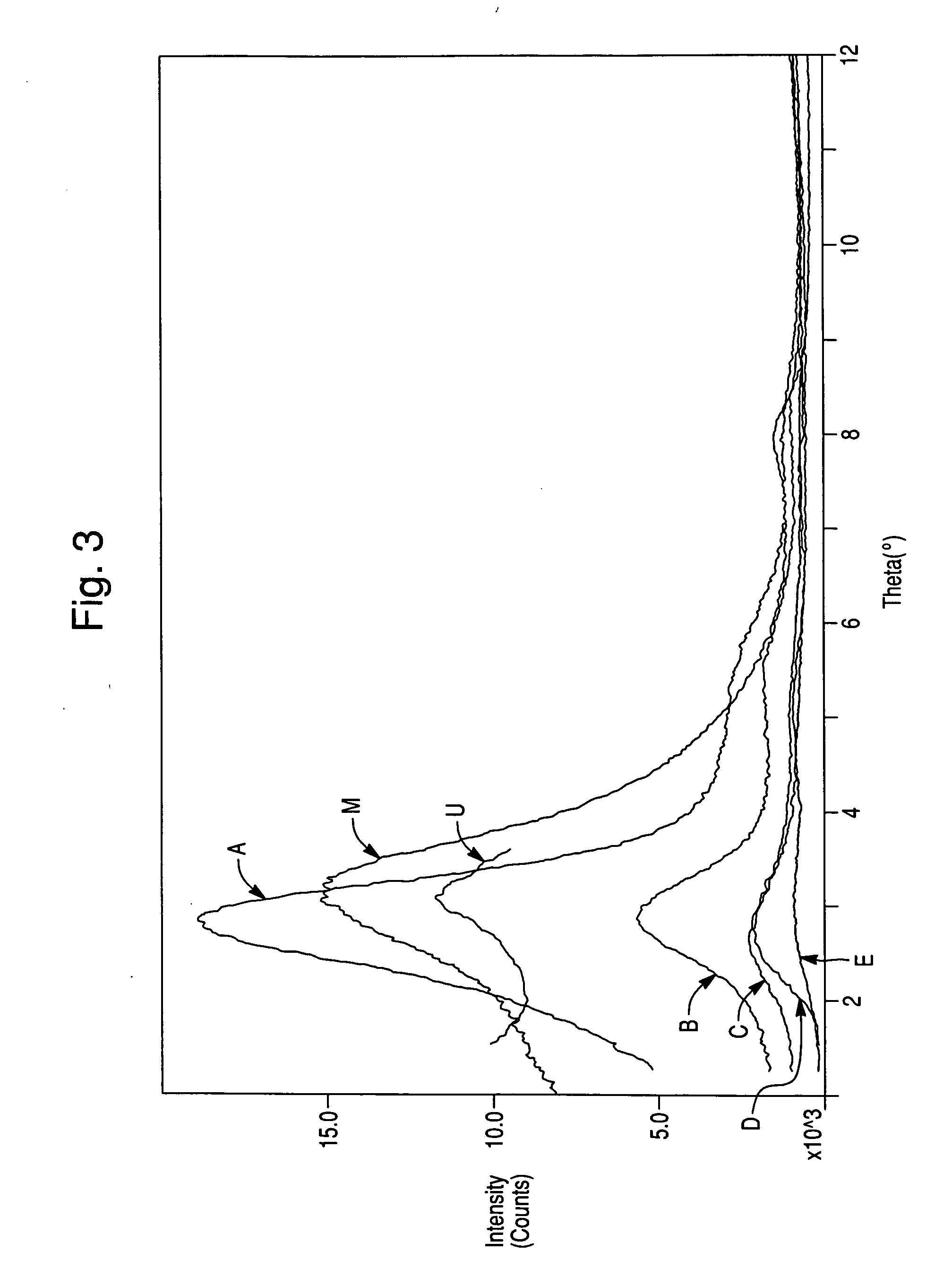

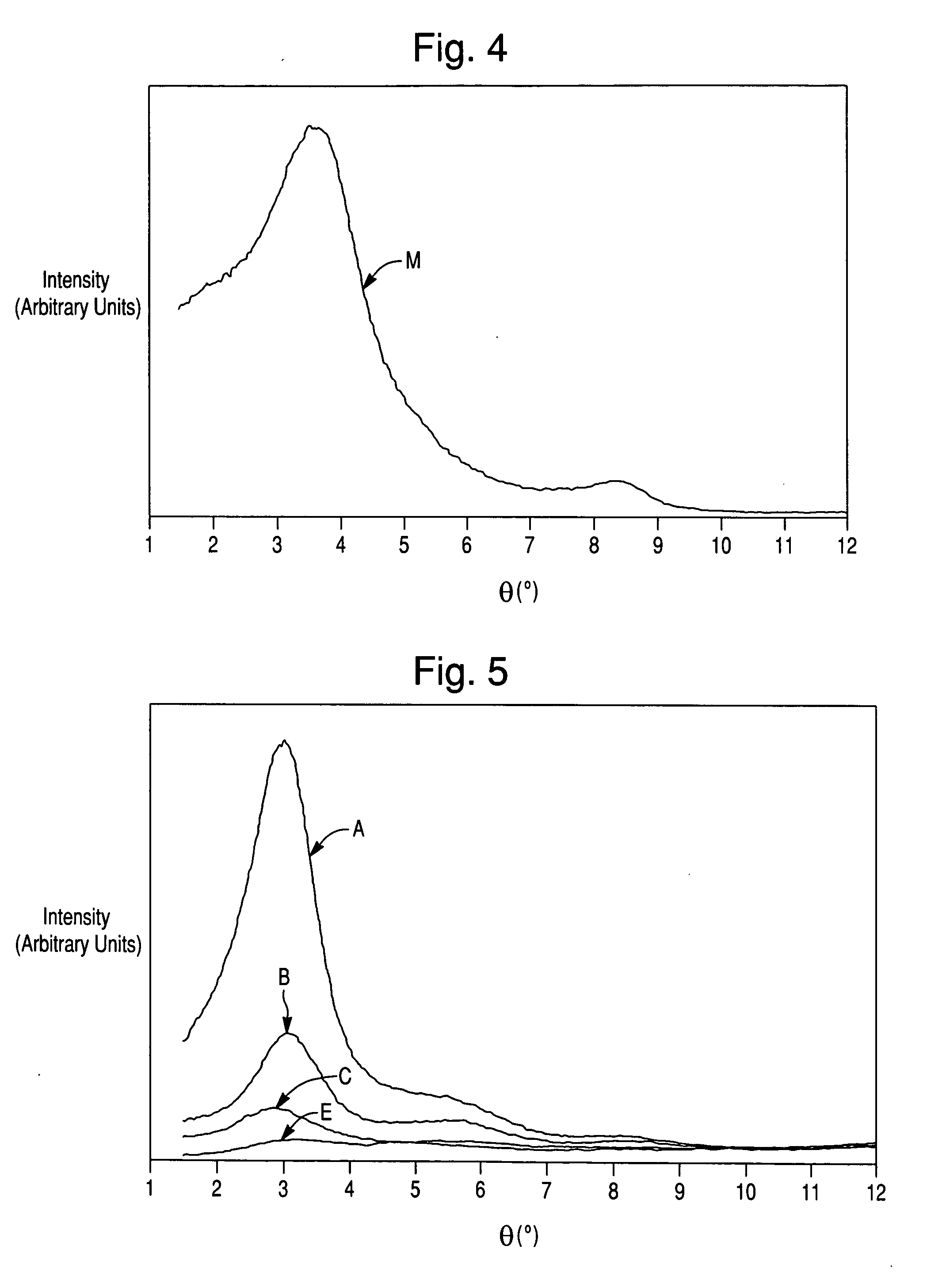

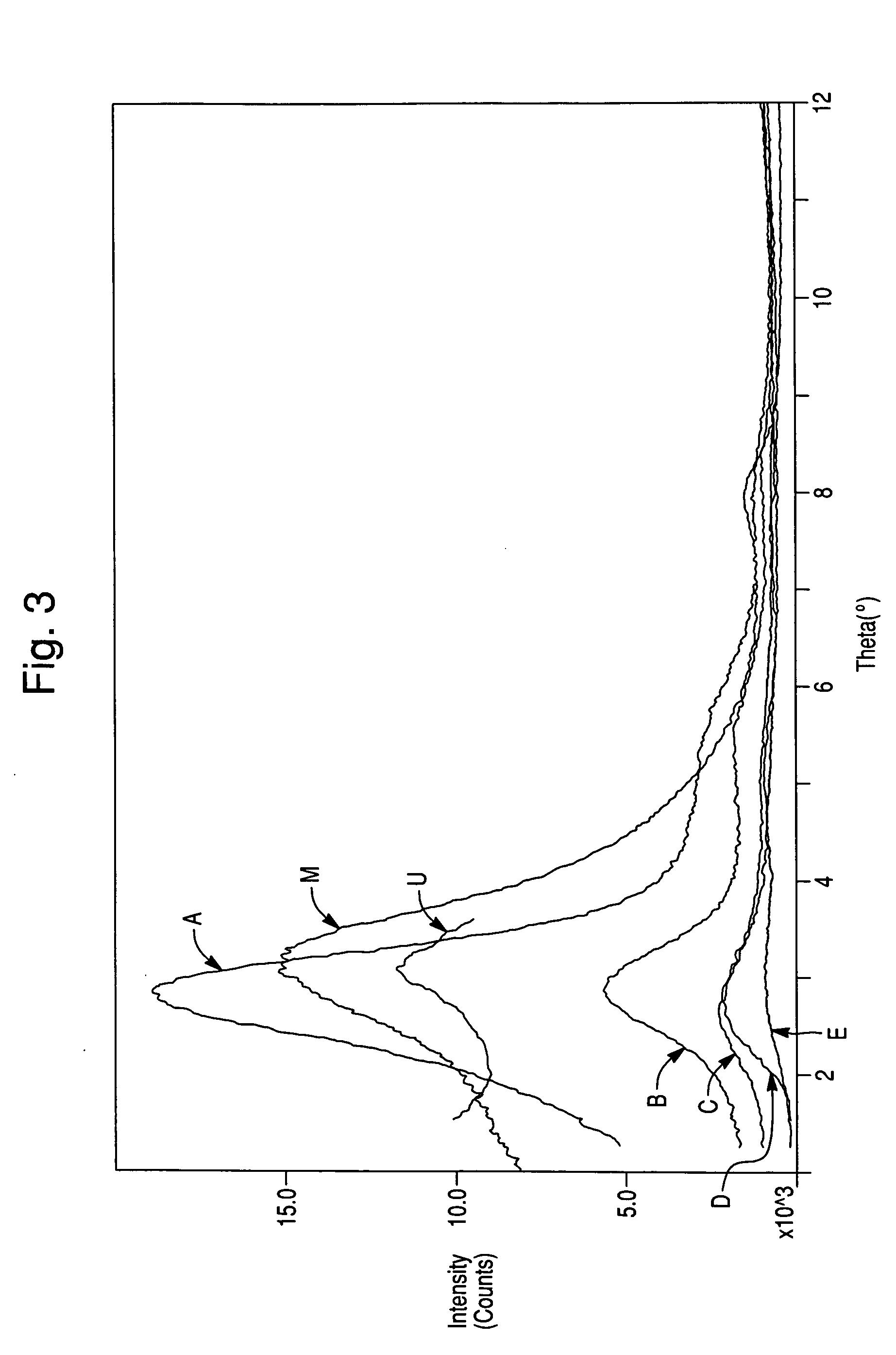

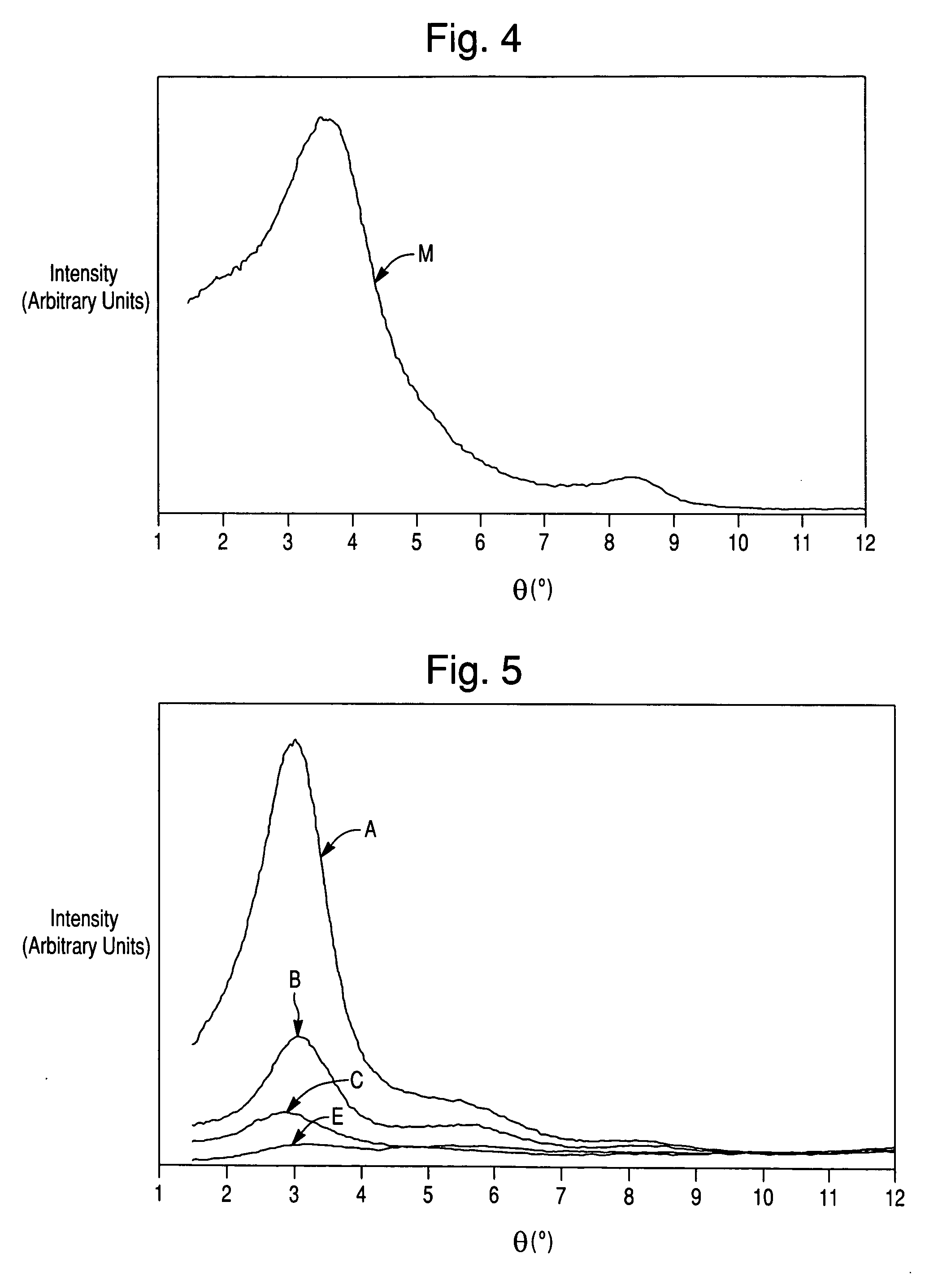

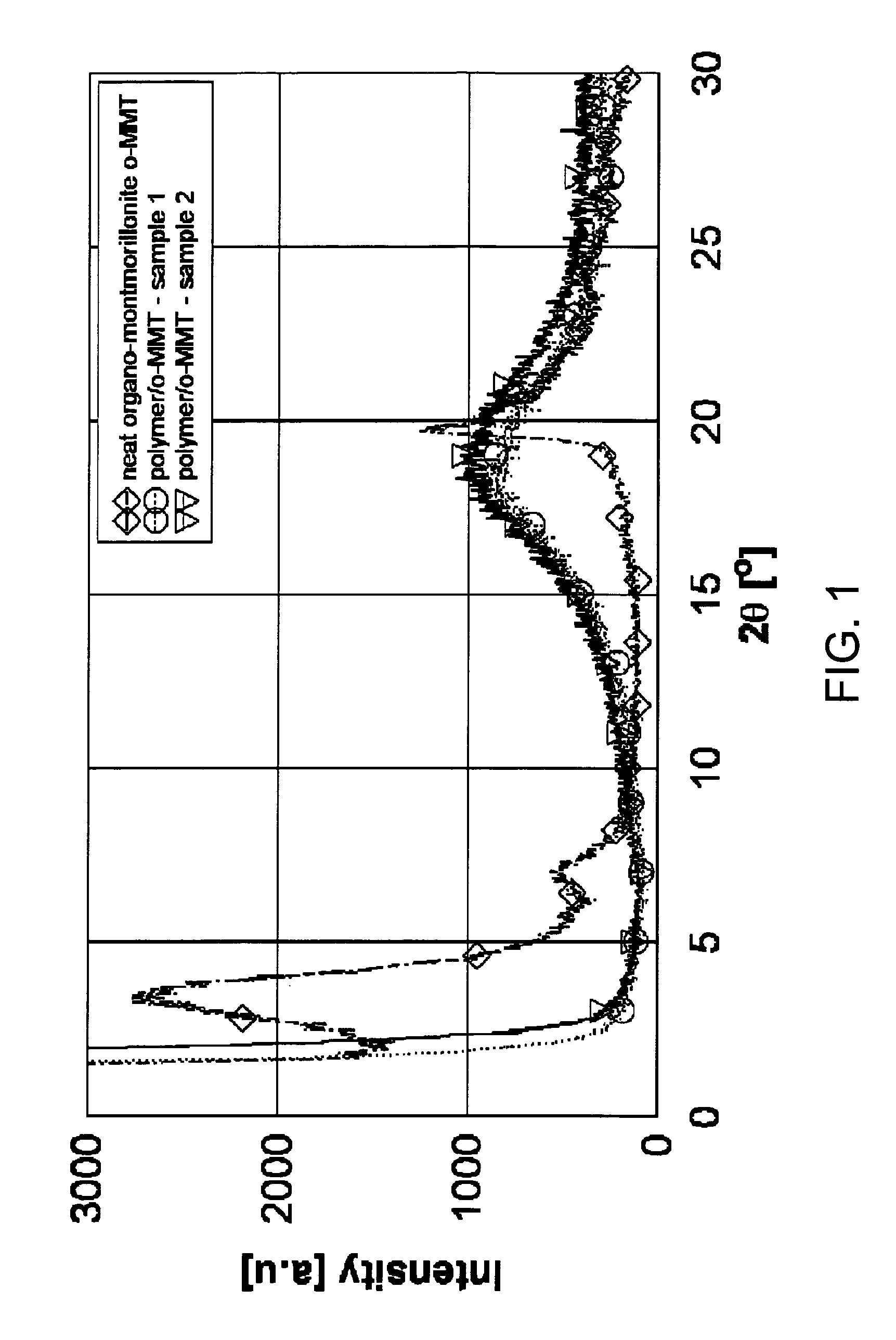

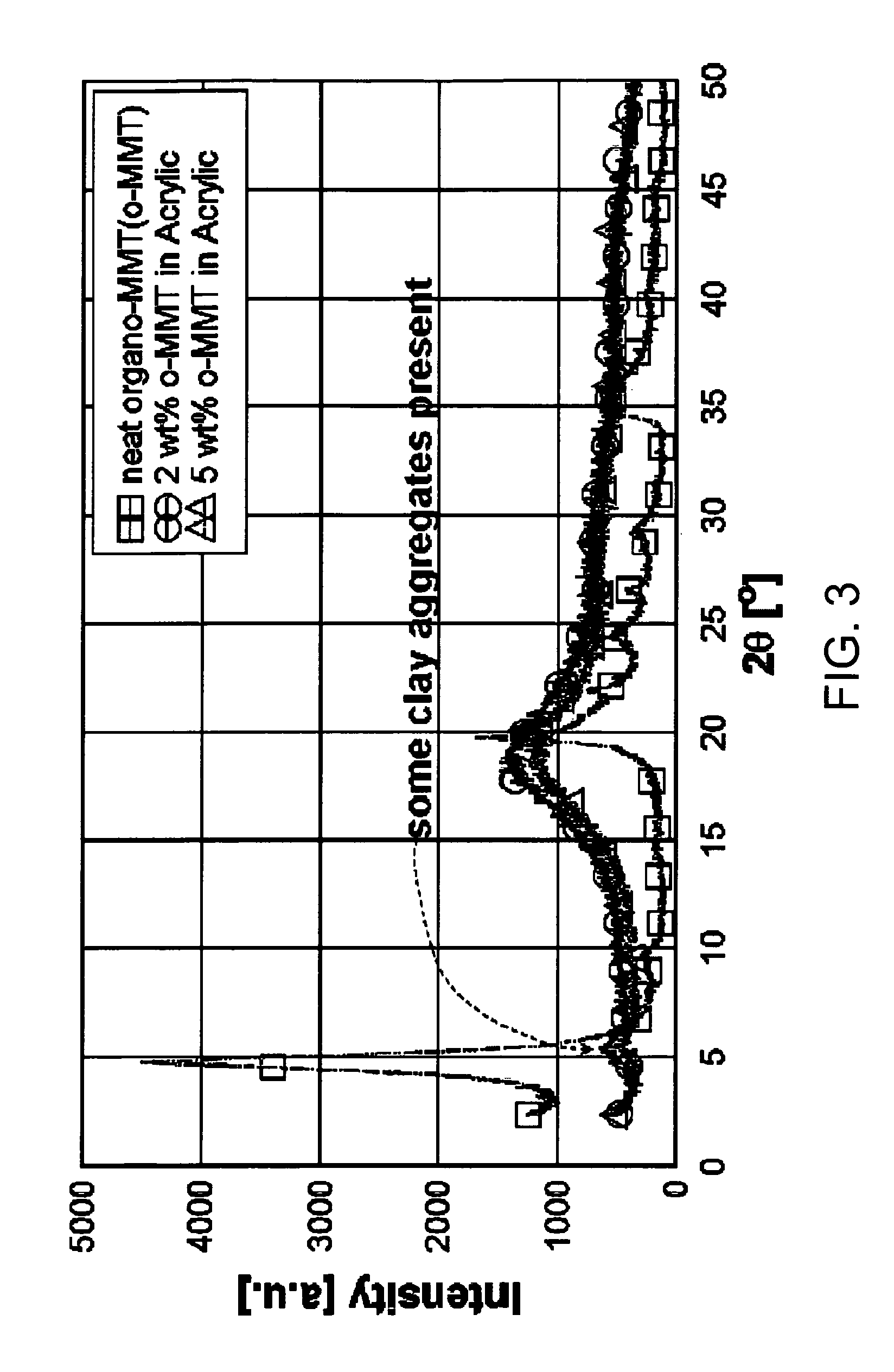

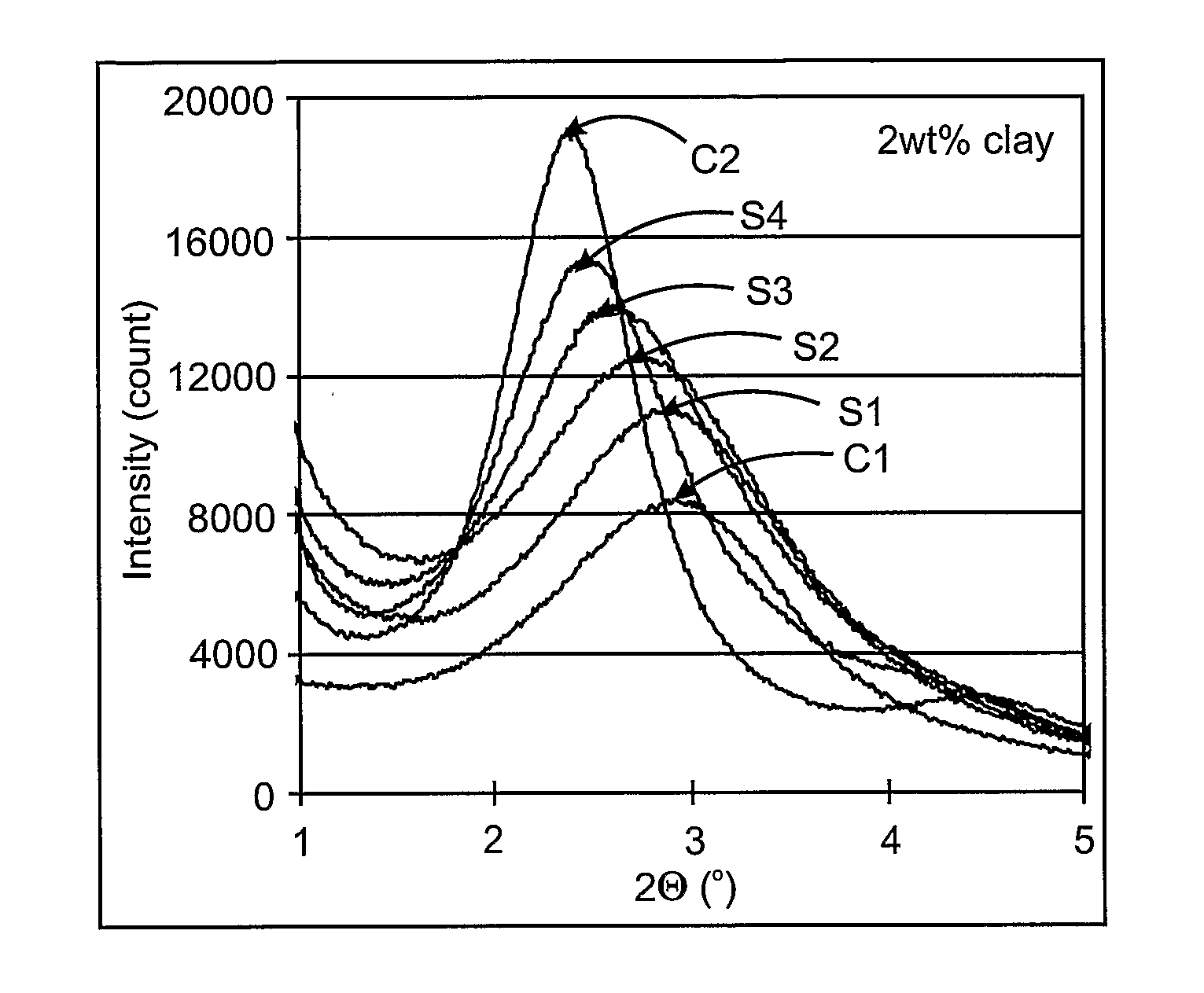

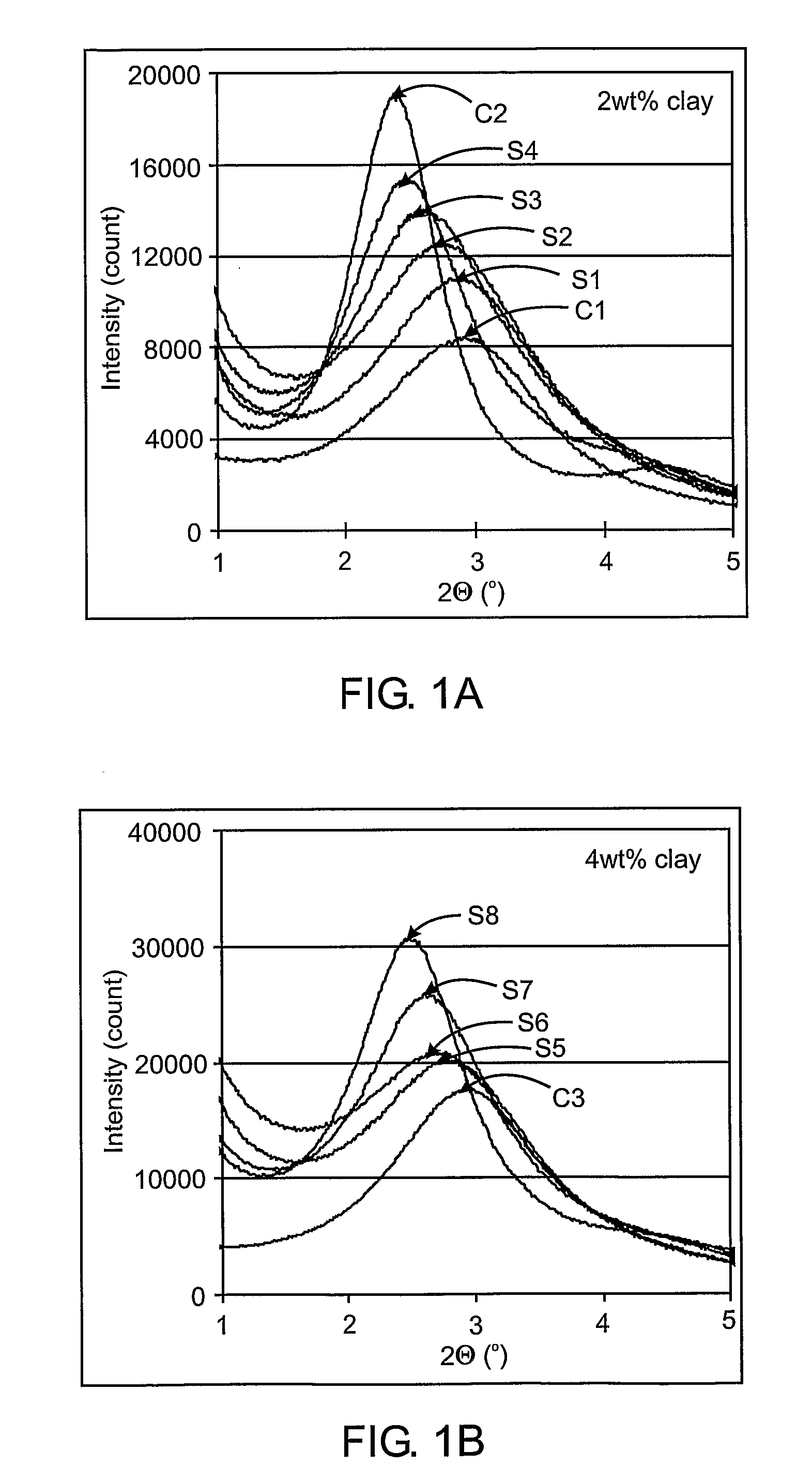

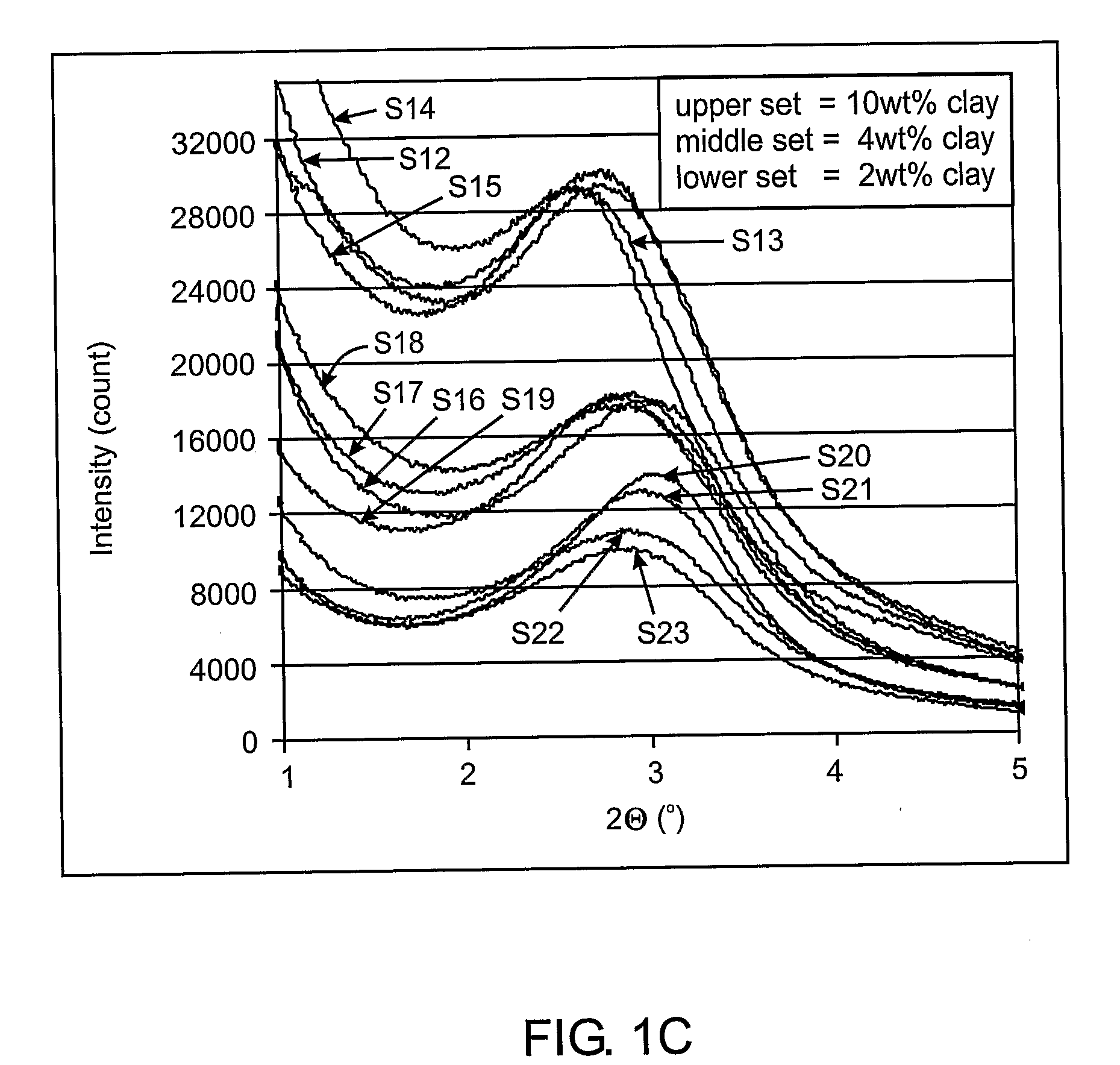

