Centrifugal fan provided with centrifugal force separation device

A centrifugal fan and separation device technology, which is applied to the components of the pumping device for elastic fluids, mechanical equipment, non-variable-capacity pumps, etc. Oil fume gas, air purification and other issues, to achieve the effect of improving the separation efficiency and quality and optimizing the circumference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

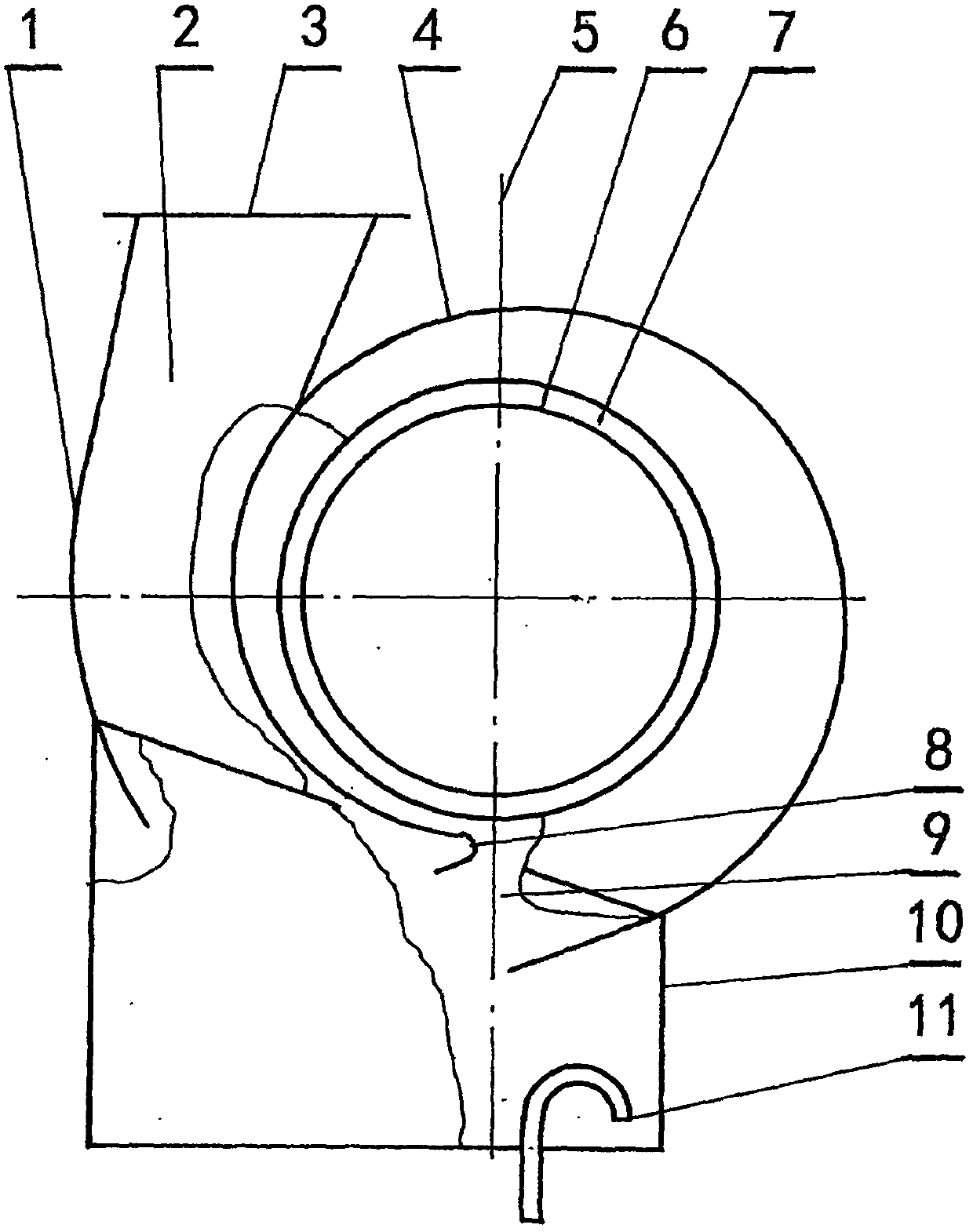

Examples

Embodiment 2

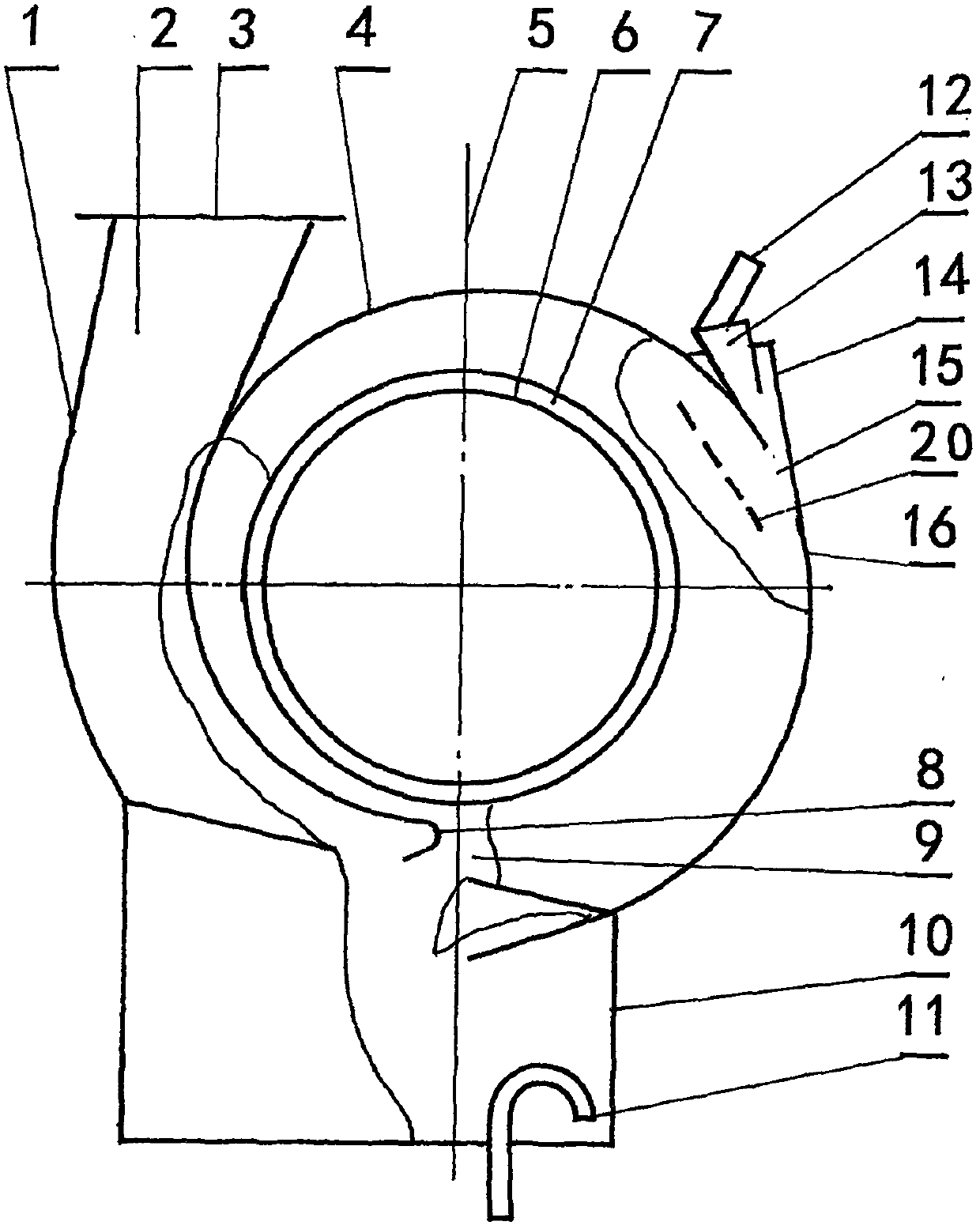

[0034] Such as figure 2 Shown, the centrifugal blower fan that installs the centrifugal force separation device in the present embodiment is on the basis of embodiment 1, wherein: it also includes by annular separation plate 4, angle groove body 14, water film spray nozzle 13. The water film spray nozzle device formed by the water film spray nozzle outlet 15 and the water inlet pipe 12 is formed by overlapping the ends of the annular separation plate 4 and the annular separation plate 16 on the side of the fan housing 1 and the center line 5. There is a corner-shaped tank 14 with an opening, and the water film spray nozzle 13 is placed in the opening of the angle-shaped tank 14. There is a gap between the outlet 15 of the water film spray nozzle and the inner wall of the annular separation plate 16, and the water inlet pipe 12 is located in the ring On the outside of the separation plate 16, the length of the angled groove body 14 is consistent with the thickness of the fan h...

Embodiment 3

[0036] Such as figure 2 As shown in the dotted line, the centrifugal fan equipped with centrifugal force separation device in this embodiment is based on the embodiment 2 with an added wind deflector 20, wherein: it also includes an annular separation plate 4 on one side of the central line 5 The water film spray nozzle 13 outlet position that the upper end is provided with is provided with deflector 20, and the upper end of deflector 20 is provided with annular separating plate 4 inwalls, and water film spray nozzle 13 is provided with gap, and the length of deflector 20 is the same as that of blower casing. Body 1 has the same thickness.

