Patents

Literature

52results about How to "Reduced risk of icing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

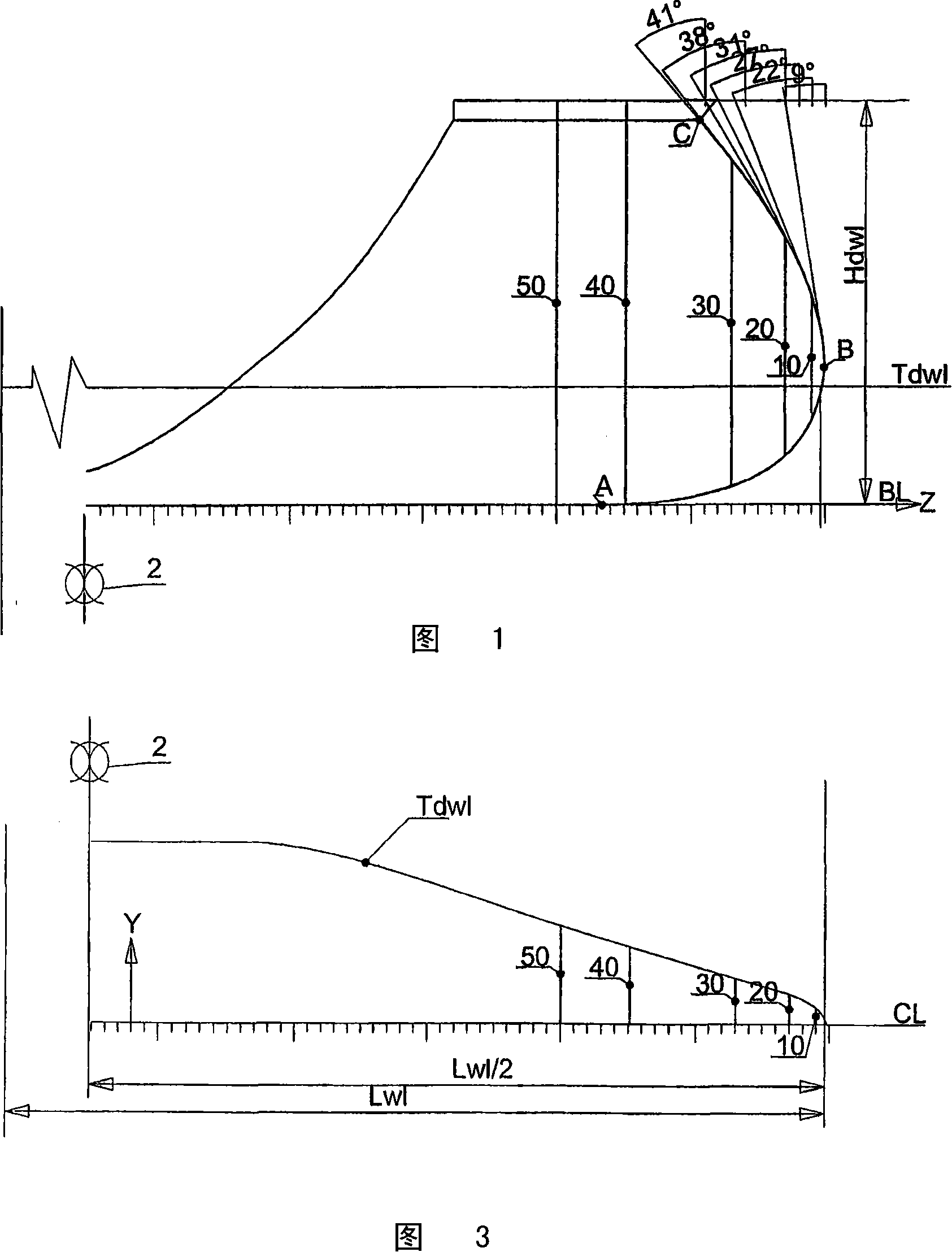

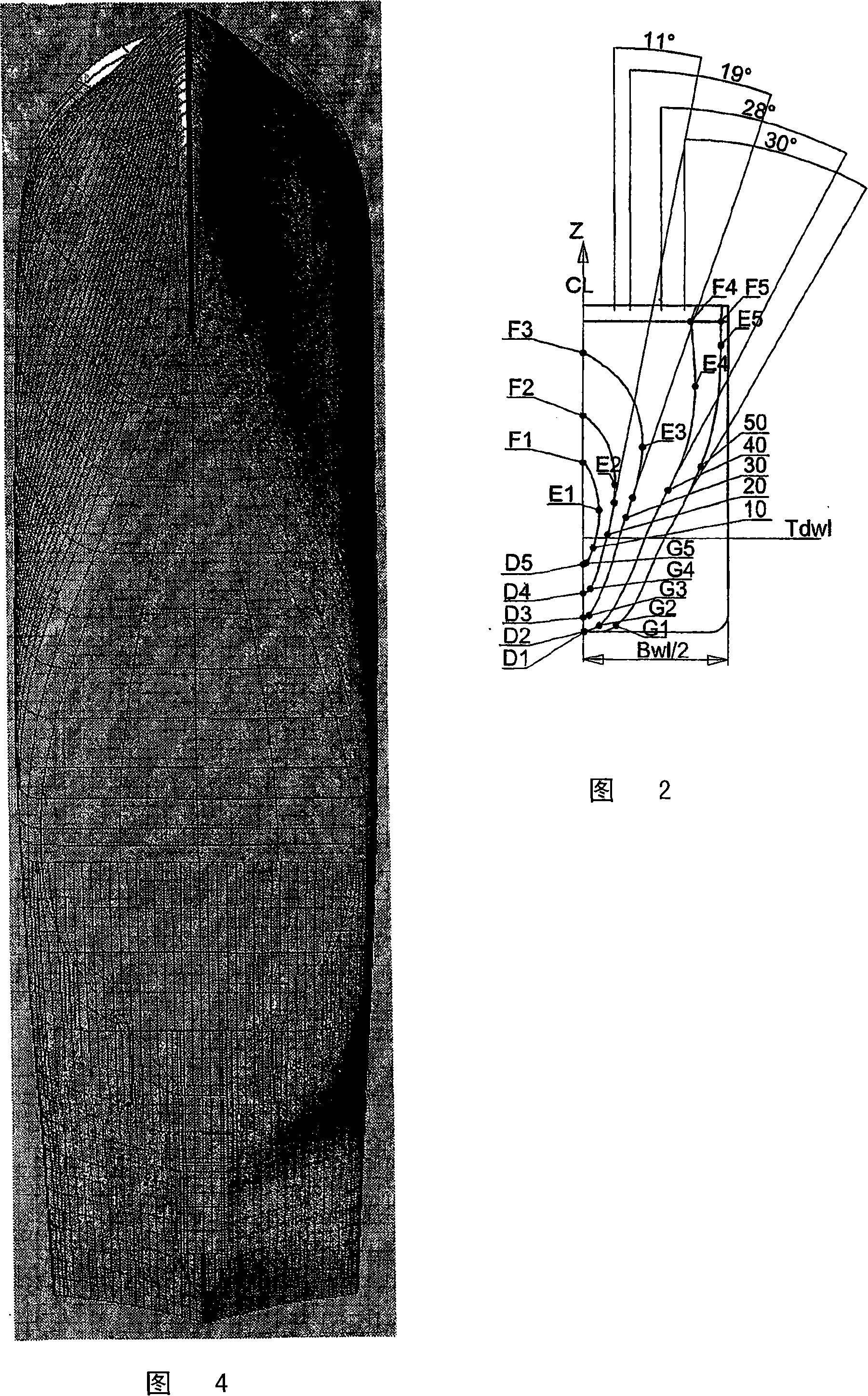

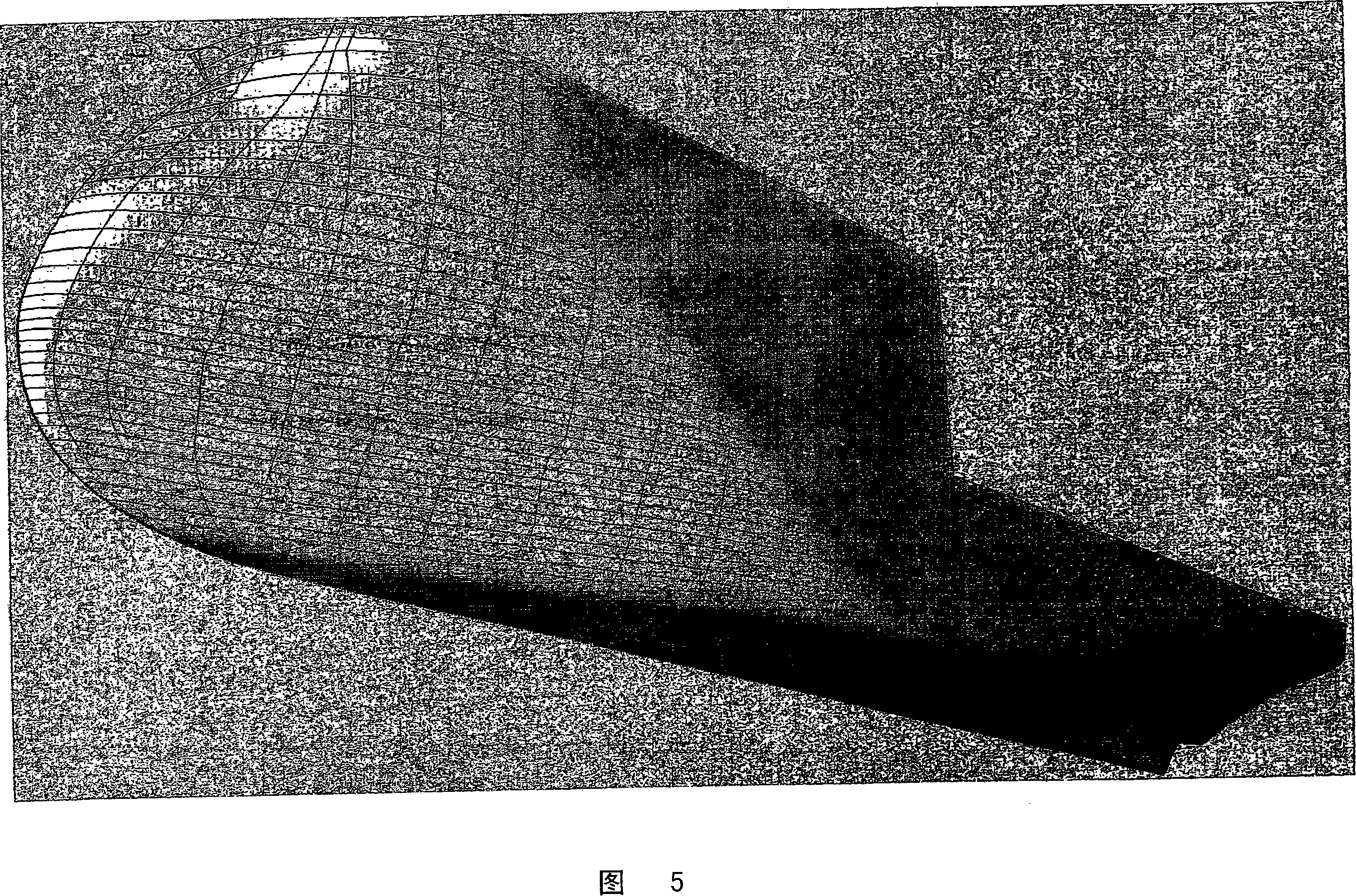

A foreship arrangement for a vessel of the deplacement type

ActiveCN101137536AReduce reflectionReduce slapWatercraft hull designVessel movement reduction by foilsMarine engineeringTransition point

A foreship arrangement for a vessel of the displacement type, which foreship consists of the part of the ship in front of the vessel's midship mark (2) and which vessel has a transversely symmetrical hull form about its centre line (CL) and a substantially conventional bow form below its design water line (Tdwl), characterised in that the stem line (1) of the vessel turns substantially backwards in relation to the length direction of the ship from a transition point (B) at or immediately above the design water line (Tdwl).