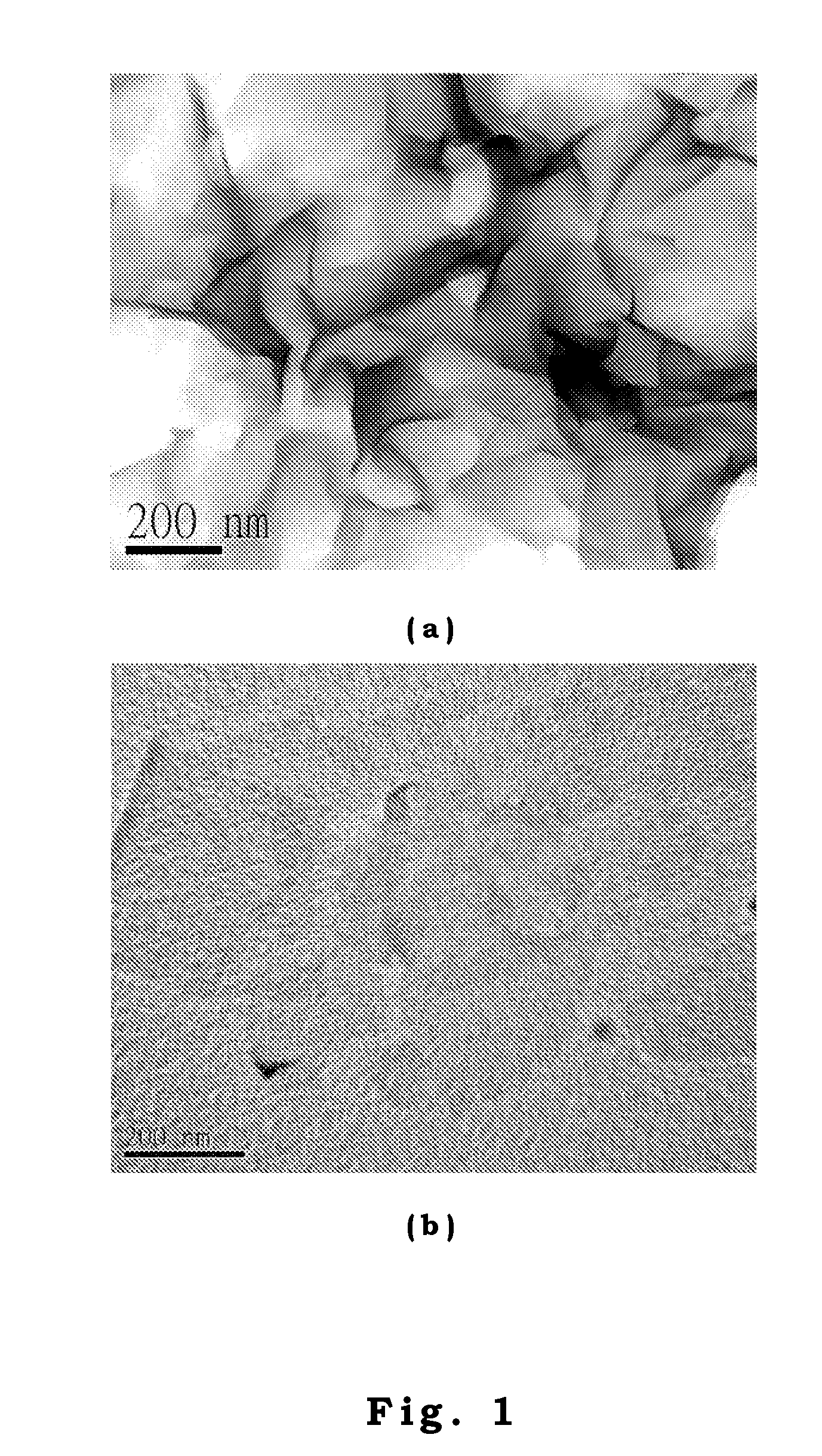

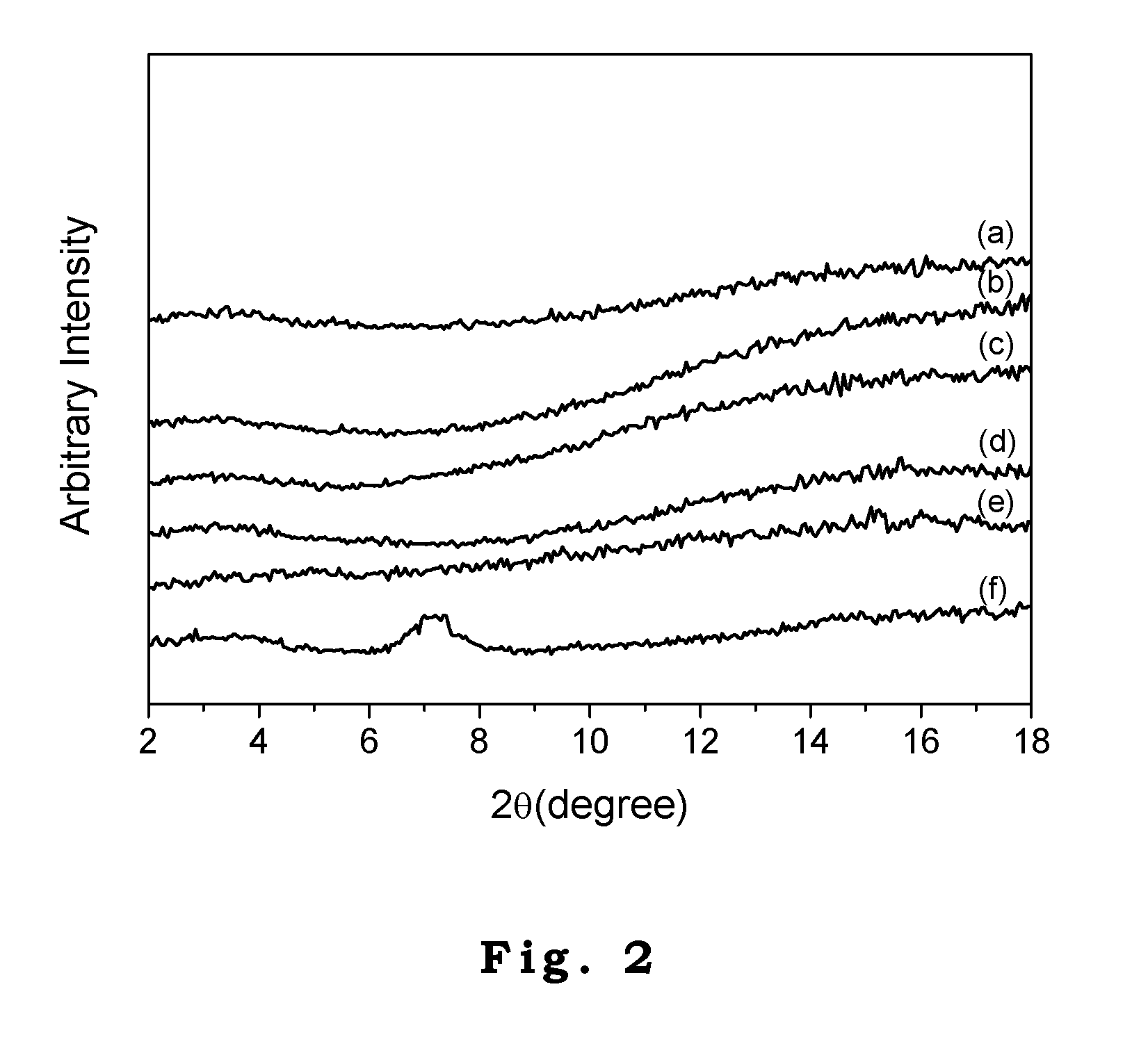

ActiveUS20050096422A1Good dispersionMaterial nanotechnologyCeramic shaping apparatusPolymer scienceNanometre

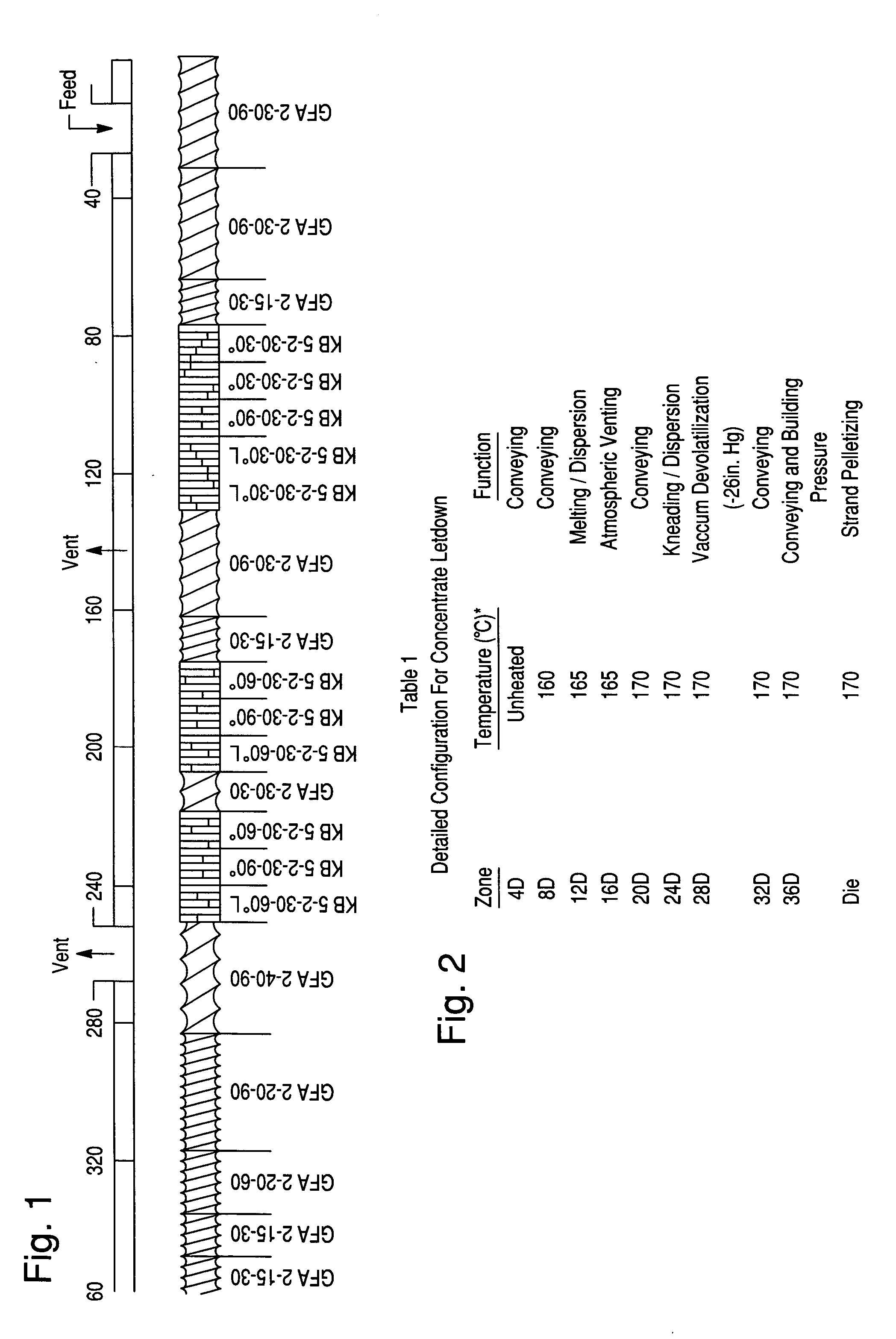

A method of producing a polymer-clay nanocomposite comprises providing a supply of polymer-clay mixture, exfoliating the mixture through solid-state shear pulverization in the presence of cooling sufficient to maintain the extruded mixture in the solid state during the pulverization, and discharging the resulting exfoliated mixture. The invention is also directed to a method of producing a polymer hybrid nanocomposite, wherein a component is dispersed throughout a polymer matrix by solid-state shear pulverization of a polymer mixed with the second component.