Embodiment 4

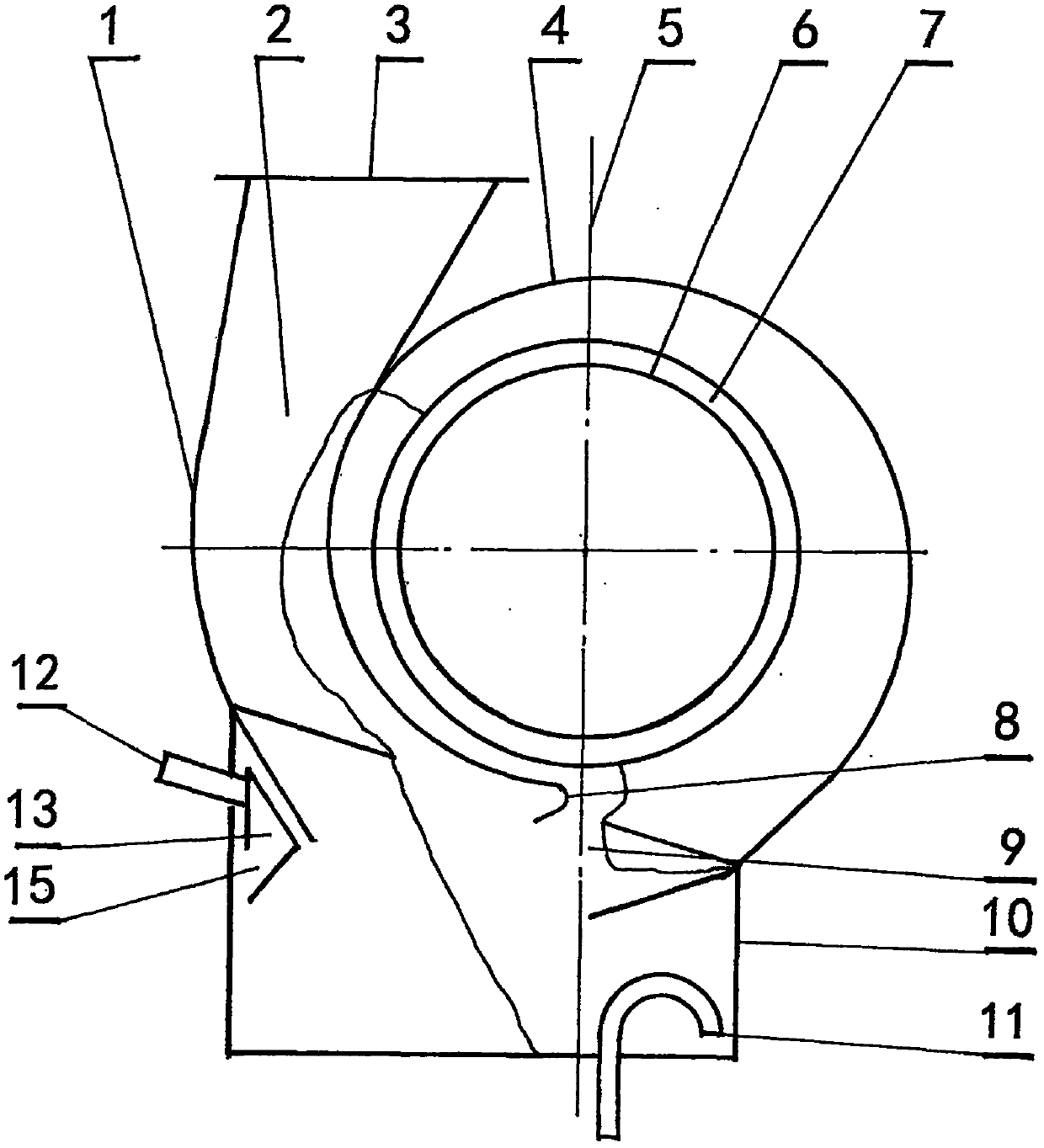

[0038] Such as image 3 As shown, the centrifugal blower equipped with the centrifugal force separation device in the present embodiment is based on the embodiment 1 and it also includes a water film spray nozzle 13 installed on the inner wall of the separation box 10 body and the fan outlet 9. On one side, a gap is provided between the water film nozzle outlet 15 and the inner wall of the separation box 10, and the water inlet pipe 12 is located at the outer end of the separation box 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com