Retarder applicable to sulphate aluminum cement

A technology of sulfoaluminate cement and retarder, which is applied in the application, fertilizer mixture, fertilizer application device and other directions, can solve the problems of short setting time, low fertilizer efficiency and utilization rate, difficult construction and operation, etc., and achieves improved fluidity and improved flow degree, the effect of prolonging the setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

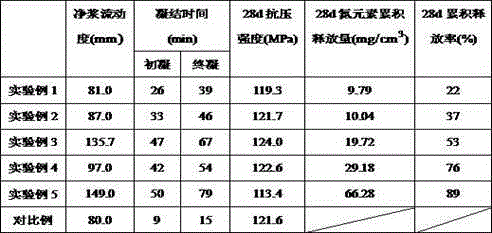

Examples

Embodiment 1

[0022] A retarder suitable for sulphoaluminate cement, which is composed of the following raw materials in parts by weight: 7 parts of urea, 11 parts of sodium lignosulfonate, 2 parts of sodium dinaphthylmethane disulfonate, and water reducer 2 parts, 70 parts of vermiculite.

[0023] As mentioned, the vermiculite is vermiculite powder, the fineness is 200 mesh, and the sieve residue is less than 10%.

[0024] As mentioned above, sodium lignosulfonate is yellow-brown powder, the content of sodium lignosulfonate is >45%, and the sieve residue is ≤4%.

[0025] As mentioned, the water reducer is an aliphatic high-efficiency water reducer.

[0026] As mentioned above, the aliphatic high-efficiency water reducer is a powder, and the effective matter content is ≥ 92%.

[0027] Usage method: mix the above raw materials evenly, add to the mixing water, fully stir to dissolve and disperse, and mix with cement according to the addition amount of 5.9% of the weight of sulphoaluminate c...

Embodiment 2

[0029] A retarder suitable for sulphoaluminate cement, which is composed of the following raw materials in parts by weight: 20 parts of urea, 9 parts of sodium lignosulfonate, 5 parts of sodium dinaphthylmethane disulfonate, and water reducer 3 parts, 60 parts of vermiculite.

[0030] All the other are with embodiment 1.

Embodiment 3

[0032] A retarder suitable for sulphoaluminate cement, which is composed of the following raw materials in parts by weight: 30 parts of urea, 7 parts of sodium lignosulfonate, 4 parts of sodium dinaphthyl methane disulfonate, and water reducer 3.5 parts, 50 parts of vermiculite.

[0033] All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com