A water-stop curtain grouting production sewage recycling control system and method

A water-stop curtain and sewage production technology, which is applied in the field of water-stop curtain grouting production sewage recycling control system, can solve problems such as increased cost, delay in construction period, and hardening of cement slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

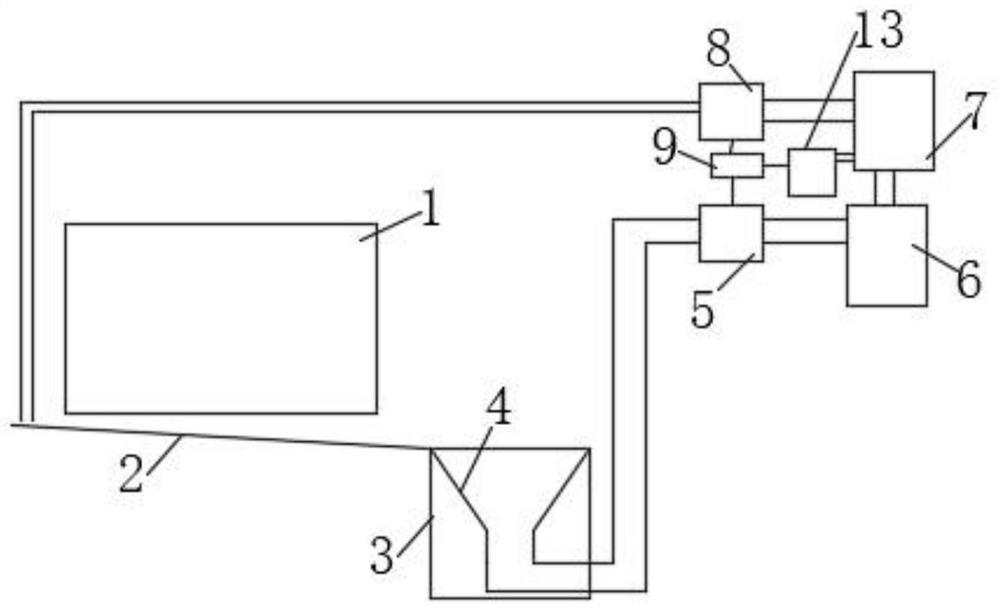

[0047] Such as Figure 1 to Figure 3 As shown, the water collection funnel 4 is arranged in the water collection well 3, and one end of the top of the water collection funnel 4 is connected to the drainage channel 2, and the bottom of the water collection funnel 4 is connected to the first water pump 5 through a pipeline, and the first water pump is connected to the sedimentation tank 6 through a pipeline, and the sedimentation tank 6 is connected to the water collecting tank 7 through pipelines, and the water collecting tank 7 is respectively connected to the clean water tank 13 and the second water pump 8 through pipelines, and the second water pump 8 is connected to the source of the drain 2 through pipelines.

[0048] In this embodiment, cement retarder is added in proportion to the water in the clean water tank 13 .

[0049] In this embodiment, the interior of the settling tank 6 is evenly sprayed with low-temperature waterproof paint. When the low-temperature waterproof ...

Embodiment 2

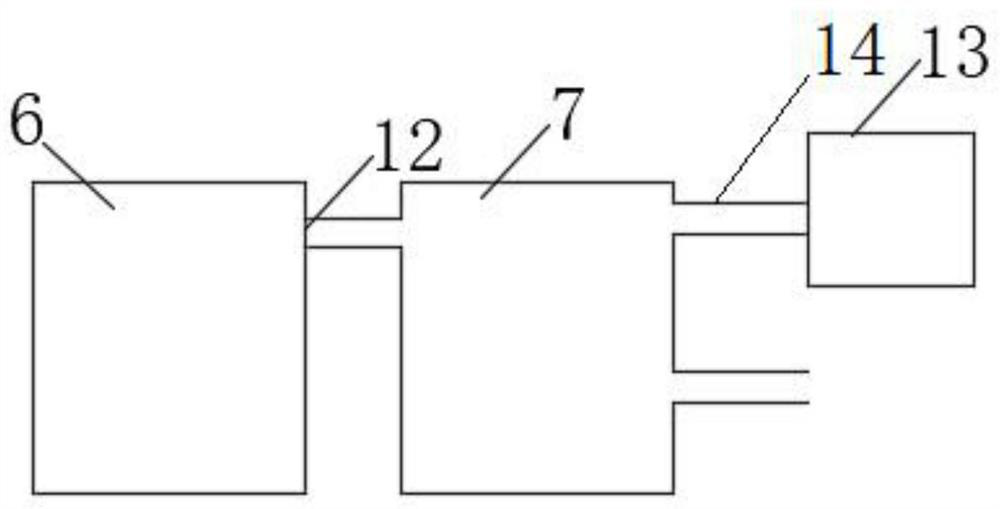

[0055] Such as Figure 4 As shown, the sewage recycling system for water-stop curtain grouting production includes:

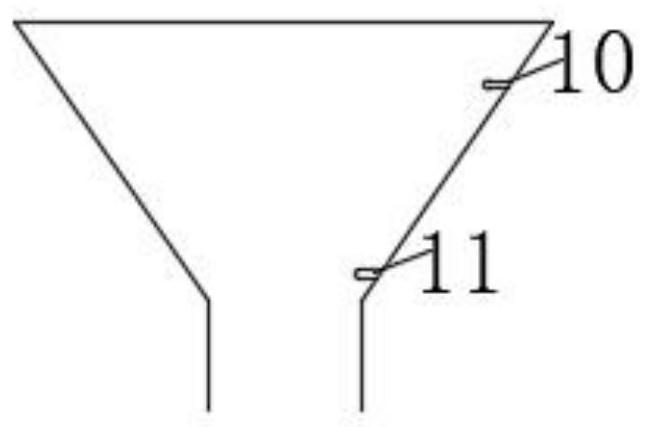

[0056] Water level monitoring module 15: connected with the main control module 18, including the first water level monitor 10 and the second water level monitor 11 and ancillary devices, used to monitor the water level in the water collecting funnel 4, and transmit the water level information to the main control module .

[0057] Conductivity detection module 16 : connected to the main control module 18 , including auxiliary devices such as a conductivity meter and a bracket, for monitoring the conductivity in the clean water tank 13 .

[0058]Flow control module 17: connected to the main control module 18, including the second water pump 8, the first water pump 5, the third water pump 14 and accessory devices, used to control the water volume in the drainage channel 2 and the water collecting funnel 4.

[0059] Main control module 18: including the controll...

Embodiment 3

[0063] Such as Figure 5 As shown, the control methods of the water-stop curtain grouting production sewage recycling system include:

[0064] S01: The conductivity detection module detects the conductivity in the clean water tank. When the conductivity meets the standard requirements, the main control module controls the third water pump in the clean water tank to inject water into the water collection tank. If the conductivity does not meet the standard requirements, continue to supply clean water Add cement retarder to the box.

[0065] S02: The main control module controls the second water pump to turn on, and presses the water in the water collection tank into the drain through the pipeline.

[0066] S03: The water in the drainage channel washes away the cement slurry flowing out under the water-stop curtain. When the water contains cement slow-release agent, the cement slurry coagulates at a slower rate and collects together into the water collection funnel in the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com