Owner:NORTHWESTERN UNIV

Clay-based concrete sealer

InactiveUS8980377B1Preventing loss of structureImprove compatibilityOther chemical processesWorking-up pitch/asphalt/bitumen by chemical meansBrickStaining

A transparent, non-yellowing, polymer-clay, concrete sealer and methods for making and applying the same. The disclosed clay-based sealer provides a tough, ultraviolet-light-, temperature-, and abrasion-resistant layer that effectively protects surfaces from moisture penetration, staining, dirt, dust, and wear. The substrates to which the clay-based sealer may be applied include, but are not limited to, above and below grade concrete structures, brick, concrete masonry unit (CMU) block, grout, plaster, gunite, tile, and aggregate. The clay-based sealer may easily be applied with airless or air-assisted sprayers, or by roller, brush, or applicator pad. Once applied, the sealer requires minimal maintenance.

Owner:STEFANESCU EDUARD A +1

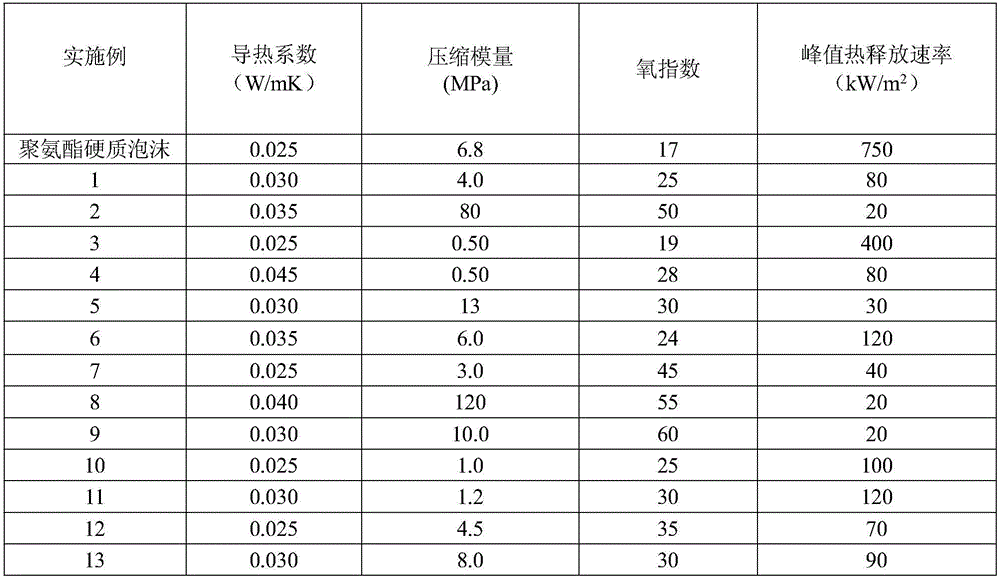

Polyurethane rigid foam-aerogel composite inflaming retarding thermal insulation material and preparation method thereof

The invention discloses a polyurethane rigid foam-aerogel composite inflaming retarding thermal insulation material and a preparation method thereof. The preparation method comprises the following steps that firstly, polymer and clay are added into water, and after stirring, colloid is obtained; secondly, the obtained colloid is evenly applied to the surface of polyurethane rigid foam, then, freezing and vacuum drying are carried out, and the polyurethane rigid foam-aerogel composite inflaming retarding thermal insulation material is obtained. Due to the facts that the post-processing is conducted on the polyurethane rigid foam and change of the structure of polyurethane is not related, the excellent performance of polyurethane will not be lowered; the adopted polymer-clay aerogel is similar to the polyurethane rigid foam in density, heat conductivity coefficient, mechanical performance and the like, and therefore the comprehensive performance of the obtained composite material is similar to that of the polyurethane rigid foam, and the obtained composite material has excellent performance; meanwhile, the process operation is easy, cost is low, and the process is easy to popularize.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Polymer-Clay Nanocomposite and Process for Preparing the Same

