Projection screen optical coating spraying equipment

A technology for spraying equipment and optical coatings, applied in the direction of spraying devices, etc., can solve the problems of low feed control accuracy, unstable spray gun operation, inaccurate control of equipment spraying feed speed, etc., to improve reliability and adjustment flexibility. , To ensure the appearance quality of the coating, the accurate and controllable effect of spraying feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

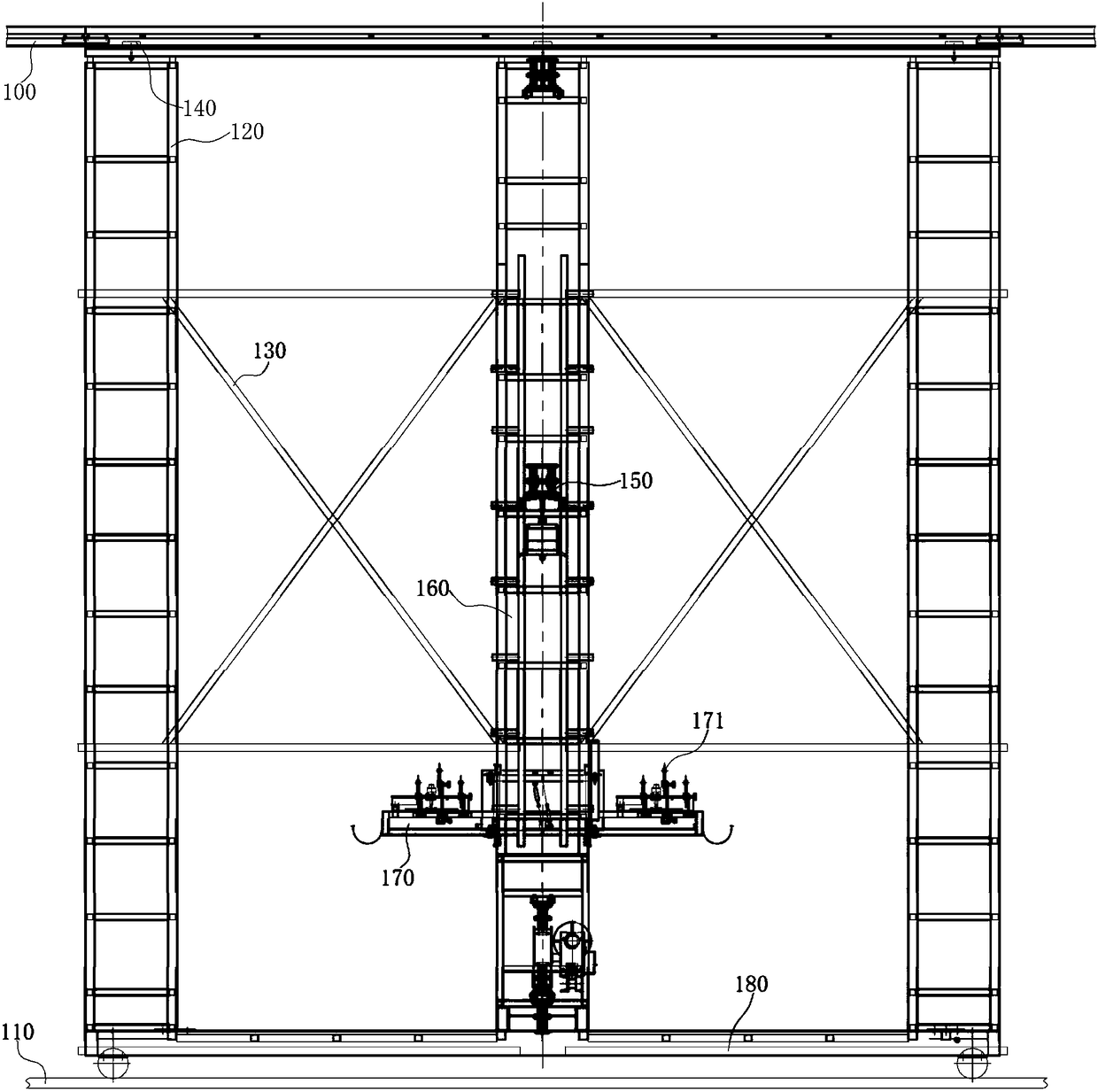

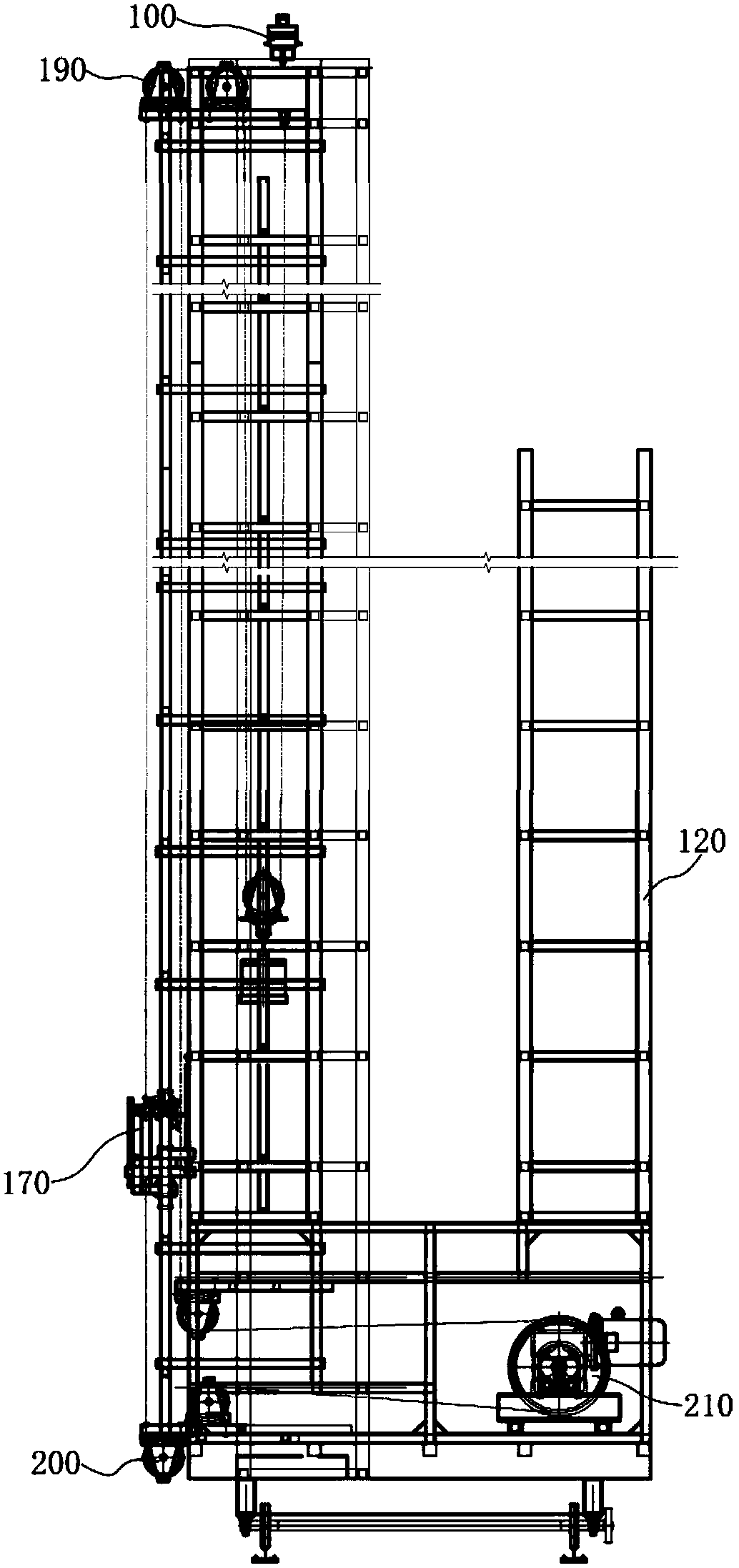

[0025] see figure 1 , figure 2 , a screen optical paint spraying equipment, including a spraying stand, the bottom of the spraying stand is perpendicular to the spraying displacement car 180 that moves smoothly left and right, and the tops of the three spraying stand sides arranged in a line are equipped with sky rails Guide wheel 140, the sky rail guide wheel 140 is embedded inside the sky rail 100, to pull the spraying stand and enhance its stability and anti-overturning performance, the rollers at the bottom of the spraying displacement vehicle 180 are installed on the ground rail that limits the movement direction of the spraying displacement vehicle 180 110, the three spraying stands arranged in a line on the surface of the spraying displ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com