Table board clearing equipment for flowing type prefabricated part mould tables

A technology for prefabricated components and cleaning equipment, applied in auxiliary molding equipment, molds, manufacturing tools, etc., can solve the problems of waste of labor, uneven fixing of production molds, affecting production progress, etc., to achieve convenient disassembly and replacement, save maintenance time, Improve the efficiency of cleaning work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The descriptions of "left" and "right" in the present invention are all based on figure 1 For the reference direction:

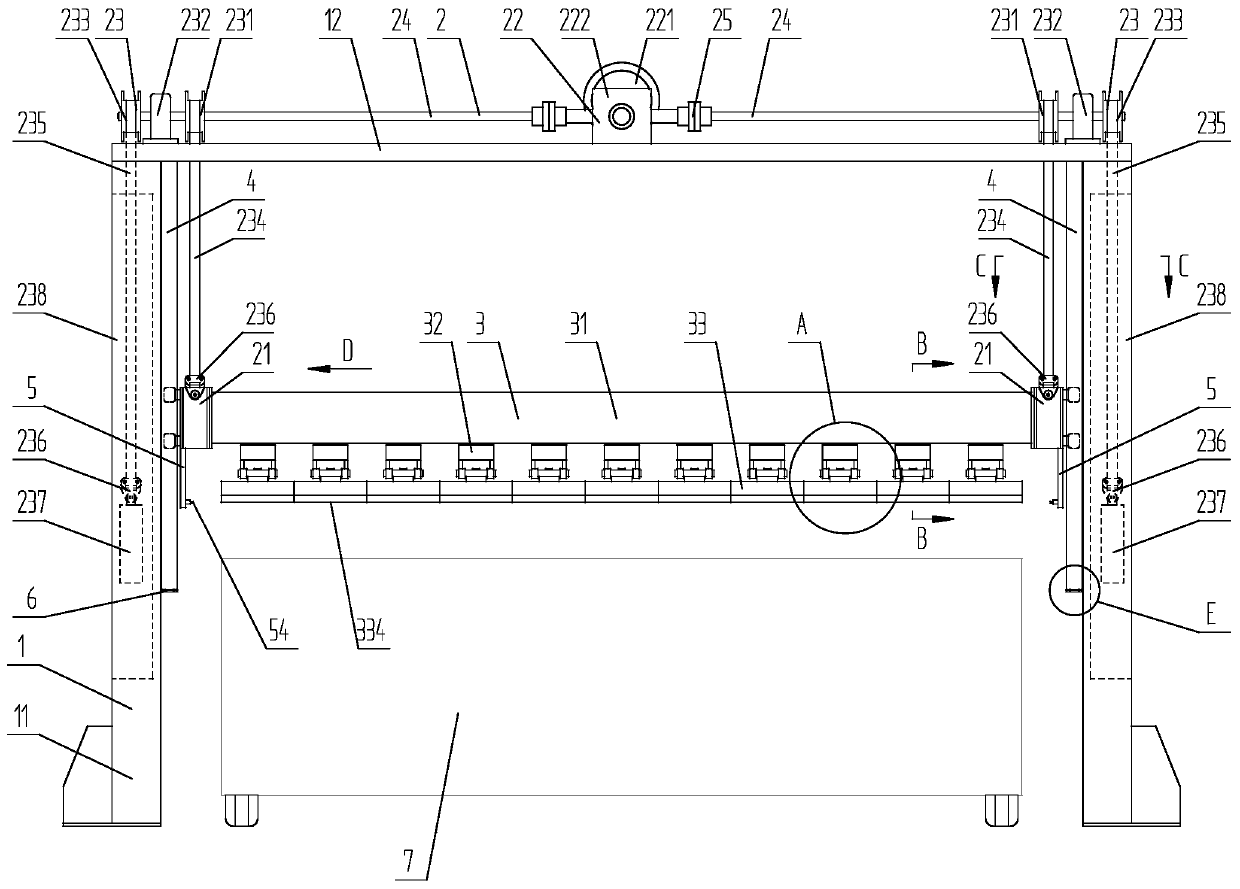

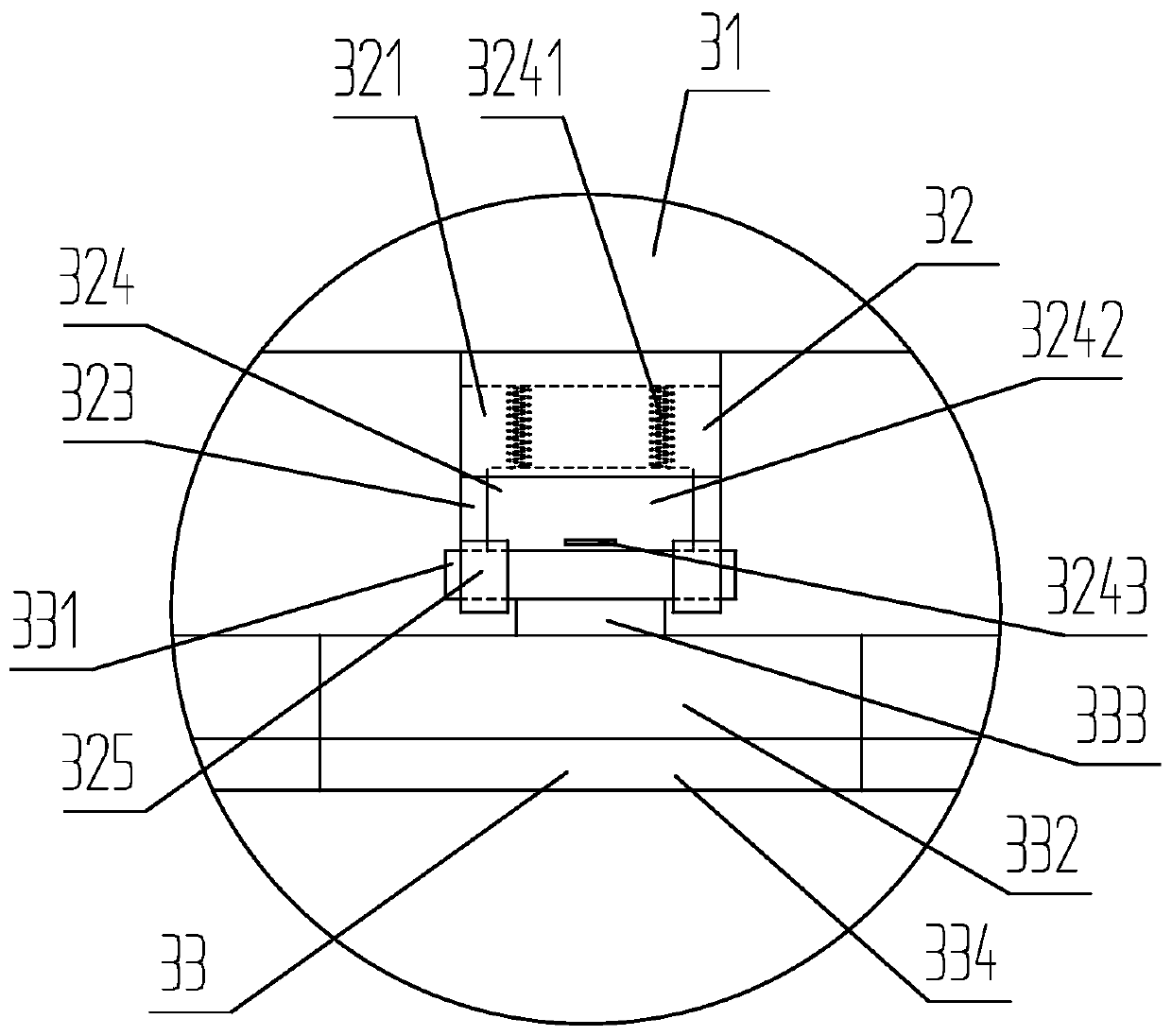

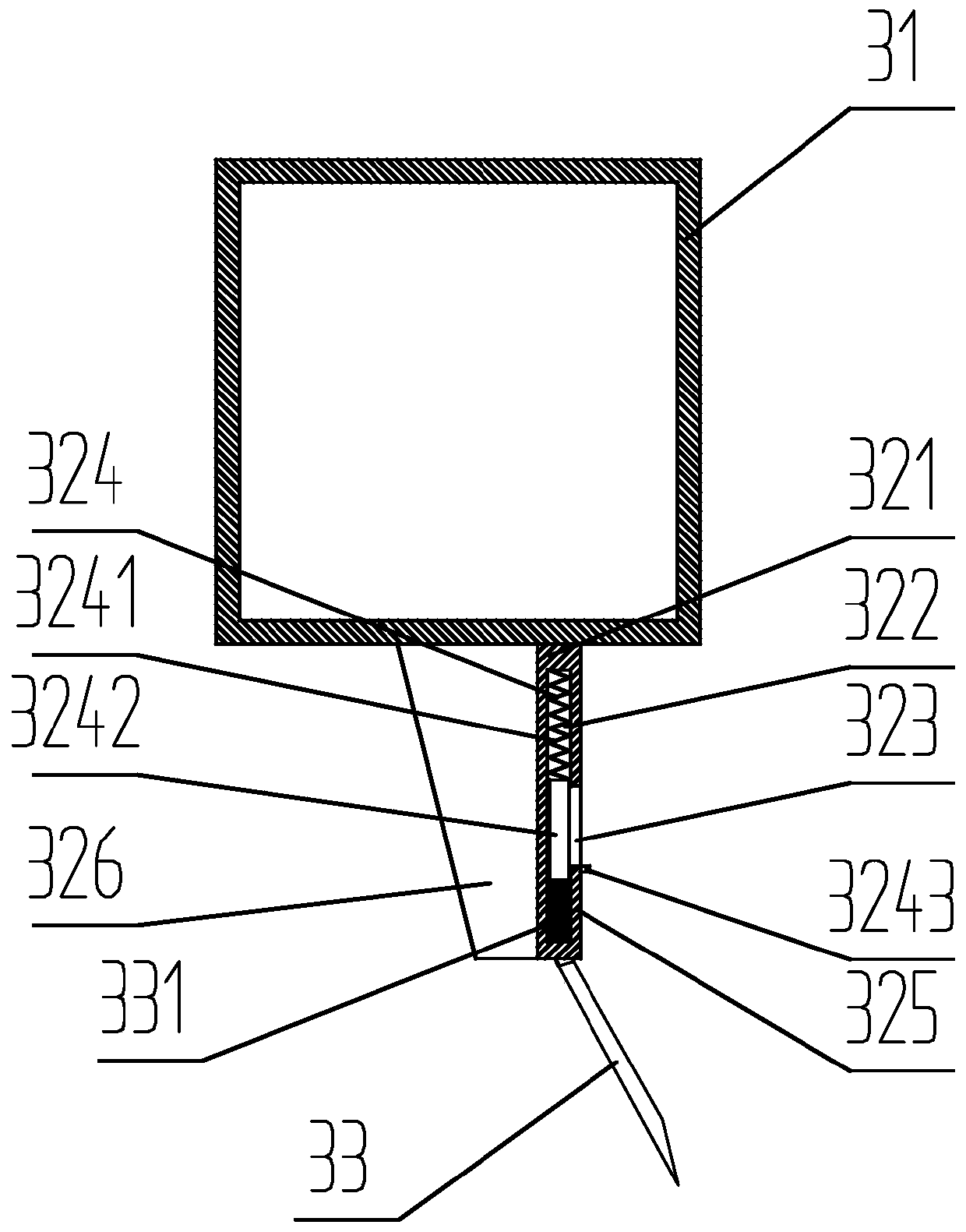

[0023] like Figure 1 to Figure 8 As shown, a table cleaning equipment for a flow-type prefabricated component mold table includes a frame body 1, a lifting transmission device 2, and a tool holder assembly 3. The frame body 1 includes a column 11, a beam 12, two columns 11 and a The crossbeams 12 are overlapped to form a "gate"-shaped frame structure, and the prefabricated component formwork 7 can move through the "gate"-shaped frame structure, and the inner walls of the two columns 11 are welded and installed with trolley movable guide rails 4, and the upper ends of the trolley movable guide rails 4 are tightly closed. Leaning against the lower end surface of the crossbeam 12, the lower end of the trolley movable guide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com