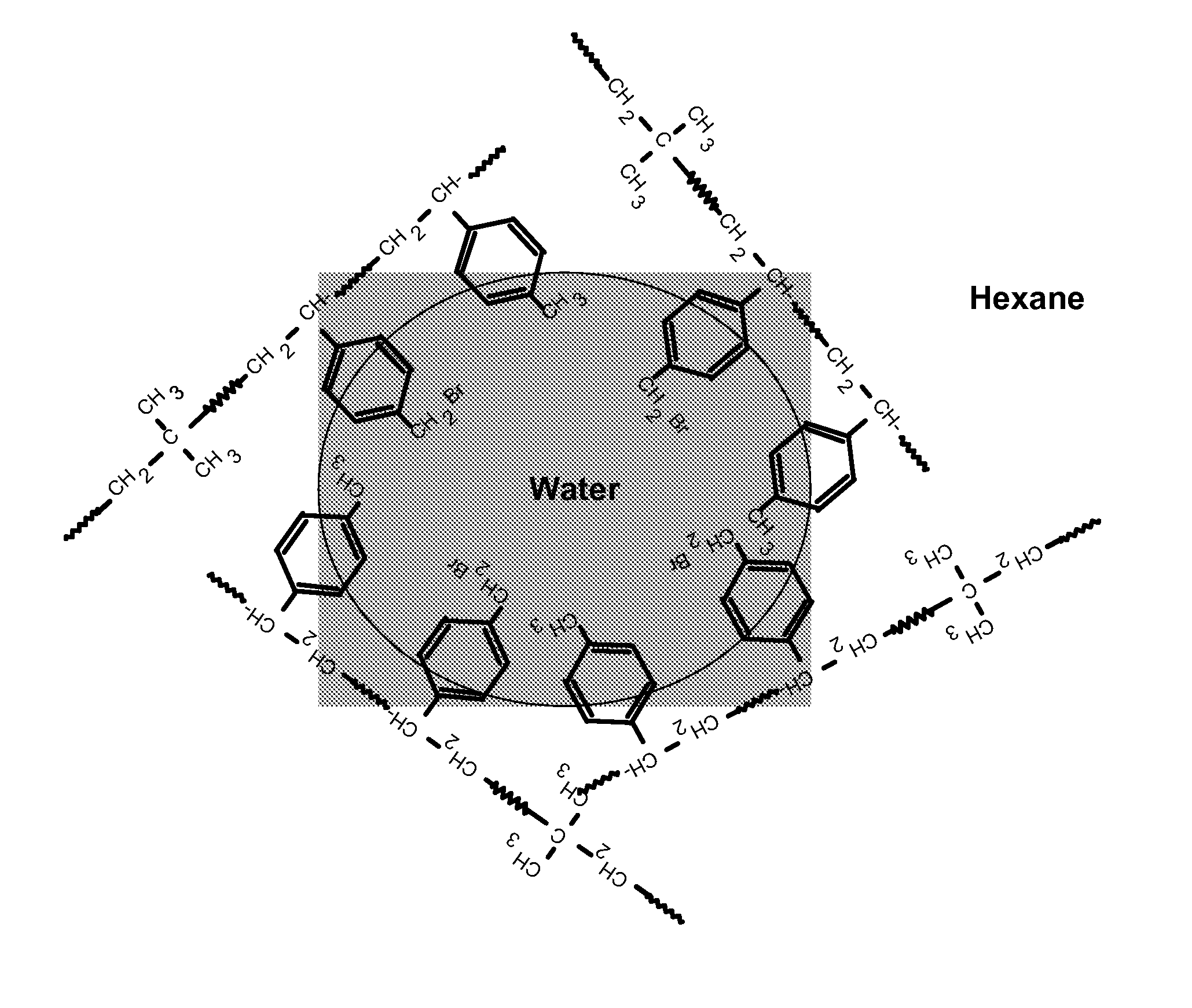

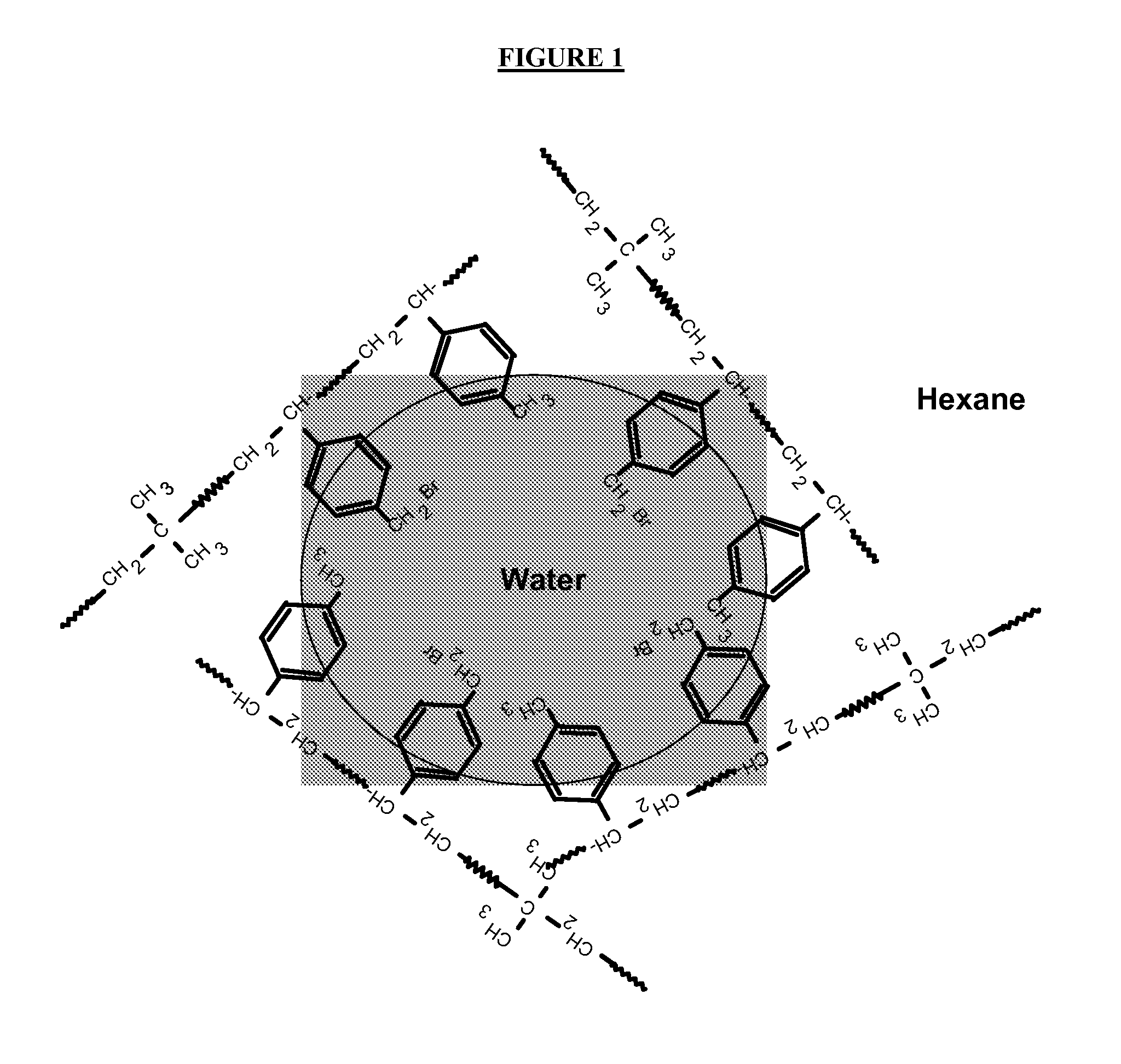

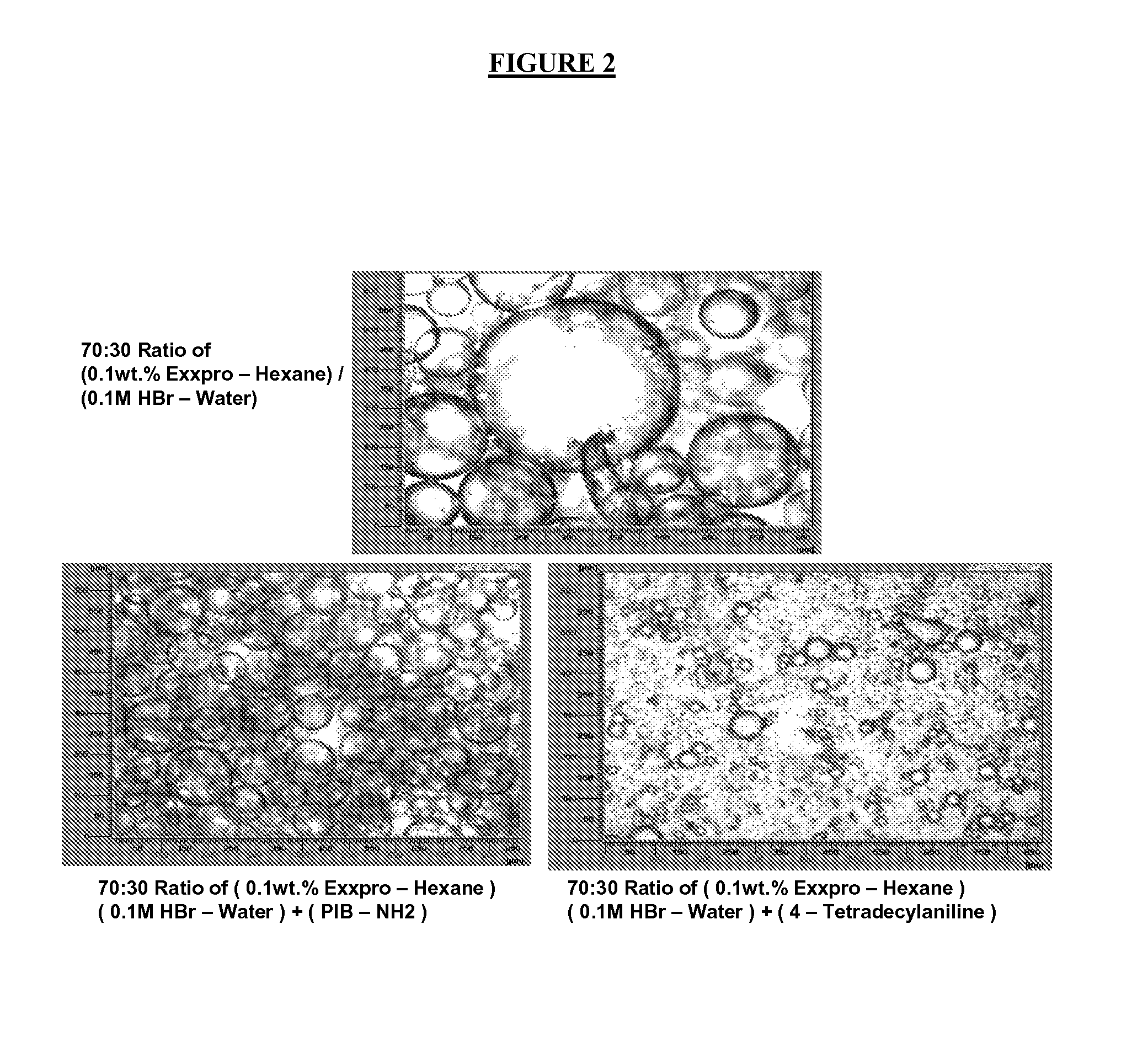

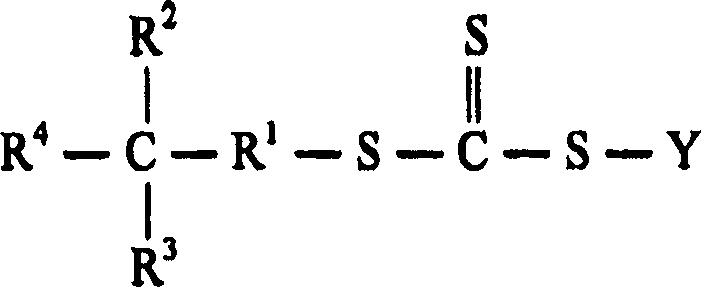

A process for producing a nanocomposite of a halogenated elastomer and an inorganic, exfoliated clay includes the in-situ protonation of a modifier, which may be an alkylamine, arylamine or an alkylarylamine. This process can be integrated with a polymer halogenation process. The nanocomposite so formed has improved air barrier properties and is suitable for use as a tire innerliner or innertube.

Owner:EXXONMOBIL CHEM PAT INC

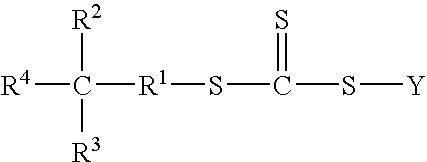

Water-based process for the preparation of polymer-clay nanocomposites

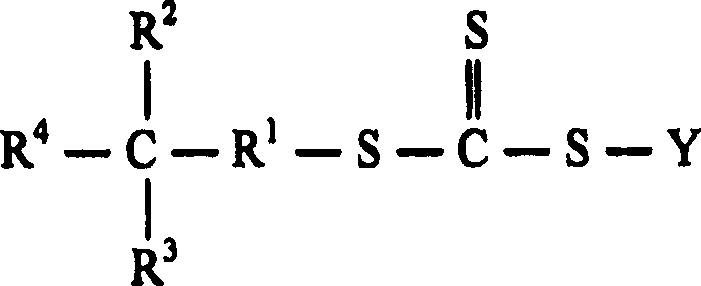

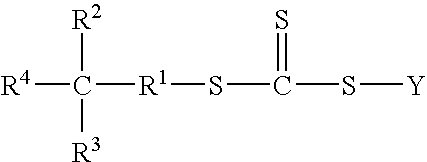

The invention relates to a water base method of making use of block polymer of latex form to prepare interposed layer and / or removed natural or composited clay. The block polymer contains at least a non-polar block and one or more cation block, inwhich the block polymer is prepared by the method of controlled latex free radical polymerization.

Owner:THE GOODYEAR TIRE & RUBBER CO

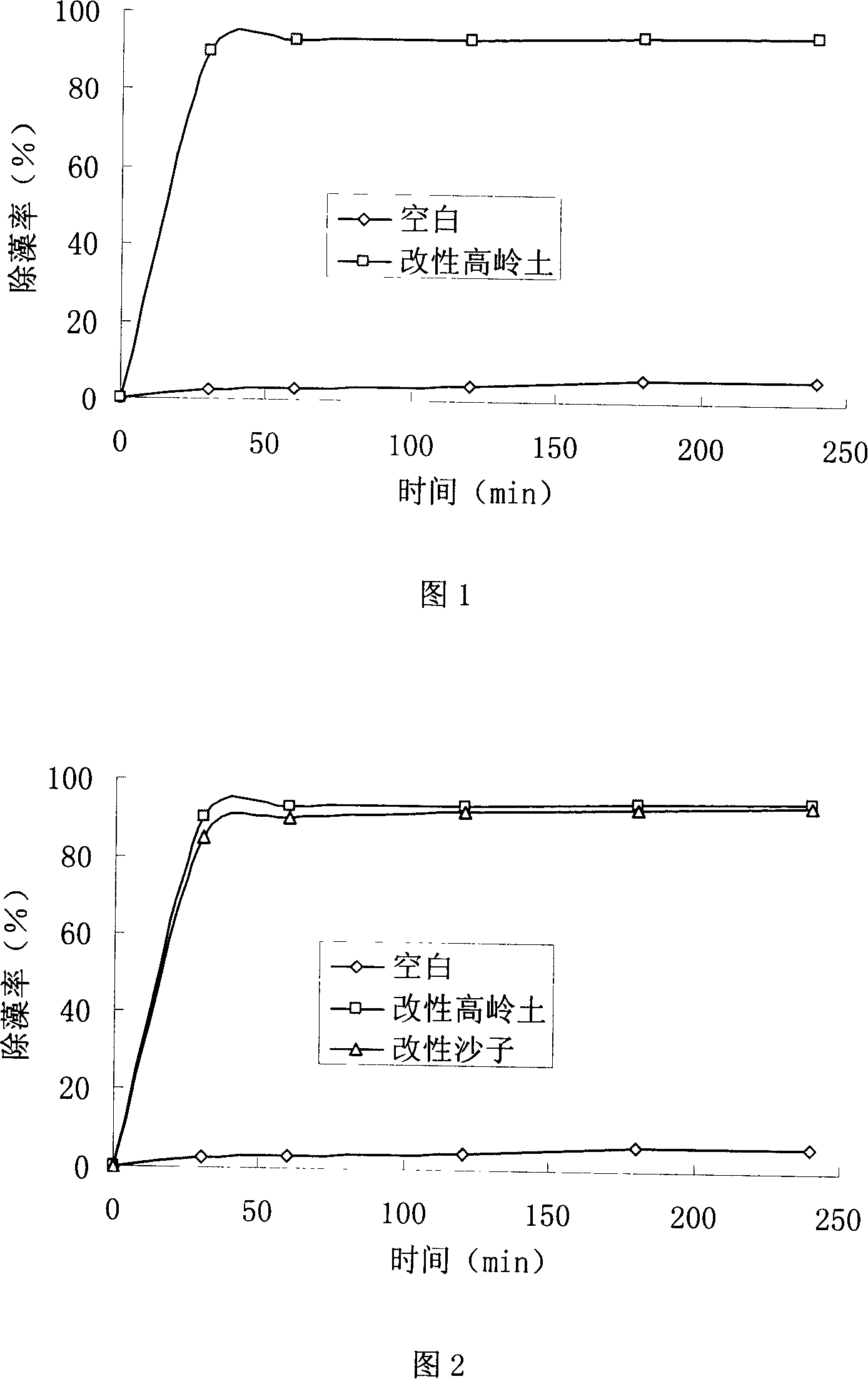

Method for preparing highly effective alga flocculating agent convenient for storing and transporting

InactiveCN101121559AReduce dosageEasy to storeWater/sewage treatment by flocculation/precipitationAlgaeBiology

The present invention relates to a preparation method of the high-efficient algae flocculating thing, which is easy to be stored and transported, in particular to a preparation method for the high- efficient algae flocculating powder, which uses a kind of innoxious, easy for biological separating and low-cost natural macromolecule polymer clay and also uses some modern separating technology including drying and freezing. The algae flocculating powder produced by the method can be used for fathering seawater tide, freshwater sublimation as well as for wiping off the deleterious algae in the riverway and the waterworks. The present invention is characterized in high-efficiency, low-cost and easy to be stored and transported. The present invention belongs to the water treatment technology region.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Three-dimensional (3D) printing method

The invention discloses a three-dimensional (3D) printing method. A 3D printer appeared in the middle of 90 years in 20th century. In practice, the 3D printer is a fast molding device by the adoption of technologies of photocuring, paper stacking and the like. An operating principle of the 3D printer is basically same as that of a normal printer. 'Materials for printing' are arranged in the printer. The 'materials for printing' are liquid or powder and the like. After the printer is connected with the computer, the 'materials for printing' are stacked layer by layer through a computer controlling, and at last a blueprint of the computer is changed into a material object. Fast molding technologies in the market are divided into a 3DP technique, an FDM melting lamination molding technique, an SLA three-dimensional planographic printing technique, an SLS precinct laser sintering, a DLP laser molding technique, an ultraviolet (UV) ray molding technique and the like. At present, the 3D printing method is used in a motor industry, a medical treatment die processing industry and the like. A printing coverage is coated on a polymer clay sheet, an image printing is carried out on the coverage by a normal color printer, the printed image is carried out on counterpoint superposition and stretching to form a 3D image.

Owner:陈绪国

Compatibilization of Polymer Clay Nanocomposites

InactiveUS20080207801A1Improve balanceSimple interfaceMaterial nanotechnologyPolymer scienceChain length

A polymer nanocomposite contains layered clay dispersed in a polymer matrix together with compatibilizers for the clay and polymer matrix. The compatibilizers are a combination of two or more graft polymers. One graft polymer has high functionality and short chain length and another graft polymer has low functionality and long chain length. Such polymer nanocomposites have improved dispersion and better strength and modulus, while maintaining good toughness and impact strength. The polymer nanocomposites are particularly useful in applications where good mechanical performance and light-weight are of importance.

