Integrated device for conveying gas and stirring materials, and bioreactor comprising same

A bioreactor and reactor technology, which is applied in gas production bioreactors, bioreactors/fermenters for specific purposes, bioreactor/fermenter combinations, etc., can solve difficult liquefaction, easy leakage, difficult storage and Transportation and other issues, to increase the contact reaction time, strengthen the biotransformation process, and achieve the effect of efficient and thorough transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

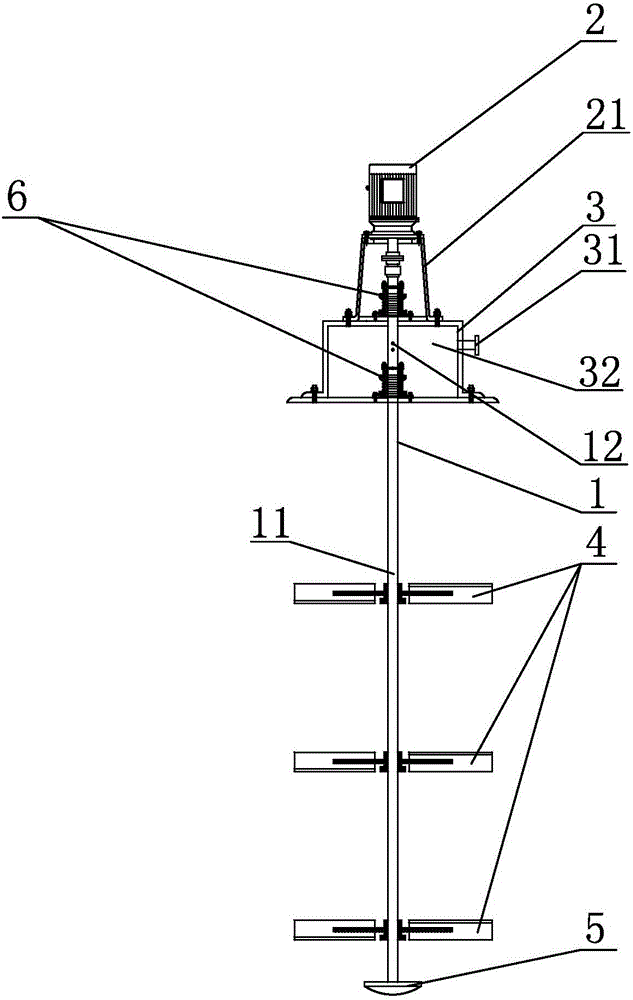

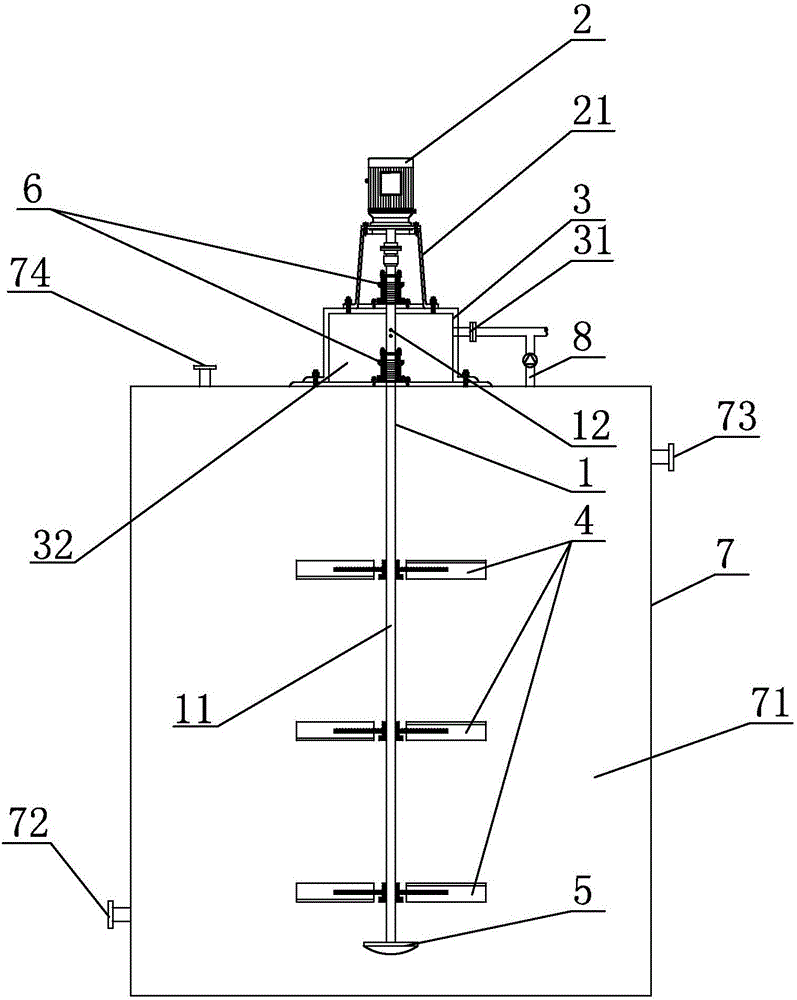

[0040] Such as figure 1 As shown, an integrated device for gas conveying and material stirring, the device includes a rotating stirring shaft 1 and a motor 2 for driving the rotating stirring shaft 1 to rotate; the motor 2 is fixed on the Above the buffer air intake chamber 3, and the main shaft of the motor 2 is connected to the rotating stirring shaft 1 through a coupling, and the axis of the main shaft of the motor 2 is the same axis as the rotating stirring shaft 1.

