AM/NAI/APEG (Acrylamide/N-Allylimidazole/Allyl Alcohol Polyoxyethylene Ether) polymer clay stabilizer and preparation method

A clay stabilizer and polymer technology, which is applied in the field of polymer clay stabilizer and its synthesis, can solve the problems of mud shale hydration, high temperature resistance, and insufficient stability of high salt, and achieve rigidity increase, viscosity and resistance Increased temperature and enhanced stabilizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 7.0g of imidazole into the reactor, dissolve it with tetrahydrofuran as a solvent, add 2.7g of NaH as a catalyst, slowly add 14.0g of allyl bromide dropwise under continuous stirring, the reaction temperature is 0°C, and the reaction time is 7h. After the reaction, slowly add a large amount of distilled water , distilled under reduced pressure, extracted with ethyl acetate solvent, washed with saturated brine, dried and filtered, and distilled the solvent under reduced pressure to obtain N-allylimidazole as a light yellow liquid (yield 99%).

[0023] The synthesis of embodiment 2 ternary copolymerization AM / NAI / APEG

Embodiment 2

[0024] Add 0.0468g of NAI prepared above into a 250ml three-necked flask according to the ratio in Table 1, then add AM, APEG, and emulsifier OP-10 to make an aqueous solution with a concentration of 10-20% of the total monomer mass, and pass nitrogen gas for 30 minutes ; Then add initiator ammonium persulfate solution and sodium bisulfite solution, the molar ratio of ammonium persulfate and sodium bisulfite is 1:1, the amount of initiator added is 0.1-0.5% of the total mass of the monomer, continue to feed nitrogen 10-20min, react at a temperature of 30-60°C for 4-10h; finally wash three times with absolute ethanol, pulverize and dry to obtain AM / NAI / APEG terpolymer.

[0025] Table 1 Addition amount of ternary polymer synthetic drugs

[0026]

[0027] Embodiment 3: AM / NAI / APEG copolymer structural characterization

Embodiment 3

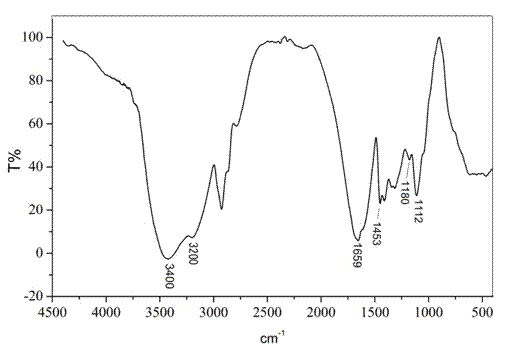

[0028] The infrared spectrogram of the terpolymer AM / NAI / APEG synthesized by embodiment 2 is as follows figure 1 shown. It is known from the figure that the hydroxyl O-H stretching vibration is divided into 3400cm -1 .N-H (-NH2) stretching vibration peak at 3200cm -1 .C=O stretching vibration peak at 1659cm -1 at 1180cm -1 、1453cm -1 It is the vibration of the aromatic ring skeleton of the imidazole ring, 1112cm -1 It is the stretching vibration peak of ether C-O-O.

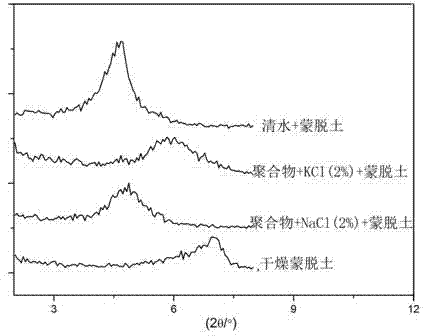

[0029] Example 4 Effect of ternary copolymerization AM / NAI / APEG solution on montmorillonite crystal spacing

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com