Owner:NAT RES COUNCIL OF CANADA

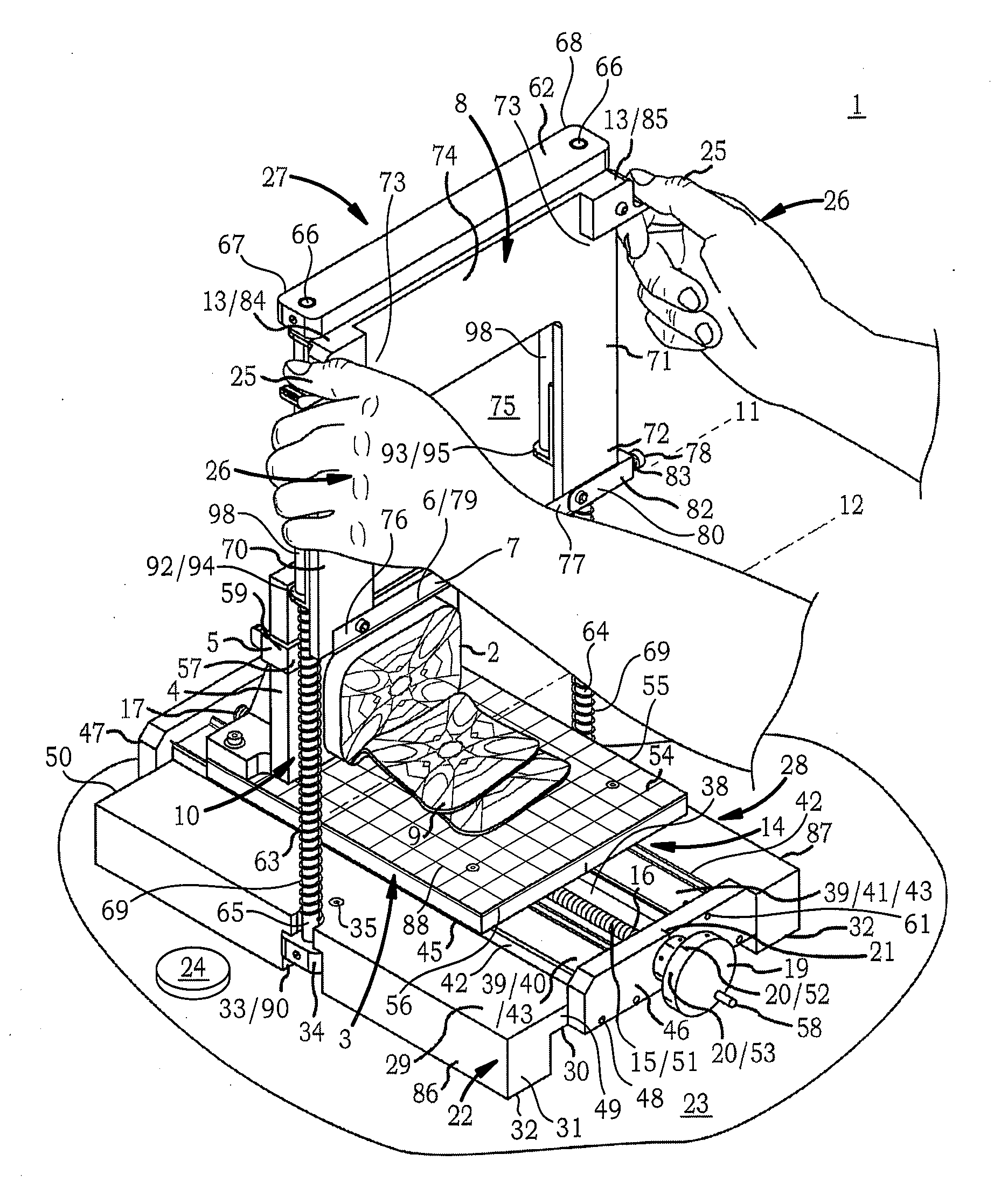

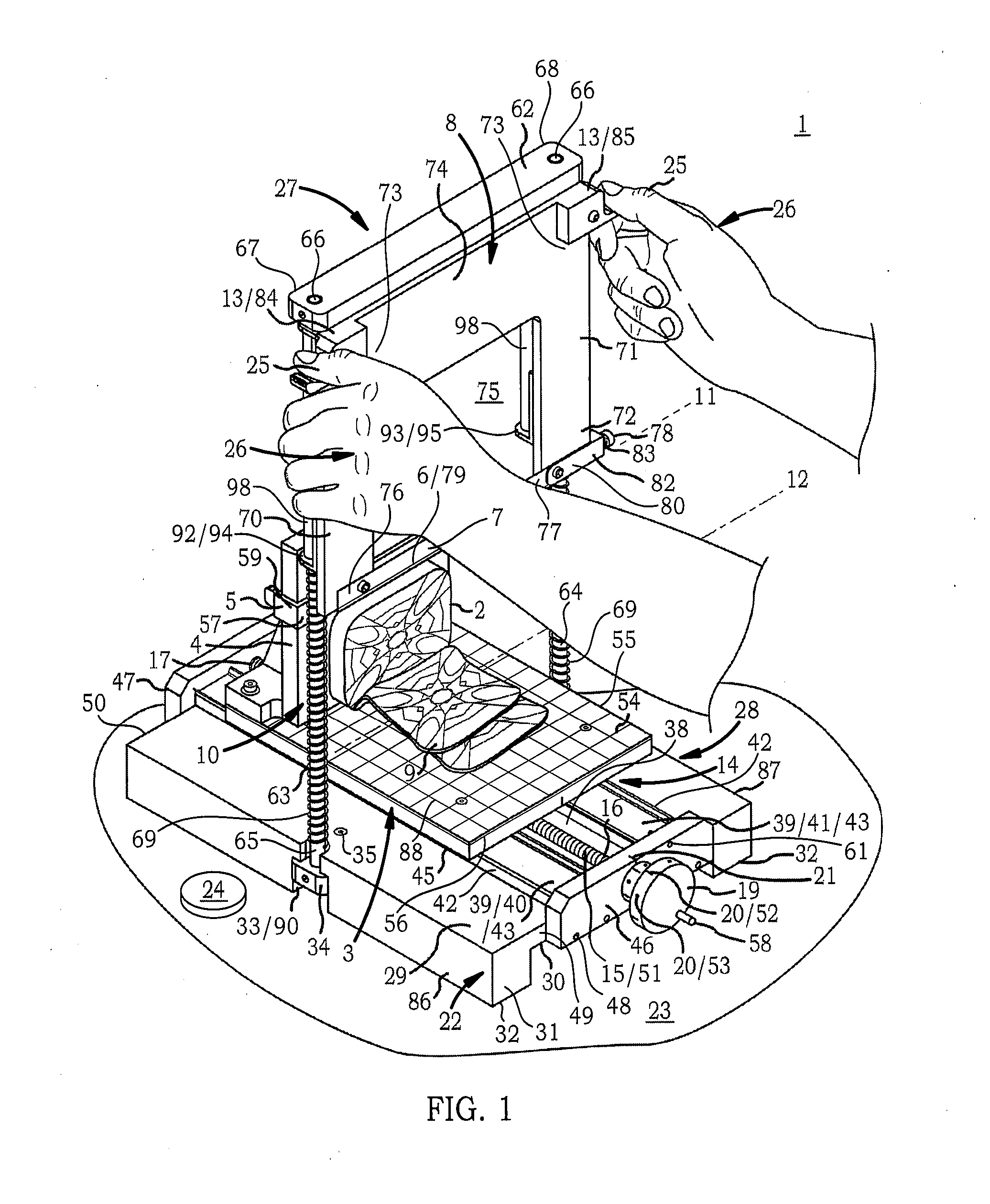

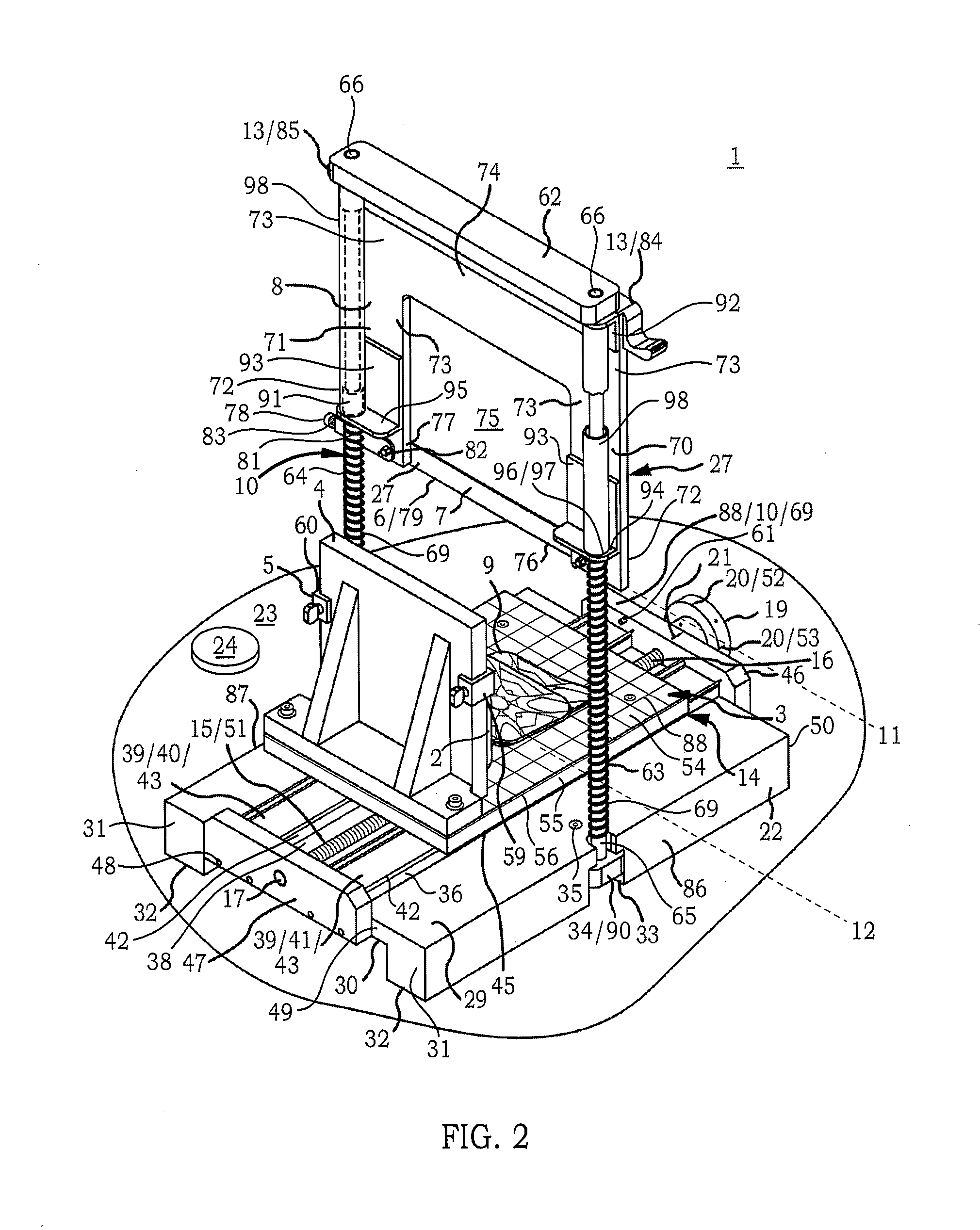

Polymer Clay Slicing System

InactiveUS20120160066A1Improve uniformityReduce interactionGang saw millsStock shearing machinesEngineeringPolymer clay

Owner:POLYMER CLAY SOLUTIONS

Method for forming polymer-clay nanocomposite latex and its application on sealing and semi-conductive materials

The present invention discloses a method to prepare the polymer-clay nanocomposite latex. At first, a clay and a water-soluble initiator are mixed in water to form an intermediate solution, in which the initiator is absorbed or intercalated into the clay. Then, at least one monomer from vinyl ester, acrylic and acrylamide derivatives is added into the intermediate solution for soap-free emulsion polymerization, which may also be added with some other monomers such as acrylic acid, maleic anhydride, vinyl chloride, acrylonitrile ethylene, et al. for copolymerization. During soap-free emulsion polymerization, the radicals from the dissociated initiators will react with the monomers to form the monomer radicals, which tend to diffuse into the interlayer region of clays for further polymerization and eventually exfoliate the clays. The prepared exfoliated polymer-clay nanocomposite latex can be cast into a vapor-impermeable film so that it can be used as a sealing material or coating. The exfoliated clay in nanoplatelet form is a two-dimensional electrolyte nanomaterial and its aqueous solution is conductive. The exfoliated clay aqueous solutions can be prepared by removing the polymer matrix from the nanocomposite latex with solvent. As the exfoliated clay solution is cast into a film with the clay content is more than or equal to 80 wt %, the film is semi-conductive. Thus, the exfoliated clay aqueous solutions can be applied to the electronic materials and organic / inorganic multilayer composite films.

Owner:NAT TAIWAN UNIV

Water-based process for the preparation of polymer-clay nanocomposites

Owner:THE GOODYEAR TIRE & RUBBER CO

Red attapulgite polymer clay powder

The invention discloses red attapulgite polymer clay powder, and the key points of the technical scheme are as follows: the red attapulgite polymer clay powder consists of attapulgite clay after purification, white bentonite, sepiolite, everbright fast red, anatase titanium dioxide, calcium chloride, sodium polyacrylate, sodium carboxymethyl cellulose and sodium stearyl lactylate. A finished product of the red attapulgite polymer clay powder is prepared by mixing ingredients of the red attapulgite polymer clay powder, inputting into a crushing machine for crushing, further inputting the mixed materials after crushing into a pulverizing mill for pulverizing and packaging. Red attapulgite polymer clay produced by adding water in the red attapulgite polymer clay powder has the characteristics of high viscosity, softness, good plasticity, small shrinkage rate, hardening after natural drying, no need of baking, no production of cracks, no skin irritation, no toxicity, no corrosion and no greasy feeling. The red attapulgite polymer clay powder has simple production process, low cost and convenient use, and is conductive to popularization, and the red attapulgite polymer clay powder is applicable to field production of the red attapulgite polymer clay.

Owner:南通江涌投资开发有限公司

Oil reservoir modification acid liquor and oil production method by using same

InactiveCN102120930AGet oil boosting effectImprove permeabilityDrilling compositionPorosityPhosphorous acid

The invention provides an oil reservoir modification acid liquor and an oil production method by using the same, belonging to the technical field of oilfield operation. The acid liquor is prepared from 50-200 parts of phosphorous acid, 100-300 parts of ammonium nitrate, 500-1000 parts of potassium chloride, 100-300 parts of hydrochloric acid, 50-200 parts of hydrofluoric acid, 100-300 parts of formic acid, 50-200 parts of acetic acid, 50-300 parts of citric acid, 50-300 parts of organic cationic polymer clay stabilizer and 0-100 parts of water. The oil reservoir modification acid liquor is applicable to various limestone and dolomite reservoirs, and various limestone, dolomite, mud and silica cemented sandstone reservoirs. The oil reservoir modification acid liquor is suitable for various reservoirs of which the porosity lower limit is 1% and the permeability lower limit is 0.1 millidarcy. The oil reservoir modification acid liquor can effectively dissolve caulking substances in pores of various reservoirs, improve the permeability of the reservoirs, and increase the yield of the crude oil.

