Jet-driven rotary type spraying head

A spray head and rotary technology, which is applied in the field of jet propelling rotary spray heads to achieve the effects of improved spray fire extinguishing ability, good fire extinguishing effect and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

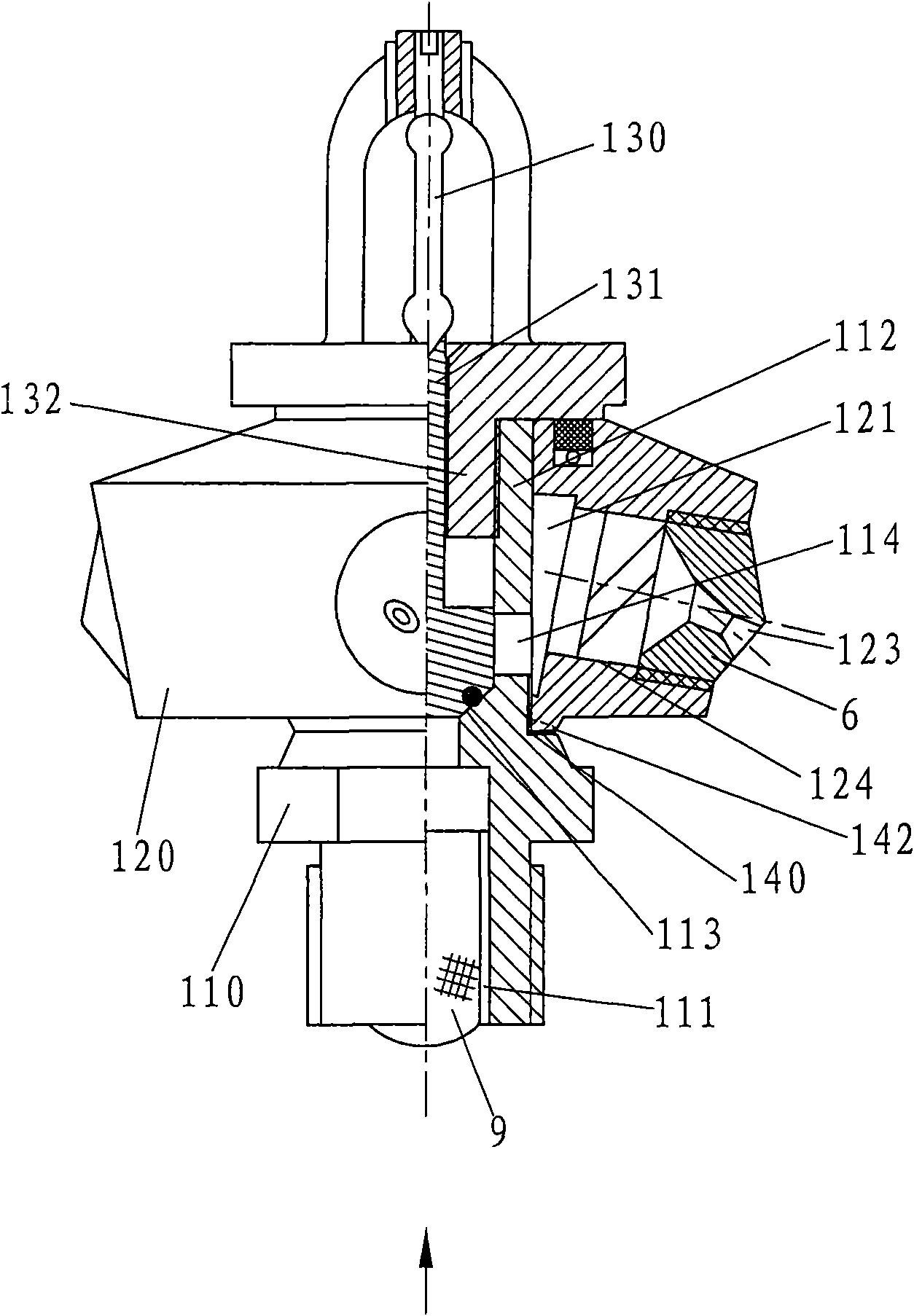

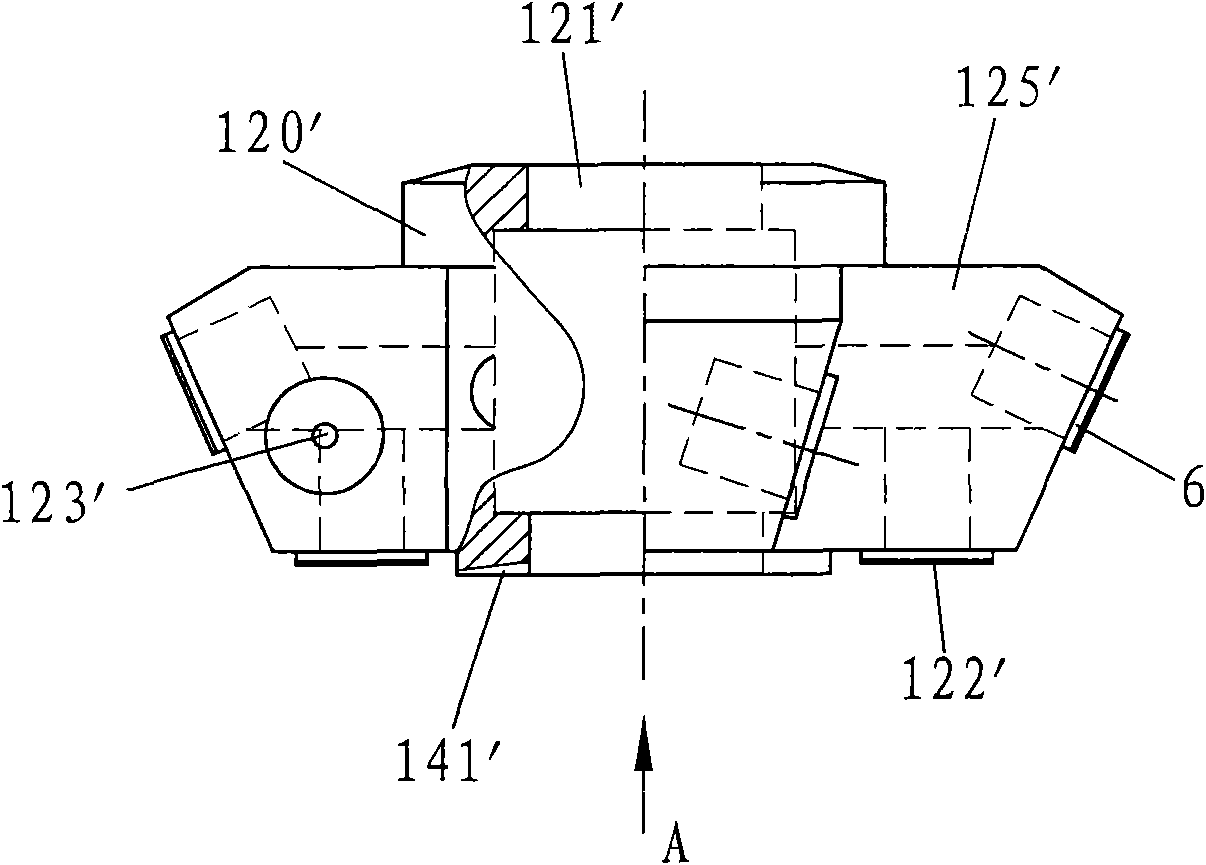

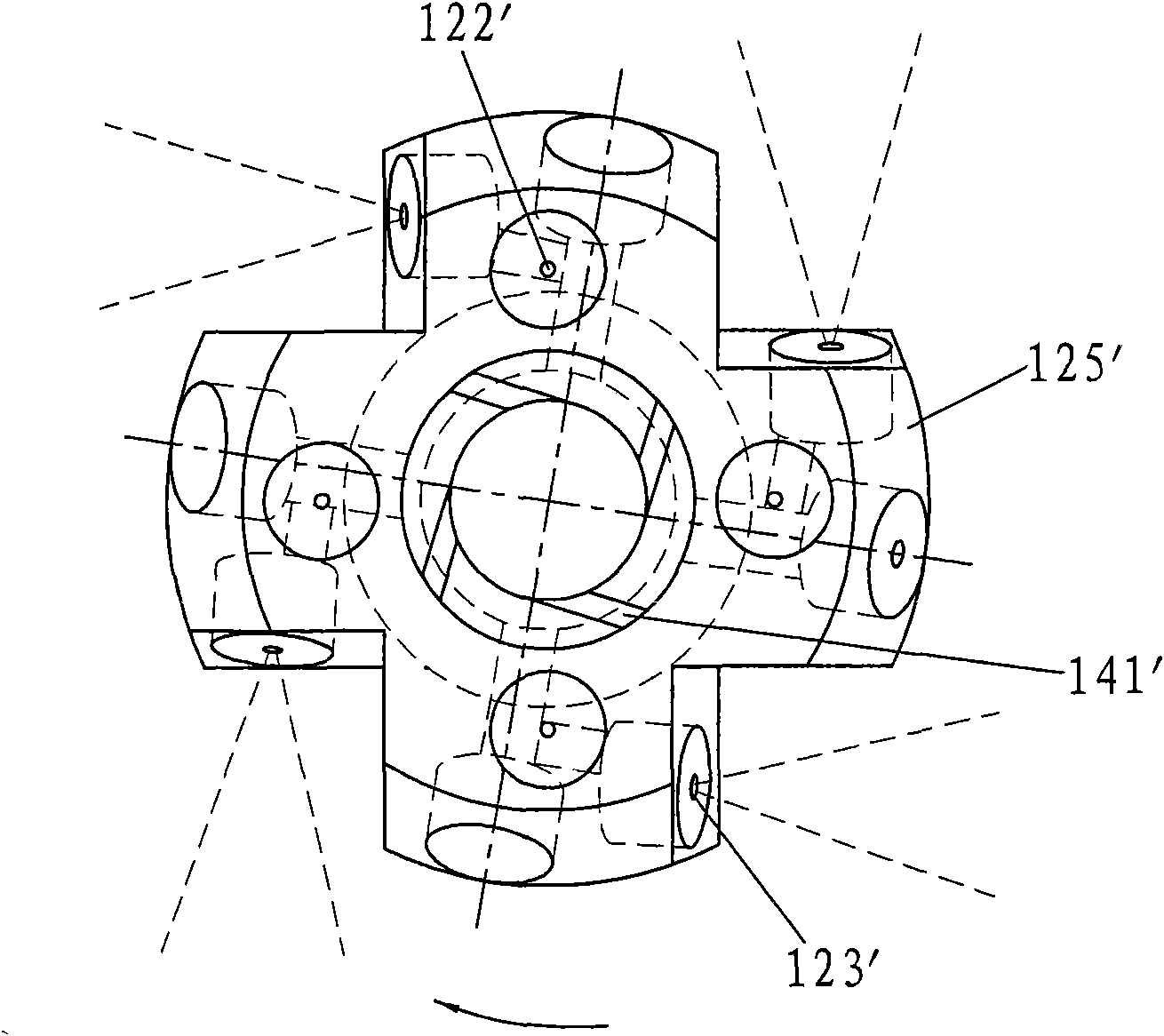

[0035] Embodiment 1: as figure 1 , Picture 1-1 and Figure 1-2 .

[0036] The jet push rotary spray head described in this embodiment is a spray push rotary closed spray head with a sleeve type spray head body, which mainly includes a seat body 110 and a spray head body 120 (such as figure 1 shown). in:

[0037] The interior of the seat body 110 is hollow, and one end thereof is an inlet 111. A filter 9 is arranged inside the inlet port 111. A screw thread is provided outside the inlet port 111 to connect with an input flow pipe (not shown in the figure). The seat body 110 is also provided with The hollow shaft 112 is provided with a through hole 114 on the wall of the hollow shaft 112 .

