Art knife

A utility knife and knife holder technology, which is applied in metal processing, artist hand tools, decorative arts, etc., can solve the problems of inconvenient operation, blade falling out of the utility knife, doubts about the use of safety, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

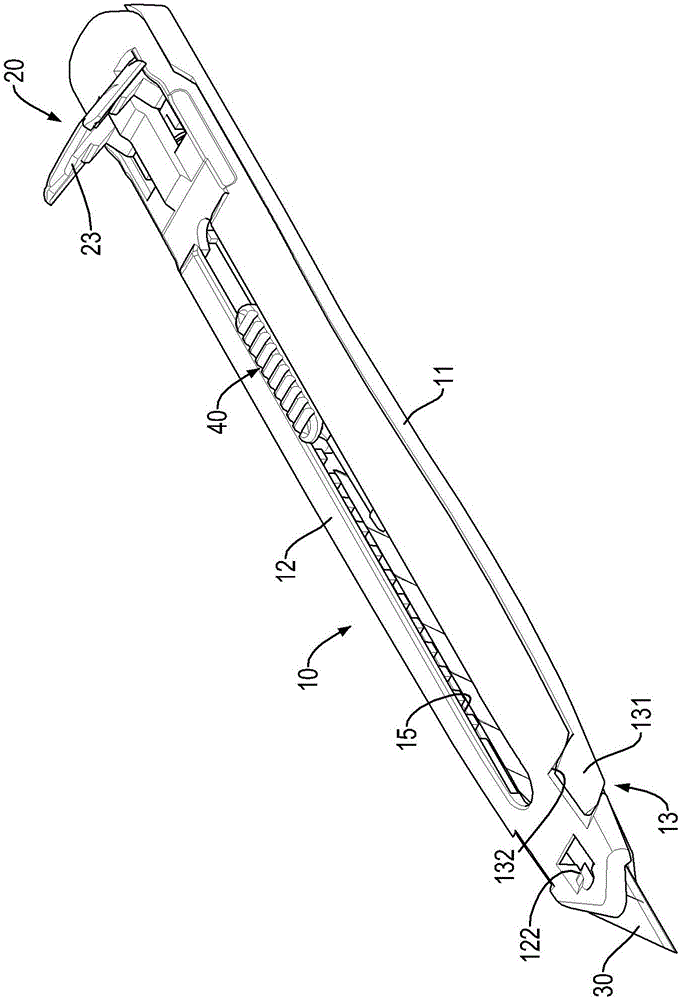

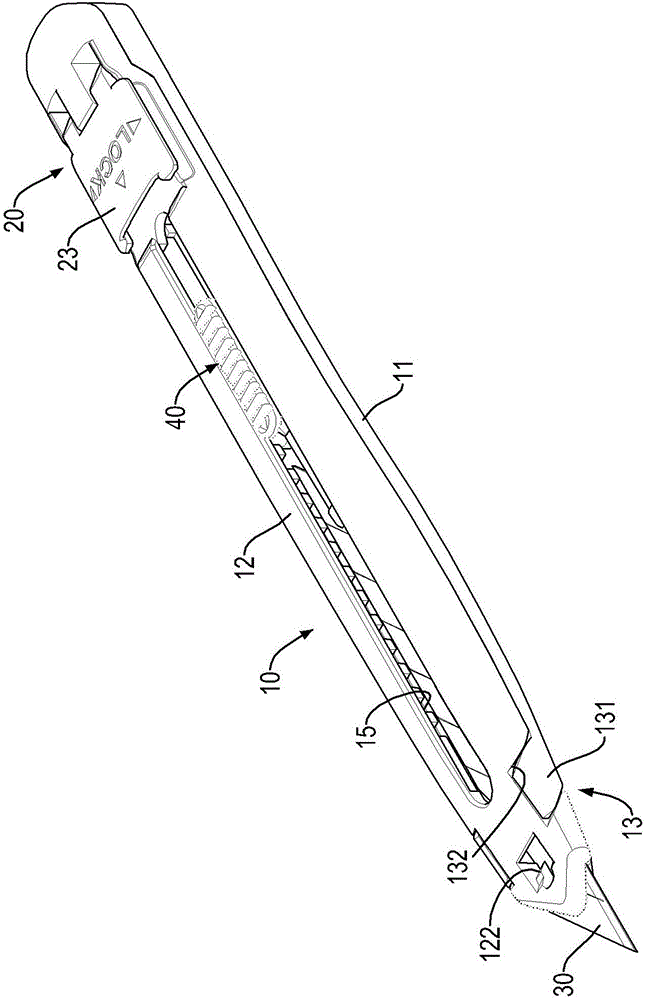

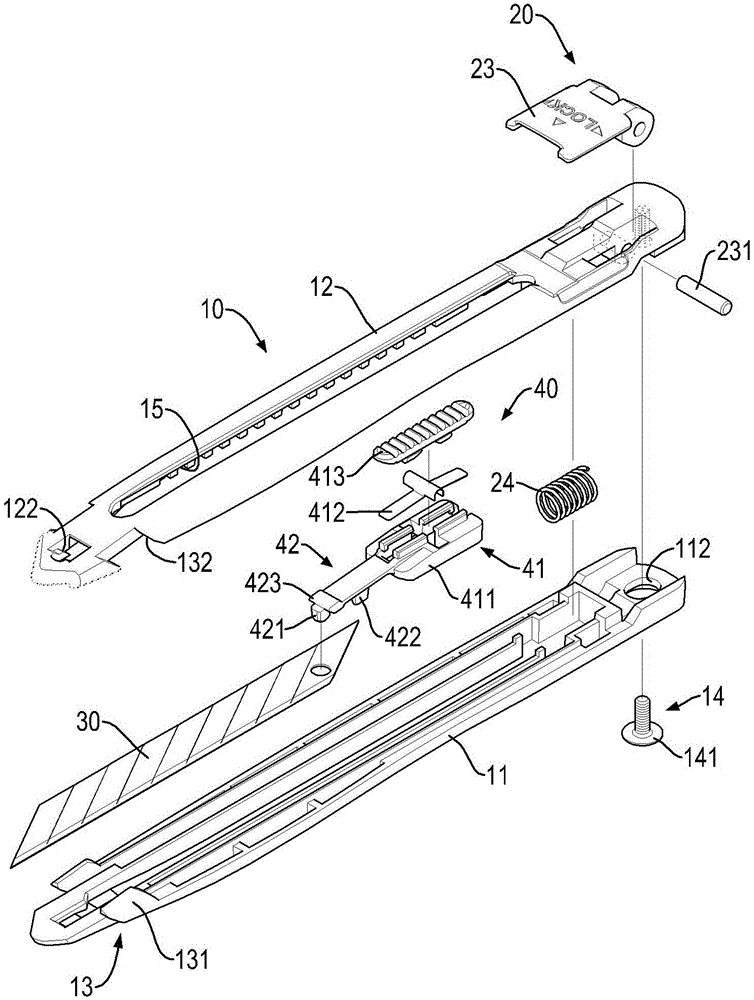

[0044] see Figure 1 to Figure 3 As shown, the utility knife proposed by the present invention includes a blade body 10, a locking structure 20, a blade 30, and a regulator 40. The blade body 10 includes a lower knife seat 11, an upper knife seat 12, and an inclined plane limiting structure 13. 1. The lower knife rests 11 and 12 can move relative to each other, and the bevel limit structure 13 is formed on a front end of the lower knife rest 11 and a front end of the upper knife rest 12, so that the front ends of the upper and lower knife rests 11 and 12 are limited by an inclined plane. The position structure 13 forms an oblique abutment; preferably, the bevel limit structure 13 is a concave-convex matching structure inclined forward from bottom to top, and the bevel limit structure 13 is respectively convexly provided with a Limiting guide blocks 131 are respectively recessed with a limiting guide groove 132 on both sides of the front end of the upper knife seat 12, and each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com