Paint spraying device for cutter base body of shield tunneling machine

A shield machine cutting tool and substrate technology, applied in spraying devices, electrostatic spraying devices, devices for coating liquid on the surface, etc., can solve problems such as unsatisfactory spraying effect, easy peeling of the paint layer, uneven spraying, etc., to achieve spraying The effect is good, the spraying effect is uniform, and the effect of reducing the probability of respraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

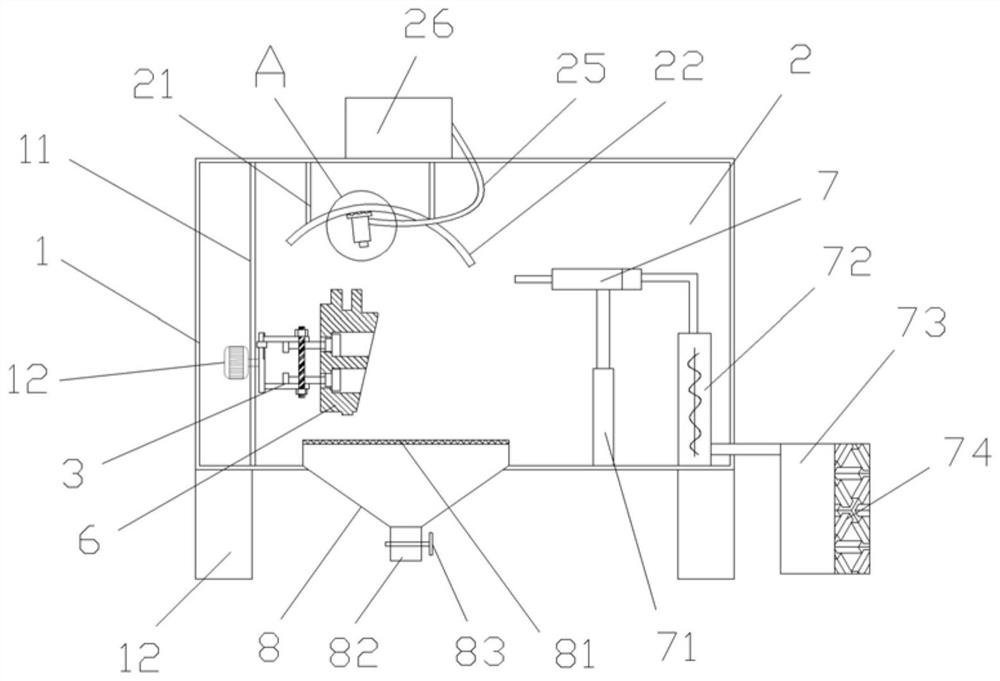

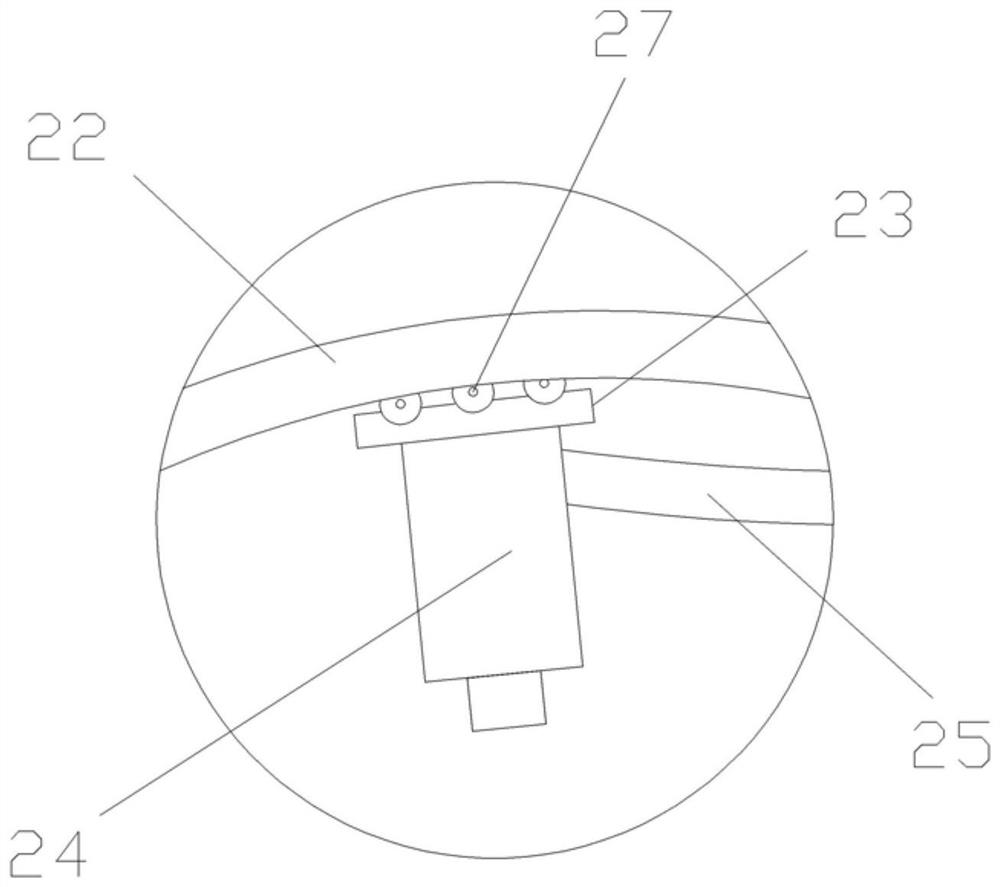

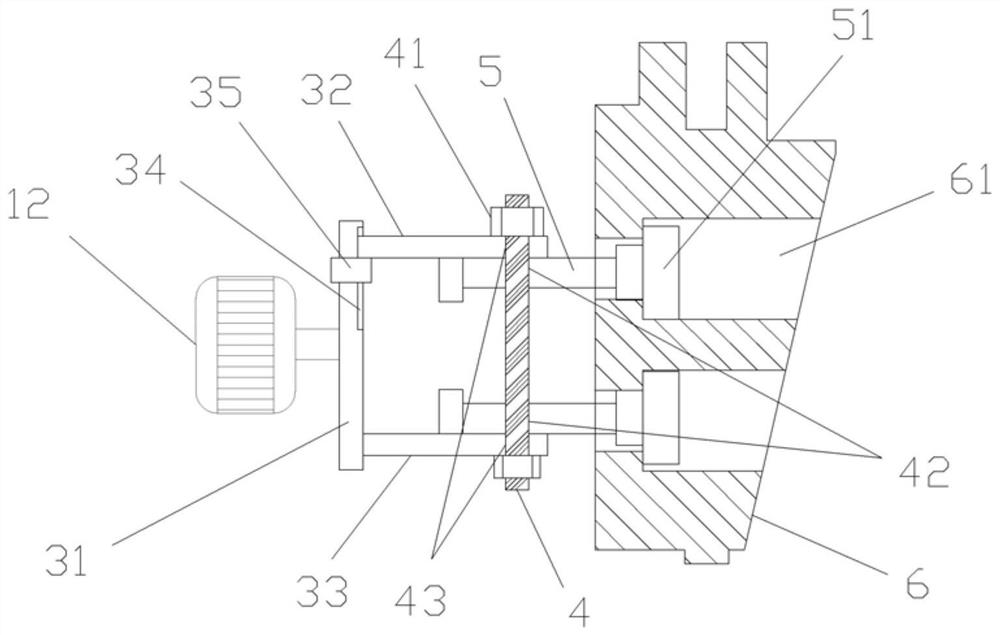

[0016] refer to figure 1 , figure 2 and image 3 , the present invention is a shield machine tool substrate painting device, comprising a box 1, the interior of the box 1 is provided with a spray booth 2, the left side of the spray booth 2 is provided with a partition 11, and on the partition 11 A fixing mechanism 3 is provided, on which a cutter base 6 is fixed, and a rotating motor 12 is provided on the left side of the partition 11, and the output end of the rotating motor 12 passes through the partition 11 and is connected to the The fixing mechanism 3 is connected, and the top of the spray booth 2 is fixed with an arc-shaped first slide rail 22 through a vertical bar 21, and a slide block 23 is slidably installed on the first slide rail 22, and the bottom of the slide block 23 An electrostatic spray head 24 is fixed, and the electrostatic spray head 24 is connected with an electrostatic spraying device 26 through a paint spraying pipe 25, and the electrostatic spraying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com