Wall surface painting device

A technology of spraying device and drying device, which is applied in the direction of construction and building structure, and can solve problems such as easy generation of falling dust, impact on working environment, threat to human life and safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

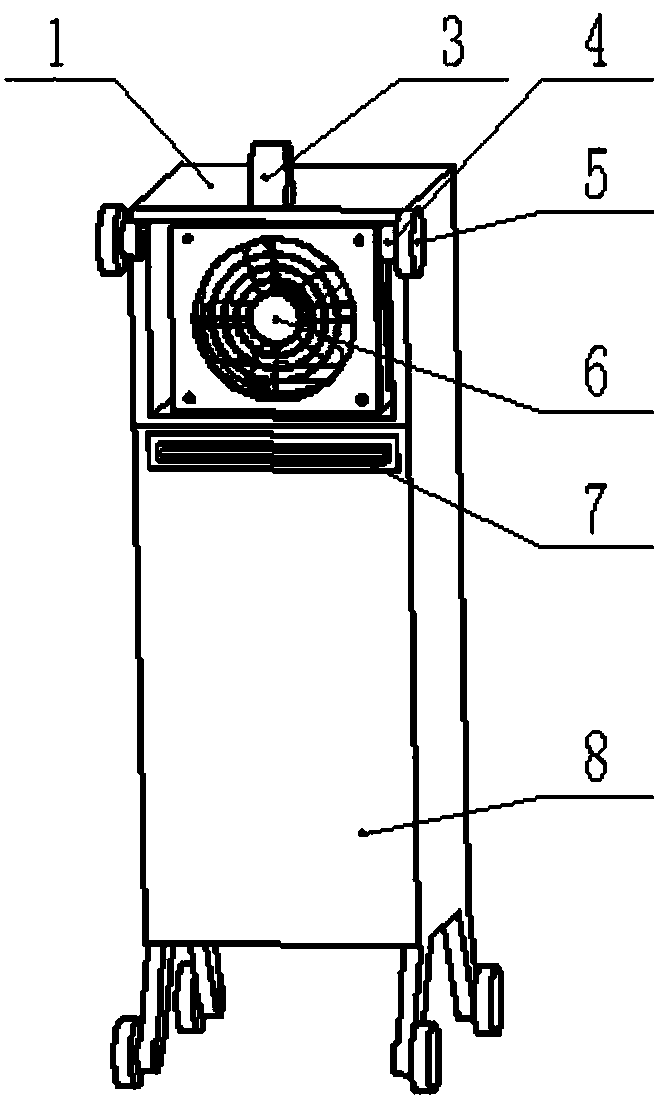

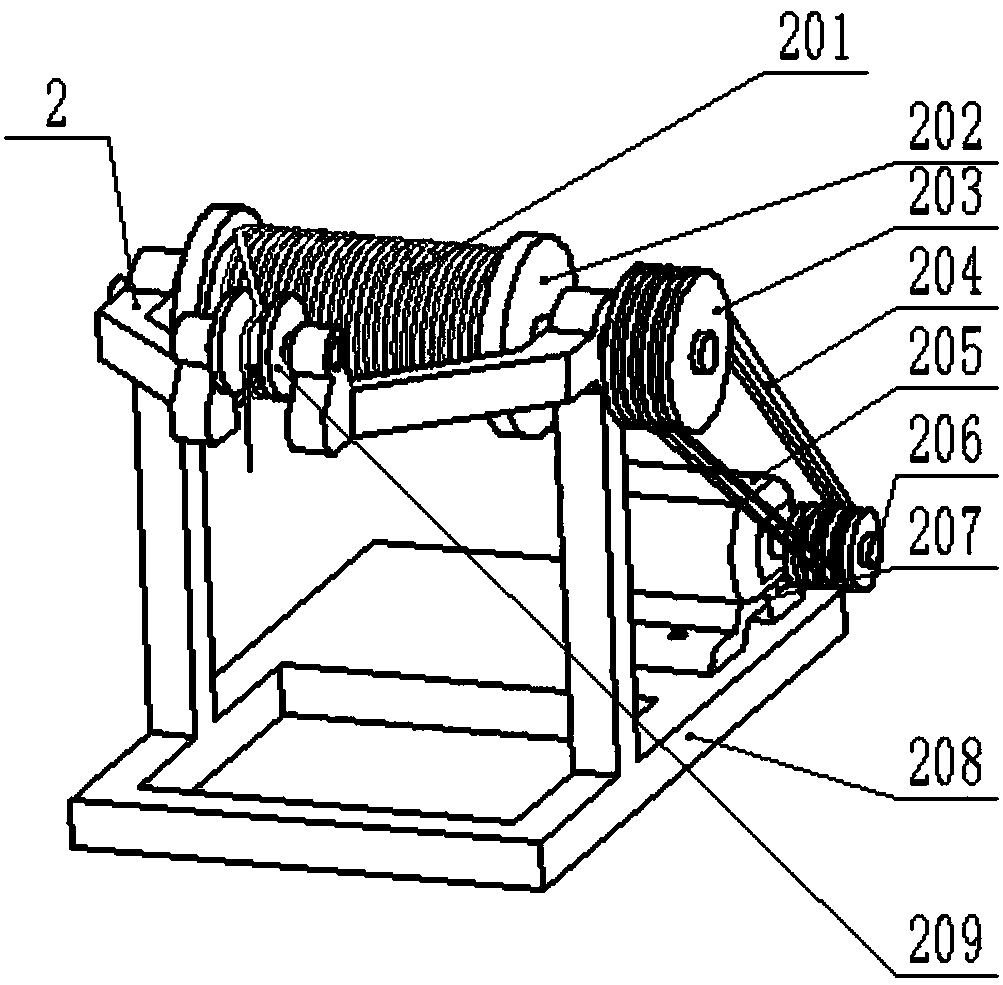

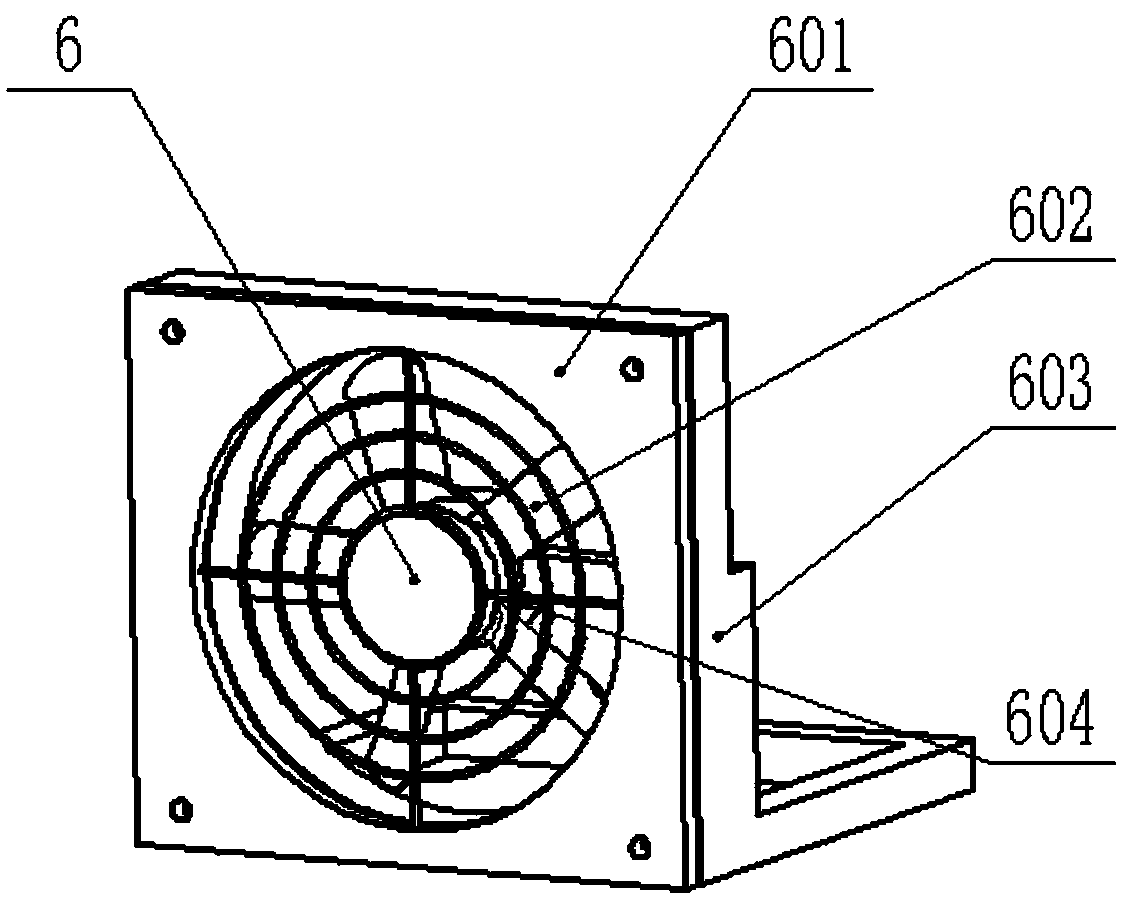

[0009] A wall surface spraying device is composed of a rope winding device 2, a drying device 6, a spraying device 7 and a casing 1. The casing 1 has a lifting lug 3, a support rod 4 structure, a support rod 4 and a wheel 5 The upper part inside the shell 1 is a drying device 6, the lower part is a spraying device 7 and has a sliding door 8, and there is a rectangular notch on the sliding door 8. The rope winding device 2 is composed of a rope 201 , drum 202, large pulley 203, belt 204, motor A205, small pulley 206, motor support 207, base 208 and fixed pulley 209, one end of rope 201 is fixed on drum 202, and the other end is fixed on shell 1 The fixed pulley 209 passes through the middle, and the two ends of the drum 202 have rotating shafts. The lengths of the rotating shafts at both ends are different, and they are all matched with the base 208 through tapered roller bearings. The longer end of the rotating shaft has a There is a keyway, which is matched with the large pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com