Owner:ULSTEIN DESIGN & SOLUTIONS AS

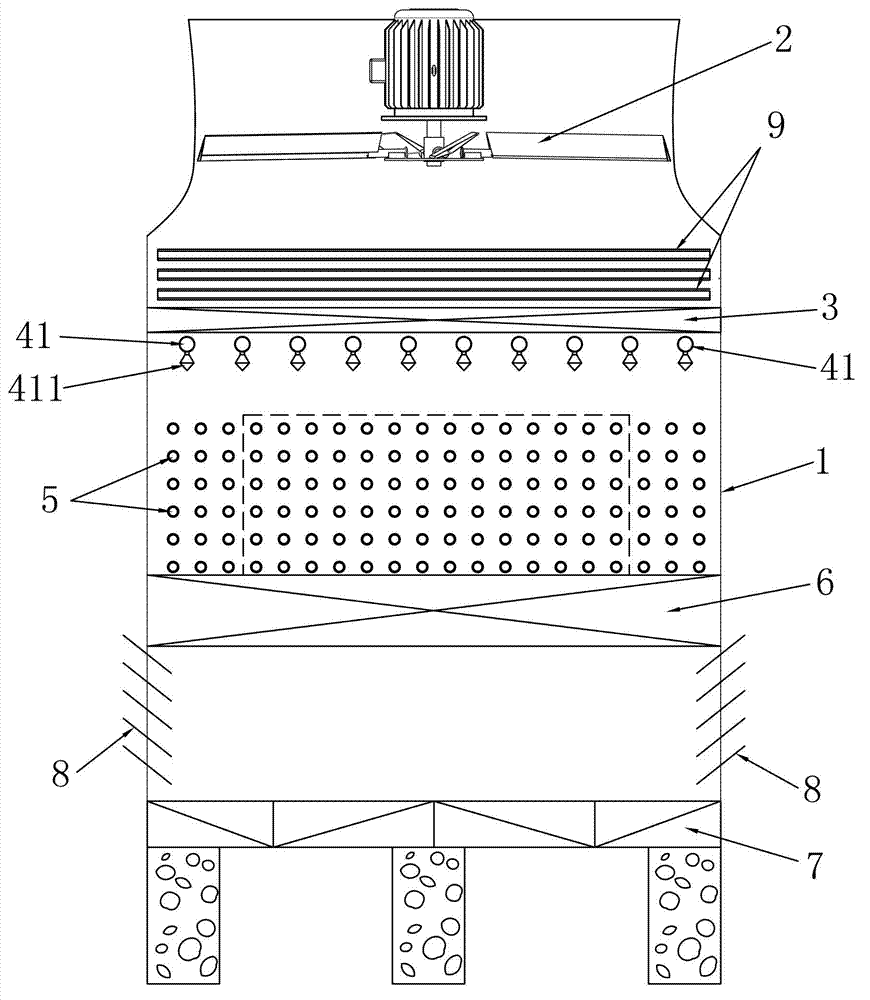

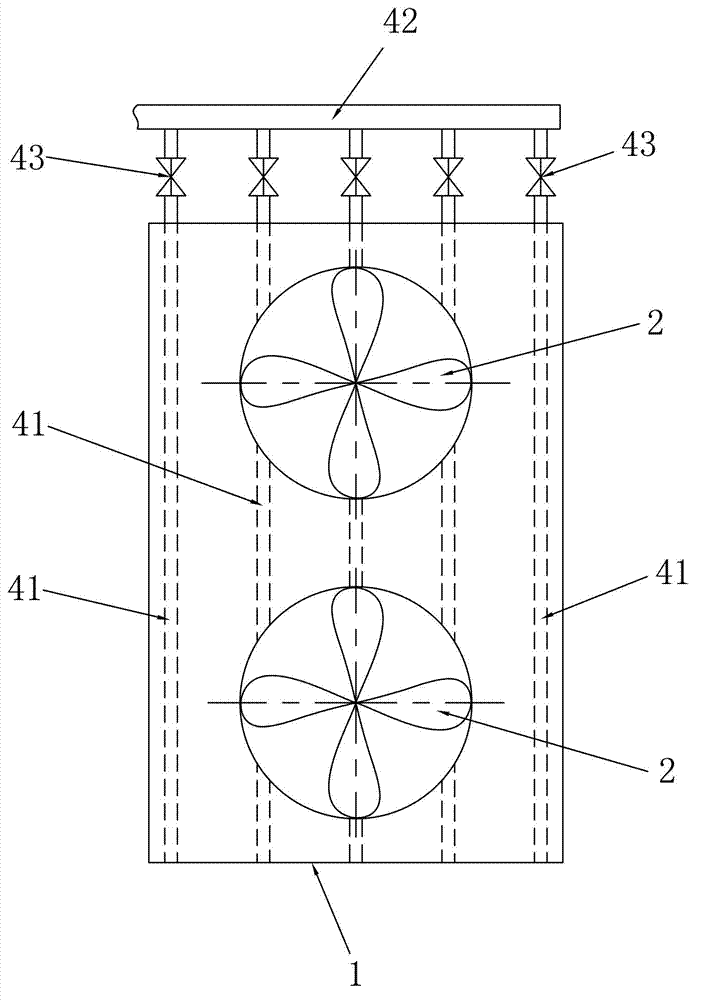

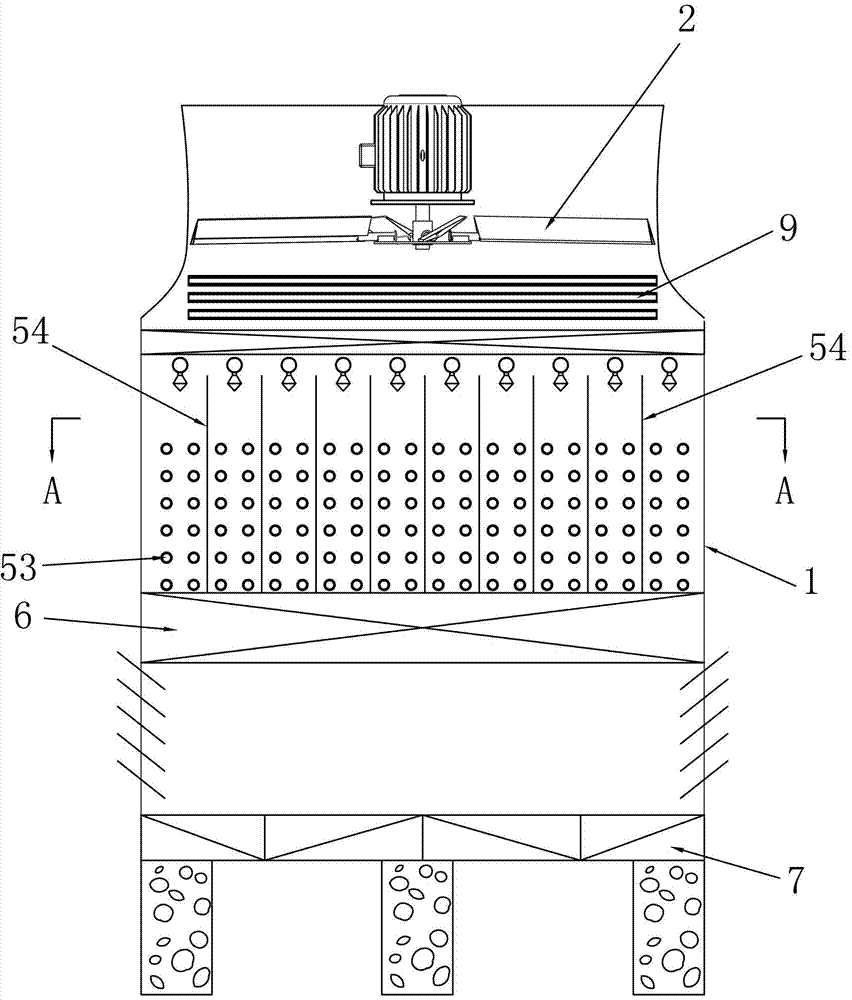

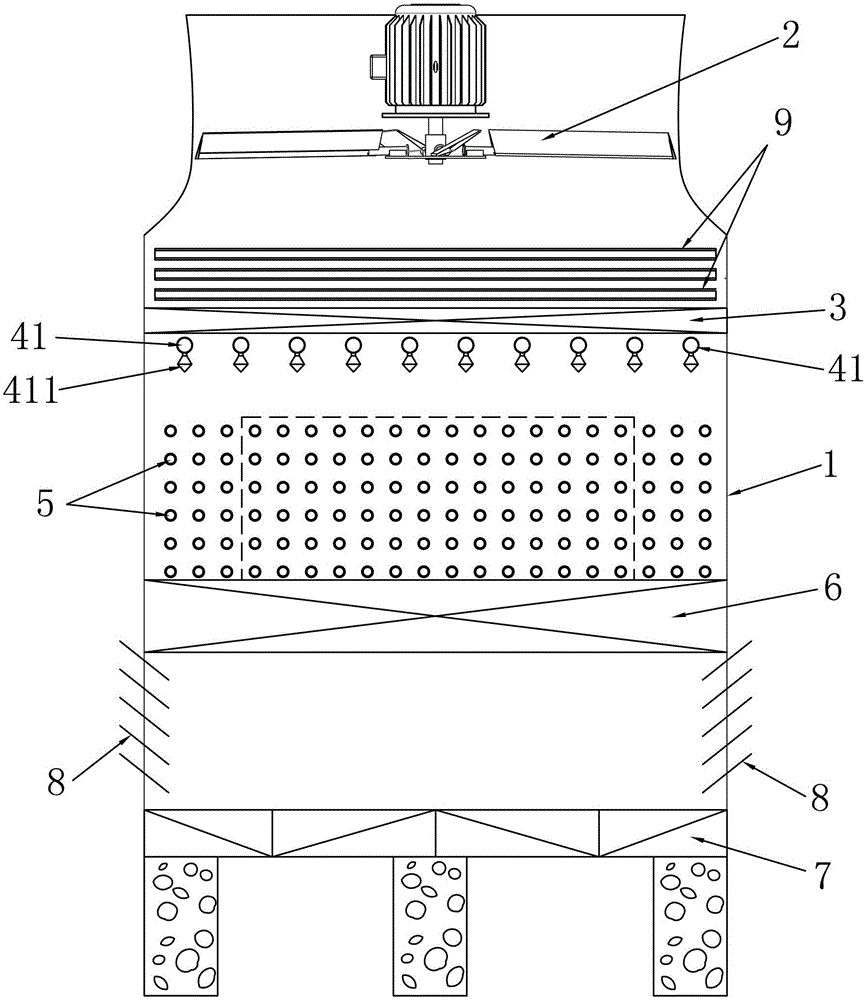

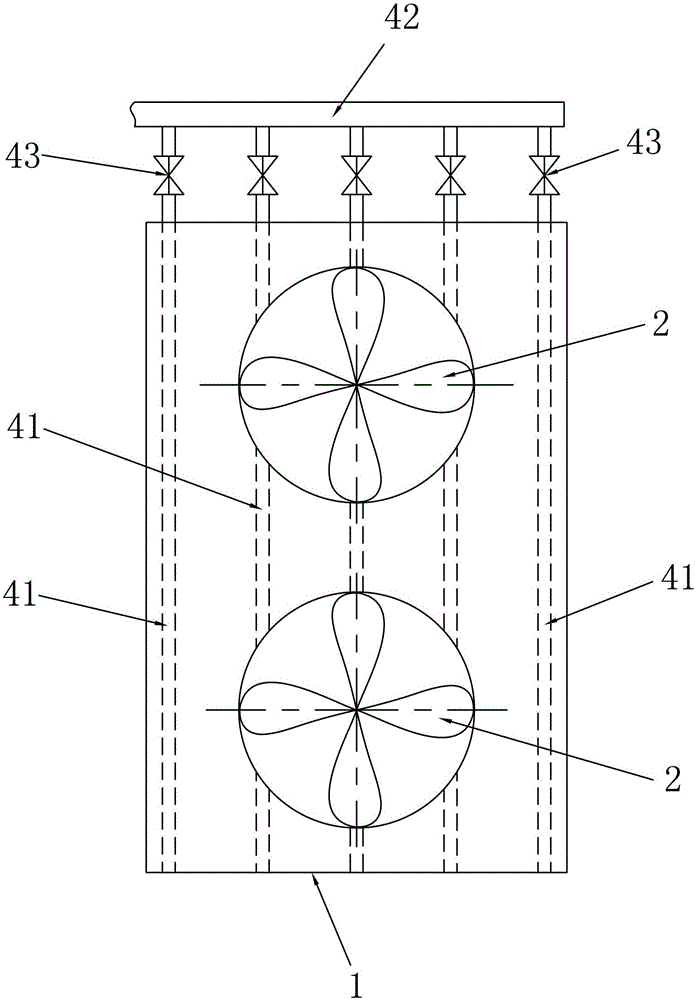

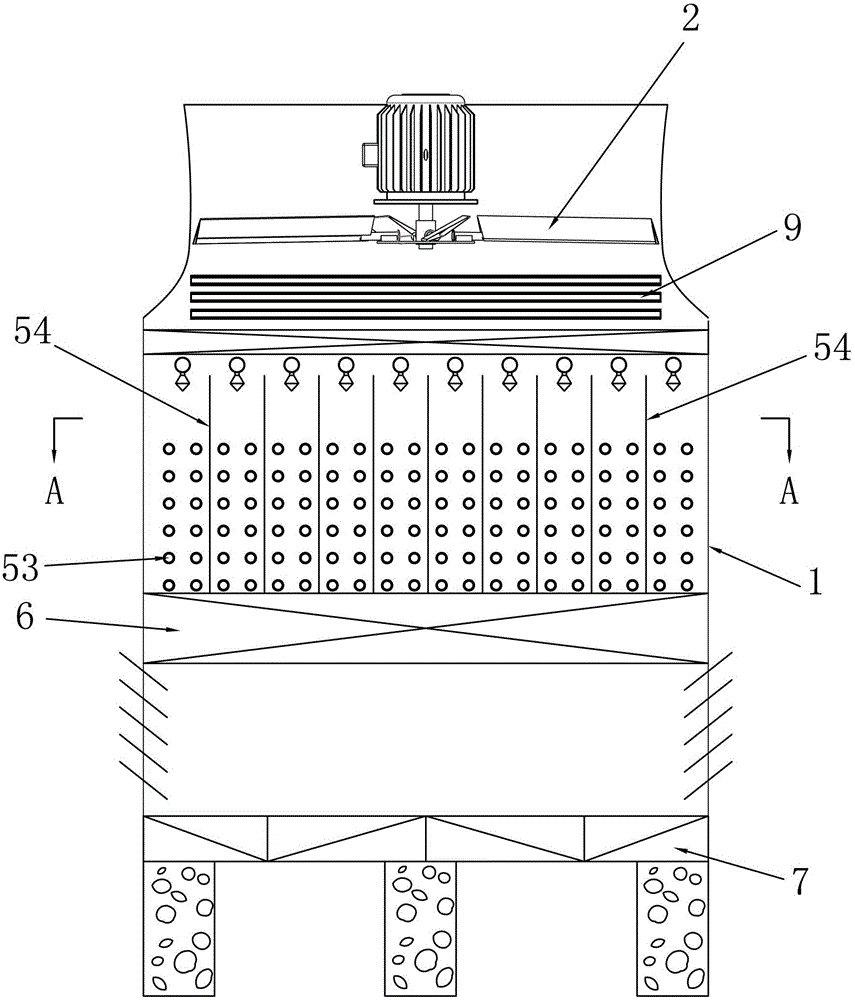

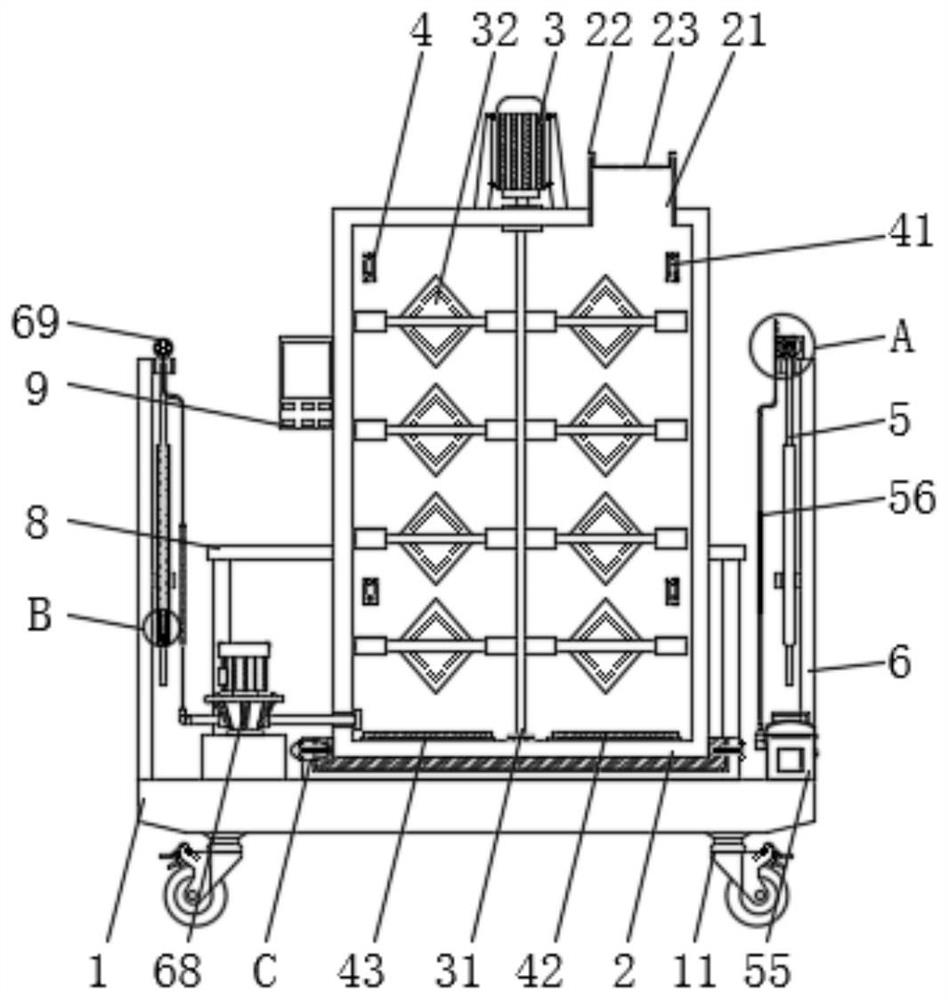

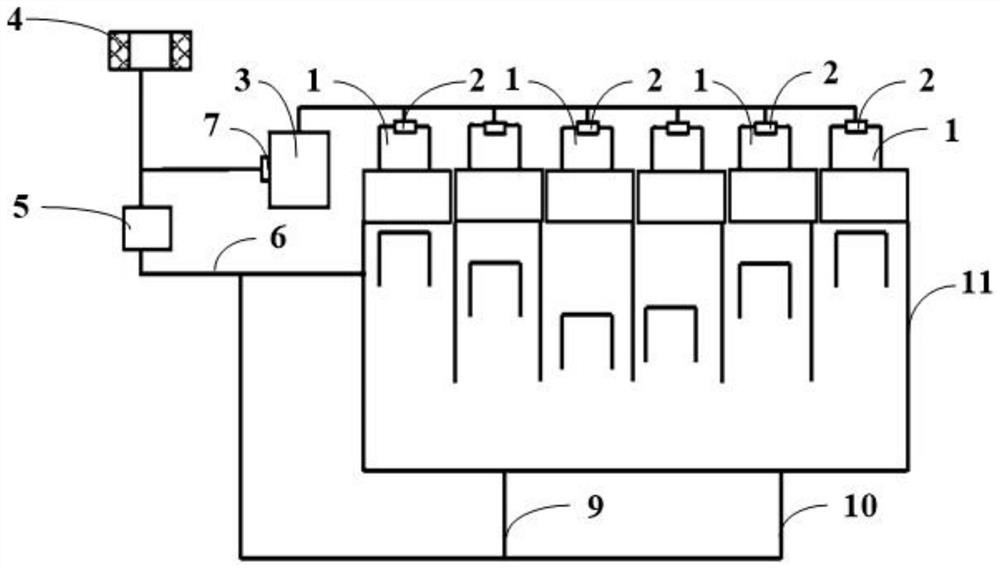

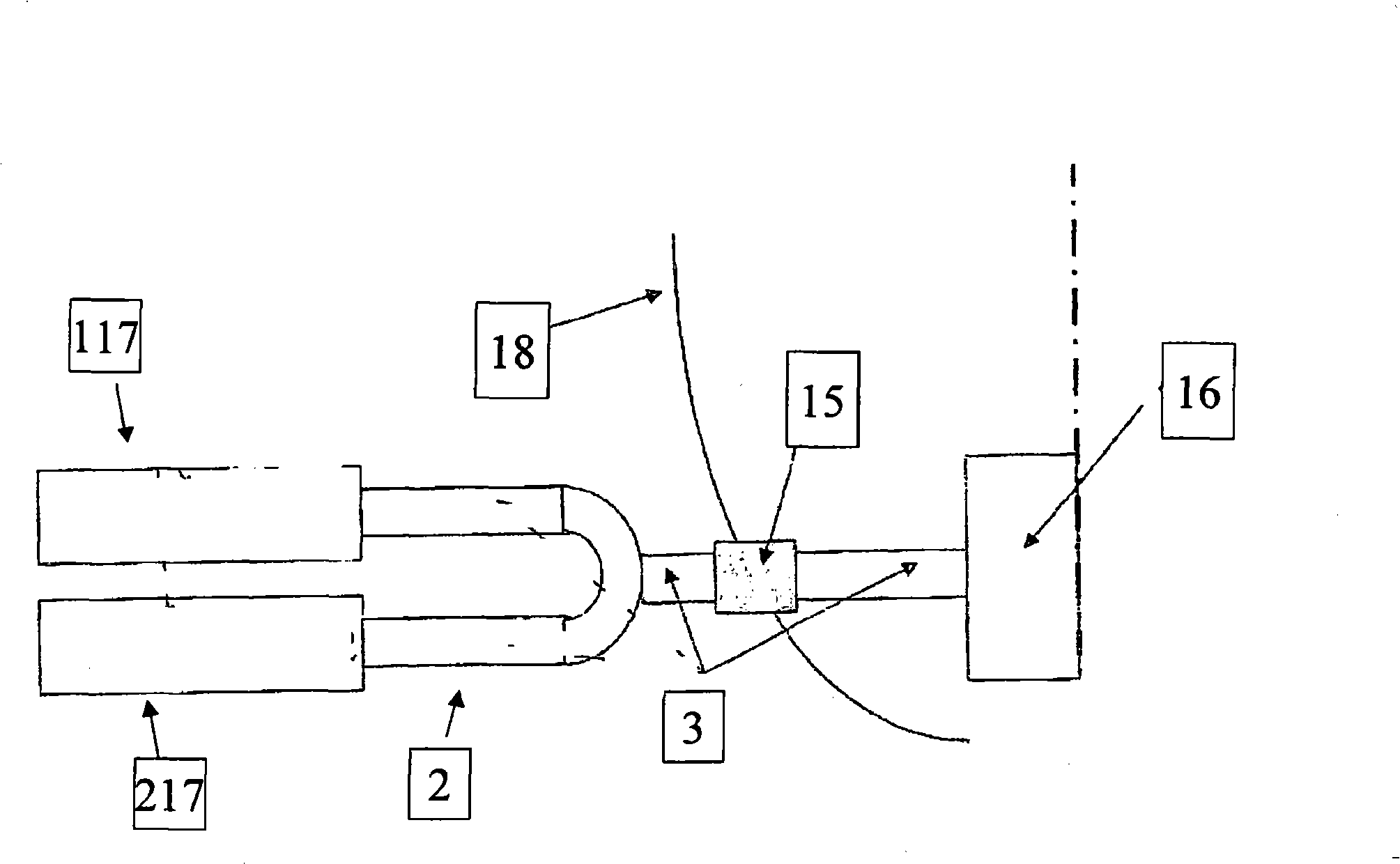

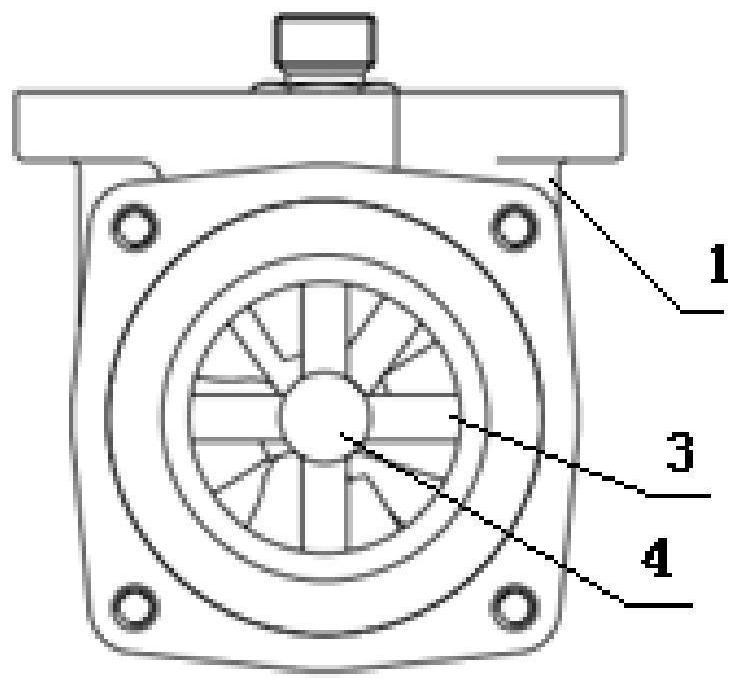

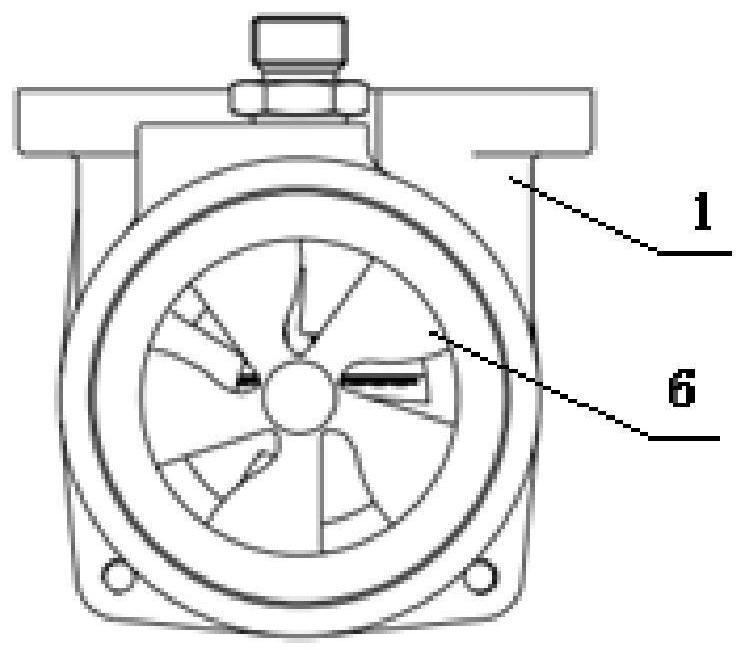

Counter-flow closed-type cooling tower

ActiveCN103776276AReduce the possibilityReduce the risk of icingHeat exchange apparatusTrickle coolersWater pipeCounter flow

The invention discloses a counter-flow closed-type cooling tower, belongs to heat exchanging equipment, particularly relates to a closed-type cooling tower which is used for preventing fogging at an air outlet, and aims to provide a counter-flow closed-type cooling tower which, during winter operation, can alleviate or eliminate fogging at the air outlet and reduce the risk of ice formation at shutters of the air outlet, and is convenient to save water. The counter-flow closed-type cooling tower comprises a tower body (1), a blower (2), a water collector (3), a water distributing device, a first heat exchanger (5), filling (6), a water collecting groove (7), air inlet shutters (8), a second heat exchanger (9), and a main water collecting pipe (42), wherein the water distributing device comprises a plurality of water distributing pipes (41); all the water distributing pipes are distributed in the tower from the middle to two sides in parallel to one another, or are distributed in the tower from the center to the periphery; a plurality of water distributing nozzles (411) are arranged on the side wall below the water distributing pipes; each water distributing pipes is connected with the main water collecting pipe through a flow rate adjustable valve (4).

