Automatic telescopic scraping arm for square/regular polygon settling basin

An automatic telescopic, regular polygon technology, applied in separation methods, precipitation separation, chemical instruments and methods, etc., can solve the problems that cannot be applied to rectangular pools, occupy land, waste resources, etc., to improve the efficiency of the water treatment industry and overcome occupation. Land, reliable and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] The sewage enters the sedimentation tank, and the chemical is added to react. The suspended particles in the sewage condense into flocs and gradually settle to the bottom of the sedimentation tank. After the settlement, the clear water in the upper part of the sedimentation tank flows out from the clear water outlet. At this time, the mud scraper works to clean up the sludge at the bottom of the settling tank 22 .

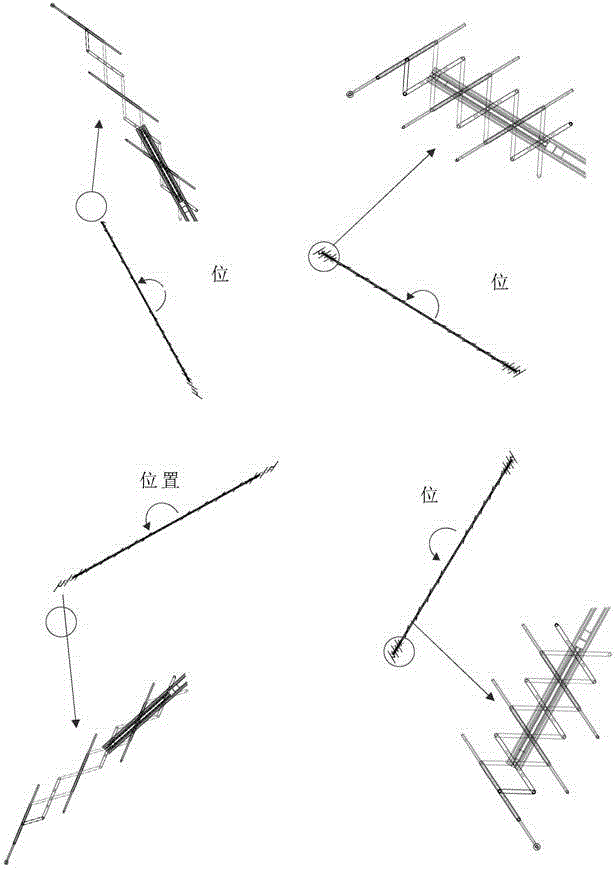

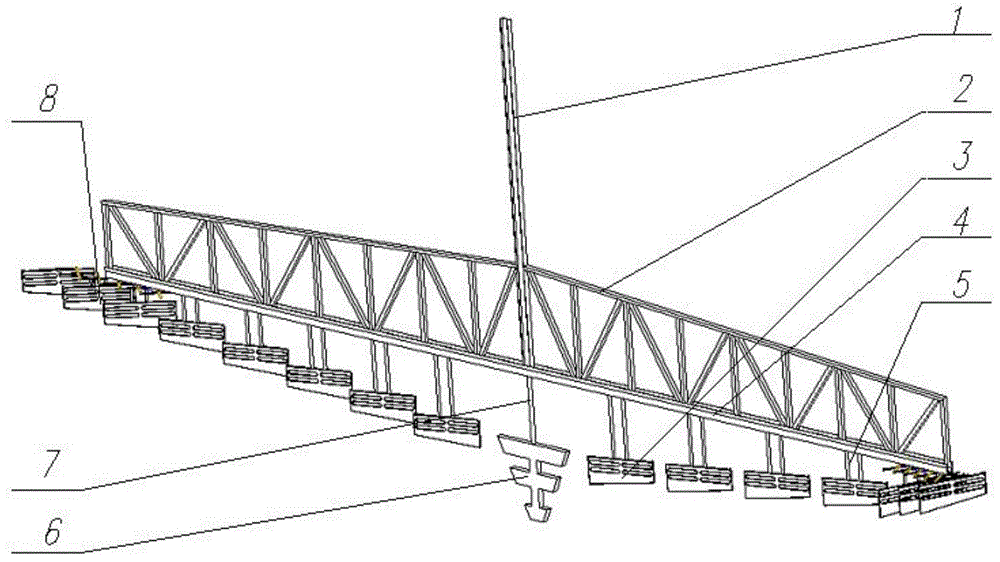

[0018] The invention as figure 1 As shown, the main shaft 1 drives the main shaft assembly 2 to perform counterclockwise circular motion. At the same time, the fixed scraper arm 4 and the automatic telescopic assembly 8 installed on the main shaft assembly 2 make a circular motion around the main shaft 1 .

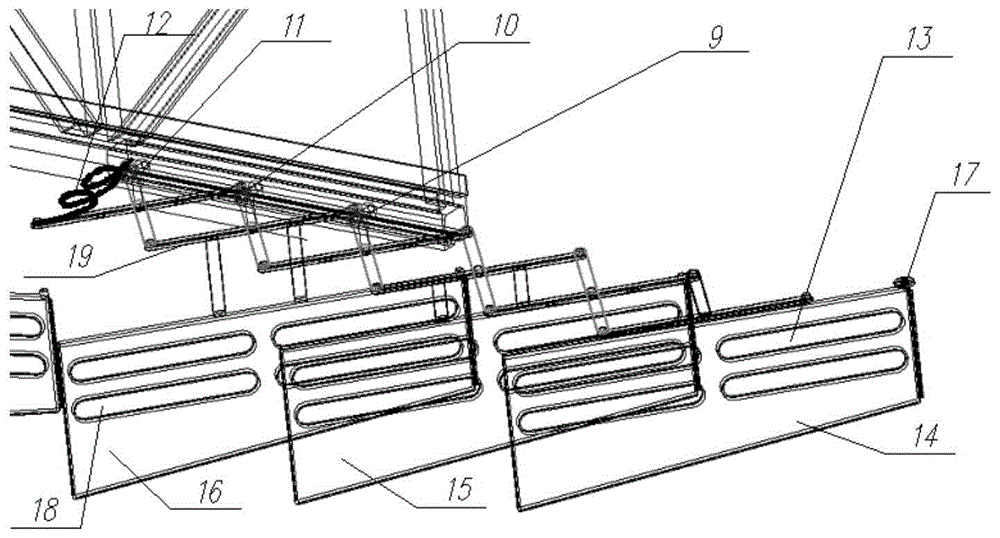

[0019] The lower end of the fixed scraper arm 4 of the present invention is equipped with a scraper connecting rib 5, and the fixed scraper 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com