Microparticle slow-sinking fish fry feed and production method thereof

A production method and micro-particle technology, applied in the field of fish seedling feed, can solve the problems of sufficient feeding of juvenile fish, affecting the cleanliness and sanitation of production sites, and inconvenient removal and recycling of small feed particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

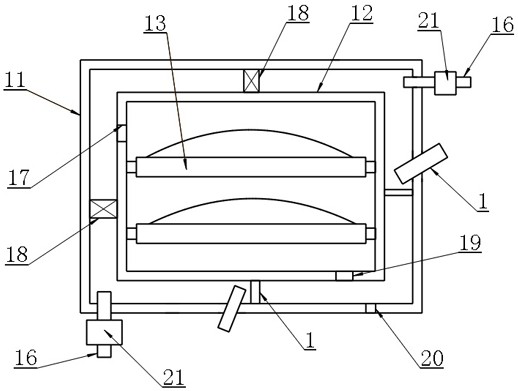

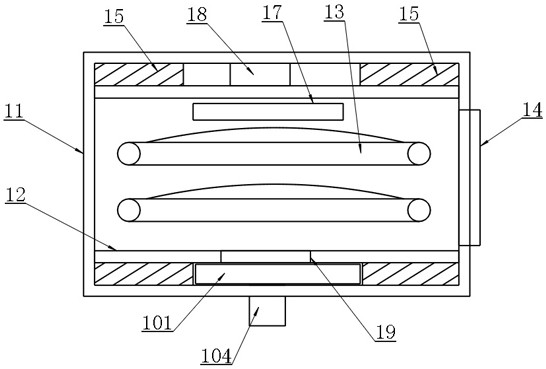

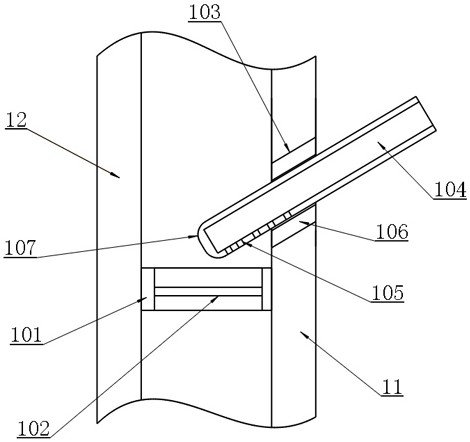

[0032] Example: as attached figure 1 , 2 and attached image 3 Shown, a kind of slowly sinking fish seedling feed of microparticles, described fish seedling feed is slowly sinking semi-suspension carnivorous fish seedling feed, the content of protein in the feed is 44-49%, in fresh water The sinking time of the first meter is 60-120s, and the stability in water is more than 3h.

[0033] In this embodiment, the fish seedling feed is suspended in water for a long time without decomposing, and its particle size is relatively small, so that young fish can eat conveniently and avoid the problem of a large amount of waste.

[0034] In addition, the fish fry feed ensures a relatively high protein demand for feed during the juvenile period by appropriately increasing the protein content.

[0035]The fish fry feed includes the following components by weight: 45-55 parts of red fish meal, 11-12 parts of peeled soybean meal, 5-9 parts of corn flour, 4-6 parts of lecithin, 1- 6 parts,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com