Owner:YANTAI EBARA AIR CONDITIONER +1

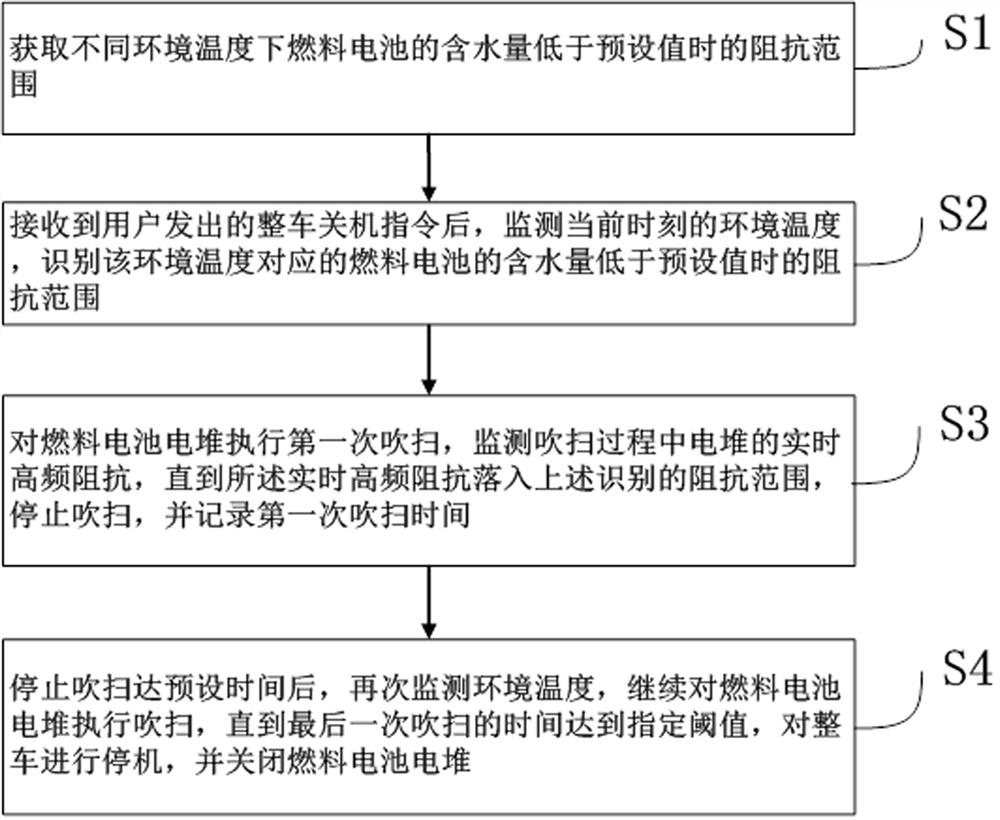

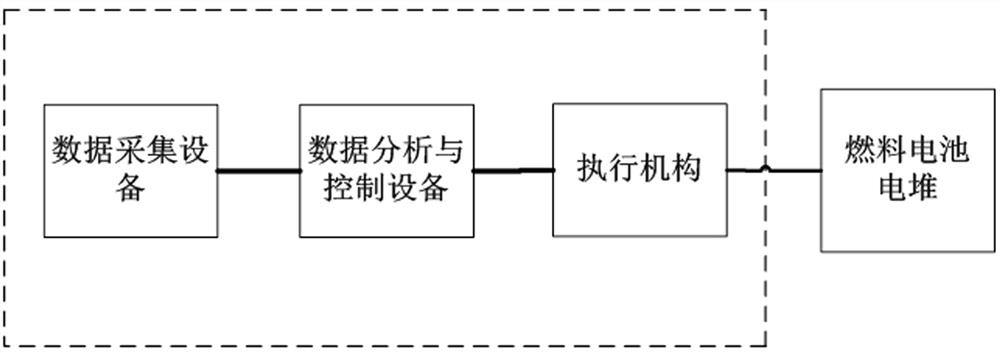

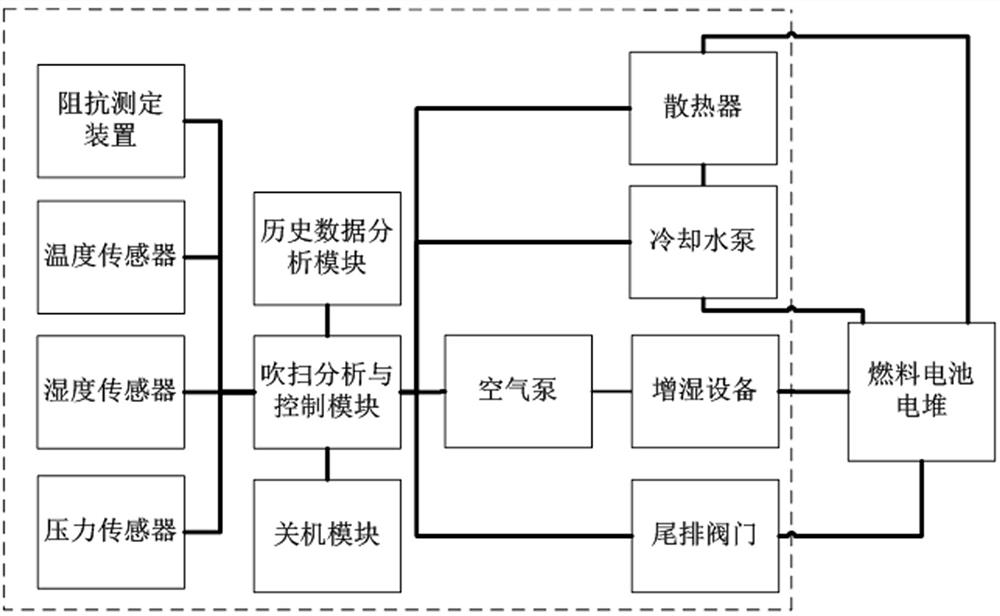

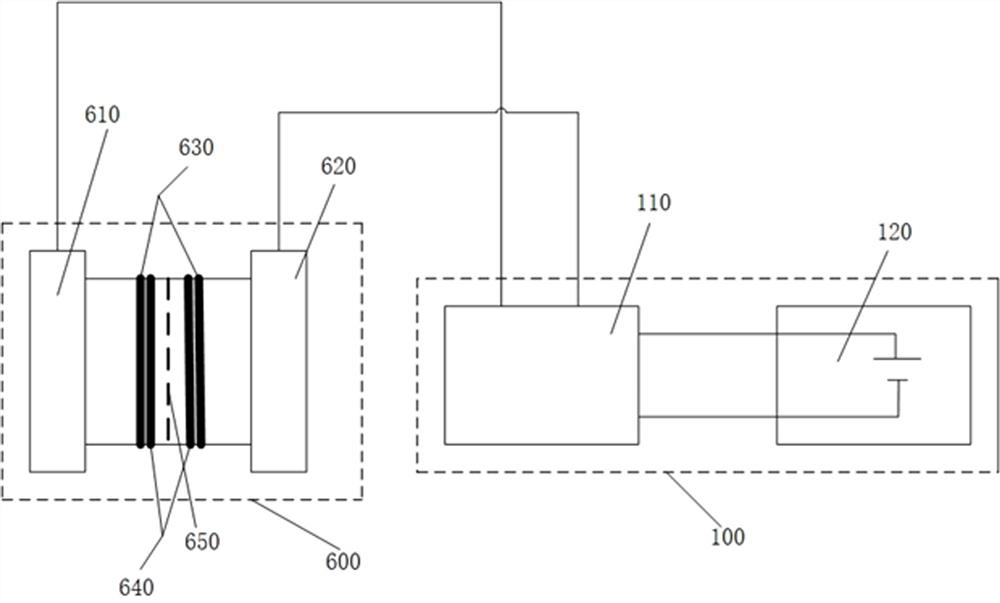

Shutdown purging method and device for fuel cell stack

The invention provides a shutdown purging method of a vehicle-mounted fuel cell, belongs to the technical field of shutdown purging of fuel cell stacks, and solves the problem that modal water in a proton exchange membrane cannot be effectively eliminated in the prior art. The method comprises the steps of acquiring an impedance range when the water content of the fuel cell is lower than a preset value at different environment temperatures; after a whole vehicle shutdown instruction sent by a user is received, monitoring the environment temperature at the current moment, and recognizing the impedance range when the water content, which corresponds to the environment temperature, of the fuel cell is lower than a preset value; performing first purging on the fuel cell stack, monitoring the real-time high-frequency impedance of the stack in the purging process, stopping purging until the real-time high-frequency impedance falls into the recognized impedance range, and obtaining the first purging time; and after the purging is stopped for a preset time, monitoring the environment temperature again, continuously performing purging on the fuel cell stack until the last purging time reaches a specified threshold value, stopping the whole vehicle, and shutting down the fuel cell stack.

