Art knife structure capable of clamping blade

A utility knife and blade technology, applied in metal processing, artist's hand tools, decorative art, etc., can solve problems such as shaking and the inability of utility knives to cut accurately, and achieve the effect of firm fixation, precise cutting, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

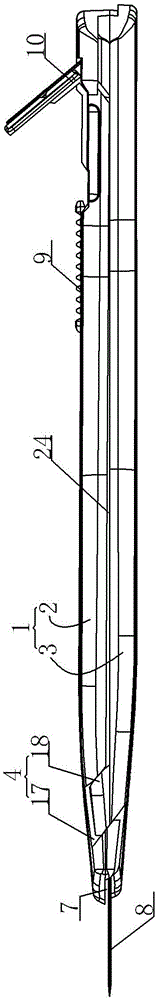

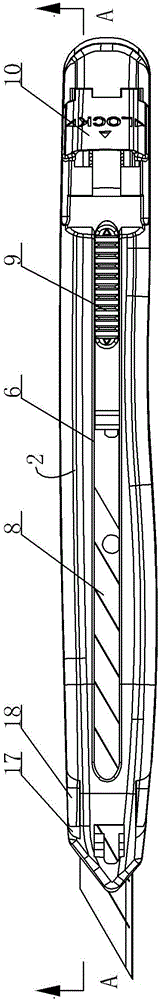

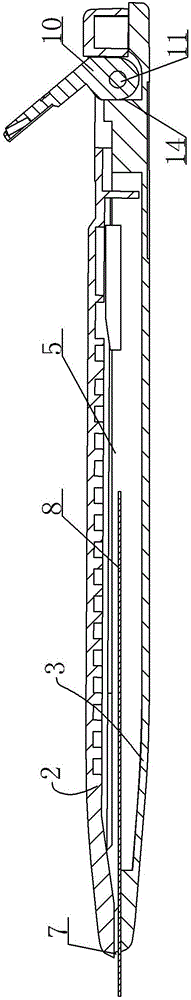

[0029] A utility knife structure capable of clamping blades, see Figure 1 to Figure 9 , which includes:

[0030] A knife body 1, it comprises the first knife body 2, the second knife body 3, the first knife body 2 is positioned at the relative top of the second knife body 3, the front end of the first knife body 2, the front part of the second knife body 3 buckle each other and form a relatively sliding Inclined surface limiting structure 4, the blade guide groove 5 is formed in the blade body after the combination of the first blade body 2 and the second blade body 3, the top of the blade guide groove 5 is provided with a blade driving guide groove 6, and the blade driving guide groove 6 is parallel to the blade guide Groove 5, the front end of knife body is that the front end goes out knife edge 7;

[0031] A blade 8; the blade 8 is located in the blade guide groove 5;

[0032] A regulator 9, the regulator 9 is used to block the blade 8 and drive the blade 8 to move forwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com