Owner:尚伟

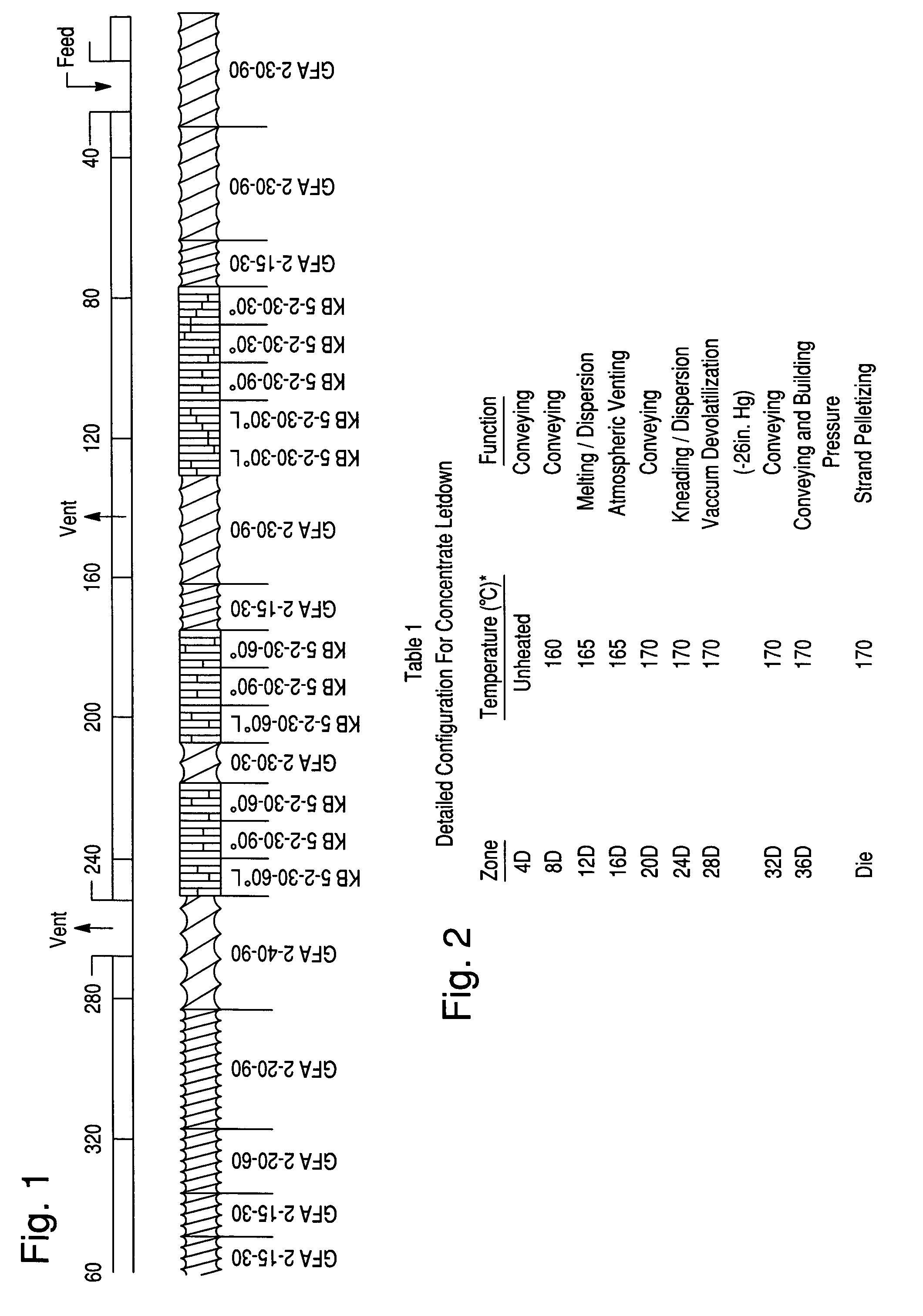

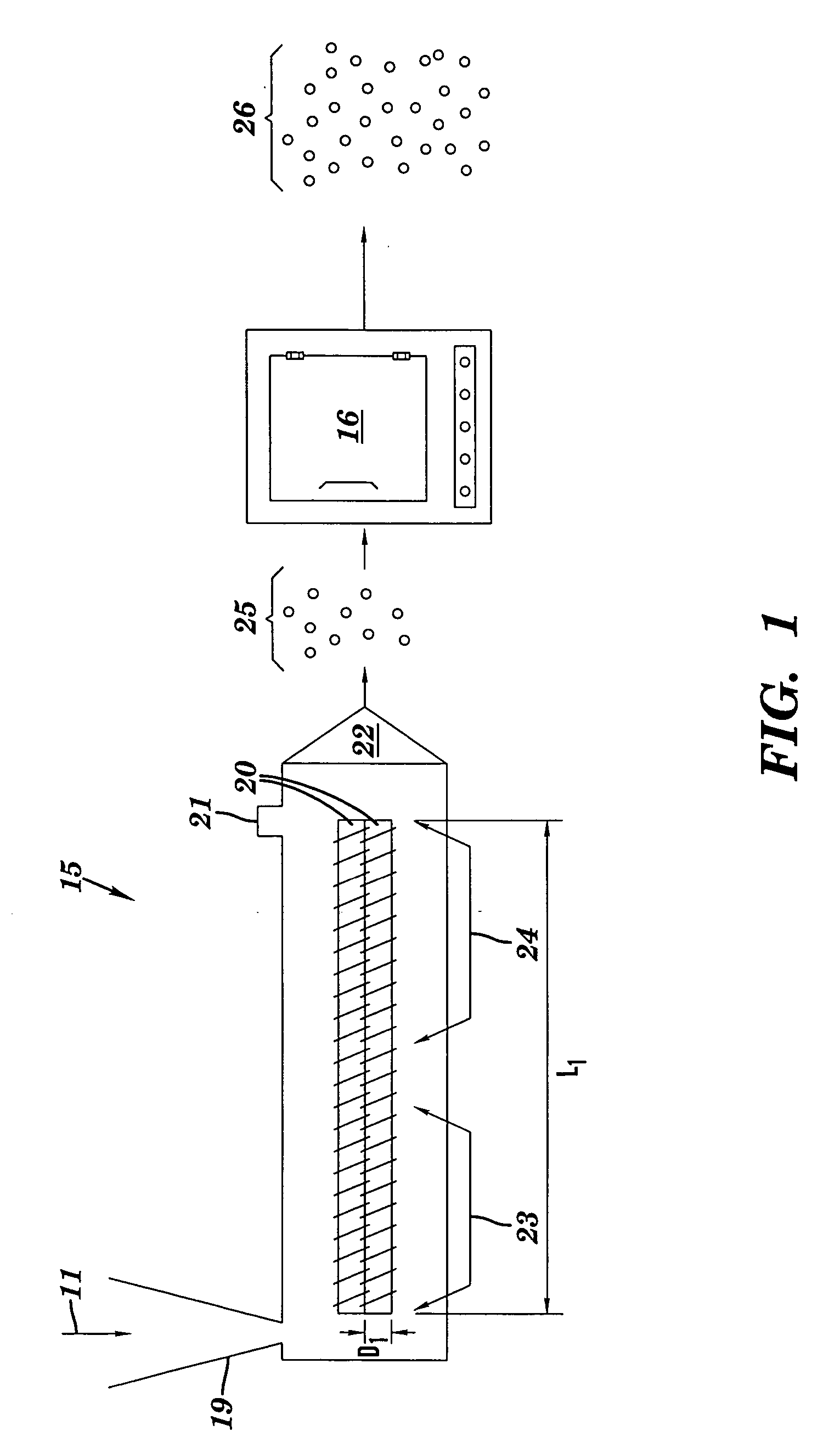

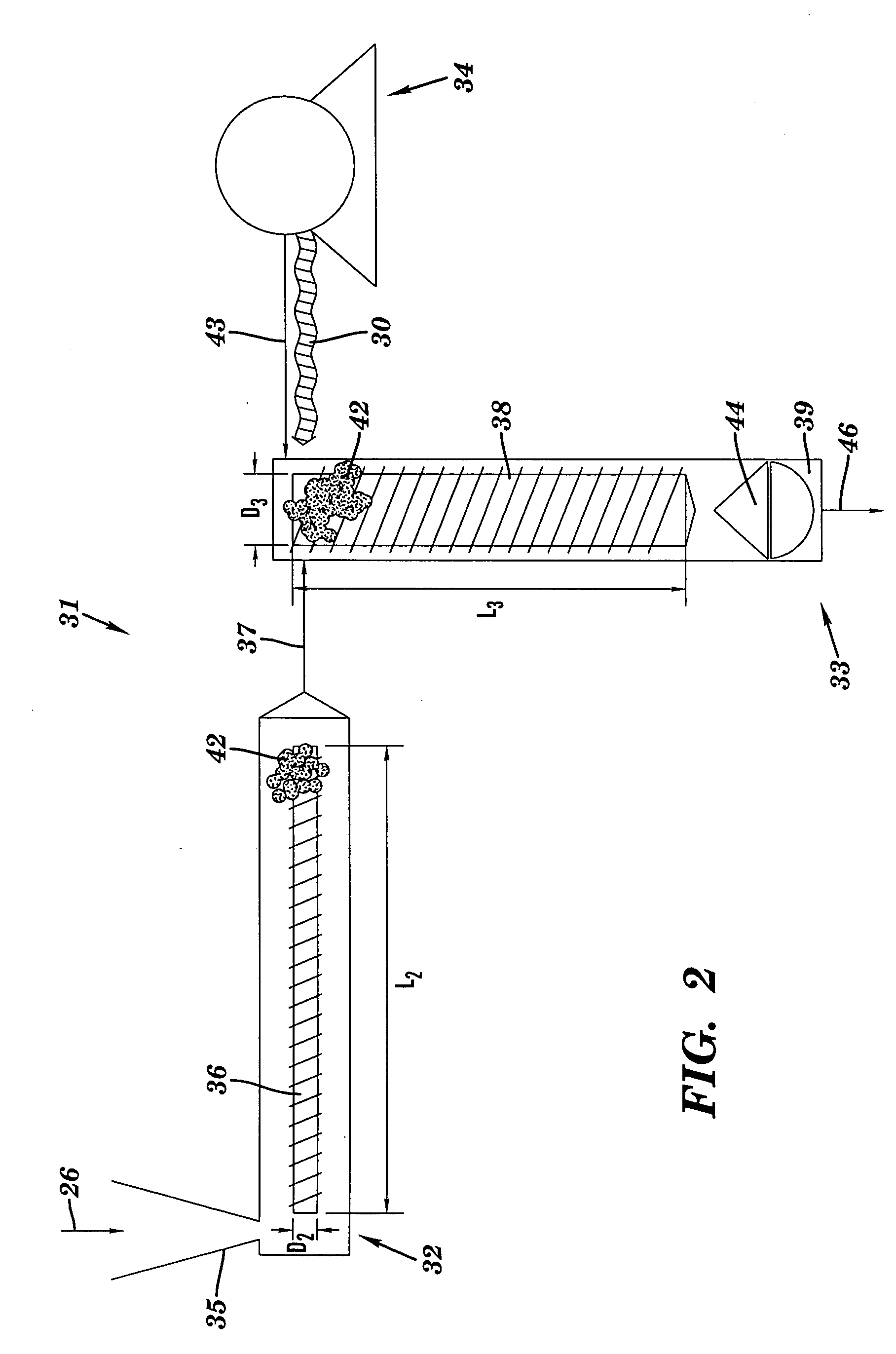

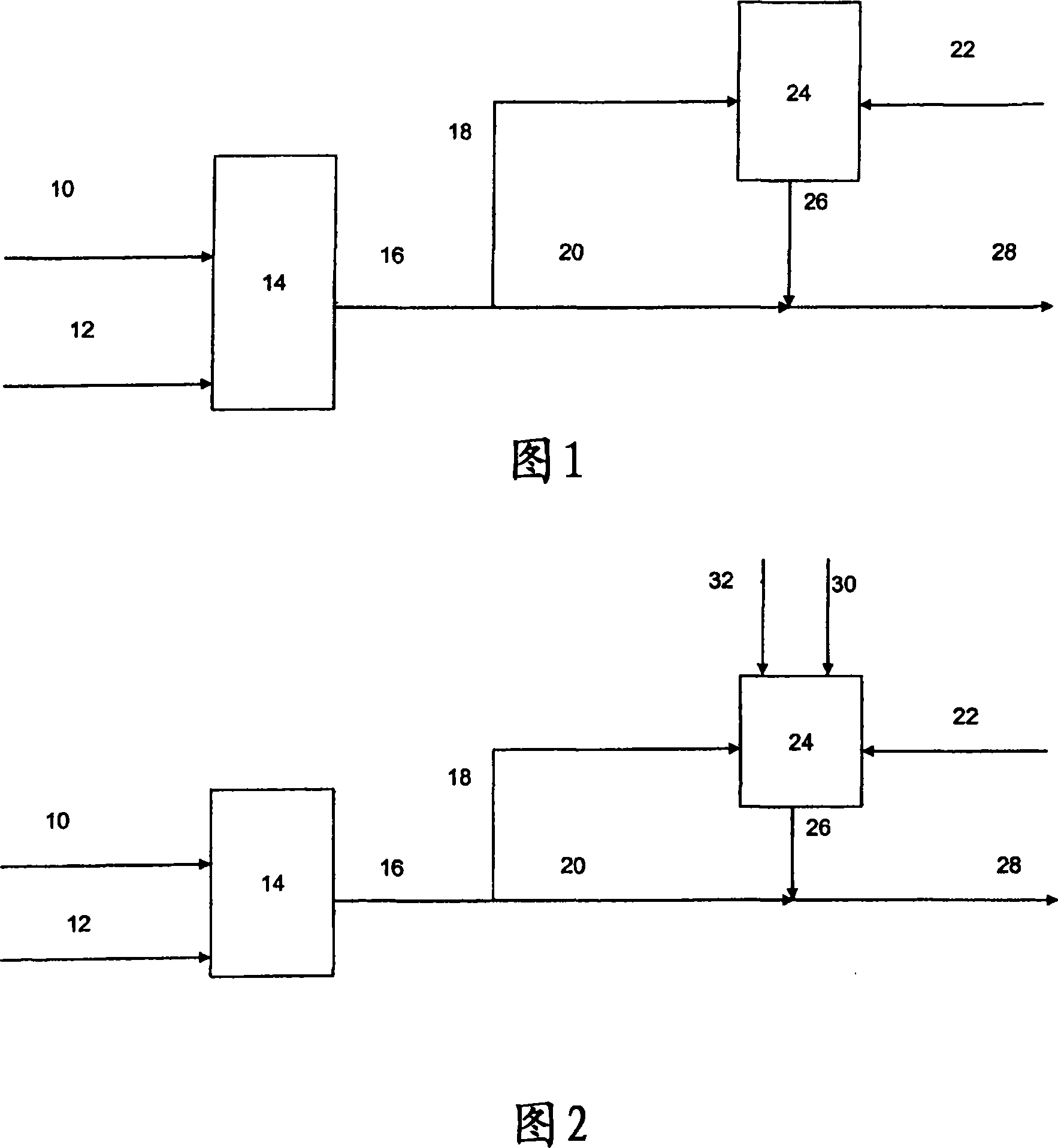

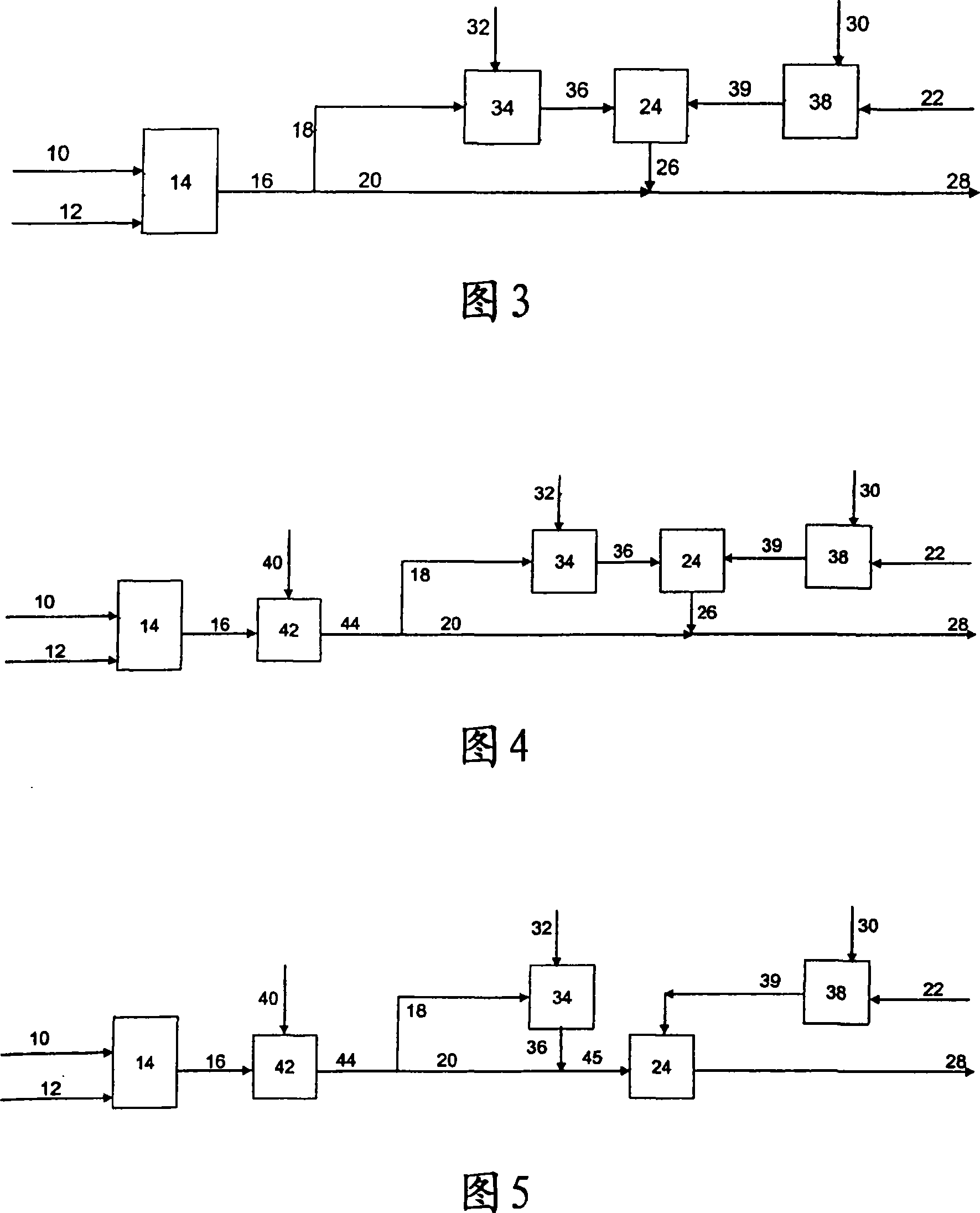

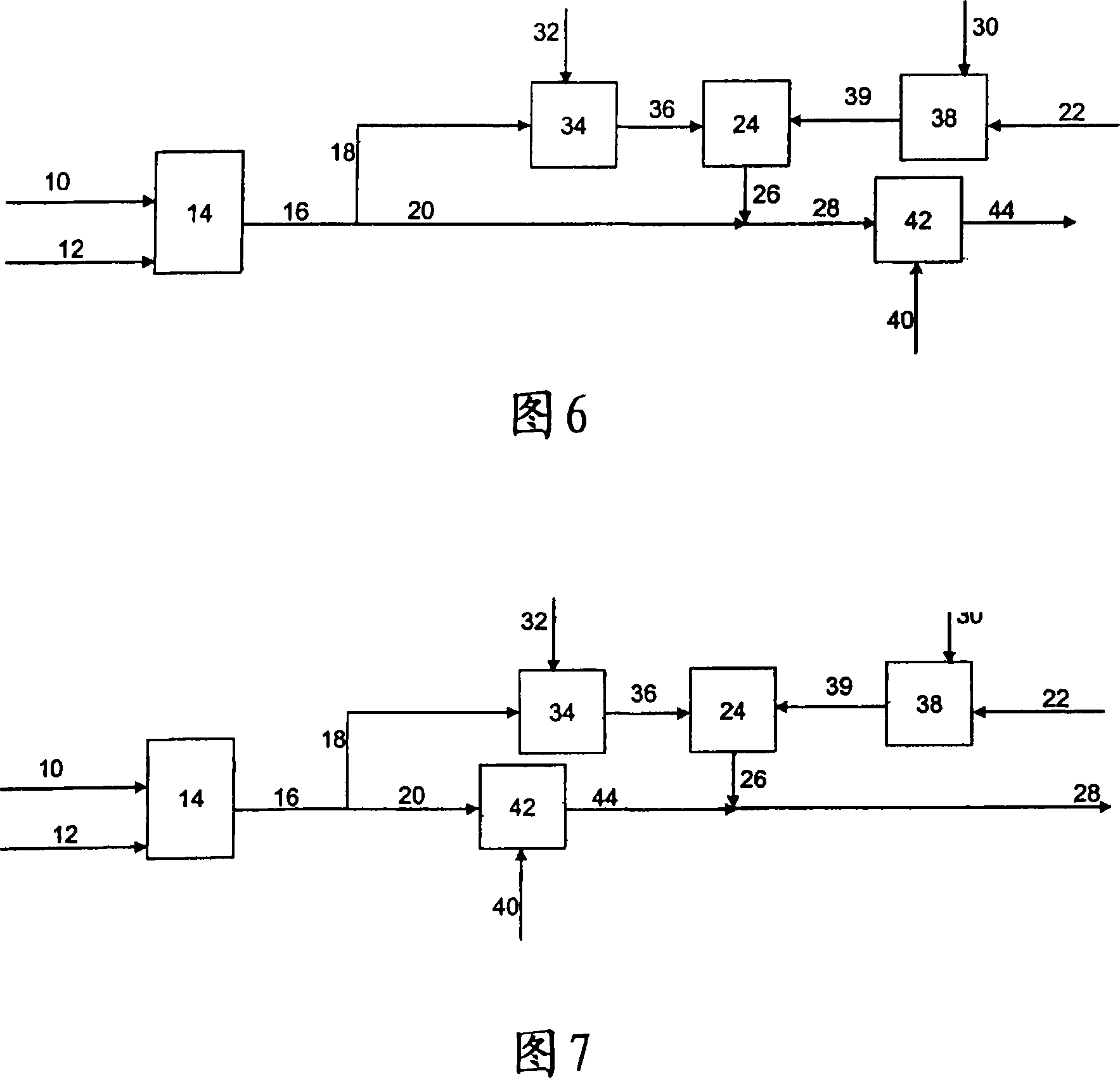

Split-stream process for making nanocomposites

The present invention is a process to produce a nanocomposite of a elastomer and organic clay, e.g. an exfoliated clay, suitable for use as an air barrier. The process can include the steps of: (a)contacting a solution (10) of butyl rubber in an organic solvent with a halogen (12) to form a halogenated butyl rubber solution (16); (b) neutralizing the halogenated butyl rubber solution; (c) functionalizing at least a portion (18). of the halogenated butyl rubber; (d) mixing a dispersion (22) of clay with the functionalized butyl rubber (18) to form a masterbatch (26) comprising a polymer-clay nanocomposite; (e) combining the masterbatch (26) with the rest of the halogenated butyl rubber solution (20) to form a second mixture (28); (f) recovering the nanocomposite from the second mixture (28). The nanocomposite so formed has improved air barrier properties and is suitable for use as a tire innerliner or innertube.

Owner:EXXONMOBIL CHEM PAT INC

High acid aqueous nanocomposite dispersions

InactiveCN1622959AHigh tensile strengthReduce penetrationMaterial nanotechnologyNanostructure manufacturePolymer scienceAdhesive

The present invention relates in part to polymer clay nanocomposites having acid-containing monomers and clay. In one embodiment, there is provided a method of preparing an aqueous polymer clay nanocomposite dispersion, wherein the method comprises: providing an aqueous dispersion comprising at least one clay, optionally at least one olefinic unsaturated monomers, and optionally at least one surfactant; providing a monomer mixture comprising at least 10% by weight of the monomer mixture of acid-containing monomers, and optionally a surfactant; water mixing the dispersion with the monomer mixture; and polymerizing the monomers to form a nanocomposite dispersion, wherein the clay is at least partially exfoliated in the nanocomposite dispersion. The invention also relates to the use of these compositions, for example as thickeners, dispersants, plastic additives, adhesives, coatings, offset printing inks, overprint varnishes and dry cement powder modifiers.

Owner:ROHM & HAAS CO

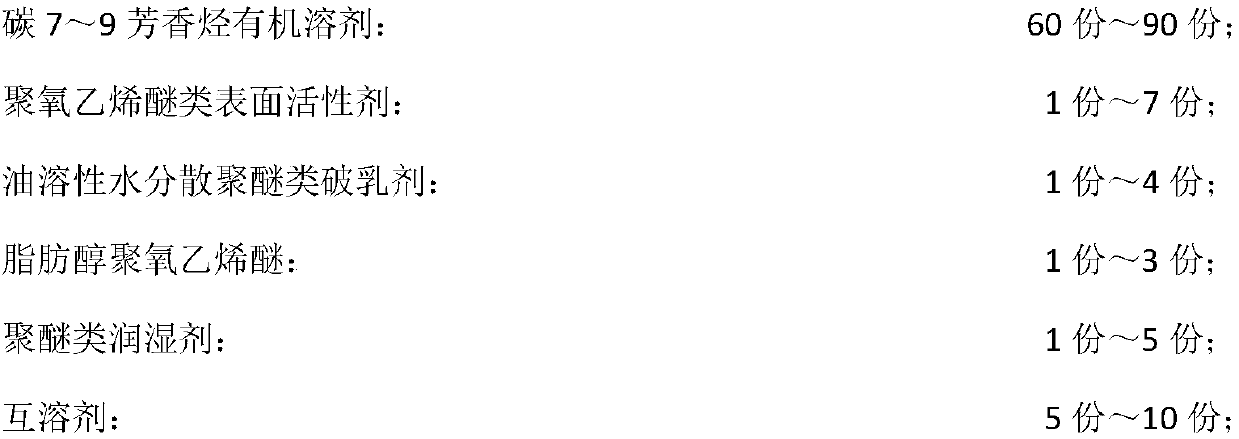

Descaling and plugging removal agent used for oil field injection and production layer

InactiveCN107057668AGood slowing effectImprove the blocking effectDrilling compositionWater dispersibleSilicic acid

The invention belongs to the technical field of oil field chemical descaling and plugging removal agents to solve the technical problem that an existing plugging removal processing effect is poor. A descaling and plugging removal agent used for an oil field injection and production layer comprises an organic multifunctional plugging removal agent, an inorganic multifunctional plugging removal agent and a multifunctional composite synergist. The organic multifunctional plugging removal agent comprises carbon 7-9 aromatic hydrocarbon, a polyoxyethylene ether surfactant, an oil-soluble water-dispersible polyether demulsifier, fatty alcohol-polyoxyethylene ether, a polyether wetting agent and a mutual solvent; the inorganic multifunctional plugging removal agent comprises hydrochloric acid, modified silicic acid, a sulfate scale complexing dispersant, a cationic polymer clay stabilizer, a water-soluble polyether demulsifier, a corrosion inhibitor, an iron ion stabilizer and a polyether wetting and improving agent; the multifunctional composite synergist comprises hydrochloric acid, acetic acid, a corrosion promoter, a polyether wetting and improving agent, a cationic polymer sand stabilizing agent, an iron ion stabilizing agent and a conversion agent.

Owner:CHENGDU DUTEWEI PETROLEUM TECH

Aqueous nanocomposite dispersions: processes, compositions, and uses thereof

Processes for utilizing various emulsion polymerization procedures for preparing aqueous nanocomposite dispersion are disclosed. The disclosed processes include both insitu polymerization in the presence of at least partially exfoliated unmodified clays as well as admixtures of polymer dispersions with at least partially exfoliated unmodified clay dispersions. The disclosed nanocomposite dispersion are useful for preparing a variety of materials, such as coatings, adhesives, caulks, sealant, plastic additives, and thermoplastic resins. Processes for preparing polymer clay nanocomposite powders and use of these powders as plastic resin and plastics additives are also disclosed.

Owner:ROHM & HAAS CO

Black attapulgite polymer clay powder