Owner:BEIJING SINOHYTEC

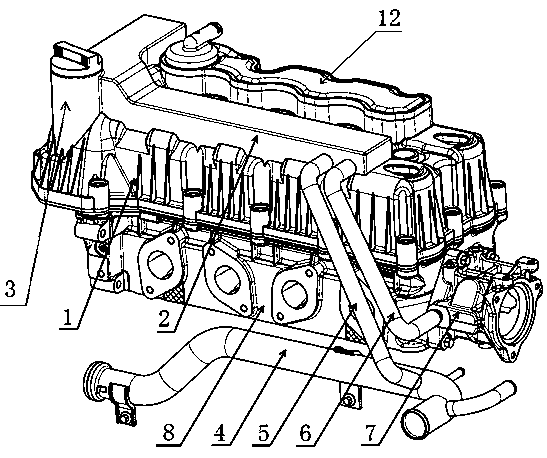

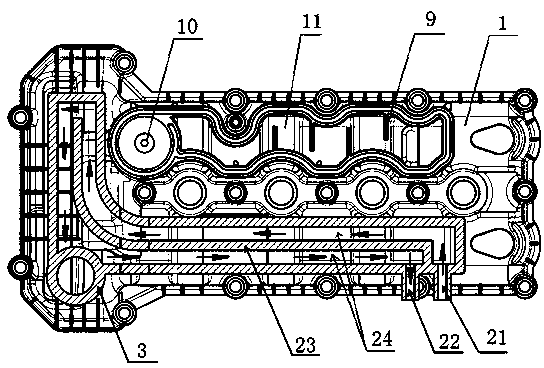

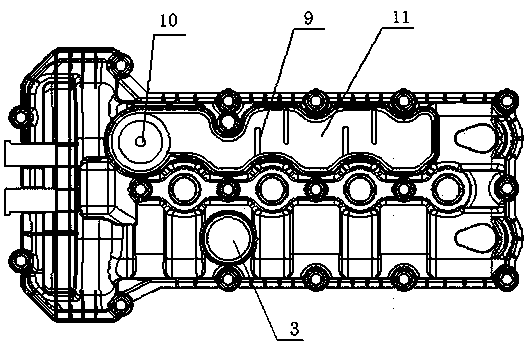

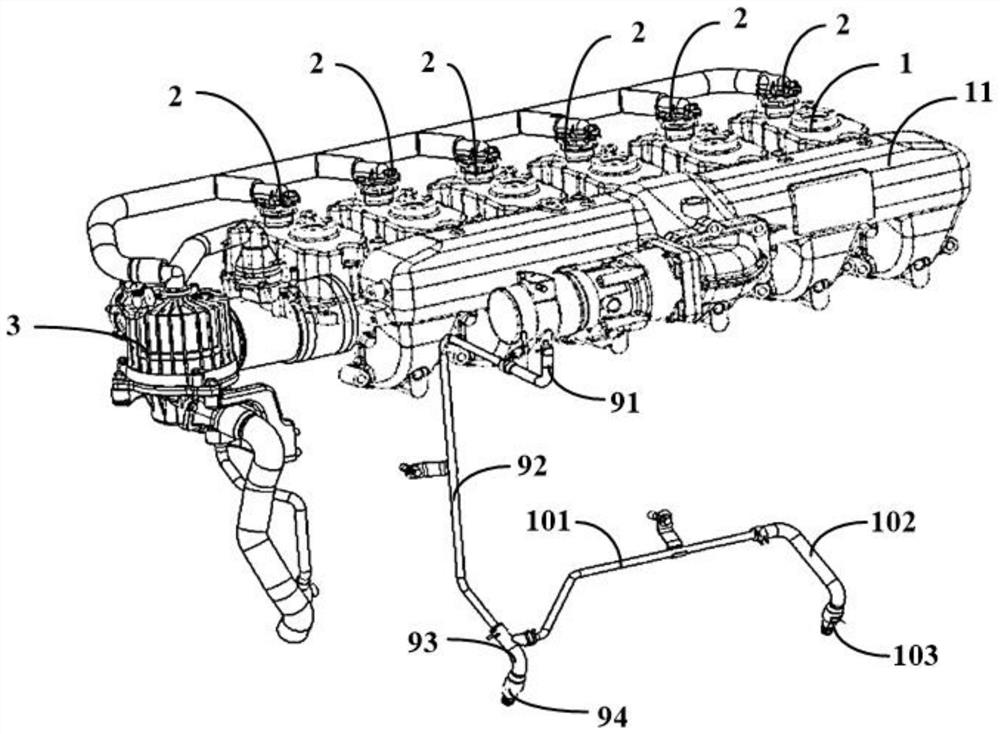

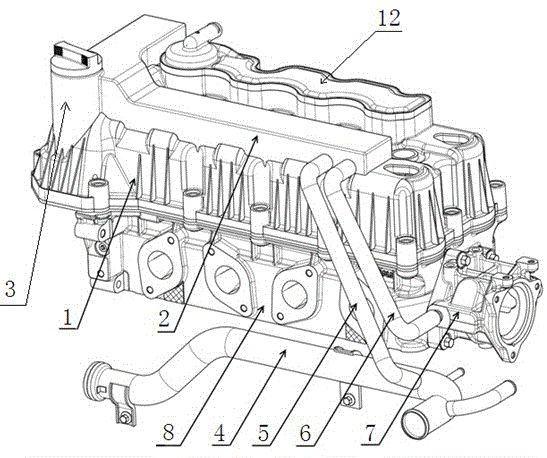

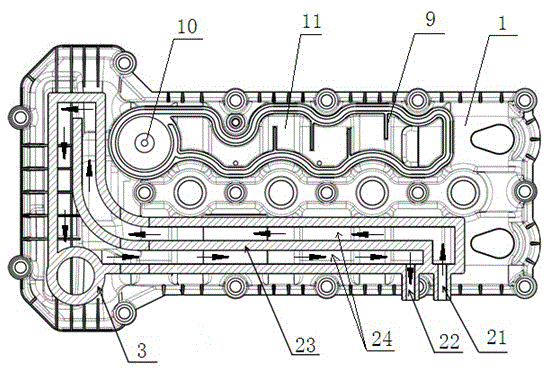

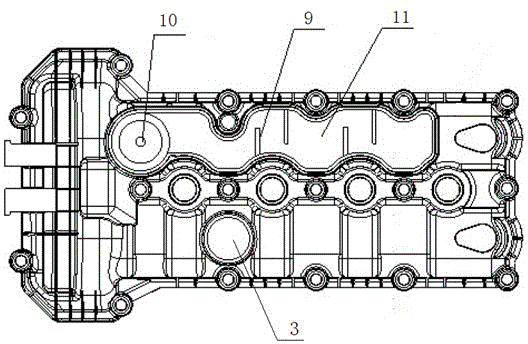

Automobile engine

ActiveCN103452697AAvoid overall overheatingReduce adverse effectsCasingsMachines/enginesEngineeringWater jacket

The invention discloses an automobile engine. The automobile engine comprises a cylinder cover, a cylinder cover hood, a temperature adjuster seat and an engine water inlet pipe, wherein the cylinder cover hood is provided with an oil filling port, a wavy oil collecting groove and a water jacket; the water jacket is positioned at one side of the oil collecting groove, is bent towards one end of the oil collecting groove and is L-shaped; the water jacket is provided with a cooling-liquid inlet, a cooling-liquid outlet and a cooling-liquid flowing channel; the cooling-liquid inlet is connected with the temperature adjuster seat by the water inlet pipe; the cooling-liquid outlet is connected with the engine water inlet pipe by a water outlet pipe; the cooling-liquid flowing channel is formed by a water jacket partition and a water jacket inner wall, and the water jacket partition is positioned in the water jacket and is L-shaped; the cooling-liquid inlet and the cooling-liquid outlet are respectively positioned at the two ends of the cooling-liquid flowing channel; the oil filling port is positioned at the outer end of the L-shaped bending position of the water jacket and is integrally connected with the water jacket. The automobile engine disclosed by the invention has the advantages that during cold starting, the cylinder cover hood can heat and rise the temperature quickly, white attachments on the cylinder cover hood and the oil filling port cover can be reduced, and simultaneously the icing risk of a crankcase ventilating system is reduced.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

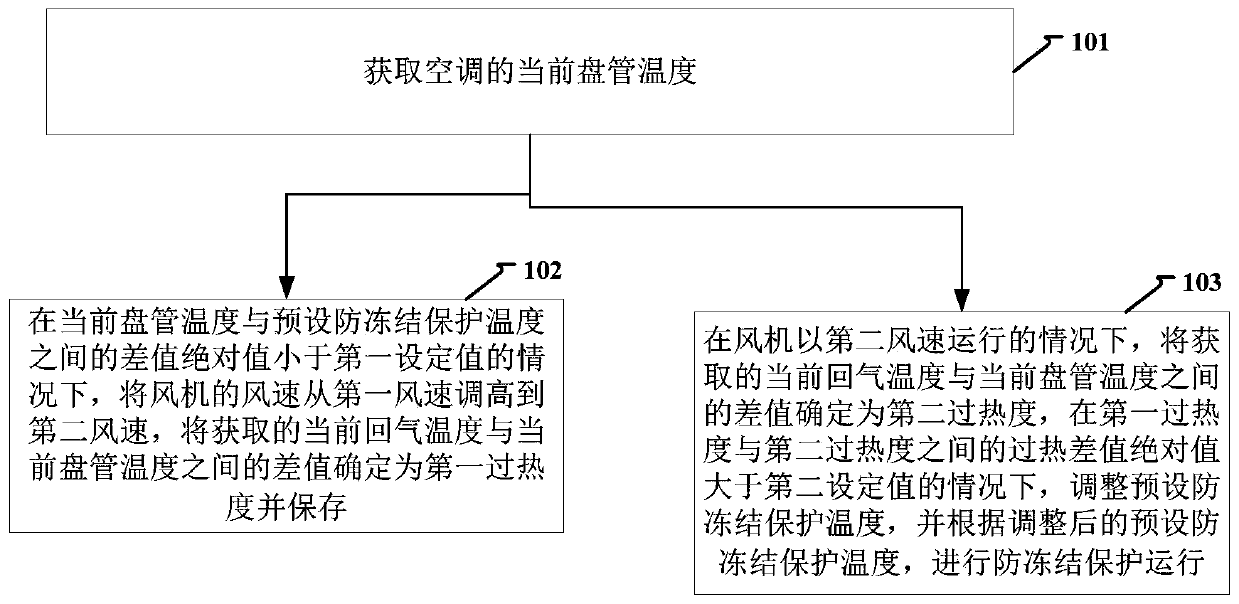

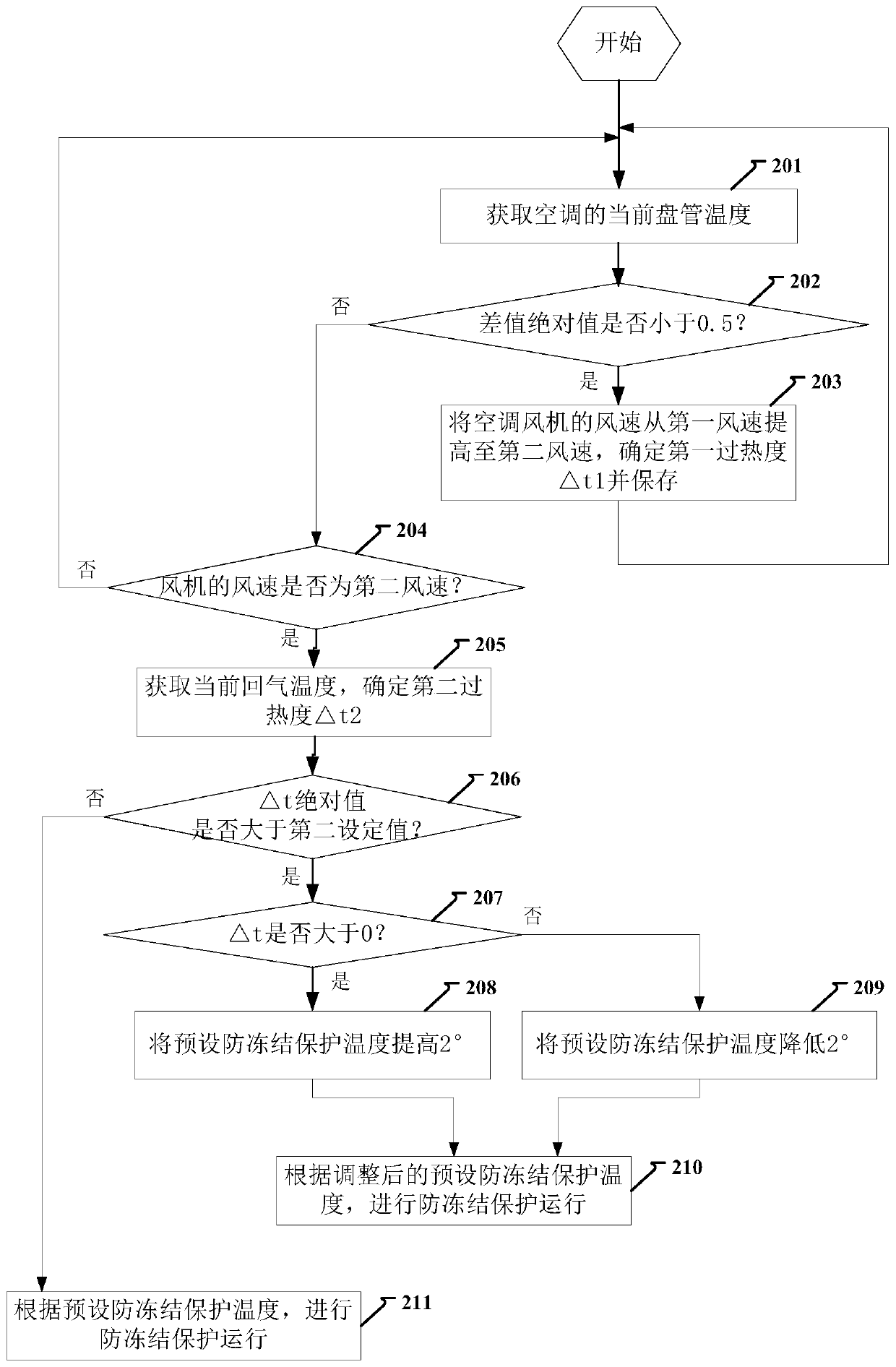

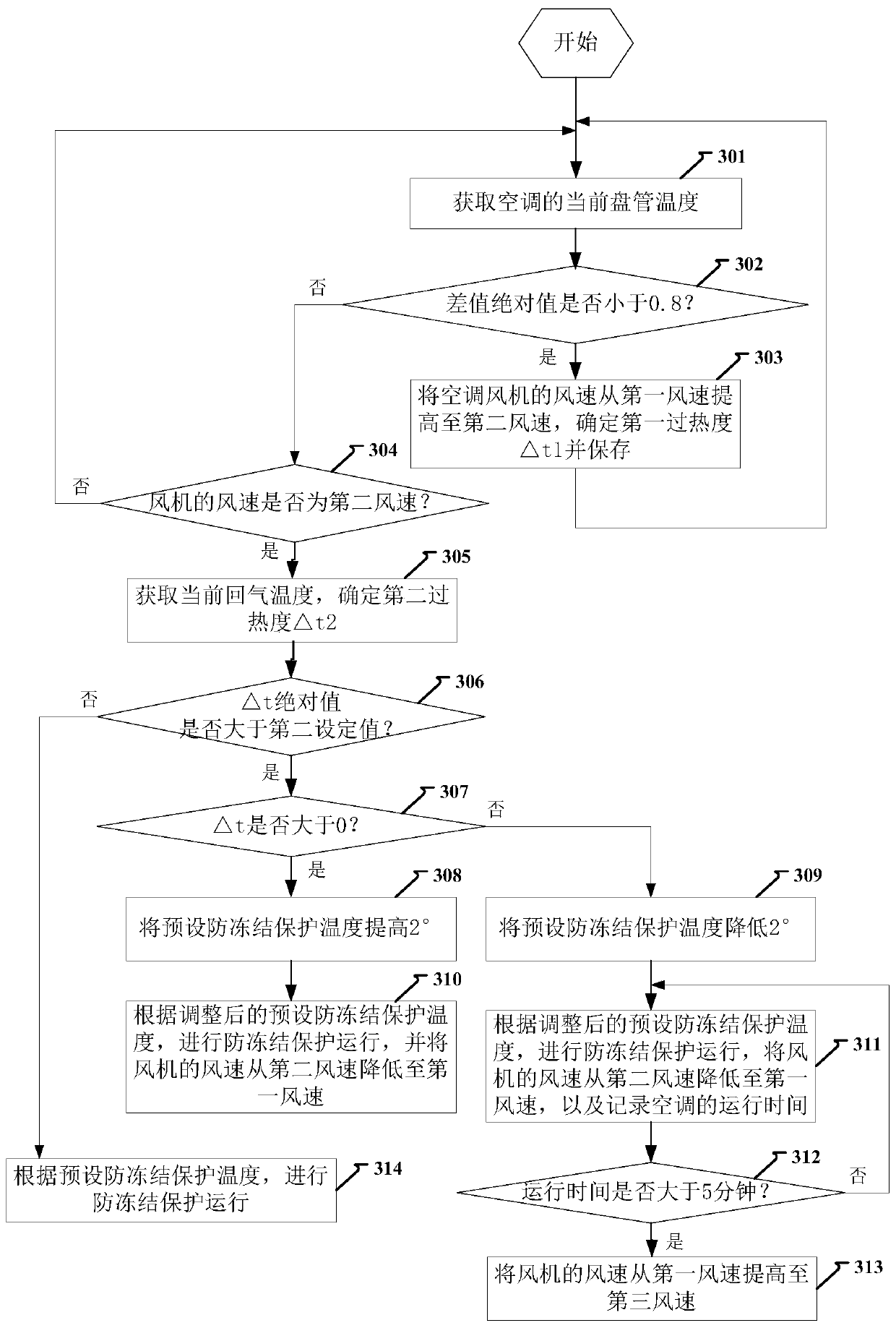

Method and device for freezing-prevention protection of air conditioner and air conditioner

ActiveCN110953689AImprove accuracyImprove intelligenceMechanical apparatusEfficient regulation technologiesThermodynamicsEngineering

The invention relates to the technical field of intelligent household electrical appliance, and discloses a method and device for freezing-prevention protection of an air conditioner and the air conditioner. The method comprises the following steps of obtaining a current coil pipe temperature of the air conditioner; under the condition that the absolute value of the difference value between the current coil pipe temperature and a preset freezing-prevention protection temperature is smaller than the first set value, increasing the wind speed of a fan to a second wind speed from a first wind speed, determining the obtained difference value between the current air returning temperature and the current coil pipe temperature as a first superheat degree and saving the difference value; and underthe condition that the fan runs at the second wind speed, determining the obtained difference value between the current air returning temperature and the current coil pipe temperature as a second superheat degree, under the condition that the absolute value of the superheat difference value between the first superheat degree and the second superheat degree is larger than the second set value, adjusting the preset freezing-prevention protection temperature, and carrying out freezing-prevention protection running according to the adjusted preset freezing-prevention protection temperature. Therefore, accuracy of freezing-prevention protection of the air conditioner can be improved.

