Manual vacuum paint can and cup-free paint gun

A paint can and vacuum technology, applied in the field of paint cans, can solve problems such as environmental pollution, increased operator workload, and waste of water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

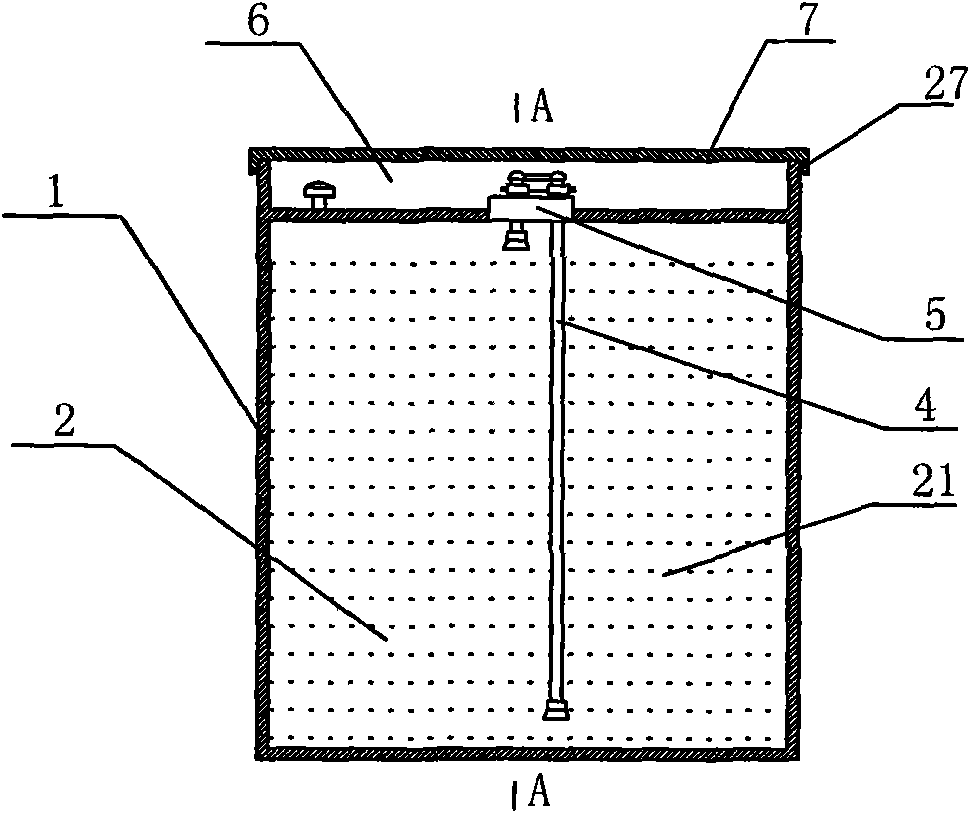

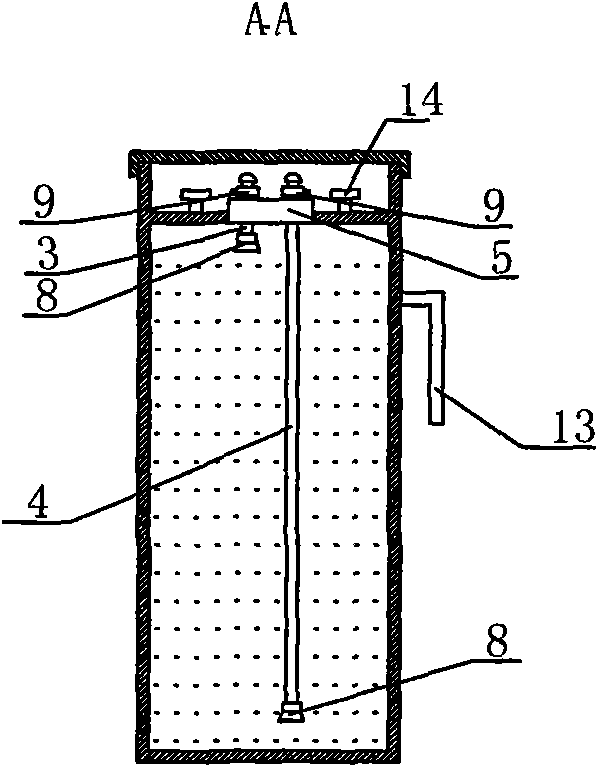

[0023] Such as Figure 1-Figure 3 As shown, the lower part of the tank body 1 of the manual vacuum paint tank has a paint storage chamber 2, and the paint storage chamber 2 is equipped with a paint 21. The upper part of the tank body 1 is a sealed chamber 6, and a top cover 7 is arranged above the sealed chamber 6, and the top cover 7 There is a sealing ring 27 between the tank body 1, which adopts snap-fit connection or threaded connection. A return air connecting pipe 3 and a paint delivery connecting pipe 4 are installed above the paint storage chamber 2, the lower end of the return air connecting pipe 3 communicates with the upper space of the paint storage room 2, and the upper end of the return air connecting pipe 3 protrudes into the sealed chamber 6; the paint delivery connecting pipe 4 The lower end stretches to the bottom of the paint storage chamber 2, and the upper end stretches into the sealed chamber 6. The lower end of the air return connection pipe 3 and the...

Embodiment 2

[0025] Such as Figure 4-Figure 6 As shown, the lower part of the tank body 1 of the manual vacuum paint tank has a paint storage chamber 2, the upper part of the tank body 1 is a sealed chamber 6, and the top cover 7 above the sealed chamber 6 is connected to the tank body 1 as a whole, and the top cover 7 has The downward protruding part 12 has a threaded opening in the protruding part 12. There is a threaded cap 10 at the threaded port. There is a sealing gasket 11 between the threaded cap 10 and the threaded port. There is a handle 15 and a clamping post 14 above the threaded cap 10. Other With embodiment 1.

Embodiment 3

[0027] Such as Figure 7 As shown, the top of the tank body 1 of the manual vacuum paint tank has a sealed chamber 6, and the bottom has a paint storage chamber 2 and a curing agent chamber 23, and the curing agent chamber 23 is separated from the paint storage chamber 2. The top of the curing agent chamber 23 has a filling port, and a manual vacuum 5 is installed at the filling port. The top of the curing agent chamber 23 is provided with a second return air connecting pipe 26 and a curing agent connecting pipe 24. The lower end of the curing agent connecting pipe 24 extends to the bottom of the curing agent chamber 23. The curing agent connecting pipe 24 communicates with the paint conveying pipe 4. A mixer 25 is provided. The lower end of the second air return connecting pipe 26 communicates with the upper space of the curing agent chamber 23 , and the upper end communicates with the air return pipe 16 . A control valve 9 is arranged on the connecting pipe 24 for curing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com