Single crystal furnace shutdown thermal field damage prevention method

A single crystal furnace and thermal field technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of container and support container damage, liquid silicon volume expansion, difficult stress, etc., to slow down silicon condensation speed, reduce stress concentration, and accelerate the effect of coagulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

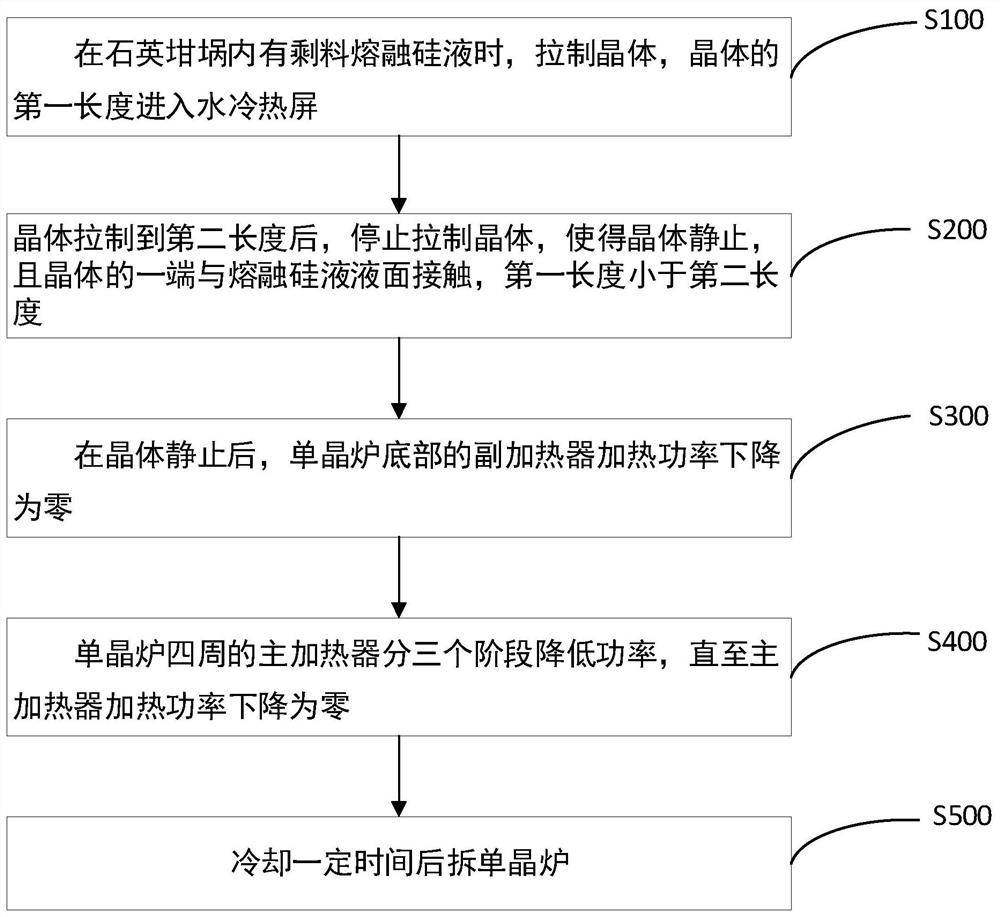

[0033] The method for stopping the single crystal furnace to prevent thermal field damage according to the embodiment of the first aspect of the present invention will be described in detail below with reference to the accompanying drawings.

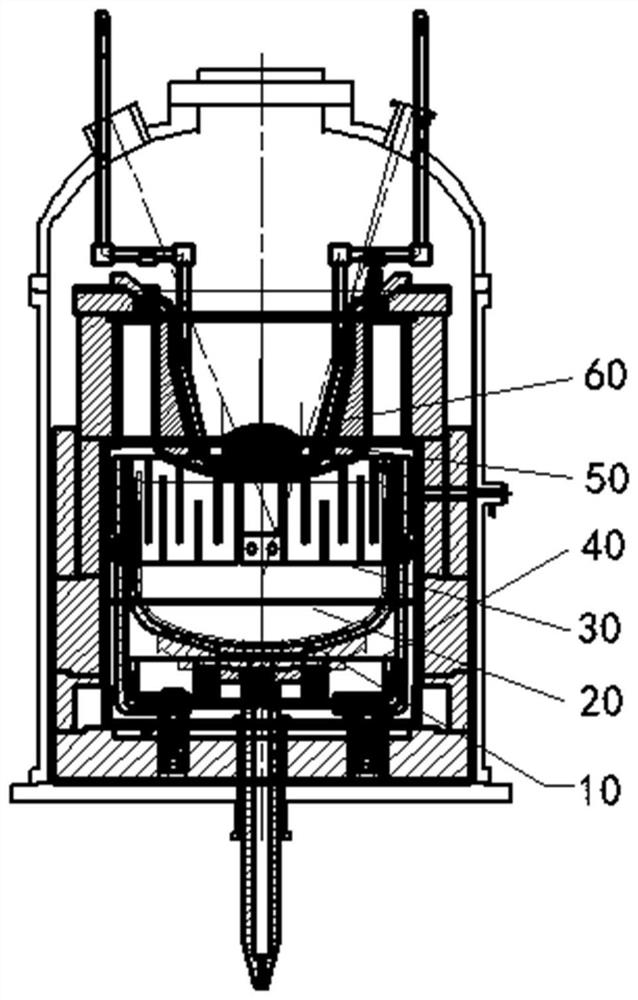

[0034] In order to facilitate the understanding of the method for stopping the single crystal furnace to prevent thermal field damage in this application, the structure of the single crystal furnace is first described, as figure 2 As shown, the single crystal furnace includes: a quartz crucible 10 for containing molten silicon liquid 20, a water-cooled heat shield 60 arranged above the quartz crucible 10, an auxiliary heater 40 arranged at the bottom of the single crystal furnace, and a 10 around and located at the main heater 30 below the water-cooled heat shield 60.

[0035] Combine below figure 1 and figure 2 , to describe in detail the method of stopping the single crystal furnace to prevent thermal field damage in the embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com