Owner:HEFEI HAIER AIR CONDITIONER

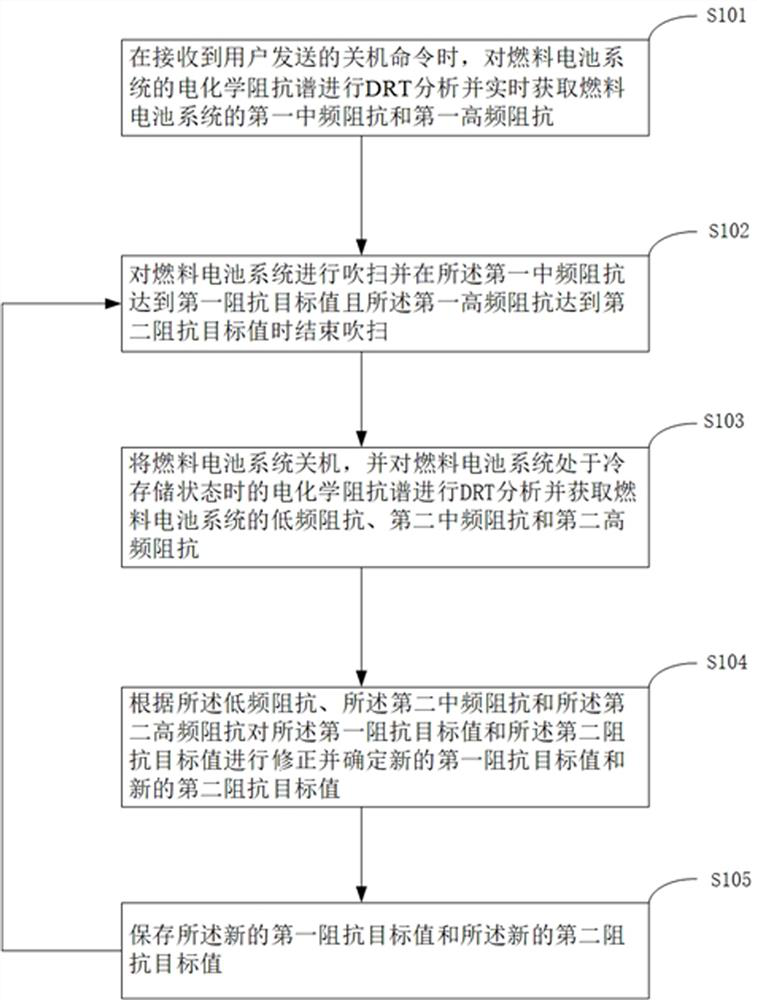

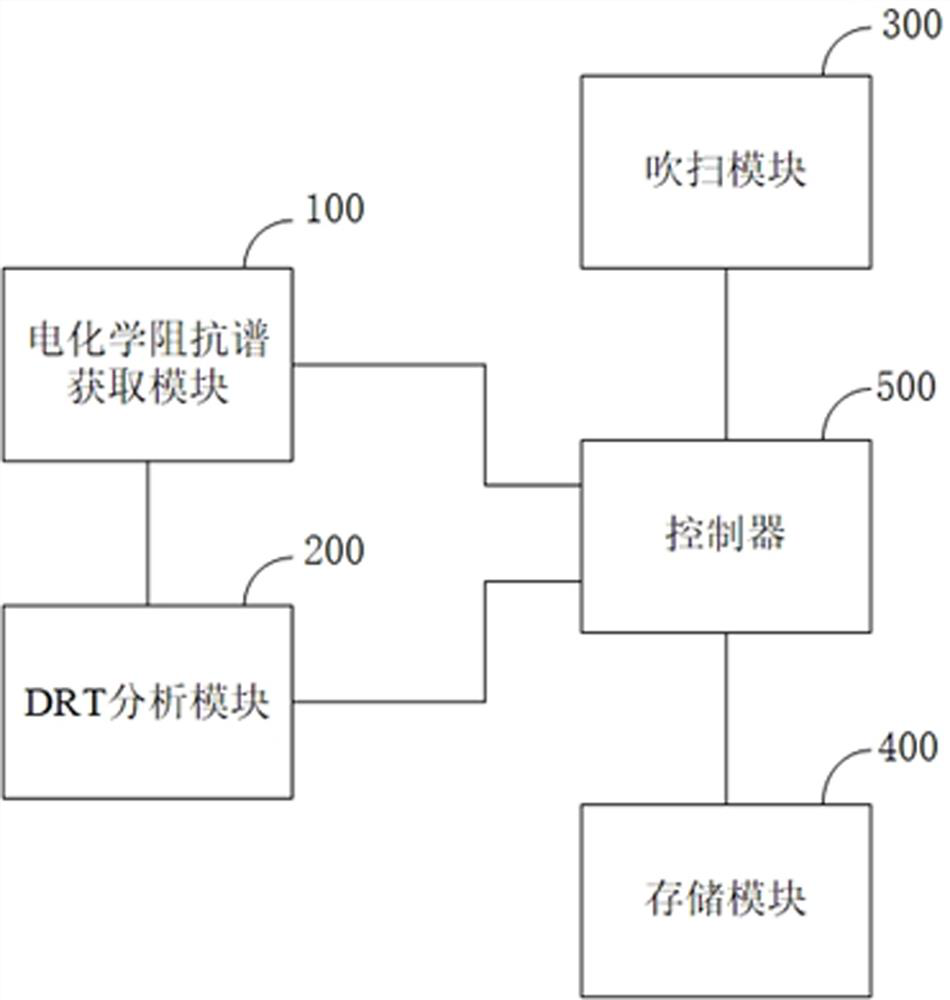

Fuel cell purging control method and device based on DRT analysis

ActiveCN114335613ARealize cold purge dynamic closed loopIncreased durabilityFuel cell heat exchangeFuel cellsImpedance spectrum

The invention provides a fuel cell purging control method and device based on DRT analysis, and the method comprises the steps: carrying out the DRT analysis of an electrochemical impedance spectrum of a fuel cell system in a cold storage state after the fuel cell system is shut down, and obtaining the low-frequency impedance, second intermediate-frequency impedance and second high-frequency impedance of the fuel cell system; correcting the first impedance target value and the second impedance target value according to the low-frequency impedance, the second intermediate-frequency impedance and the second high-frequency impedance, and determining a new first impedance target value and a new second impedance target value; and storing the new first impedance target value and the new second impedance target value, so as to purge the fuel cell system according to the new first impedance target value and the new second impedance target value before the next shutdown, thereby realizing the dynamic closed loop of the cold purge of the fuel cell based on the optimized purge criterion, reducing the freezing risk of cold storage, and improving the reliability of the fuel cell system. Meanwhile, the cold start performance of the stack is improved, and the durability and service life of the fuel cell are improved.

