Ironclad motor cast-aluminum rotor end surface burr cleaning device

A technology of cast aluminum rotor and cleaning device, which is applied in the direction of grinding drive device, manufacturing stator/rotor body, grinding/polishing safety device, etc. It can solve the problems of motor noise, inability to absorb burrs, and poor efficiency of manual grinding. Achieve the effect of improving the production qualification rate, avoiding the noise problem of the single motor, and improving the versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

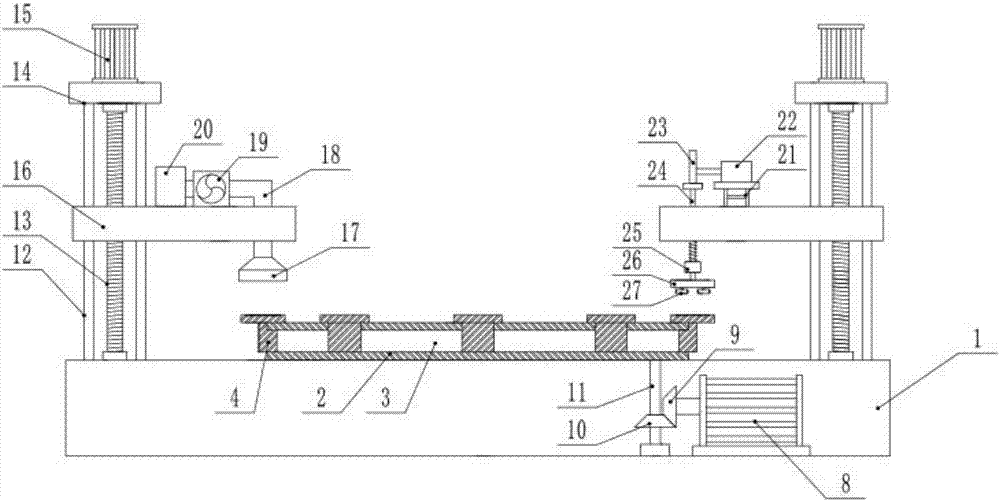

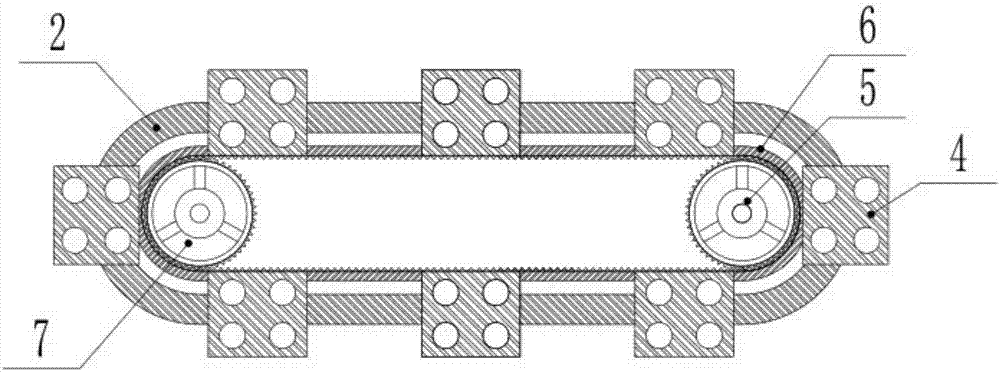

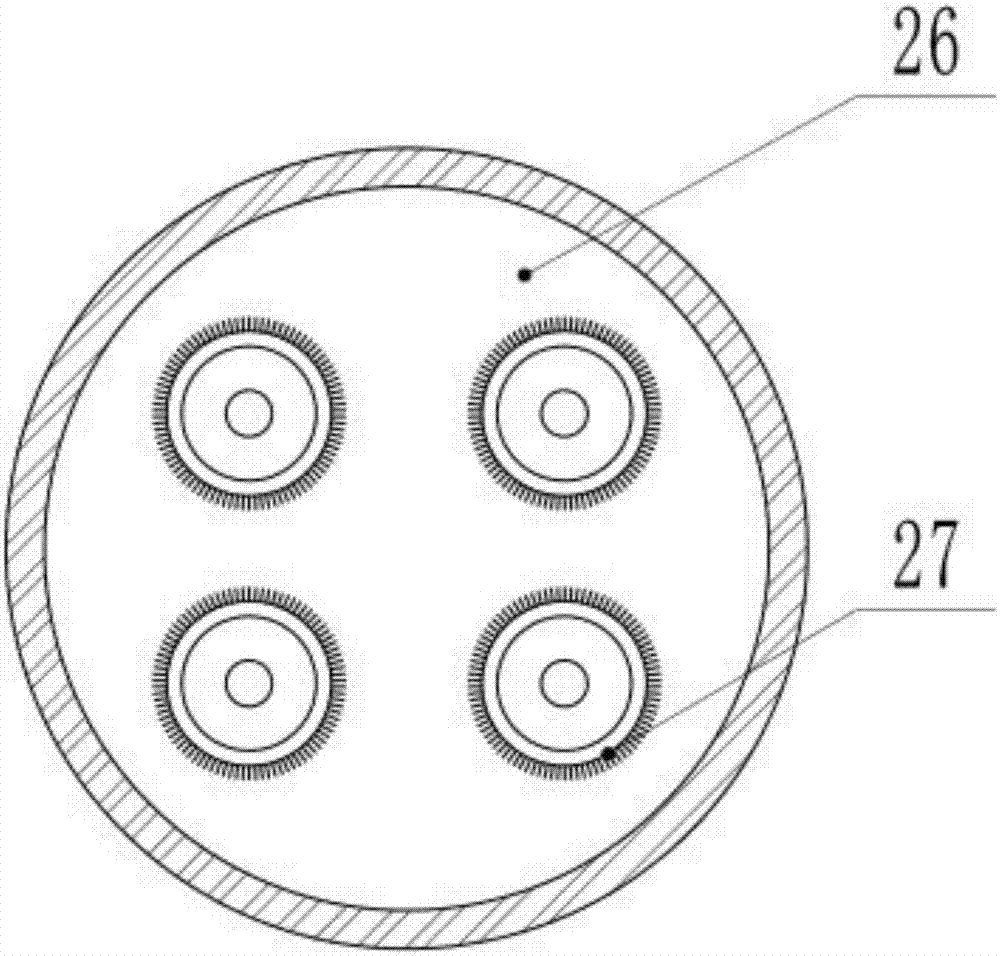

[0021] see Figure 1-3 , a device for cleaning burrs on the end surface of cast aluminum rotors of iron shell motors, including slideways 2, driving gears 5, toothed belts 6, driven gears 7, driving motors A8, screw rods 13, driving motors B15, lifting platforms 16, high-voltage suction The fan 19, the round wheel 26 and the grinding head 27, the upper surface of the base 1 is fixed with a slideway 2 by screws, the outer surface of the slideway 2 is provided with a chute 3, and several groups of slideways are installed on the chute 3. Block 4, the upper surface of the slider 4 has a rotor placement groove, the rotor placement groove is a circular groove, and the depth of the circular groove is 30-35mm, the inside of the base 1 is a hollow structure, and the inside of the base 1 is fixedly installed with a drive The motor A8 and the output shaft of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com