Method of producing exfoliated polymer-clay nanocomposite and polymer-clay nanocomposite produced therefrom

a polymer-clay nanocomposite and nanocomposite technology, applied in the field of exfoliation of polymer-clay nanocomposites, can solve the problems of insufficient the inability of pure clay to mix and interact with most polymer matrices, and the inability to provide quantitative measurement of the exfoliation level of the entire sample. , to achieve the effect of high dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

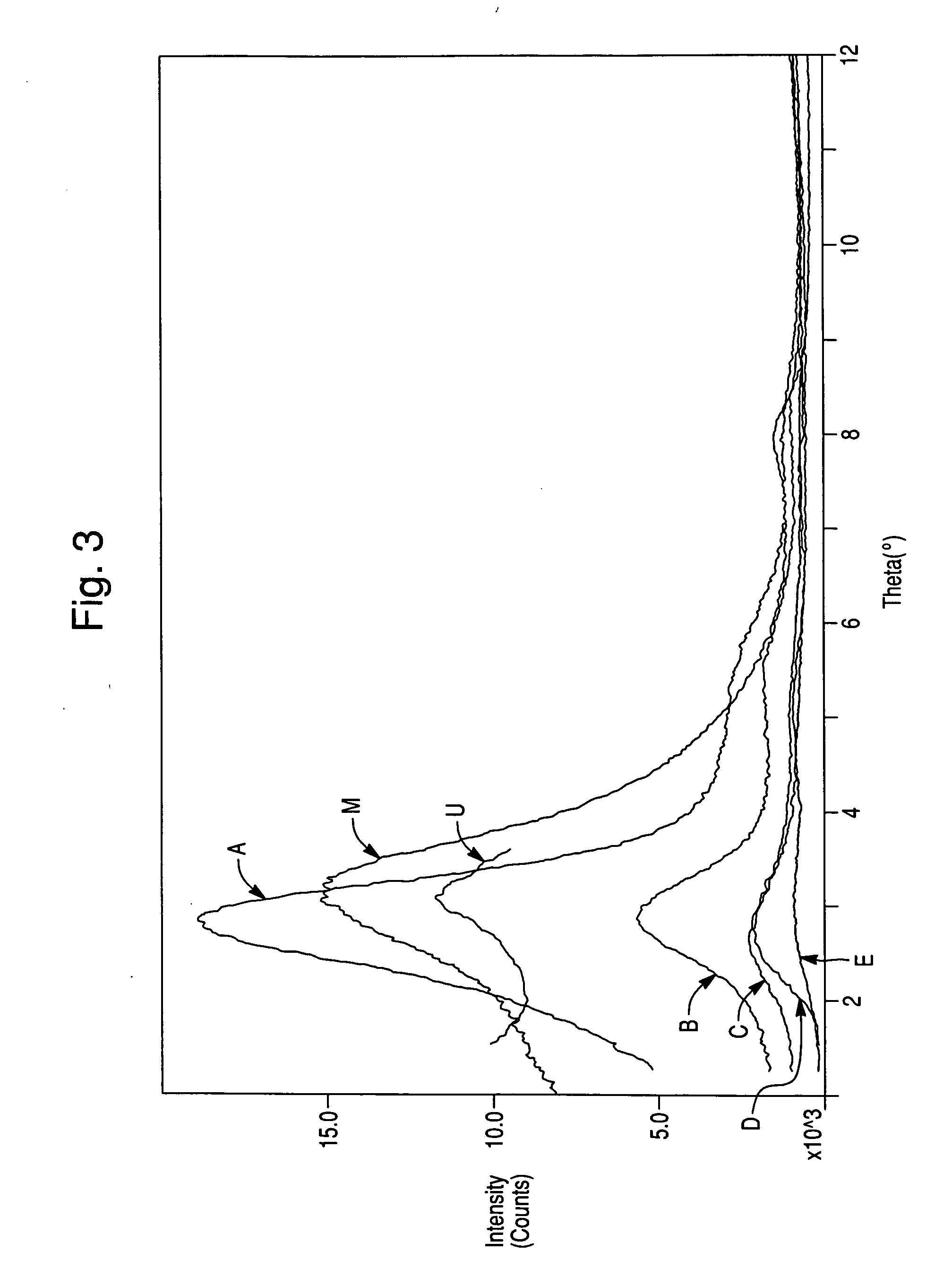

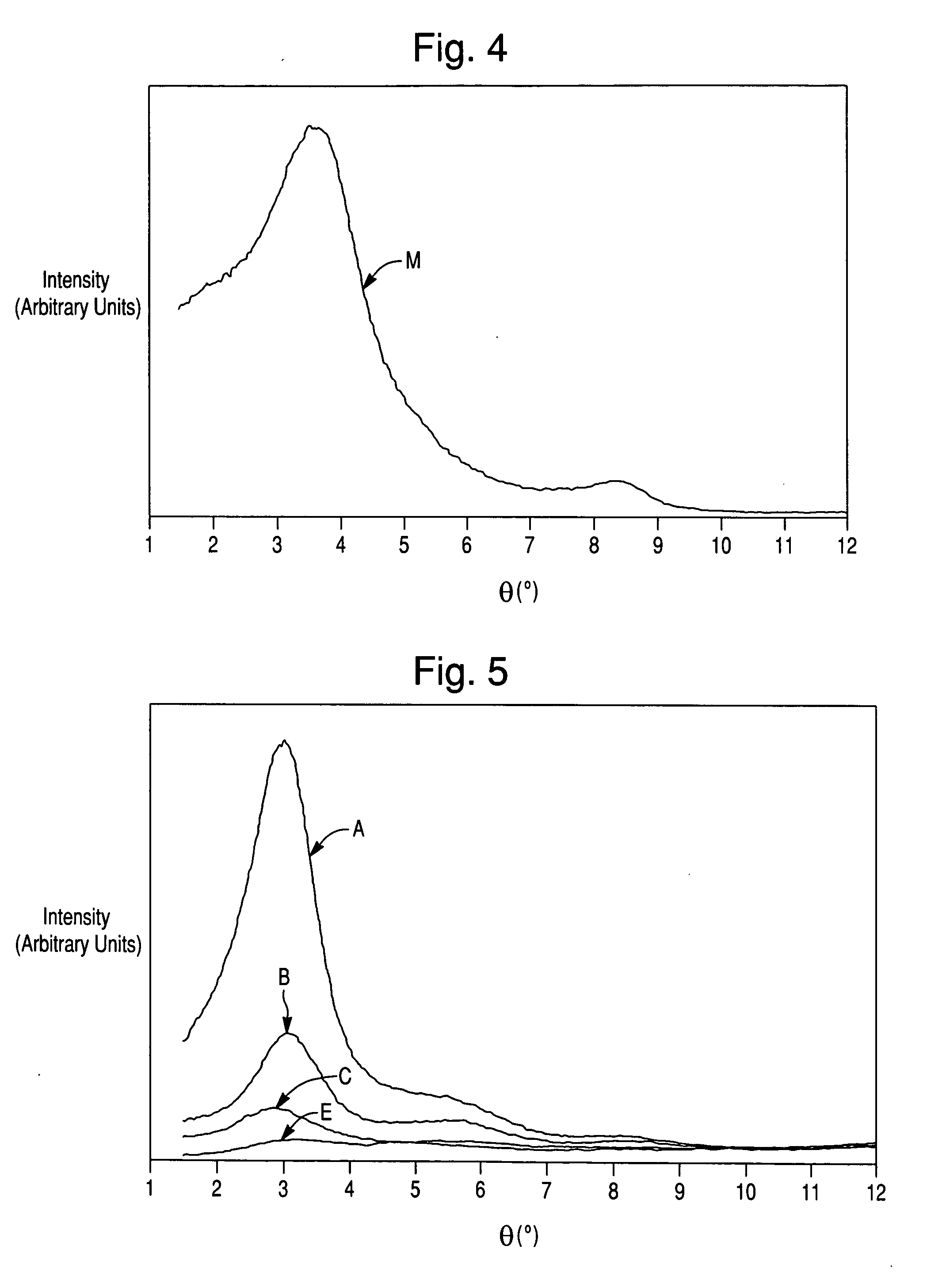

[0031] A mixture of polypropylene-organoclay was provided, comprising about 90% polypropylene and about 10% organoclay. The organoclay was obtained from Nanocor™, and contained about 40-50% clay content and about 50-60% organic content. Specifically, Nanocor™ C.30P clay was used, which is a montmorillonite nanoclay in de-agglomerated form. (Physical properties of C.30P: 40-50% nanoclay content; 38-42 lb. / ft.3 bulk density; 0.2% max. moisture).