Owner:BEIJING SINOHYTEC

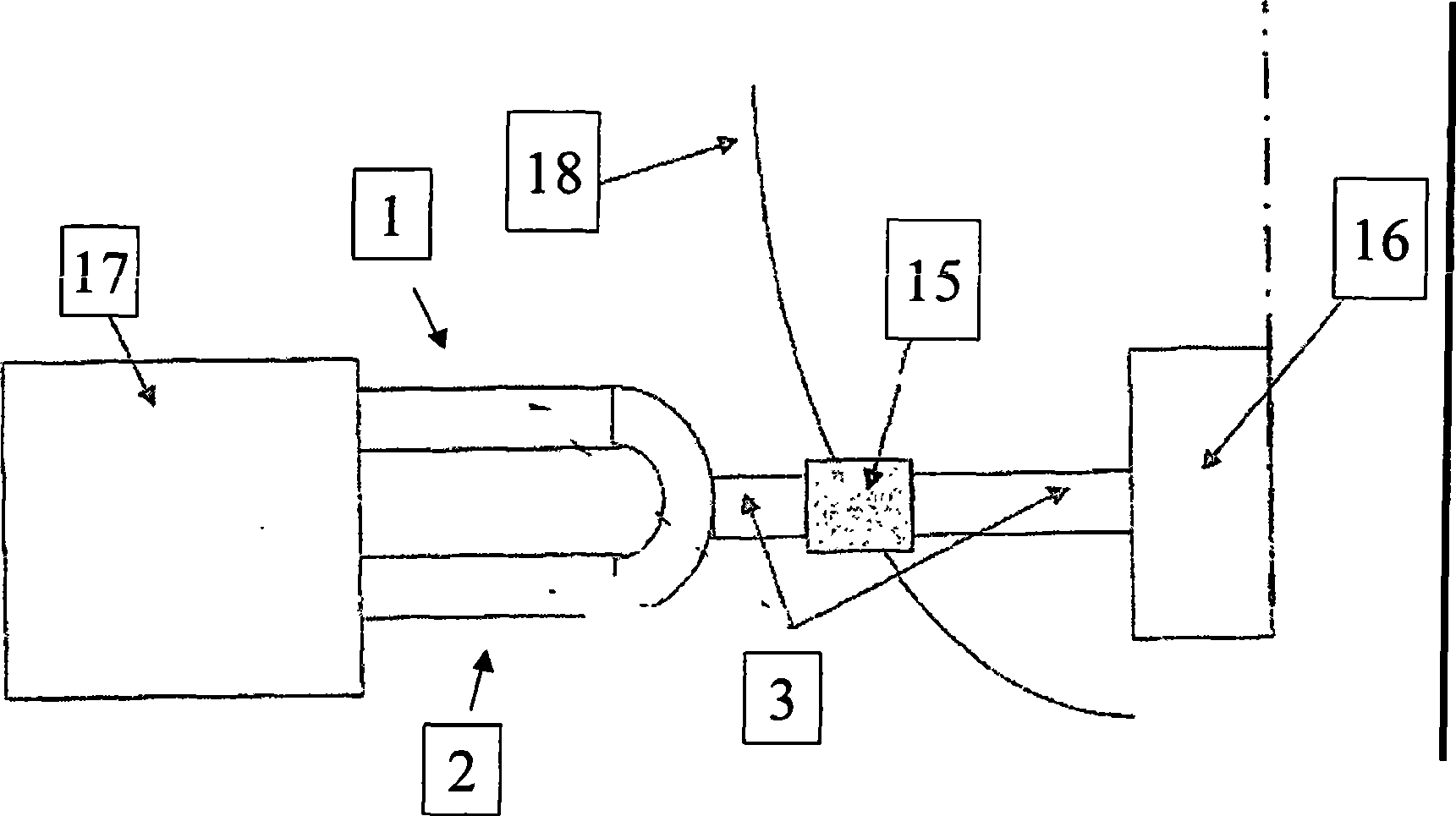

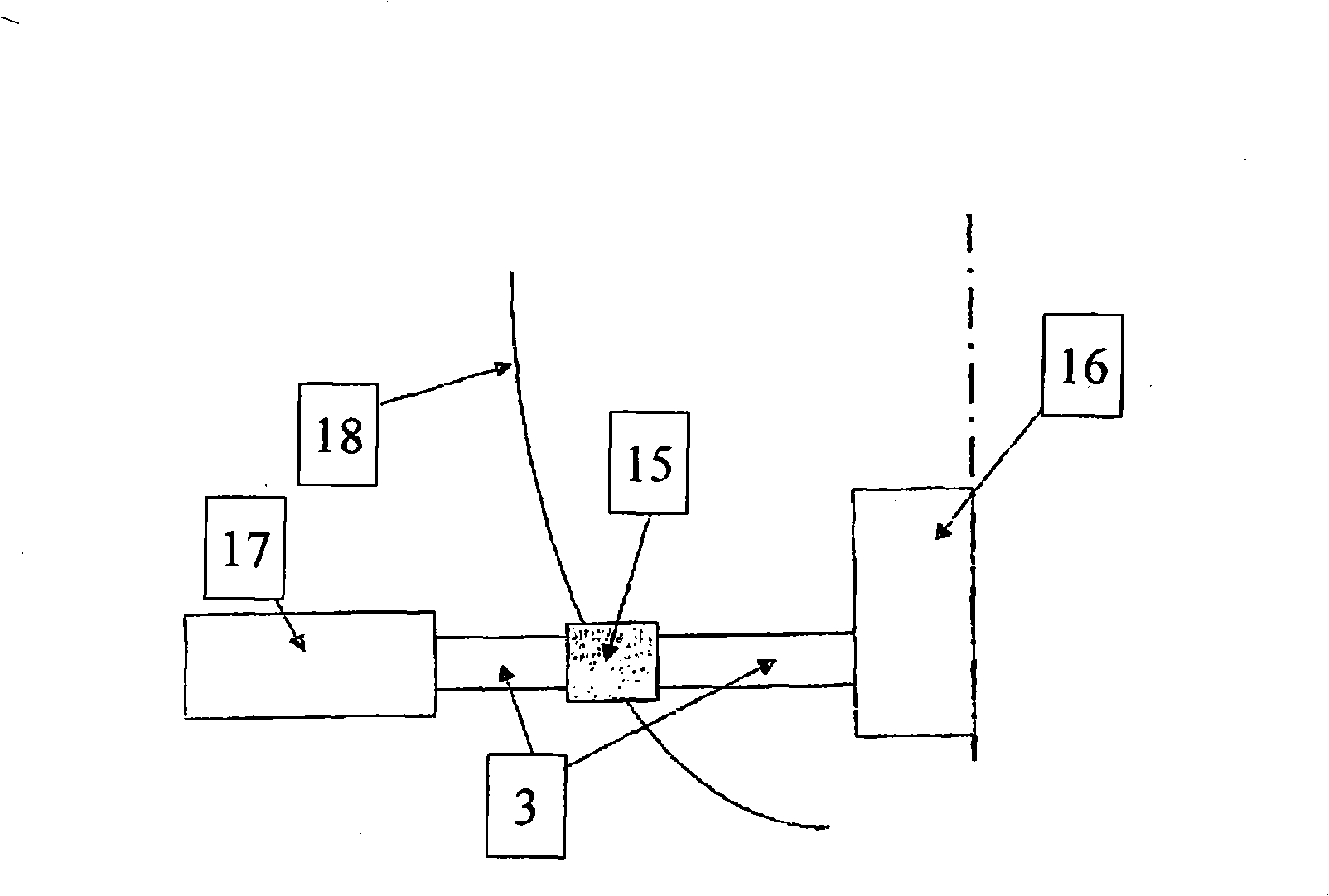

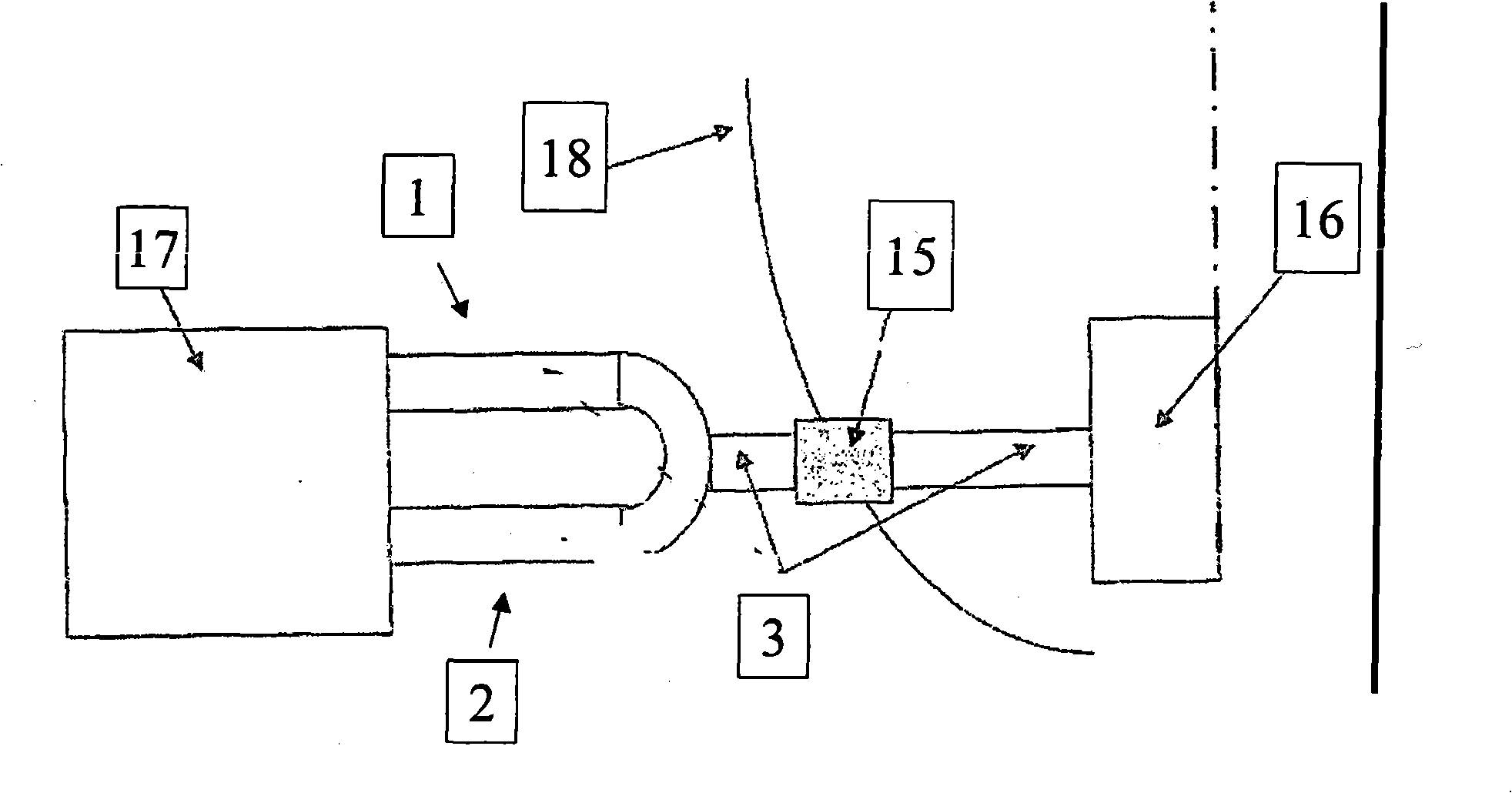

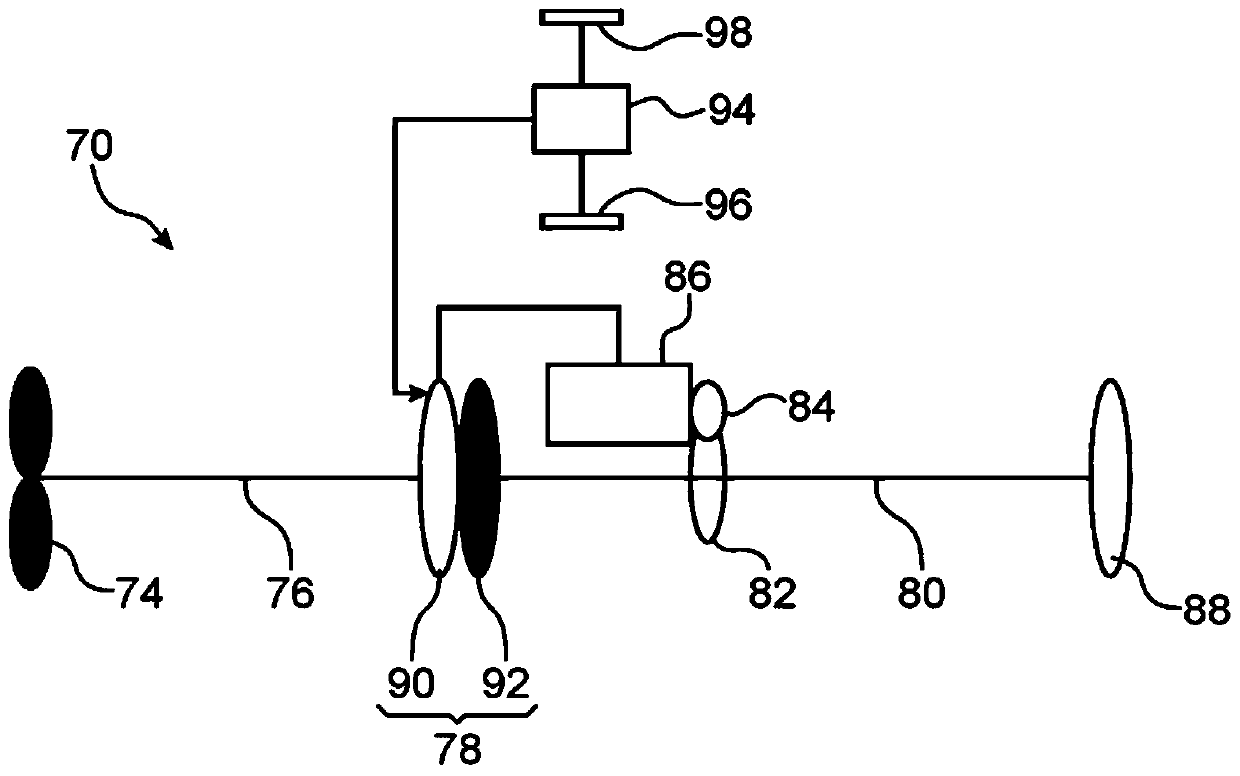

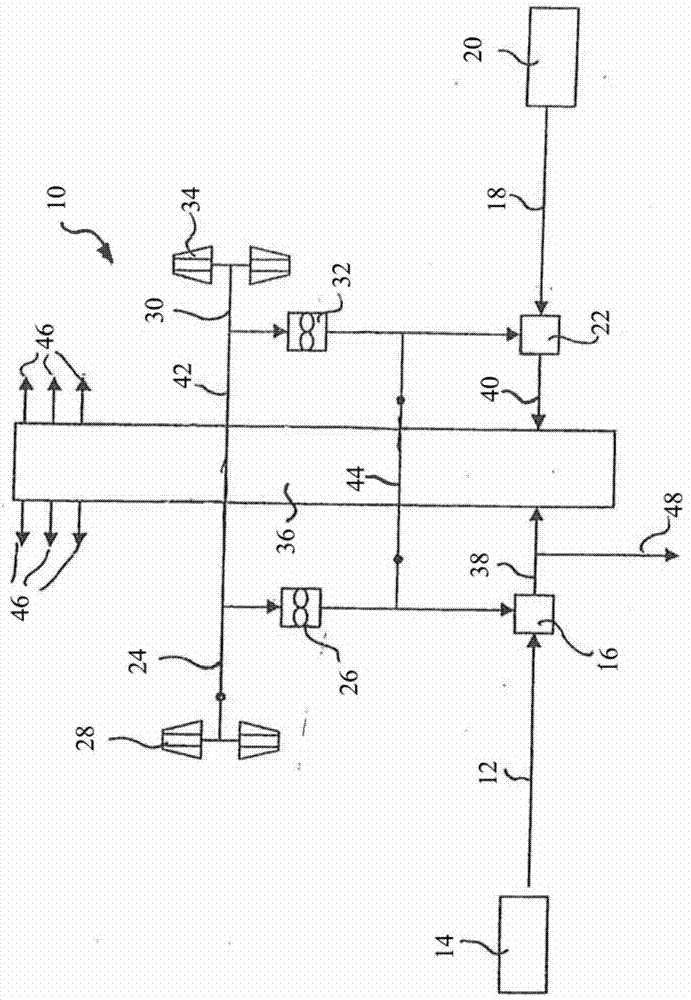

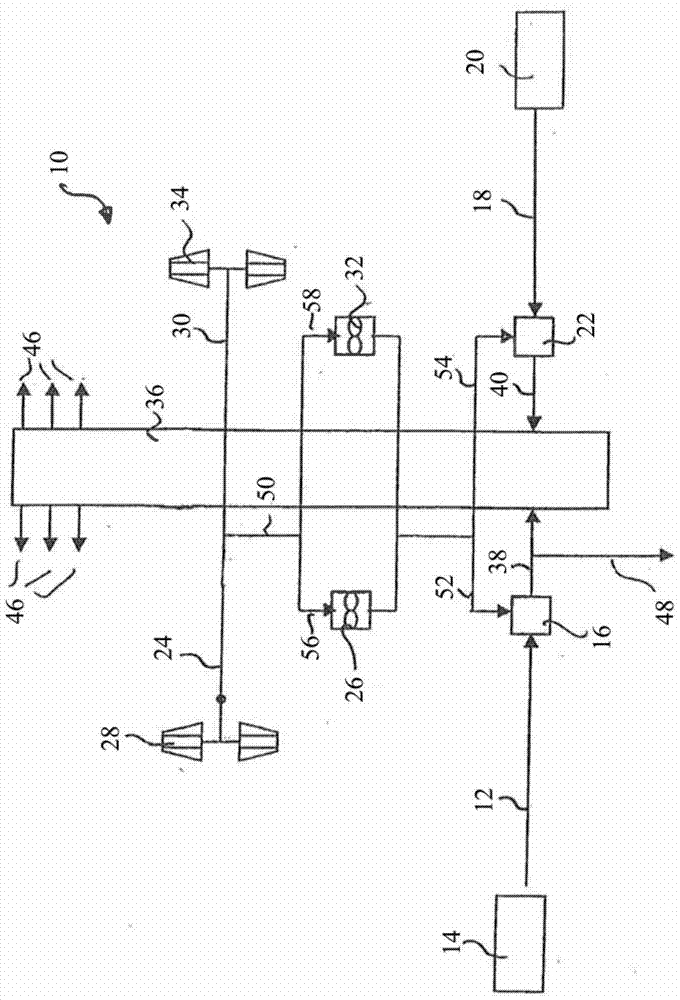

Optimized defrosting regulation of parallel arranged fresh air outlets of air conditioners

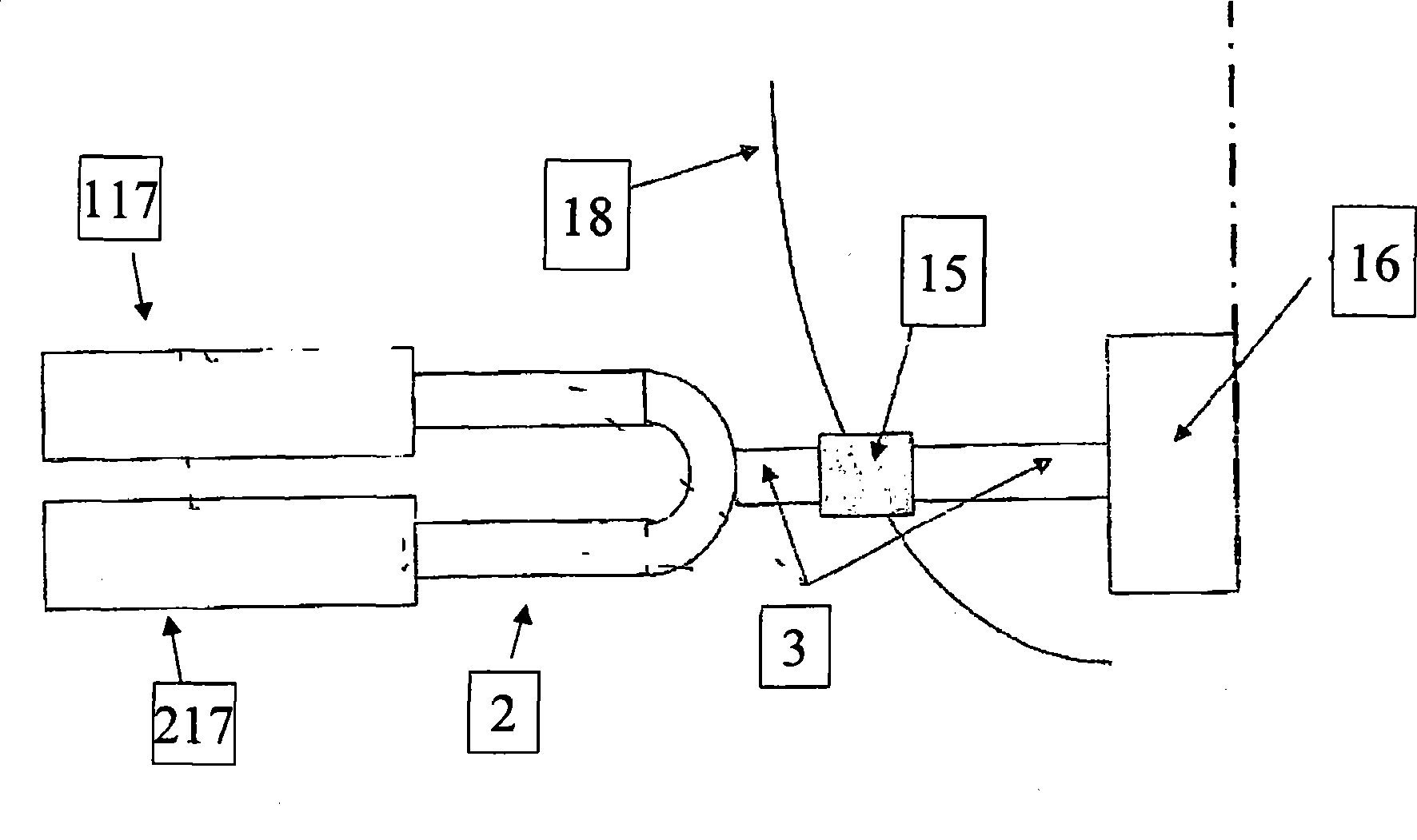

InactiveCN101522522AReduced risk of freezingPrevent freezingAir-treatment apparatus arrangementsThin material handlingFresh airBleed air

The present invention relates to an arrangement for deicing pipeline connections of an aircraft, which are connected to all fresh air outlets of an air conditioner, whose construction comprises the functions of multiple turbines and heat exchangers, having a first pipeline (1), which is connected to a first turbine (TA), and a second pipeline (2), which is connected to a second turbine (TB), the two pipelines (1, 2), which are each connected downstream from the two turbines (TA, TB) and to which process air is fed at the turbine outlets, being connected at the pipe ends and being continued using a third pipeline (3). The arrangement is characterized in that a first hot air source (11) is fed hot fresh air from a bleed air system of the aircraft and is connected at its outlet to a fourth pipeline (4), into which temperature-reduced fresh air is fed from the hot air source (11). The fourth pipeline (4) is connected at its pipe end to two further valve-regulated pipelines (5,6), of whicha fifth or a sixth pipeline (5, 6) is connected to the first or the second pipeline (1, 2), and through which temperature-reduced fresh air is transported and fed valve-regulated to the first and / or second pipeline (1, 2).

