Spray manipulator device

A technology of manipulators and robotic arms, applied in the direction of spraying devices, etc., can solve problems such as large manual labor, insufficient product uniformity, and affecting product quality, and achieve the effects of reducing occupied area, fast speed, and uniform spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

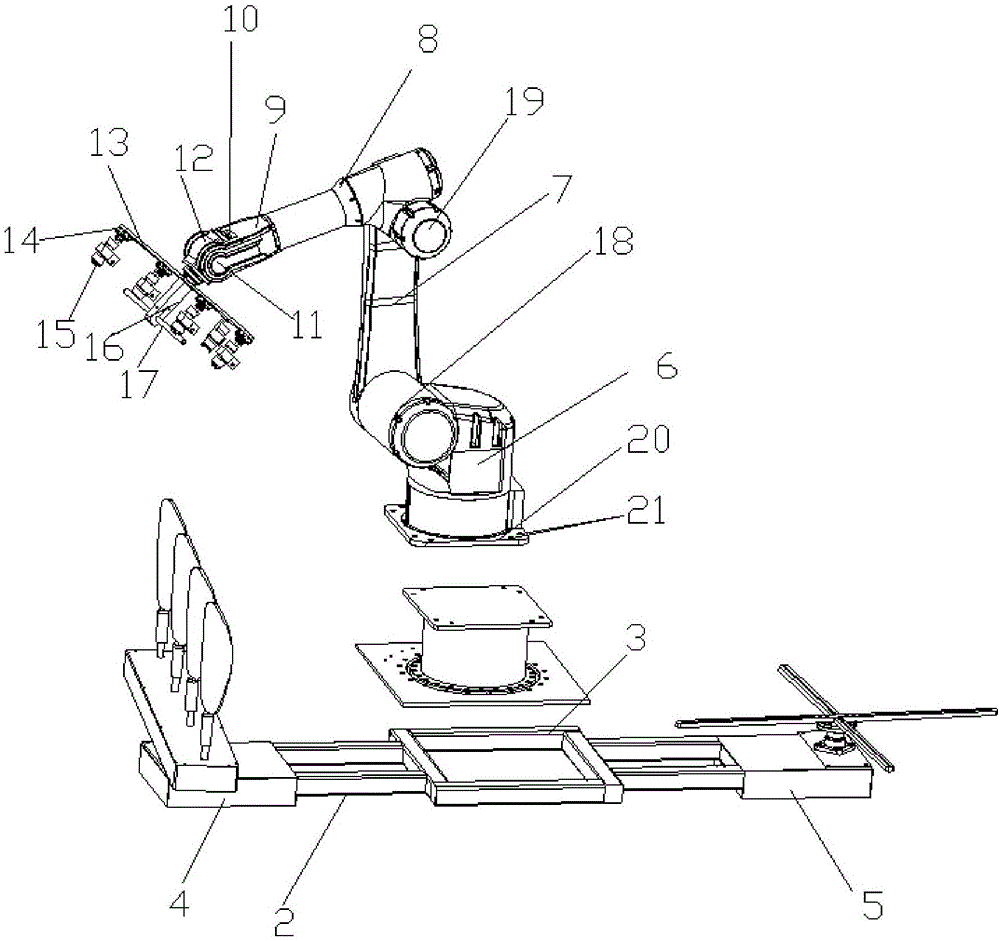

[0019] The present invention will be further described below according to the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