[0032] Samples of 90 / 10 wt % polypropylene-organoclay mixture were processed as follows: 1) sample A was processed by twin-screw melt extrusion (1 pass); 2) sample B was processed by twin-screw melt extrusion followed by a second twin-screw melt extrusion (2 passes); 3) samples C and D were processed by solid-state shear pulverization, using two different screw element configurations; and 4) sample E was processed by twin-screw melt extrusion followed by solid-state shear pulverization.

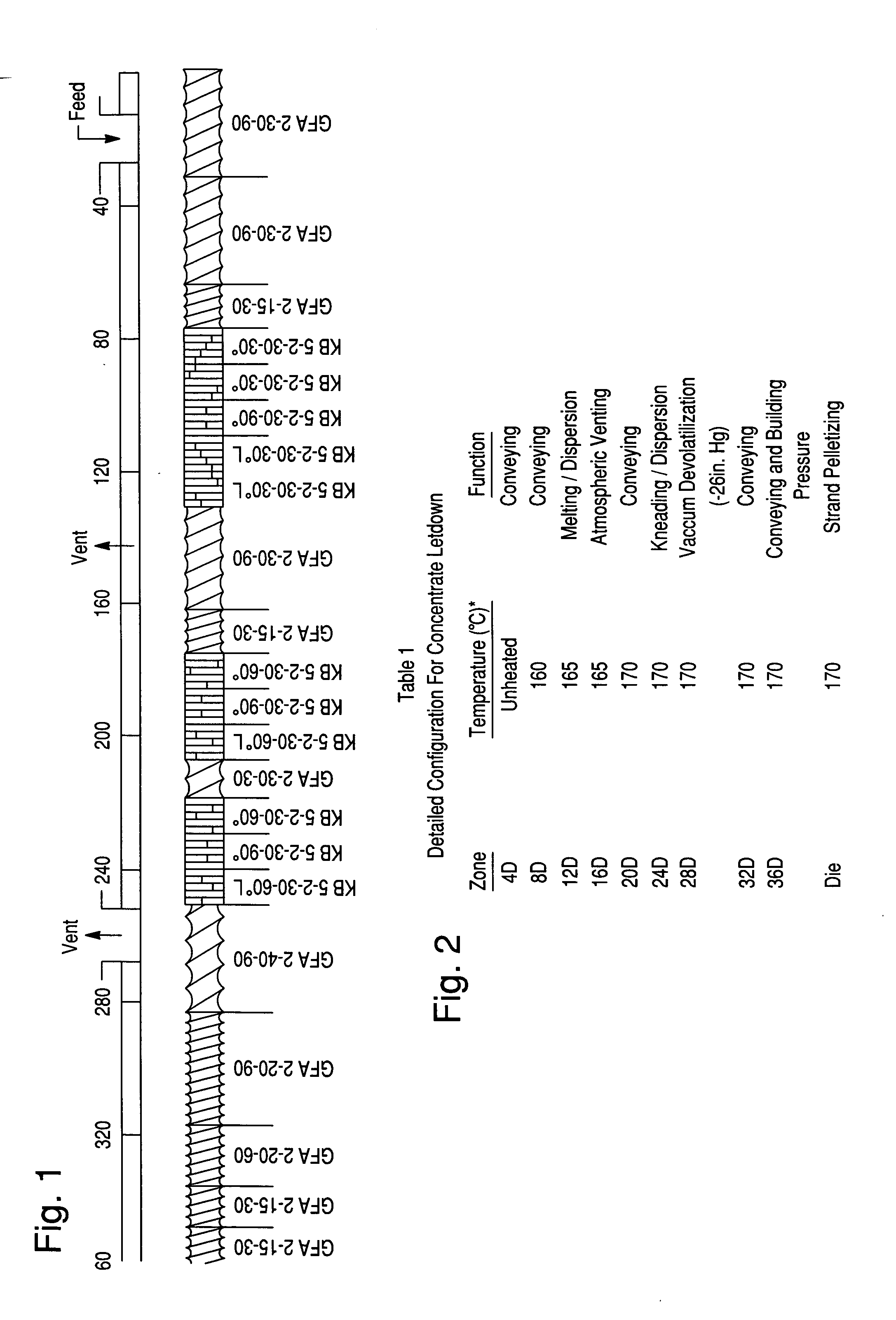

[0033] Processing parameters for the twin-screw extruder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| interlayer distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com