A method for cleaning solar water heater scale

A technology for solar water heaters and cleaning methods, which is applied in the field of scale cleaning of solar water heaters, and can solve problems such as water pipe freezing and cracking, slow water temperature heating in water storage tanks, and drainage pipes freezing, so as to achieve the effect of avoiding freezing and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

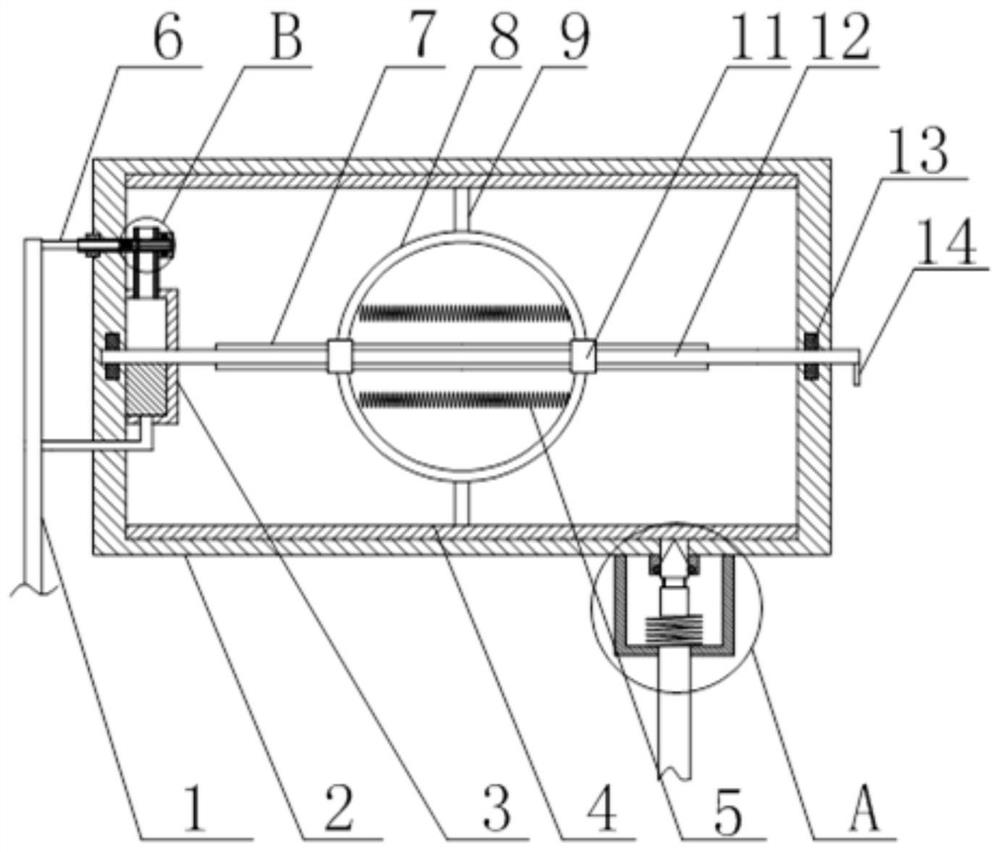

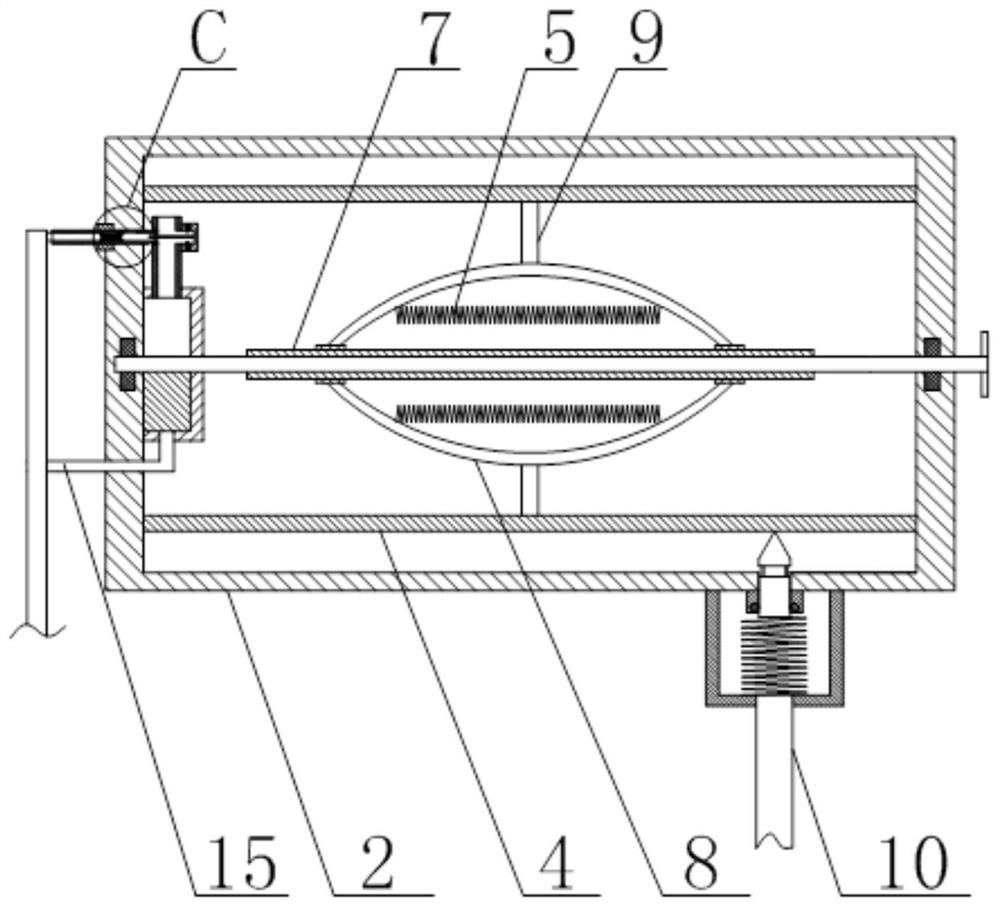

[0050] Such as Figure 1 to Figure 8 Shown, the cleaning method of a kind of solar water heater scale of the present invention comprises the following steps:

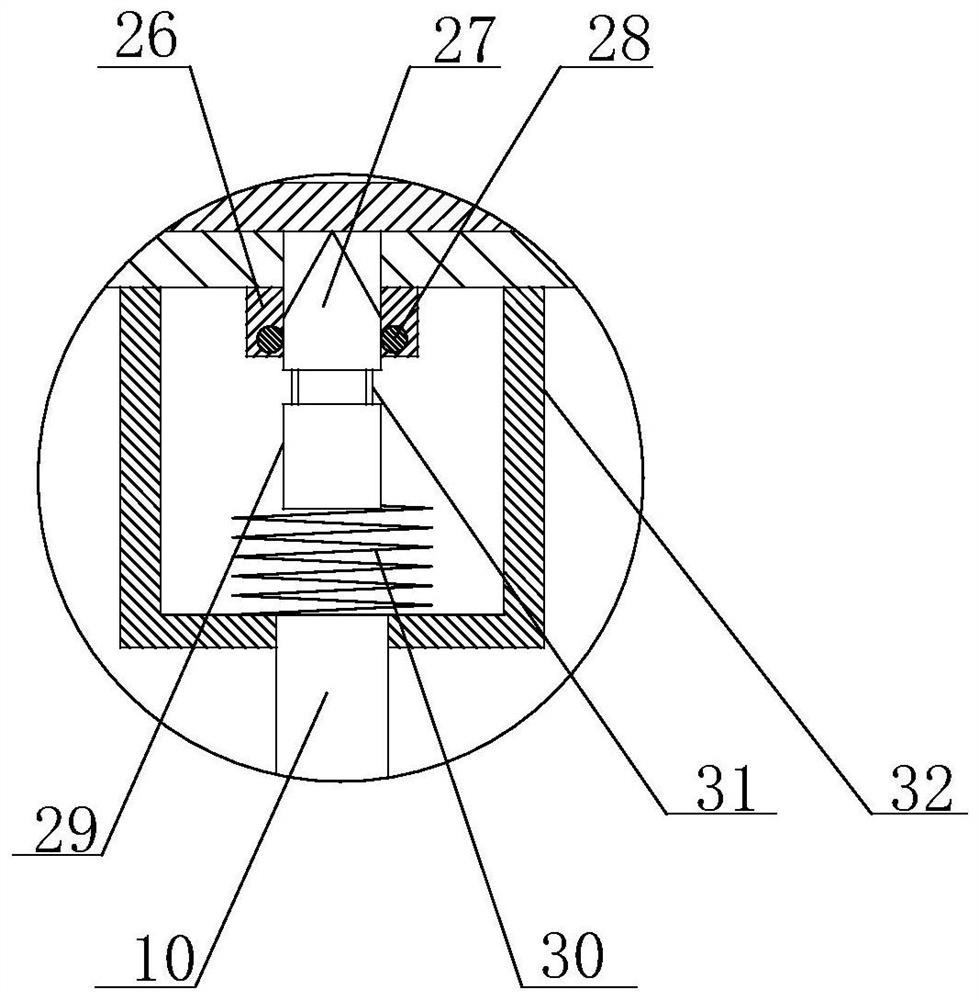

[0051] 1) Open the valve on the drain pipe 10 to drain the water in the water storage tank 2;

[0052] 2) Turn on the valve and water pump on the water inlet pipe 1, use the water pump to pass high-pressure water into the water inlet pipe 15, and the high-pressure water enters the fixed box 3, and drives the first blade 35 and the second blade 36 to rotate in the fixed box 3, Thereby, the rotating shaft 12 is driven to rotate in the fixed 3, so that the scraper 4 cleans the scale on the inner wall of the water storage tank 2;

[0053] 3) The water acting on the first vane 35 and the second vane 36 is then sprayed upwards onto the inner wall of the water storage tank 2 through the outlet pipe 21, and the scale scraped loose by the scraper 4 is washed from the inner wall to the inner bottom of the water storage tank 2 ,...

Embodiment 2

[0061] On the basis of Embodiment 1, the rotating shaft 12 is also provided with two movable blocks 11, and the two ends of the arc-shaped plate 8 are respectively connected with the two movable blocks 11, and the movable block 11 is provided with a The connecting hole 39 is provided, and the rotating shaft 12 is inserted into the connecting hole 39 , and the movable block 11 can move on the rotating shaft 12 along the axial direction of the rotating shaft 12 .

Embodiment 3

[0063] On the basis of Embodiment 2, guide plates 7 are provided on both sides of the outer circumferential wall of the rotating shaft 12, and the guide plates 7 are distributed along the axial direction of the rotating shaft 12. Both sides of the inner wall of the connecting hole 39 are provided with guiding The plate 7 matches the guide groove 40, and the guide plate 7 is located in the guide groove 40.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com