[0038] The nozzle body 120 is a rotary shape, and its shape can be various. In this embodiment, the nozzle body 120 is a truncated polyhedral cone with a central through hole, which is rotatably sleeved on the hollow shaft 112 of the seat body 110. The inside of the nozzle body 120 is...

Embodiment 2

[0047] Embodiment 2: as figure 2 , Figure 2-1 and Figure 2-2 shown.

[0048] The spray-push rotary spray head described in this embodiment also includes a seat body 210 and a spray head body 220 . in:

[0049] The seat body 210 is hollow inside, and its outer wall is provided with thread to connect with the input flow pipe (not shown in the figure), and the inner hole 212 and the outlet of the seat body 210 are provided with upper and lower ring surfaces 215, 216.

[0050] The nozzle body 220 is provided with an inlet pipe 226 above and a composite square body 225 below. The inlet pipe 226 is rotatably sleeved in the inner hole 212 of the seat body 210 . The outer periphery of the inlet end of the nozzle body 220 inlet pipe 226 is provided with an upper circular step 227 and a collar 224, and the outer peripheral top ring of the nozzle exposed outside the inner hole 212 of the seat body 210 forms a lower circular step 228, and the upper and lower circular steps 227, 228...

Embodiment 3

[0053] Embodiment 3: as image 3 , Figure 3-1 , Figure 3-2 and Figure 3-3 shown.

[0054] The spray-push rotary spray head described in this embodiment also includes a seat body 310 and a spray head body 320 . in:

[0055] The interior of the seat body 310 is hollow, and one end thereof is an inlet 311. The filter 9 is arranged in the inlet 311. The inlet 311 is provided with a screw thread to be connected with an input flow pipe (not shown in the figure). The inner hole of the seat body 310 Two annular surfaces 315, 316 are arranged on the top and the exit of 312.

[0056]The nozzle body 320 is in the shape of a space generatrix revolution, and its inner cavity forms a fluid channel 321. The nozzle body 320 is composed of a separate inlet pipe 326, a nozzle body seat 3201 and a nozzle body body 3202. The inlet pipe 326 can be It is rotatably nested in the inner hole 312 of the seat body 310 for radial positioning, and the inlet pipe 326 is screwed on the top of the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com