Production process for motor casing

A production process and casing technology, which is applied in the field of production technology of motor casings, can solve problems such as inability to ensure full utilization of materials, inability to guarantee molding effect, and increase recycling steps, and achieve convenient processing steps, good casting performance and resistance to resistance. corrosion resistance, the effect of not easy to cast cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

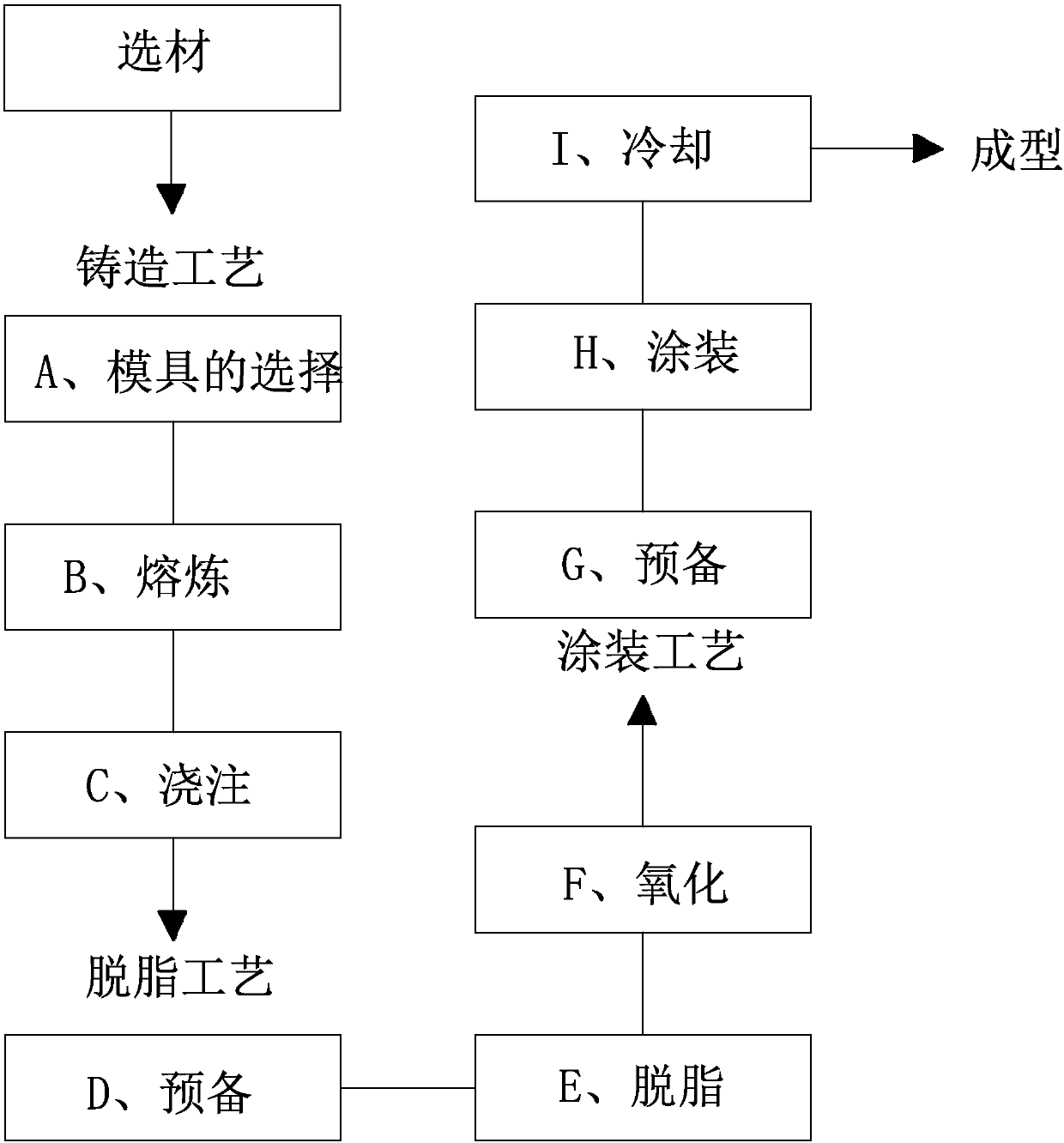

[0030] A production process of a motor casing, including the following steps: (1) Material selection: A356-T6 aluminum material is selected, the components of the aluminum material and the contents of each component are: Si6.5-7.5, Mg0.3-0.45, Fe< 0.12, Cu<0.1, Zn<0.05, Mn<0.05, Ti<0.2;

[0031] (2) Casting process: A. Mold selection: select the mold according to the structure of the required casting, and design the mold into a 6-opening structure. In addition to the upper and lower mold openings, the peripheral 4 molds are opened, and the core-pulling on the low-pressure casting machine is adopted. cylinder;

[0032] B. Smelting: Melt the aluminum material to about 800-850°C, refine the aluminum alloy through GBF treatment, degas and remove slag, and let it stand for 10 minutes, then transfer the refined and degassed aluminum liquid to the low-pressure casting machine Protect the furnace and control the molten aluminum to be poured between 690°C and 700°C;