Owner:AIRBUS OPERATIONS GMBH

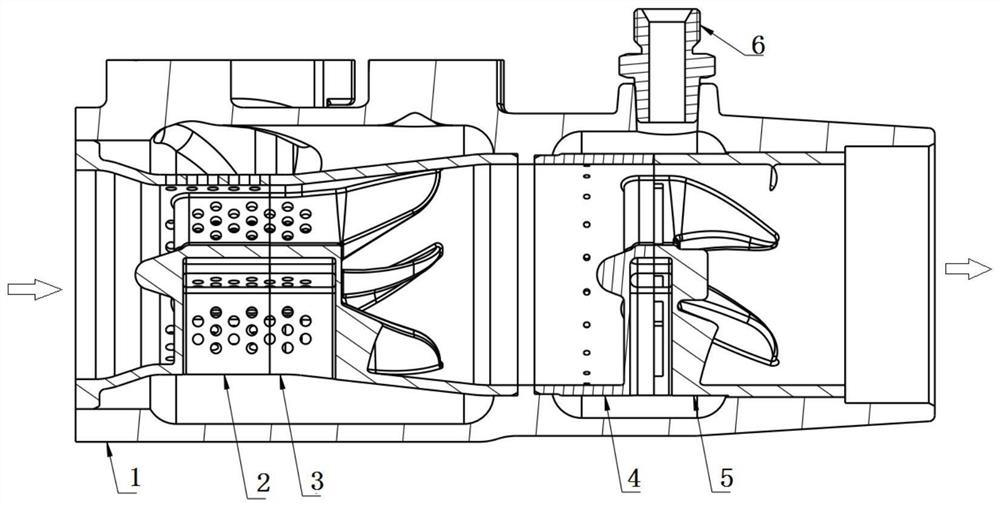

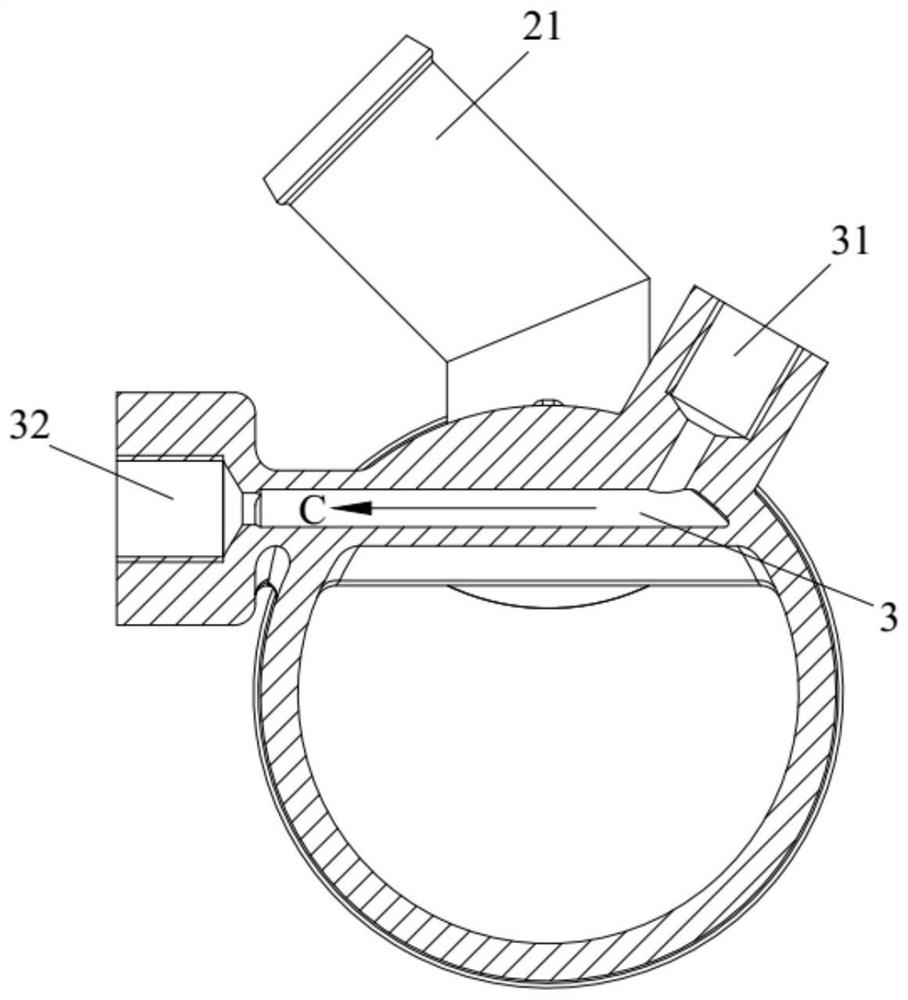

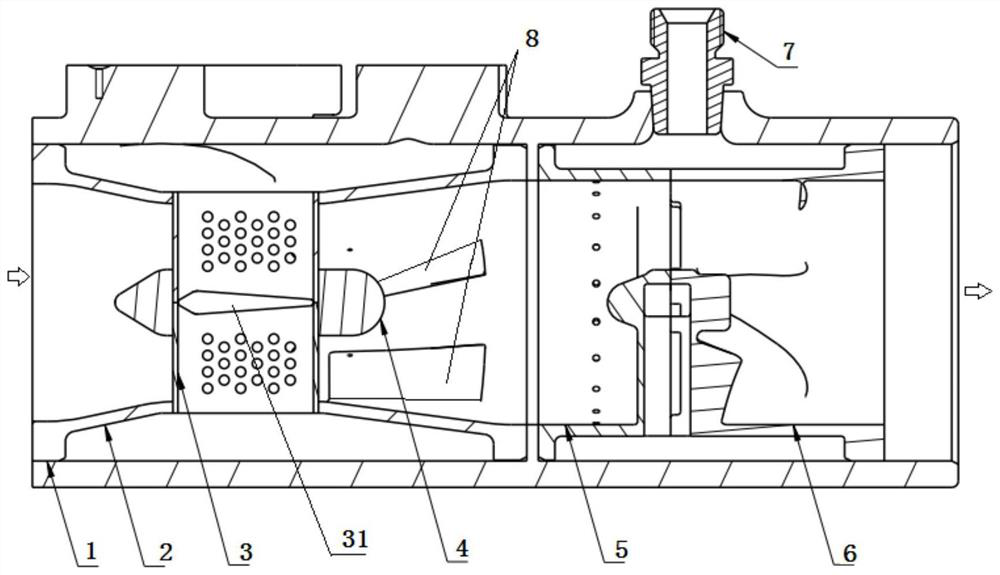

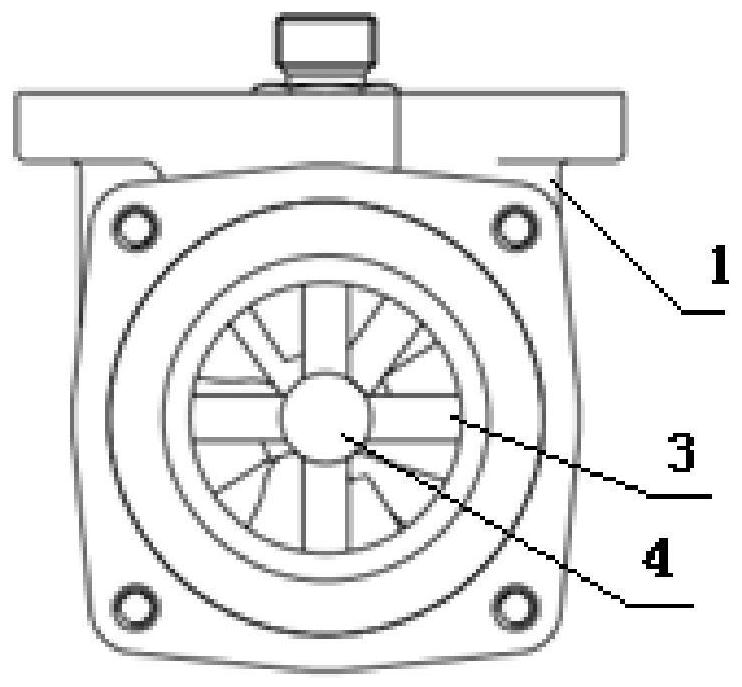

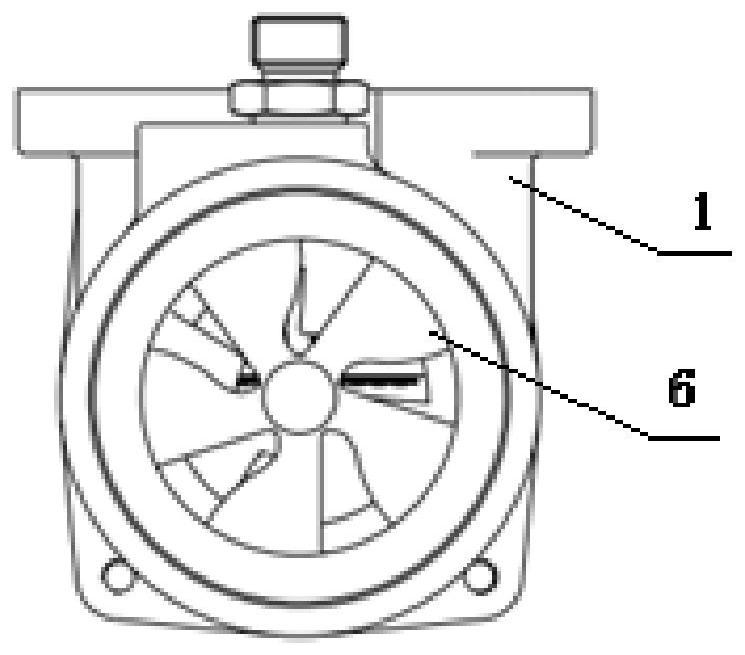

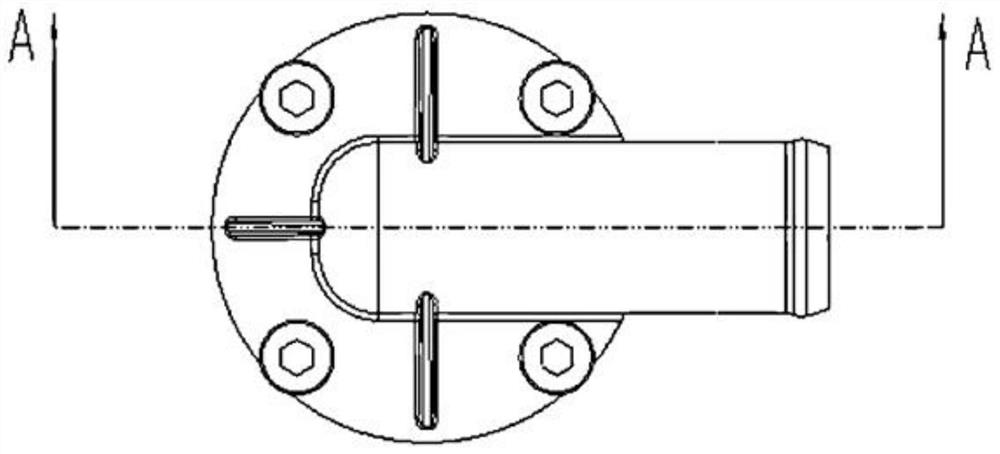

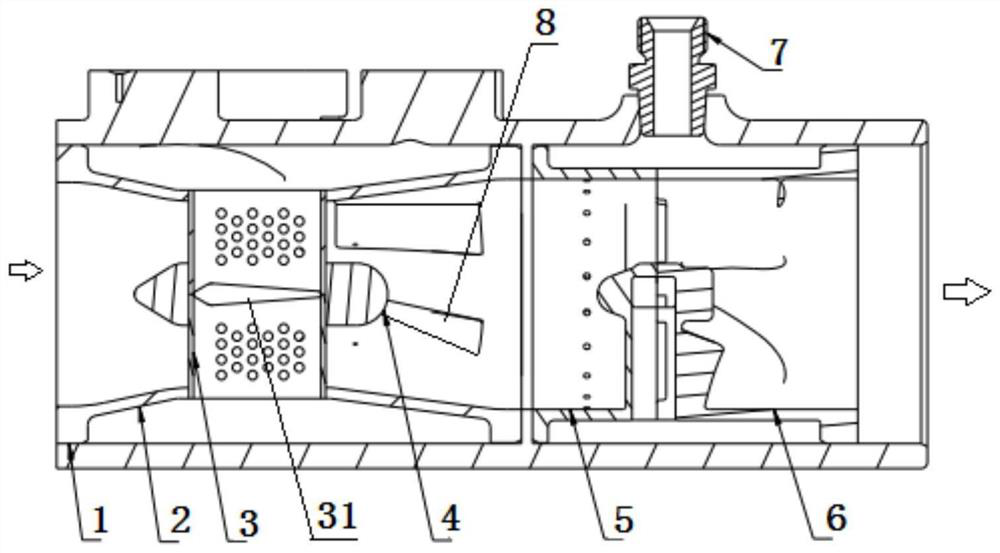

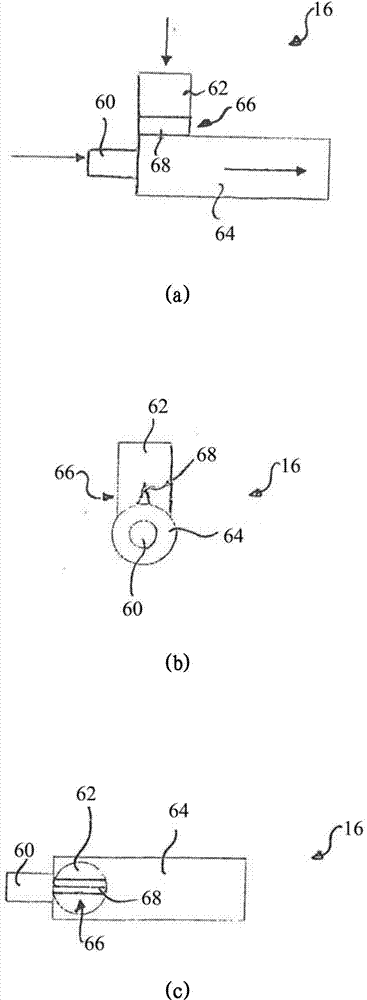

Turbulent-flow opposite-impact type Venturi integrated mixer

ActiveCN113417774AImprove mixing uniformityReduce resistanceFlow mixersExhaust gas recirculationImpellerExhaust fumes

The invention relates to a turbulent-flow opposite-impact type Venturi integrated mixer. The integrated mixer comprises an outer shell, an EGR cross beam, an EGR impeller, a natural gas cross beam and a natural gas impeller, wherein the EGR cross beam and the EGR impeller are fixed to form an EGR core with a Venturi structure; the natural gas cross beam and the natural gas impeller are fixed with the outer shell after being fixed into a whole; air enters a gas channel from an inlet, EGR waste gas passes through a wall-surface round hole of the EGR core and a central gas hole and then enters the gas channel to be mixed with the air, the flow speed of the gas is increased by means of the Venturi structure, mixing is promoted by means of the relationship between the flow speed and pressure, and the gas is subjected to primary rotating mixing after passing through the EGR impeller; and natural gas passes through a wall-surface gas hole of the natural gas cross beam and a central gas groove of the natural gas impeller and then enters the channel to be mixed with the mixed gas obtained after the primary rotating mixing, then new mixed gas is subjected to secondary rotating mixing with under the flow guide effect of the natural gas impeller, the rotating direction of the primary rotating mixing and the rotating direction of secondary rotating mixing are opposite, and mixing is promoted by sudden change of the flow direction of the gas.

Owner:DONGFENG COMML VEHICLE CO LTD

Counterflow closed cooling tower

ActiveCN103776276BReduced risk of icingReduce or eliminate white fog phenomenonHeat exchange apparatusTrickle coolersWater savingCooling tower

The invention discloses a counter-flow closed-type cooling tower, belongs to heat exchanging equipment, particularly relates to a closed-type cooling tower which is used for preventing fogging at an air outlet, and aims to provide a counter-flow closed-type cooling tower which, during winter operation, can alleviate or eliminate fogging at the air outlet and reduce the risk of ice formation at shutters of the air outlet, and is convenient to save water. The counter-flow closed-type cooling tower comprises a tower body (1), a blower (2), a water collector (3), a water distributing device, a first heat exchanger (5), filling (6), a water collecting groove (7), air inlet shutters (8), a second heat exchanger (9), and a main water collecting pipe (42), wherein the water distributing device comprises a plurality of water distributing pipes (41); all the water distributing pipes are distributed in the tower from the middle to two sides in parallel to one another, or are distributed in the tower from the center to the periphery; a plurality of water distributing nozzles (411) are arranged on the side wall below the water distributing pipes; each water distributing pipes is connected with the main water collecting pipe through a flow rate adjustable valve (4).

