Spraying device of liquid material thin film and spraying method thereof

A material film, spraying device technology, applied in the direction of photo-engraving process coating equipment, etc., can solve the problems of easy fatigue damage of materials, unable to meet industrial production, unable to meet the requirements of nozzle design life and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

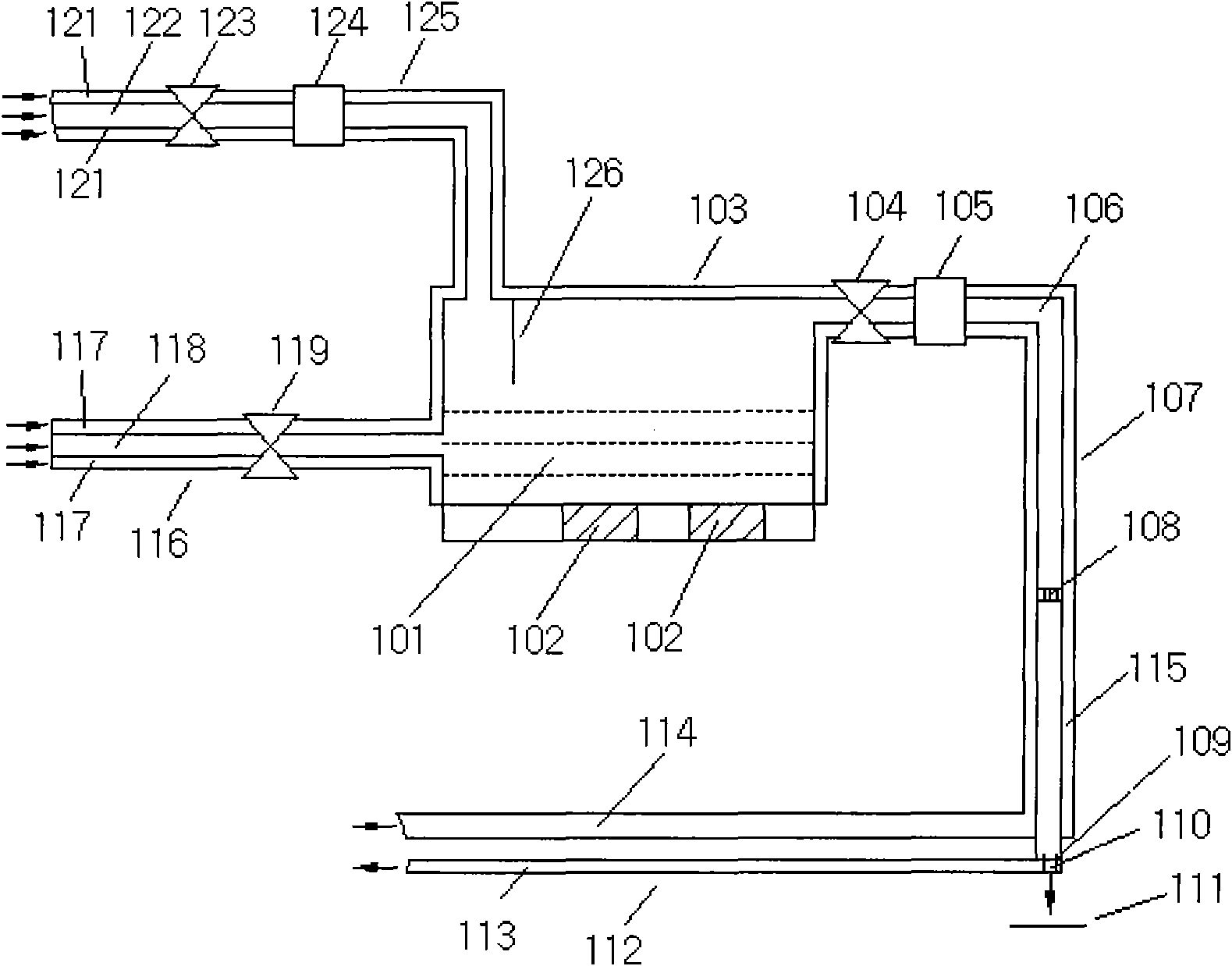

[0057] This embodiment specifically describes the spraying device and method for realizing photoresist film according to the technical solution of the present invention.

[0058] First of all, the spraying device for the photoresist film adopts a working form similar to that of an ultrasonic humidifier. The high-frequency mechanical oscillation generated by the ultrasonic oscillator is directly transmitted to the liquid surface through the liquid, and surface tension waves are formed on the liquid surface, which can be obtained For finer atomized particles, multiple such ultrasonic oscillators can be installed to obtain the required amount of ultrasonic atomization.

[0059] As shown in Figure 1, the spraying device includes:

[0060] The atomization container 103 is used to contain the photoresist solution 101 and provide an atomization space;

[0061] The ultrasonic vibrator is arranged at the bottom of the atomization container 103 and includes several ultrasonic oscillati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com