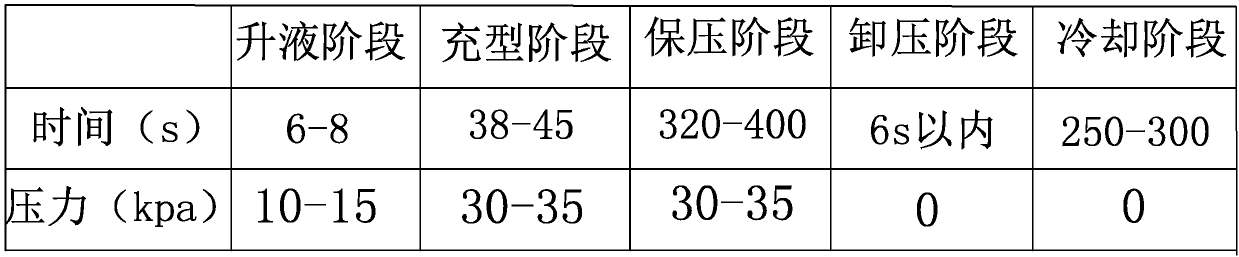

[0033] C. Pouri...

Embodiment 2

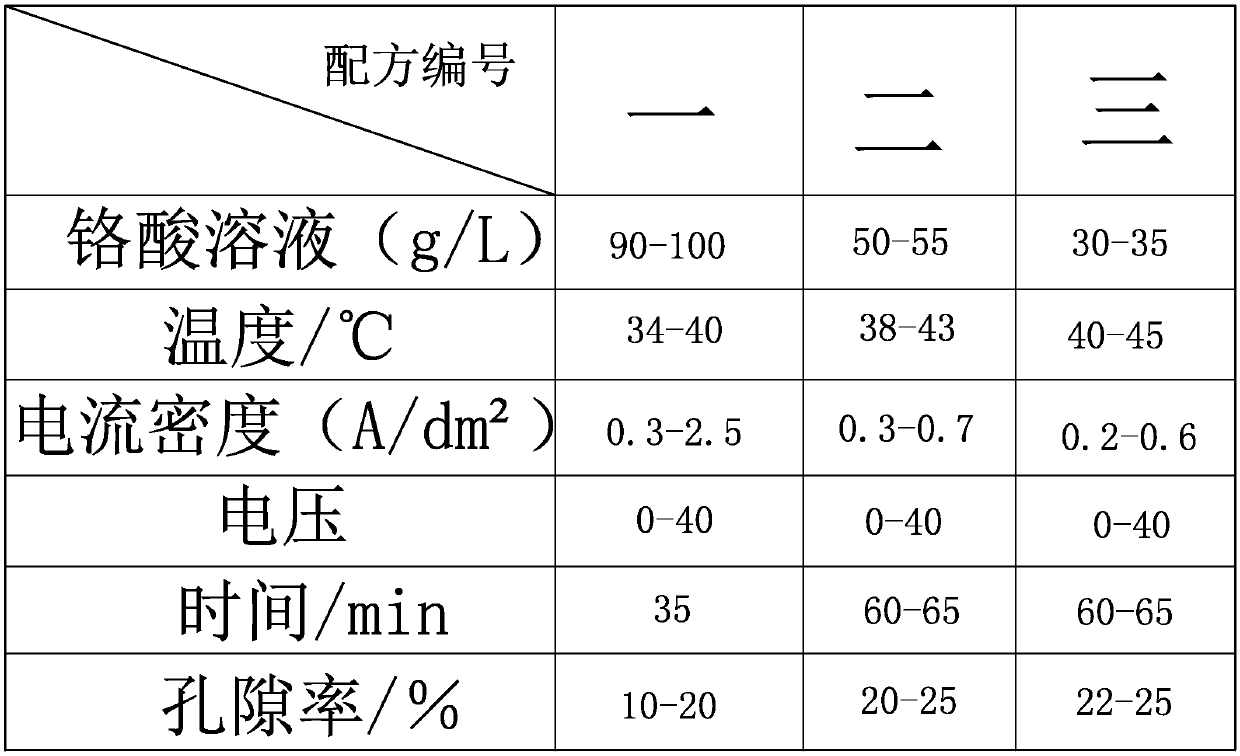

[0042] The operation steps of this embodiment are basically the same as that of Example 1, the only difference is that the concentration of chromic acid in step F in step (1) degreasing process is 50g / L-55g / L, and the temperature is controlled at 38°C-43 Between ℃, the current density is controlled between 0.3A / dm²-0.7A / dm², the voltage is controlled between 0-40V, and the oxidation time is 60min-65min, so that an oxide film is formed on the surface of the molded casting.

Embodiment 3

[0044] The operating steps of this embodiment are basically the same as in Example 1, the only difference is that the concentration of chromic acid in step F in step (1) degreasing process is 30g / L-35g / L, and the temperature is controlled at 40°C-45 Between ℃, the current density is controlled between 0.2A / dm²-0.6A / dm², the voltage is controlled between 0-40V, and the oxidation time is 60min-65min, so that an oxide film is formed on the surface of the molded casting.

[0045] The present invention is further set as, after step F, the molded casting obtained in step F is immersed in 20g / L CrO 3 Solution, passivation treatment at room temperature for 5-15s, and then drying at a temperature lower than 50°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com