[0041] The rotary stirring shaft 1 is provided with a buffer air intake chamber 3 with an air inlet 31, the buffer air intake chamber is a box structure, the rotary stirring shaft 1 can rotate relative to the buffer air intake chamber 3, and the The joint between the rotating stirring shaft 1 and the buffer air intake chamber 3 is sealed by an oily graphite packing box 6 , and the oily graphite packing box 6 is arranged around the rotating stirring shaft 1 . Two oily graphite stuffing boxes 6 are provided in...

Embodiment 2

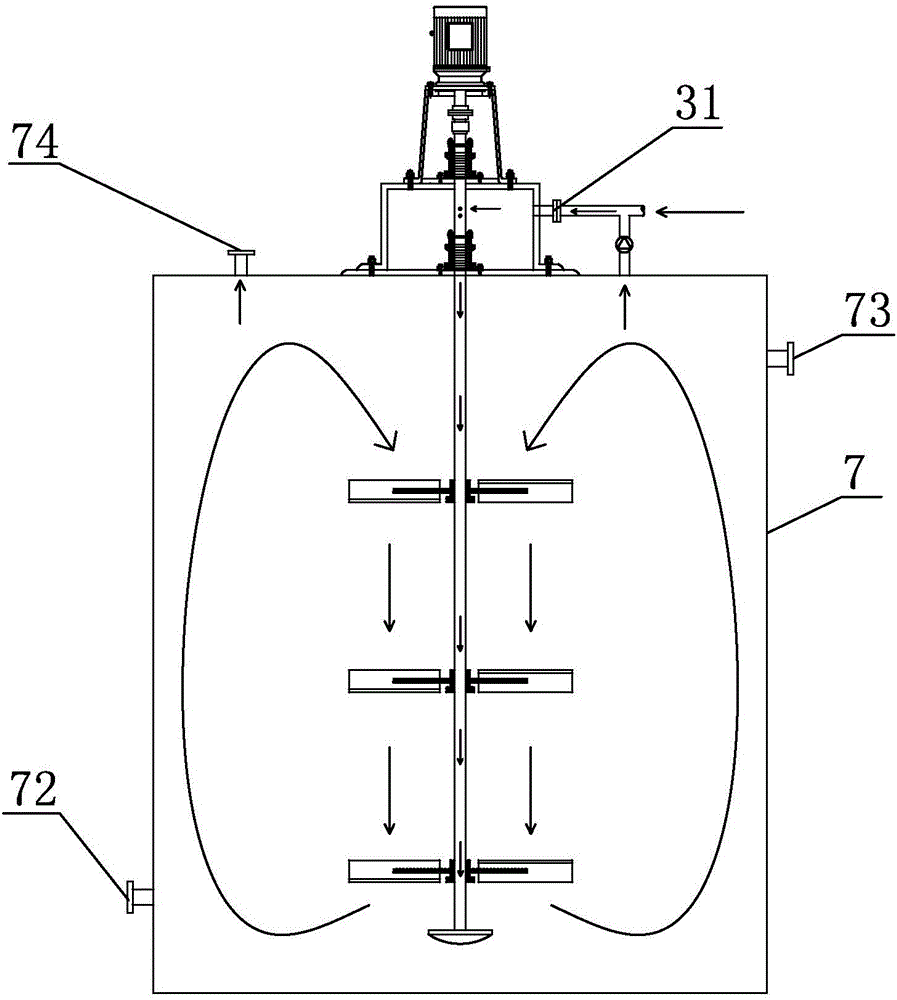

[0045] Such as figure 1 , 2 , 3, a bioreactor comprising the above-mentioned integrated device, the bioreactor comprises a reactor body 7 with an inner chamber 71, the reactor body 7 is provided with a feed inlet 72, a discharge Port 73 and gas outlet 74, wherein the feed inlet 72 is located at the bottom of the reactor main body 7, and the feed outlet 73 and gas outlet 74 are respectively located at the top of the reactor main body 7; The chamber 3 is arranged above the reactor main body 7 , and the stirring portion 11 of the rotating stirring shaft 1 is located in the inner cavity 71 of the reactor main body 7 .

[0046] The inner chamber 71 of the reactor main body 7 communicates with the inner chamber 32 of the buffer air inlet chamber 3 through the air inlet chamber provided in the rotating stirring shaft 1 . Through this setting, the gas in the buffer gas inlet chamber 3 can only enter the inner cavity 71 of the reactor main body 7 through the ventilation hole 12 provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com