Wet cooling tower core component arrangement method for wind direction stable area

A technology of wet cooling and layout method, which is applied in water shower coolers, direct contact heat exchangers, lighting and heating equipment, etc., can solve the problem of difficult customization of cooling tower components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

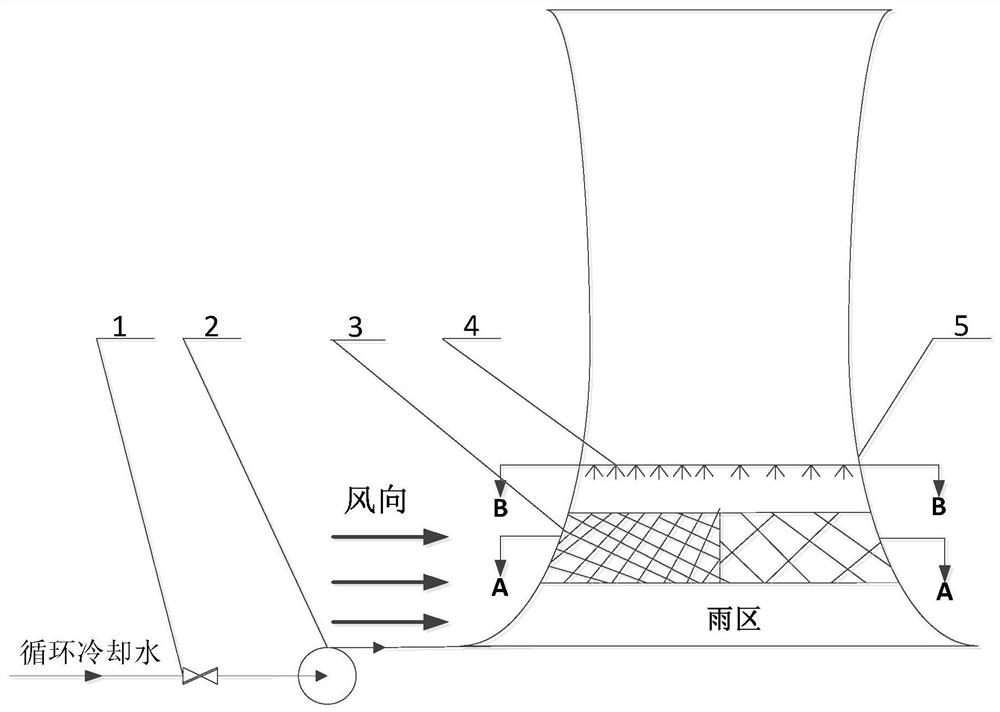

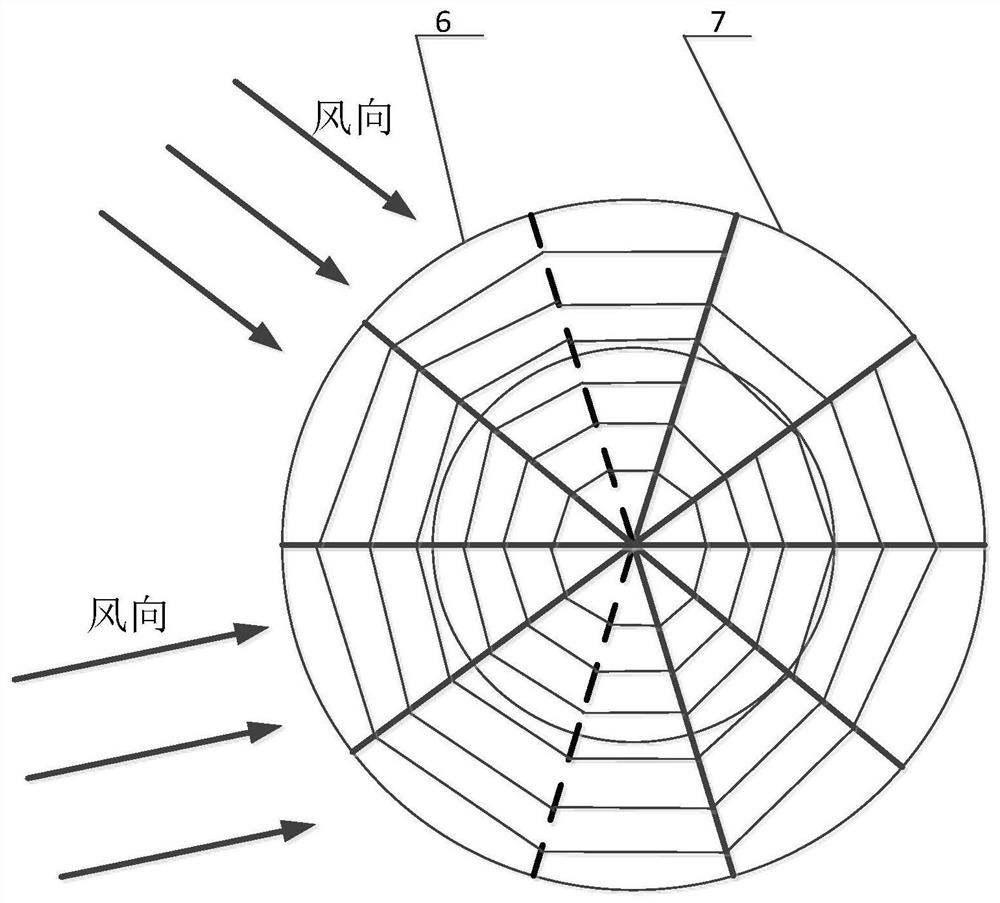

[0024] When designing a cooling tower, after the conventional design analysis, the wind speed and direction of the past ten years should be studied and analyzed. If the wind direction is relatively fixed, different tower core components can be arranged in the area where the wind direction is fixed.