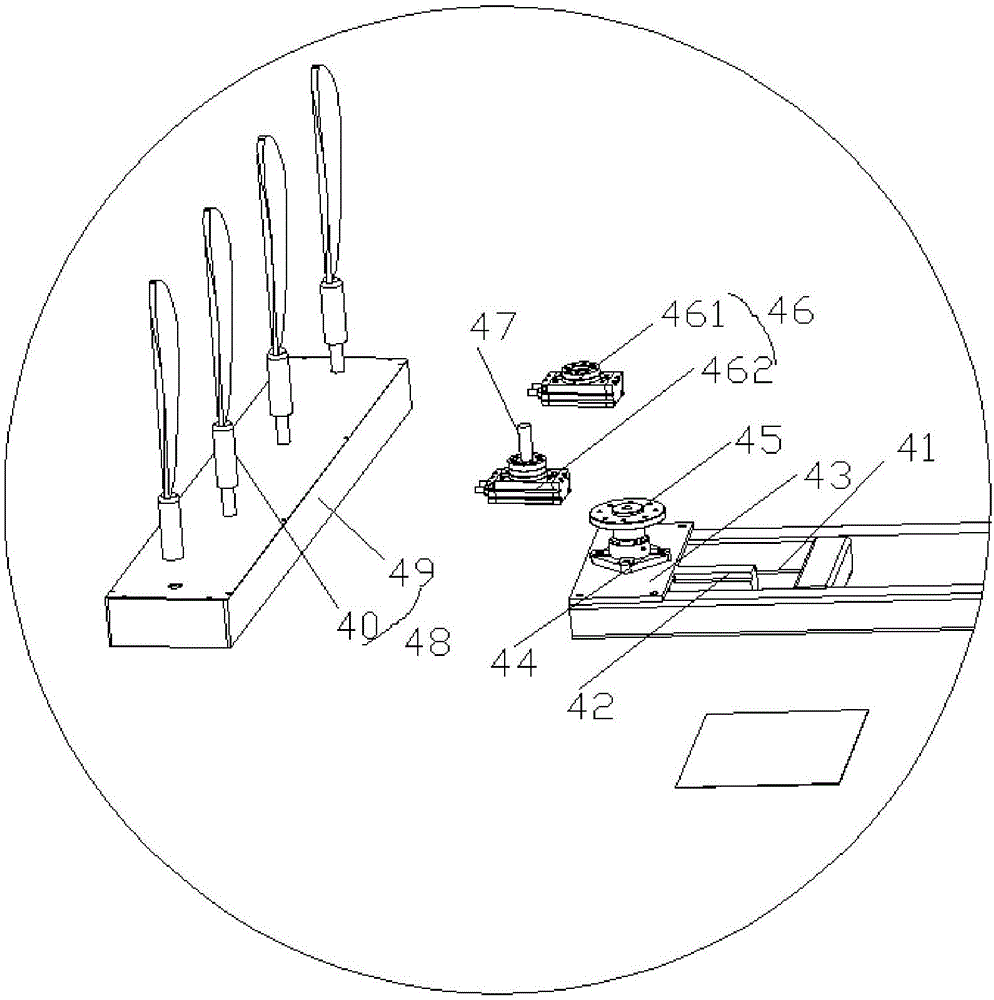

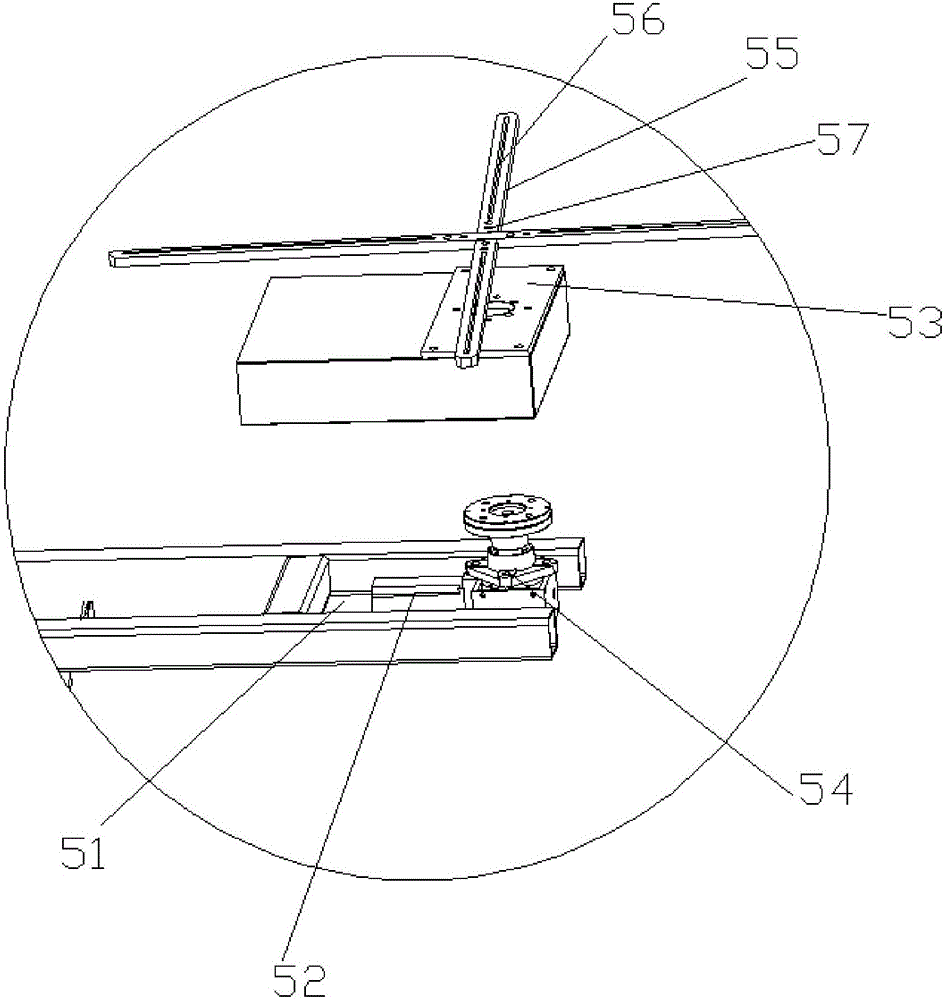

[0020] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a spraying manipulator device includes a horizontal support platform 2 and a manipulator device 1, a central frame 3 is provided in the middle of the horizontal support platform 2, and a product fixing steering device 4 for fixing upright products is provided at one end of the horizontal support platform 2 , the other end of the horizontal support table 2 is provided with a horizontally placed product fixing steering device 5 for fixing horizontally placed products, and a terminal mechanical arm 9 is provided at the end of the manipulator device 1, and a U-shaped notch is provided at the end of the terminal mechanical arm 9 10. The two side arms of the U-shaped notch 10 are respectively equipped with a transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com