Descaling and plugging removal agent used for oil field injection and production layer

A plug remover, oilfield technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of affecting the effect of acidification plug removal, poor deep treatment effect, excessive dissolution, etc., and achieves excellent retardation effect and protection. The effect of oil layer and easy sand production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

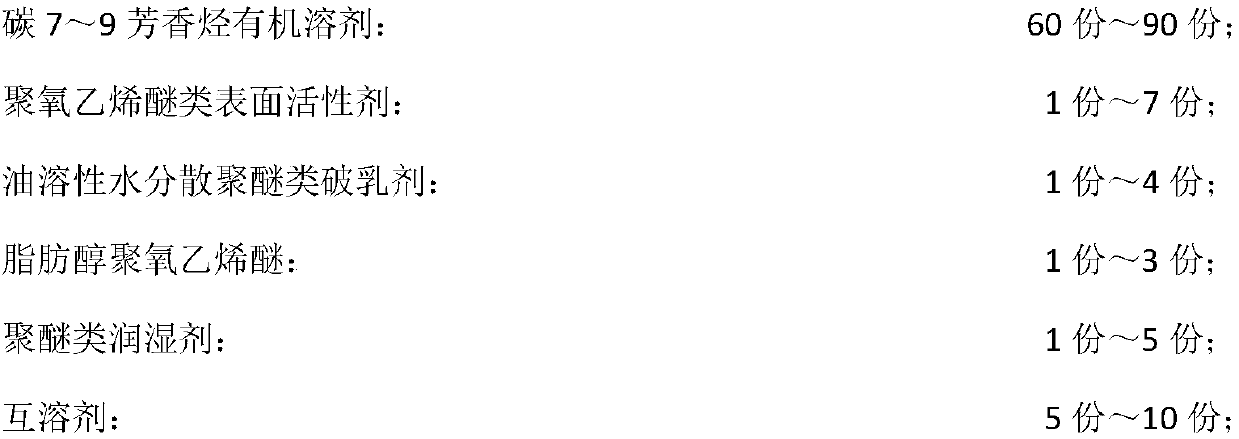

[0063] Organic multifunctional plugging remover

[0064]

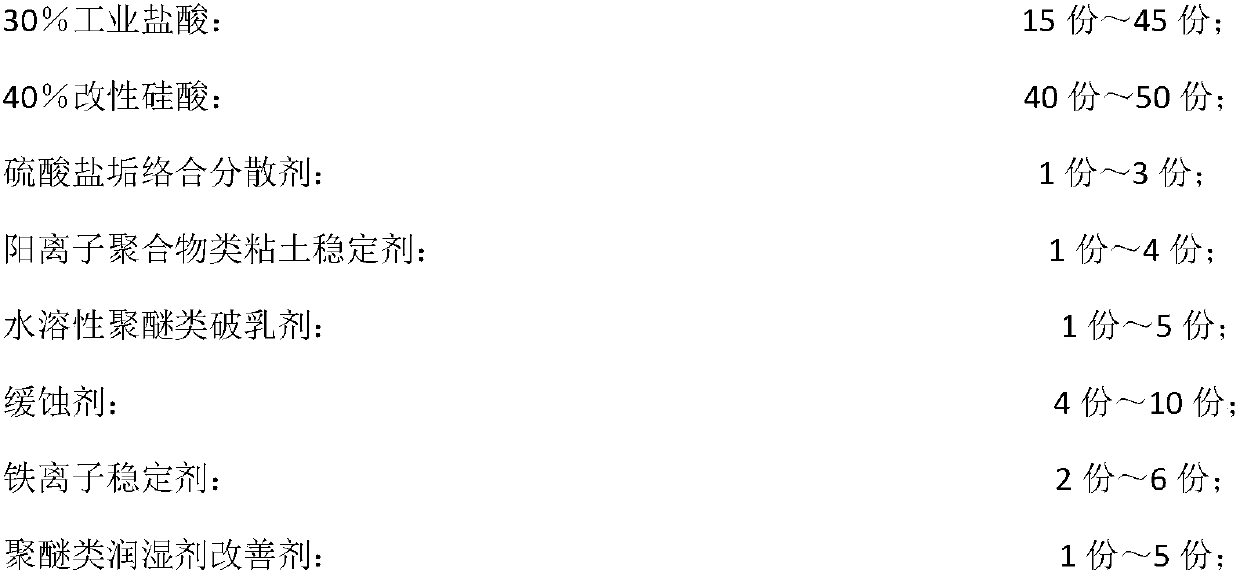

[0065] Inorganic multifunctional plugging remover

[0066]

