Efficient conductive slurry production device

A technology for conductive paste and production device, which is applied to mixers, circuits, electrical components and other directions with rotary stirring devices, can solve the problems of waste of paste, low cleaning intensity and low cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

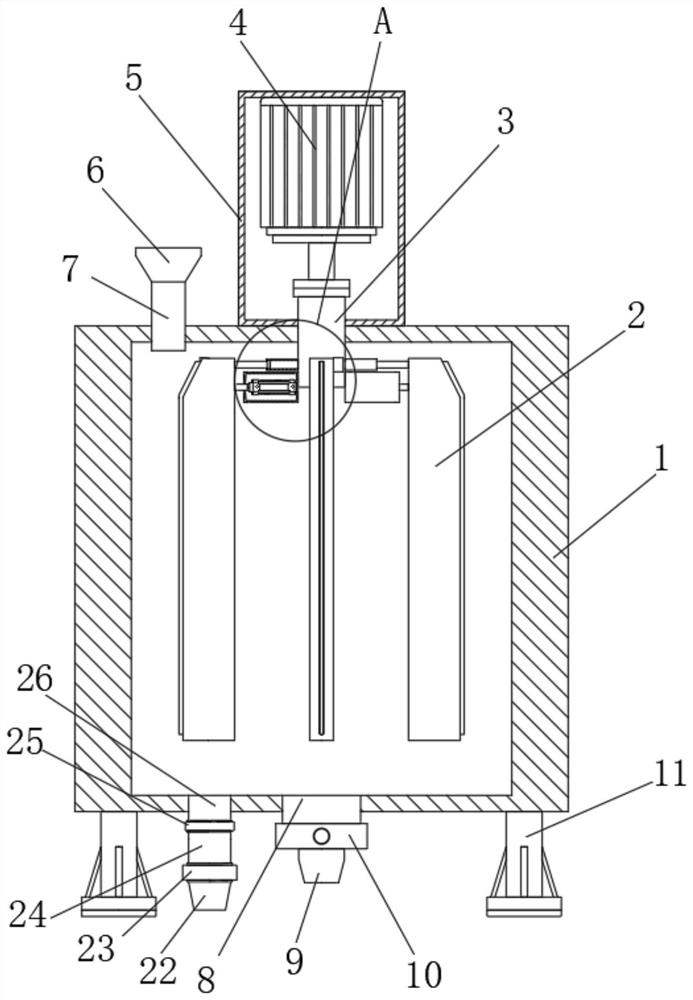

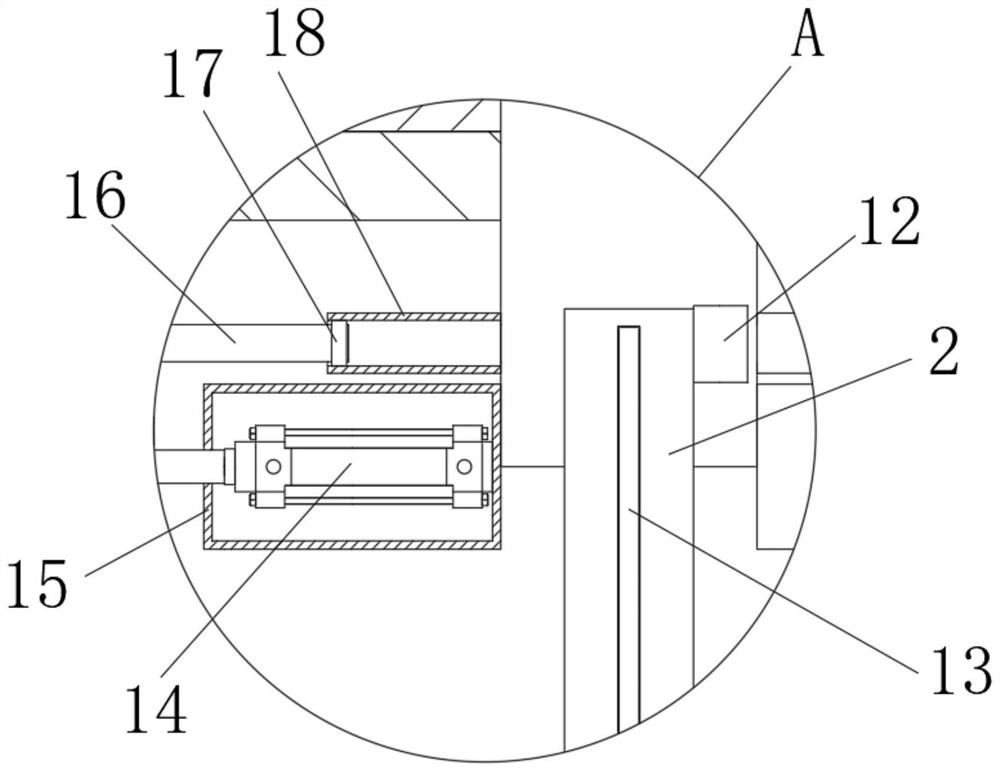

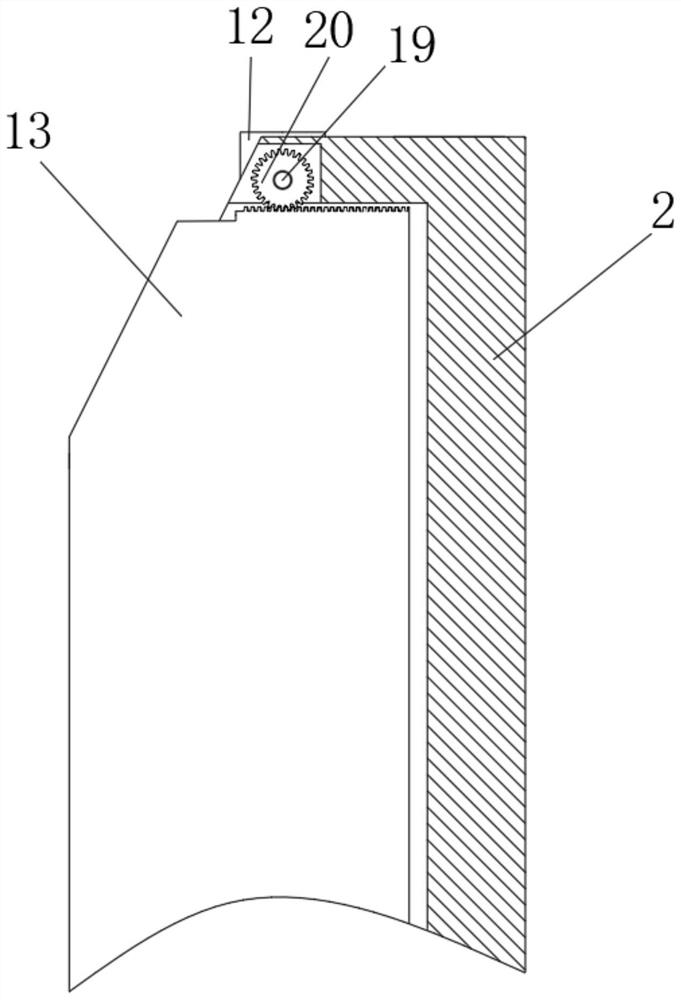

[0035] like Figure 1-6 As shown, the embodiment of the present invention provides a high-efficiency conductive paste production device, including a stirring device 1, the outer wall of the top of the stirring device 1 is fixedly connected to an organic case 5, the inner wall of the top of the case 5 is fixedly mounted with a rotating motor 4, and the output shaft of the rotating motor 4 The bottom is fixedly connected with a rotating shaft 3; the outer wall of the rotating shaft 3 is fixedly connected with a cylinder box 15, and the inside of the cylinder box 15 is provided with a telescopic cylinder 14, and one end of the output shaft of the telescopic cylinder 14 is fixedly connected with a stirring rod 2; the top of the cylinder box 15 is provided with There is a sleeve 18, a telescopic rod 16 is fixedly connected to one end of the stirring rod 2; a scraper 13 is arranged inside the stirring rod 2, a motor box 12 is fixedly connected to one end of the stirring rod 2 corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com