Table top cleaning equipment of fixing type prefabricated component mold table

A technology of prefabricated components and cleaning equipment, which is applied to auxiliary forming equipment, cleaning methods using tools, manufacturing tools, etc., can solve problems such as waste of manpower, uneven fixing of production molds, and influence on production progress, and achieve convenient disassembly and replacement. Save maintenance time and improve cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The descriptions of "left" and "right" in the present invention are all based on figure 1 For the reference direction:

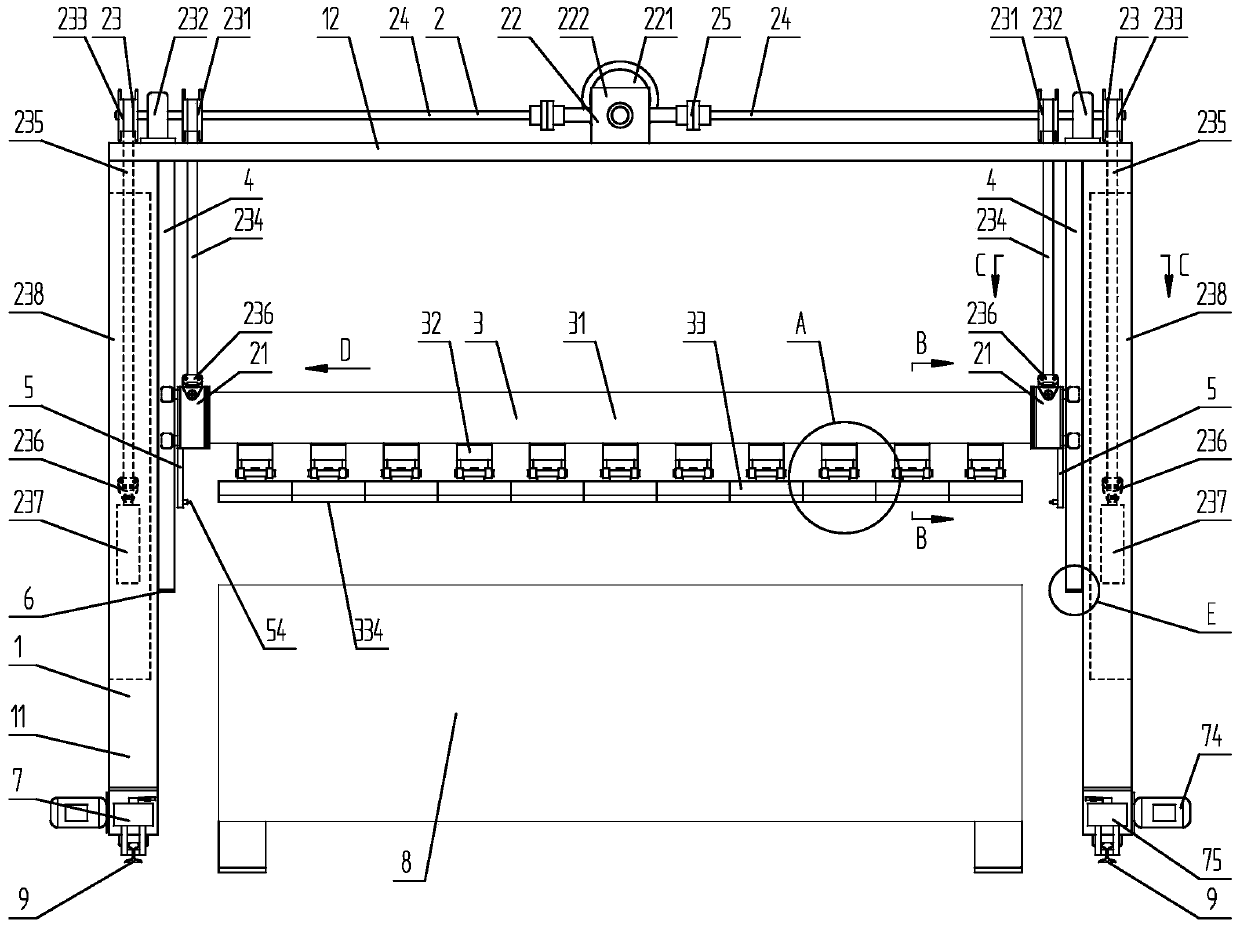

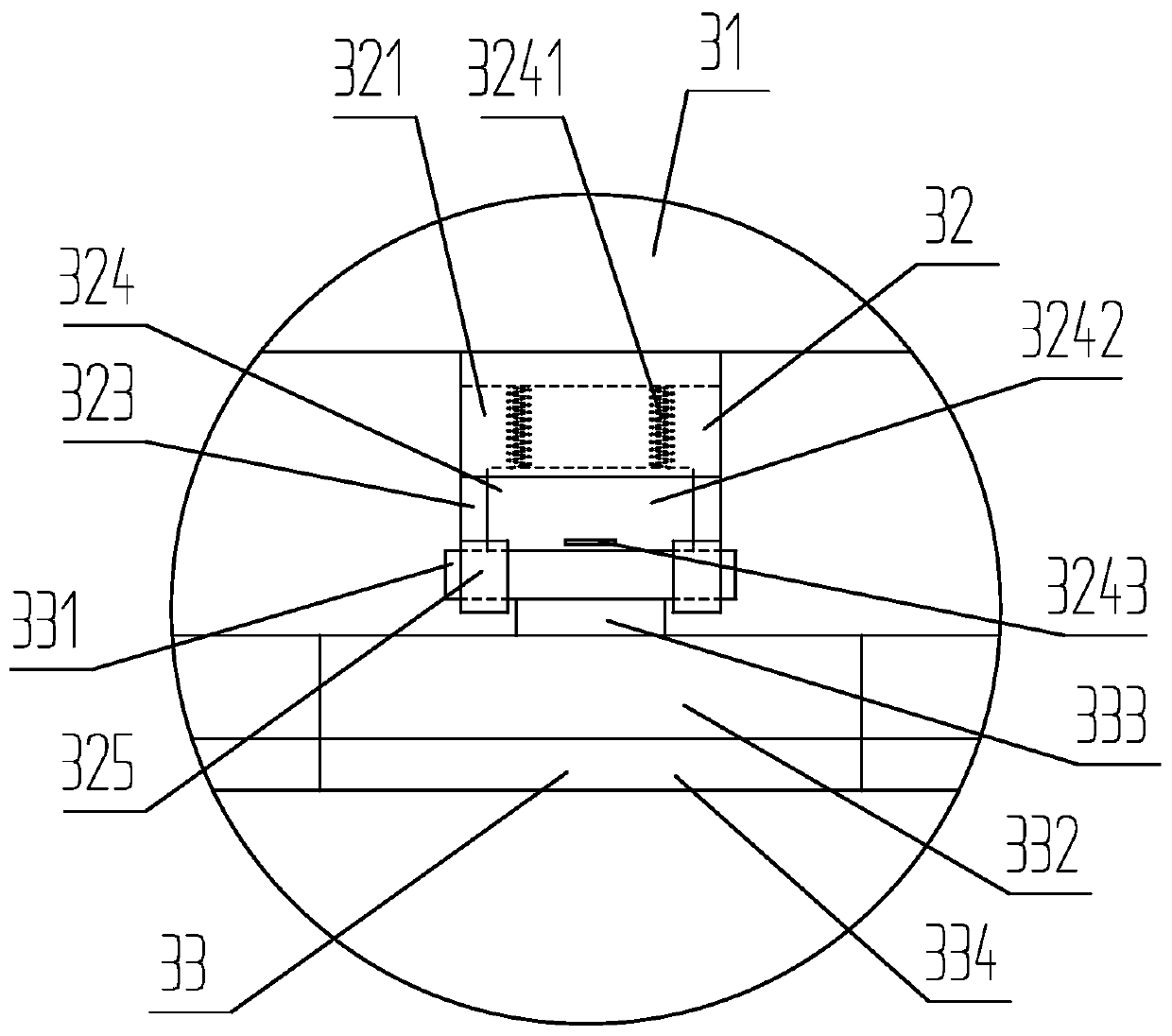

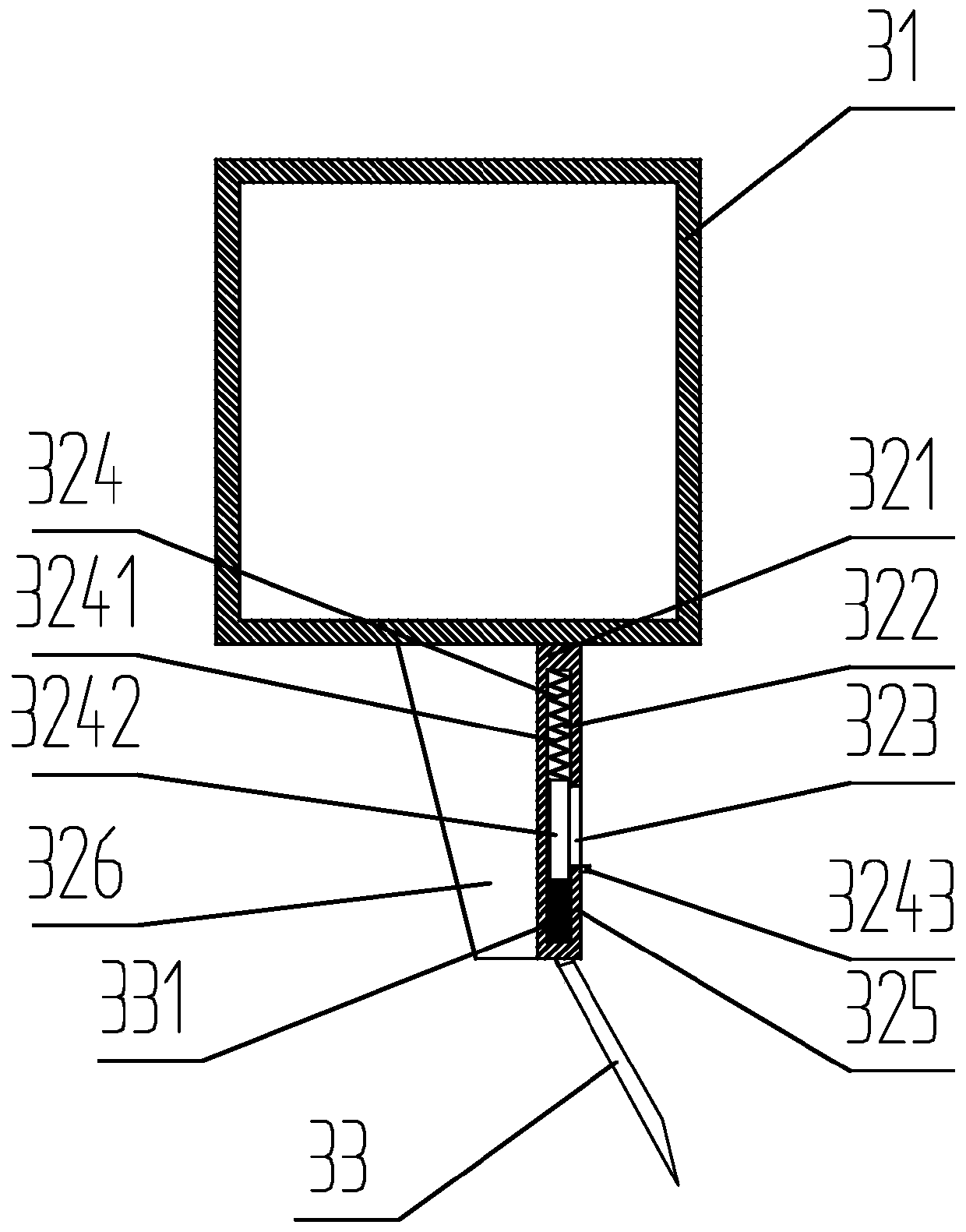

[0030] like Figure 1 to Figure 13 As shown, a table cleaning equipment for a fixed prefabricated component mold table includes a frame body 1, a lifting transmission device 2, and a tool holder assembly 3. The frame body 1 includes a column 11, a beam 12, two columns 11 and a beam 12 Lap joints form a "door"-shaped frame structure, and the inner walls of the two columns 11 are welded with trolley movable guide rails 4. The upper end of the trolley movable guide rail 4 is close to the lower end of the beam 12, and the lower end of the trolley movable guide rail 4 is installed with a trolley movable limiter. Component 6, trolley activity limit component 6 is used to limit the movement of the trolley 21 in normal use, and also f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com