Spraying device in production system of hub bearing

A production system, wheel bearing technology, applied in the direction of spraying device, etc., can solve the problems of high labor cost, uneven spraying, manual manual spraying, etc., and achieve the effect of enhanced spraying effect and uniform spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

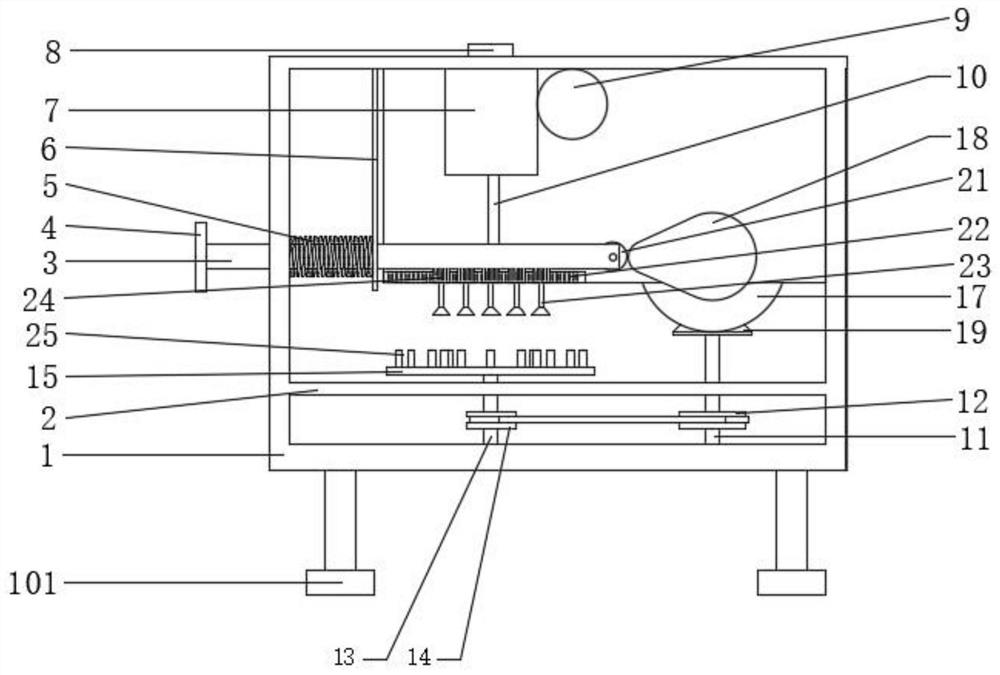

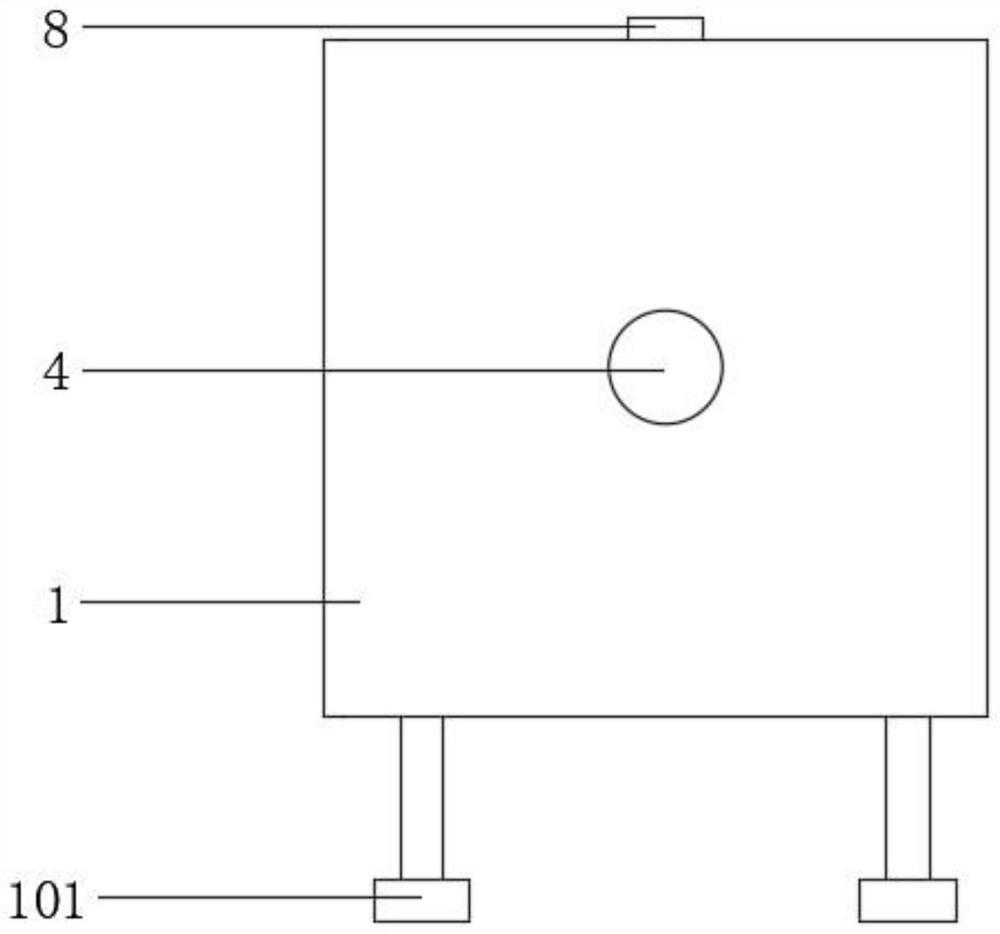

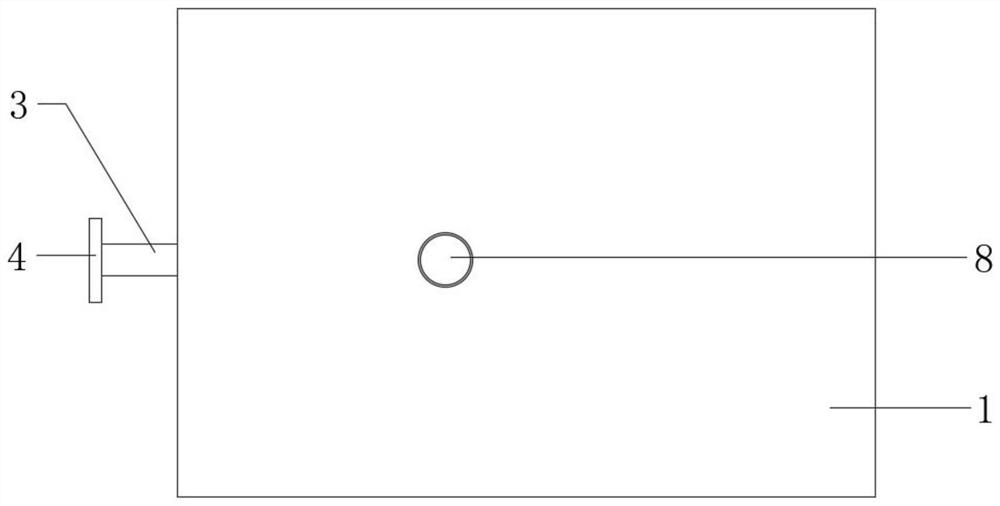

Embodiment 1

[0035] refer to Figure 1-11 , the spraying device in the production system of the hub bearing comprises a box body 1, the inner wall of the box body 1 is fixedly connected with a motor 16, the output end of the motor 16 is fixedly connected with a first bevel gear 17 and a cam 18, and the inner wall of the box body 1 is rotatably connected with a second A rotating shaft 11, the outer wall of the first rotating shaft 11 is fixedly connected with the first pulley 12 and the second bevel gear 19, the inner wall of the box body 1 is rotatably connected with the second rotating shaft 13, and the outer wall of the second rotating shaft 13 is fixedly connected with the second pulley 14 and The discharge tray 15, the inner wall of the box body 1 is fixedly connected with a stabilizing plate 6, the box body 1 is slidably connected with a slide bar 3, the outer wall of the slide bar 3 is rotatably connected with a nozzle 23, and the slide bar 3 is rotatably connected with a roller 21, a...

Embodiment 2

[0039] refer to Figure 1-11 , the spraying device in the production system of the hub bearing is basically the same as that of Embodiment 1, furthermore, the first bevel gear 17 is meshed with the second bevel gear 19, and the first bevel gear 17 transmits power to the second bevel gear 19.

[0040] A through groove is dug on the box body 1 and the stabilizing plate 6, and the slide bar 3 is slidably connected in the through groove, so that the slide bar 3 slides more smoothly.

[0041]There is a rotary groove inside the slide bar 3, and a rotating block is arranged on the spray head 23, which is rotatably connected in the rotary slot. .

[0042] Belts are sheathed on the first pulley 12 and the second pulley 14, so that the first pulley 12 can drive the second pulley 14 to rotate.

[0043] The top of the liquid storage tank 7 is provided with a liquid inlet 8, and the liquid inlet 8 is threadedly connected with a sealing cover to seal the liquid storage tank 7 and prevent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com