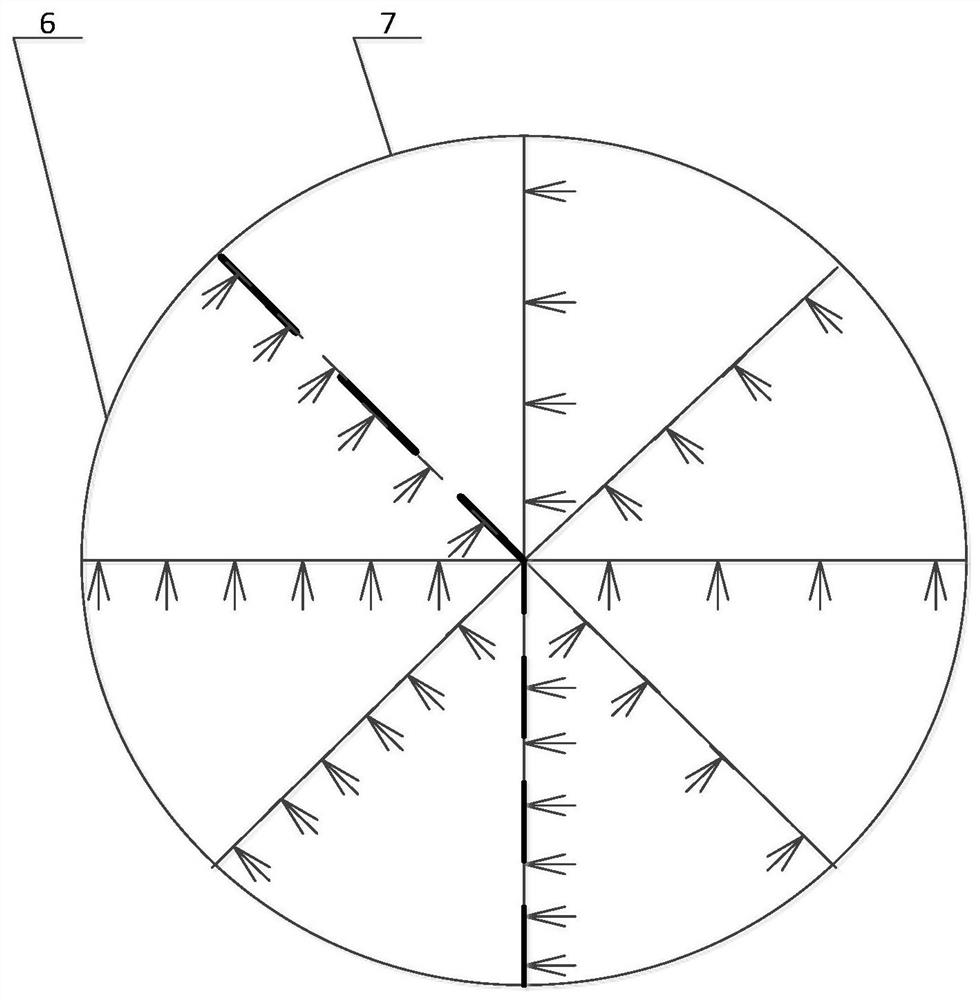

[0025] From the A-A and B-B views of the cooling tower packing, it can be seen that in the stable wind direction area 6, the packing arrangement and sprinkler arrangement in the stable wind direction area 6 are mainly considered to increase the heat exchange volume of the packing area 3 on the windward side, and Strengthen water distribution and enhance the cooling effect on the windward side. Arrange fillers with normal spacing (30mm spacing) in the windless area 7, arrange fillers with small spacings (26mm spacing) around the stable wind direction area 6, and increase the filling height in the stable wind direction area 6. The height of the fillers in the stable wind direction ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com