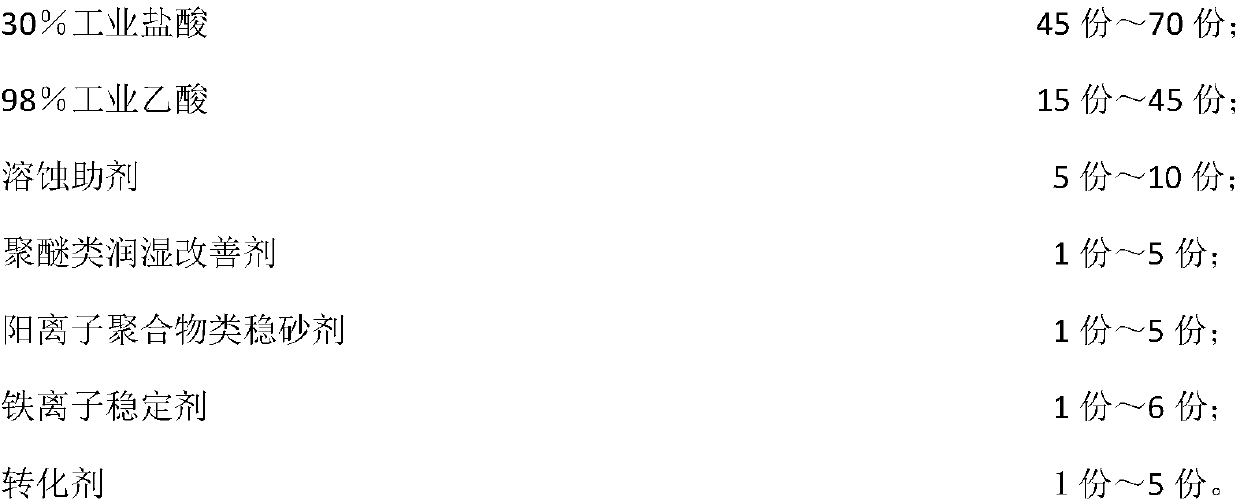

[0067] multifunctional compound synergist

[0068]

[0069]

[0070] The organic multifunctional plugging agent is made into an aqueous solution of 50% by mass; the inorganic multifunctional plugging agent is made into an aqueous solution of 25% by mass; the multifunctional composite synergist is made into an aqueous solution of 25% by mass.

[0071] The method of use is in accordance with the usual method of using a plugging agent. The three agents can be injected into the treatment oil-water well in the order of organic multifunctional plugging remover A / inorganic multifunctional plugging remover B / multifunctional composite synergist C according to the designed slug structure within the concentration range specified above to exert Their respective effects and mutual synergies can achieve the best plug-removing effect.

Embodiment 2

[0073] Organic multifunctional plugging agent A

[0074]

[0075] Inorganic multifunctional plugging remover B

[0076]

[0077] Compound multifunctional synergist

[0078]

[0079] The inorganic multi-functional plug-removing agent is formulated into a 50% mass fraction aqueous solution; the multifunctional composite synergist is formulated into a 50% mass fraction aqueous solution. According to the usual method of using plugging agents, the three agents can be used in the order of organic multifunctional blocking agent A / inorganic multifunctional blocking agent B / multifunctional composite synergist C according to the designed slug structure and in the above Inject into oil and water wells within the specified concentration range to exert their respective effects and mutual synergies to achieve the best plugging removal effect.

Embodiment 3

[0081] Organic multifunctional plugging remover

[0082]

[0083] Inorganic multifunctional plugging remover

[0084]

[0085] multifunctional compound synergist

[0086]

[0087]

[0088] The organic multifunctional plugging agent is made into an aqueous solution with a mass fraction of 75%, the inorganic multifunctional plugging agent is made into an aqueous solution with a mass fraction of 35%, and the multifunctional composite synergist is made into an aqueous solution with a mass fraction of 35%.

[0089] The method of use is in accordance with the usual method of using a plugging agent. The three agents can be injected into the treatment oil-water well in the order of organic multifunctional plugging remover A / inorganic multifunctional plugging remover B / multifunctional composite synergist C according to the designed slug structure within the concentration range specified above to exert Their respective effects and mutual synergies can achieve the best plug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com