The invention discloses black attapulgite polymer clay powder, and the key points of the technical scheme are as follows: the black attapulgite polymer clay powder consists of attapulgite clay after purification, bentonite, sepiolite, black iron oxide, carbon black, calcium chloride, sodium polyacrylate, sodium carboxymethyl cellulose and sodium stearyl lactylate. A finished product of the black attapulgite polymer clay powder is prepared by mixing ingredients of the black attapulgite polymer clay powder, inputting into a crushing machine for crushing, further inputting the mixed materials after crushing into a pulverizing mill for pulverizing and packaging. Black attapulgite polymer clay produced by adding water in the black attapulgite polymer clay powder has the characteristics of high viscosity, softness, good plasticity, small shrinkage rate, no deformation, hardening after natural drying, no need of baking, no production of cracks, no mildew, no skin irritation, no toxicity, no corrosion and no greasy feeling. The black attapulgite polymer clay powder has simple production process, low cost and convenient use, and is conductive to popularization, and the black attapulgite polymer clay powder is applicable to field production of the black attapulgite polymer clay.

Owner:南通江涌投资开发有限公司

Soft pottery clay and manufacturing method thereof

InactiveCN102503240ABeautiful colorTo achieve the effect of long-term placementWhite powderPolyvinyl chloride

The invention relates to soft pottery clay and a manufacturing method thereof. The soft pottery clay comprises the following components which are mixed together: polyvinyl chloride paste resin, aluminum distearate, zinc stearate, calcium stearate, dioctylphthalate, titanium white powder, mixed resins and silicon dioxide. The manufacturing method of the soft pottery clay comprises the following steps: 1) supplying polyvinyl chloride paste resin, aluminum distearate, zinc stearate, calcium stearate, dioctylphthalate, titanium white powder, mixed resins and silicon dioxide, mixing and stirring, and then standing by and cooling; 2) after cooling, placing into a stirrer for stirring, and then taking out and naturally cooling; 3) after cooling, placing into the stirrer for stirring again, and then taking out and naturally cooling; and 4) after cooling, mixing with white powder and uniformly stirring, and cooling, thereby obtaining an end product. The soft pottery clay can be processed into various patterns through a handicraft and the patterns can be attached to the surface and the interior of an object. If the soft pottery clay is not processed at high temperature, the soft pottery clay is reusable and is ultrahigh in plasticity and viscidity.

Owner:丁森

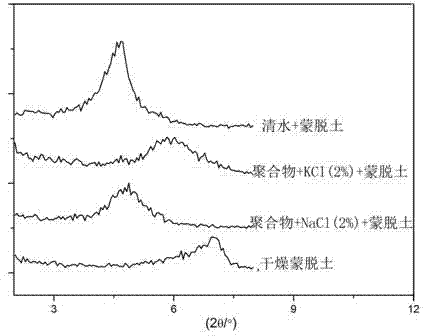

AM/NAI/APEG (Acrylamide/N-Allylimidazole/Allyl Alcohol Polyoxyethylene Ether) polymer clay stabilizer and preparation method

InactiveCN102898599AHigh viscosityImprove temperature resistanceDrilling compositionPolymer scienceSodium hydrogen sulphite

The invention relates to an AM / NAI / APEG (Acrylamide / N-Allylimidazole / Allyl Alcohol Polyoxyethylene Ether) polymer clay stabilizer for inhibiting clay hydration in a well drilling process and a synthesis method thereof. The technical scheme provided by the invention is that the used monomer comprises the following components in percentage by mass: 88.5-94.8 percent of acrylamide (AM), 0.2-1.5 percent of N-allylimidazole (NAI) and 5-10 percent of allyl alcohol polyoxyethylene ether (APEG). The preparation method comprises the following steps of: adding 10 g of AM, 0.05 g of NAI and 2 g of APEG into a reactor of 250 m to prepare aqueous solution with monomer total mass percentage concentration of 10-20 percent; adjusting pH (Potential of Hydrogen) to be 2-3 by using hydrochloric acid; introducing nitrogen for 20 minutes, wherein the molar ratio of ammonium persulphate to sodium hydrogensulfite is 1:1, and the amount of added initiator is 0.1-0.5 percent of the total mass of the monomer; continuously introducing nitrogen for 10 minutes; reacting at the temperature of 30-70 DEG C for 4-12 hours; and finally washing for three times by using absolute ethanol, crushing and drying to prepare AM / NAI / APEG terpolymer. The indentation hardness of clay shale reaches up to 416.92 MPa by compounding the polymer with 10 percent KCl, and the dendrite arm spacing of sodium montmorillonite can be reduced to 14.96767 angstroms by compounding with 2 percent KCl.

Owner:SOUTHWEST PETROLEUM UNIV

Blue attapulgite polymer clay powder

The invention discloses blue attapulgite polymer clay powder. The technical scheme is characterized in that the blue attapulgite polymer clay powder is prepared from purified blue attapulgite clay, white bentonite, sepiolite, anatase titanium dioxide, phthalocyanine blue, calcium chloride, sodium polyacrylate, sodium carboxymethylcellulose and sodium stearoyl lactylate by the following steps of: mixing the ingredients of the blue attapulgite polymer clay powder, feeding in a crusher to crush, feeding the crushed mixture into a pulverizer to be pulverized into powder and packaging into a finished product of the blue attapulgite polymer clay powder. Blue attapulgite polymer clay made by adding water and methyl silicone oil to the blue attapulgite polymer clay powder has the advantages of high viscosity, good flexible plasticity, small shrinkage, no corrosiveness and no greasy feeling, is hardened after natural drying without baking and is crackless. The invention has the characteristics of simple production process and low cost, is convenient to use and benefits popularization and use, and the blue attapulgite polymer clay powder is suitable for making blue attapulgite polymer clay on site.

Owner:南通江涌投资开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com