Owner:YANTAI EBARA AIR CONDITIONER +1

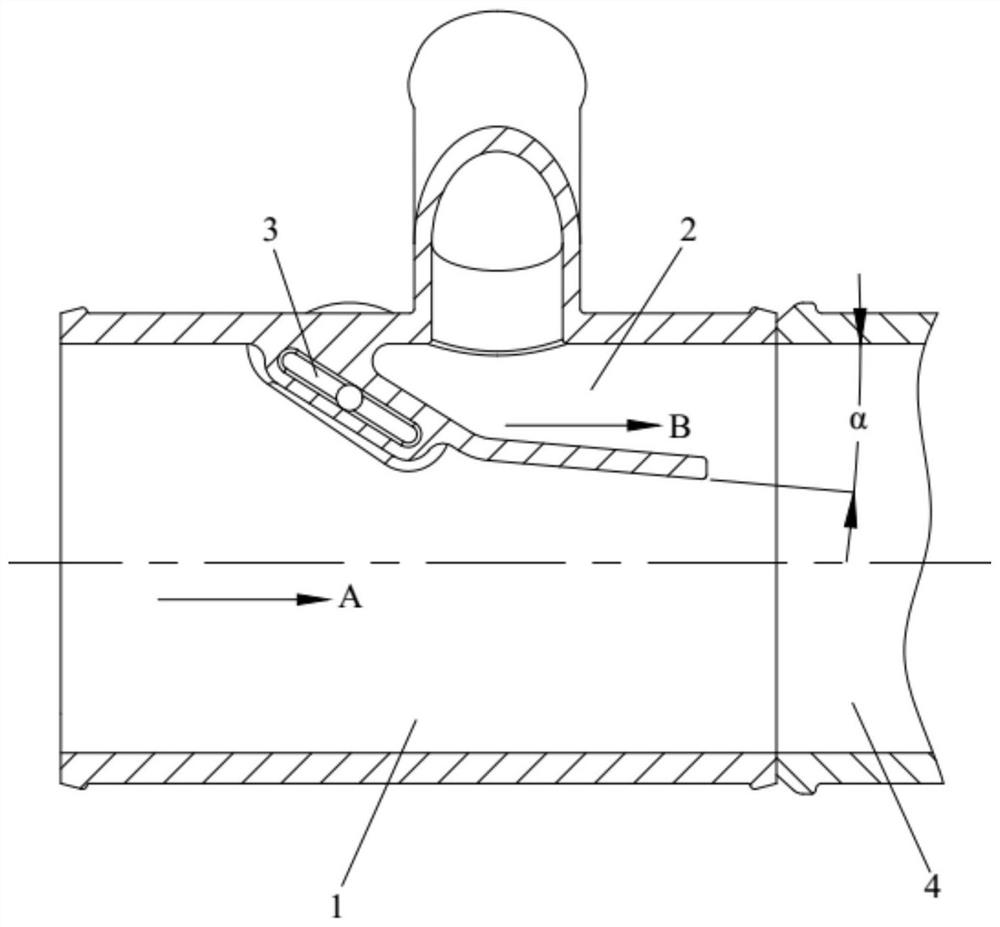

Supercharger air inlet connecting pipe and engine

InactiveCN111927593ASimple structurePrevent freezingMachines/enginesCrankcase ventillationExhaust fumesEngineering

The invention discloses a supercharger air inlet connecting pipe and an engine, and belongs to the technical field of automobiles. The supercharger air inlet connecting pipe comprises a first passagefor air circulation and a second passage, a first inlet for air inflow and a first outlet for air outflow are formed in the first passage, the first outlet is connected with a supercharger air inlet,and the inner diameter of the first outlet is the same as that of the turbocharger air inlet; and the second passage is used for the exhaust gas circulation in a crankcase, the second passage communicates with the supercharger, the second passage and the first passage are arranged at intervals, and an inclination angle alpha is arranged between the wall surface, close to the first passage, of thesecond passage and the horizontal direction, a third passage for the circulation of cooling water in the engine is arranged on the peripheral wall of the second passage, and the third passage is usedfor the peripheral wall walling of the second passage. The supercharger air inlet connecting pipe has the advantages of avoiding icing in the turbocharger air inlet connecting pipe, and has the characteristics of simple structure.

Owner:FAW JIEFANG AUTOMOTIVE CO

Efficient spraying equipment for indoor and outdoor decoration construction

InactiveCN114016710AReduced risk of icingReduce harmBuilding constructionsLiquid spraying apparatusCold weatherScrew thread

The invention discloses efficient spraying equipment for indoor and outdoor decoration construction. The equipment comprises a base and a stirring bin, wherein a fixing block is fixedly installed at the center position of a top face of the base, the stirring bin is arranged above the fixing block, threaded grooves are formed in surfaces of the two sides of the fixing block, and handle bolts are in threaded connection with the interiors of the threaded grooves; a feeding hole is fixedly formed in one side of a top surface of the stirring bin, and a mounting shell is arranged on a top surface of the feeding hole. The paint spraying device is advantaged in that the paint can be filtered through a filter screen, the influence of impurities on the spraying effect is reduced, a purpose of heating the paint in severe cold weather can be achieved by arranging a heating plate, the risk that the paint is frozen in the severe cold weather is reduced, and the movable stirring bin is arranged, difficulty of vertical carrying in the multi-storey house is reduced, labor intensity of equipment carrying is relieved, a wall surface can be polished before spraying by arranging a polishing piece, and the friction force between the coating and the wall surface is increased.

Owner:九江立帆科技有限公司

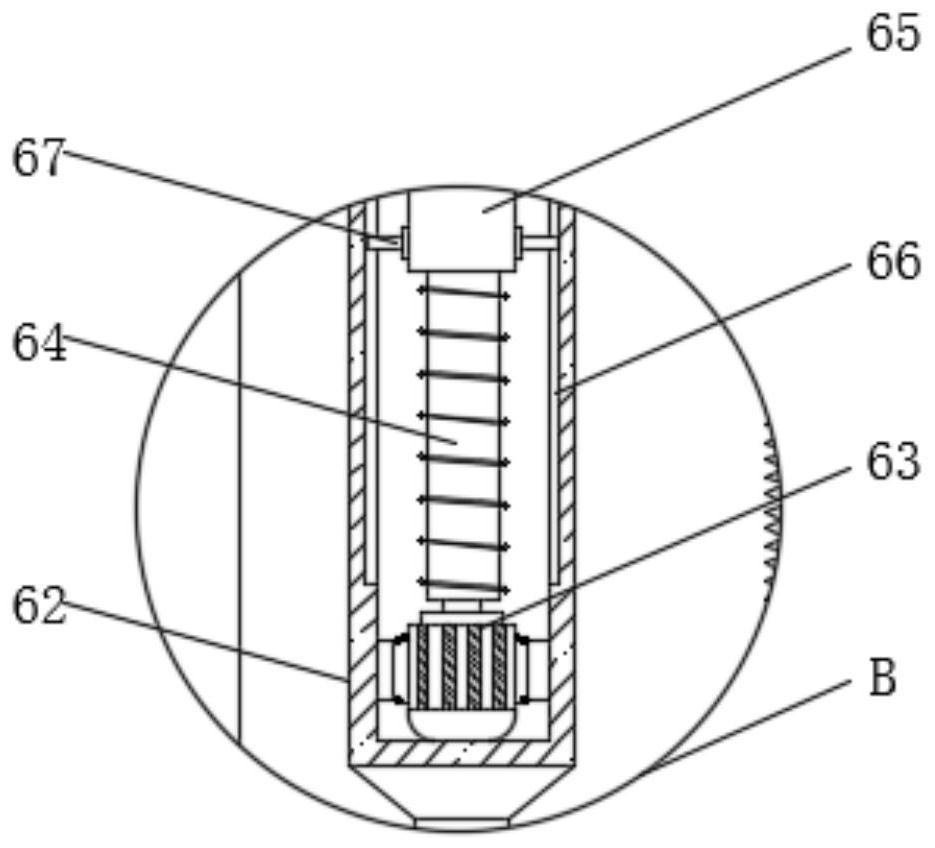

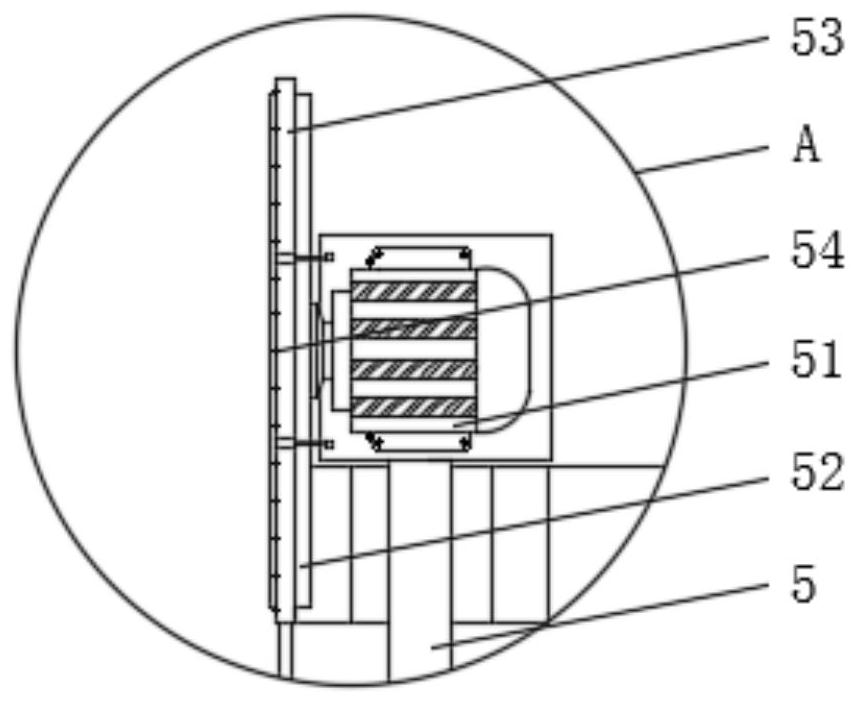

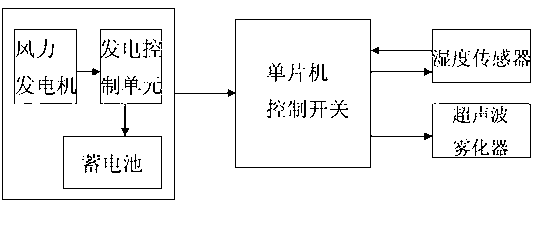

Ultrasonic anti-freezing device of power transmission tower

The invention discloses an ultrasonic anti-freezing device of a power transmission tower, comprising a wind generating set, a humidity sensor, a single chip microcomputer control switch and an ultrasonic atomizer, wherein the wind generating set is electrically connected with the ultrasonic atomizer by the single chip microcomputer control switch; the humidity sensor is electrically connected with the single chip microcomputer control switch; the wind generating set comprises a wind generator, a generating control unit and a storage battery; and the generating control unit is respectively and electrically connected with the wind generating set and the storage battery. The ultrasonic anti-freezing device disclosed by the invention has the beneficial effects that (1) the working of a high-altitude wind generating system is relatively stable, and continuous power supply can be provided; and (2) the ultrasonic atomizer is combined with the humidity sensor for use, so that no collection of excessive water on the surface of the power transmission tower is effectively ensured and the icing risk of a steel structure of the power transmission tower is reduced.

Owner:STATE GRID CORP OF CHINA +1

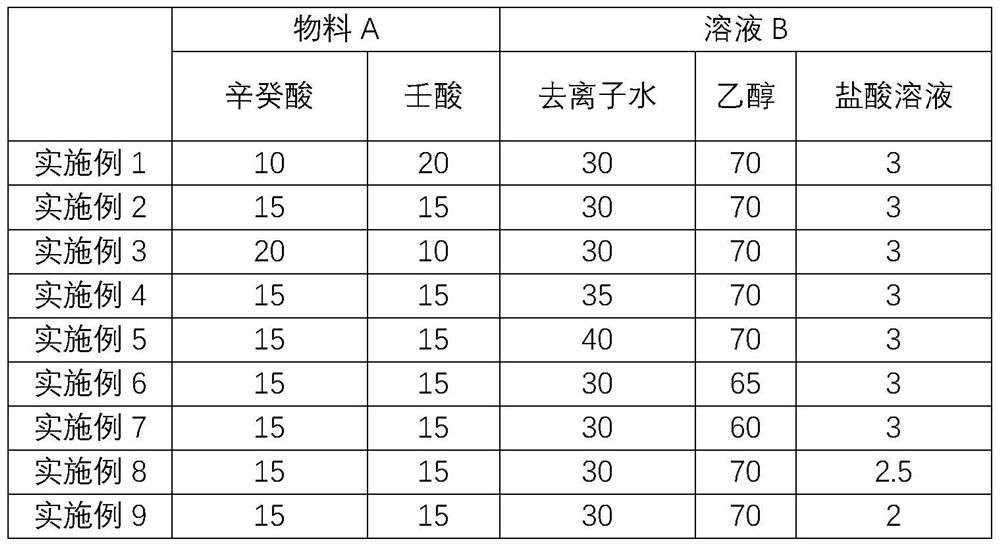

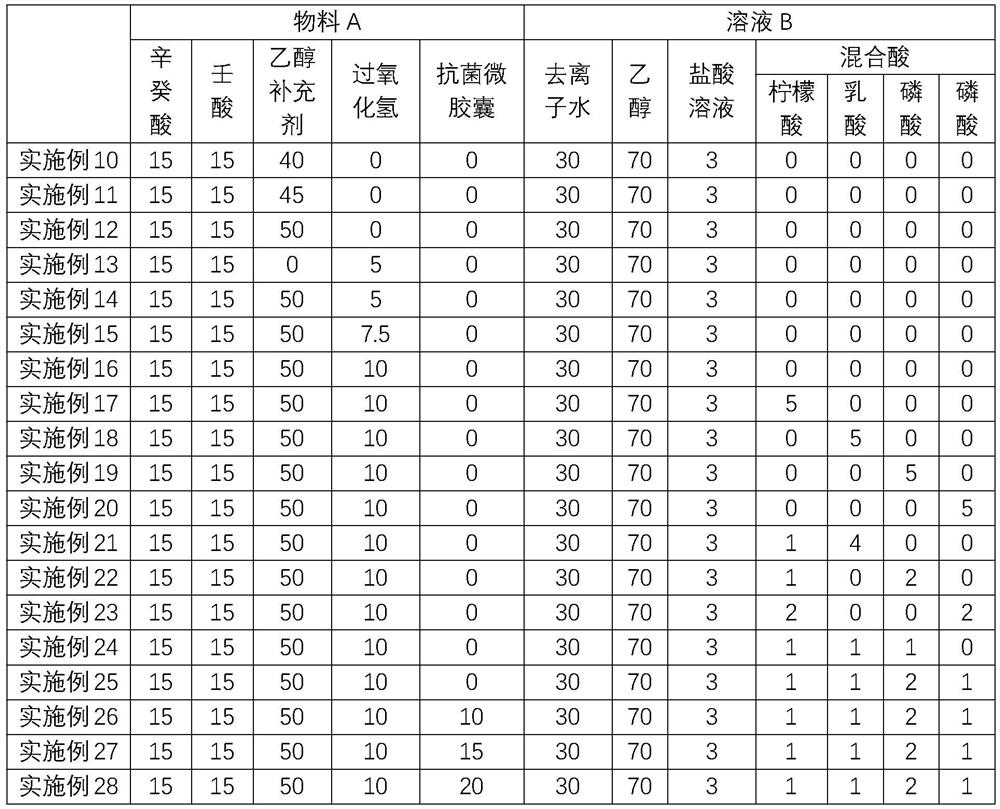

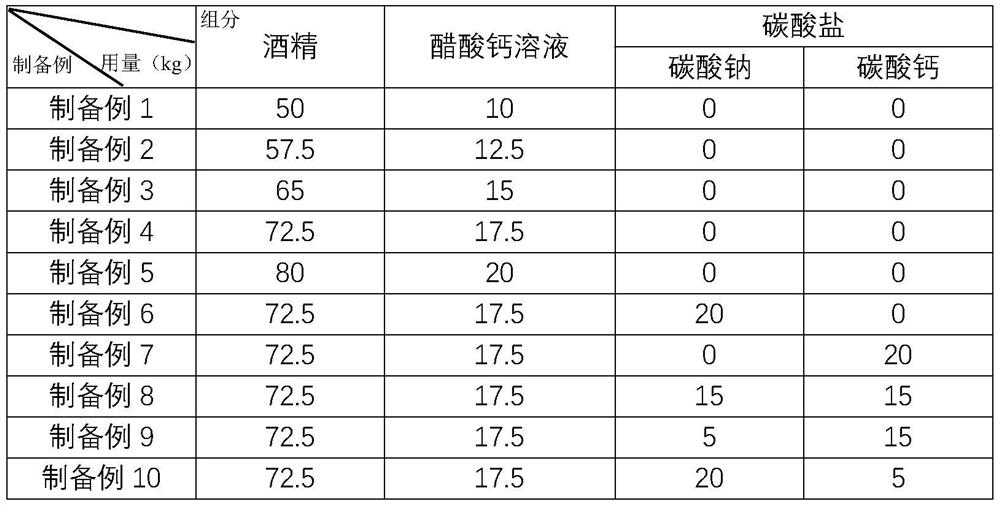

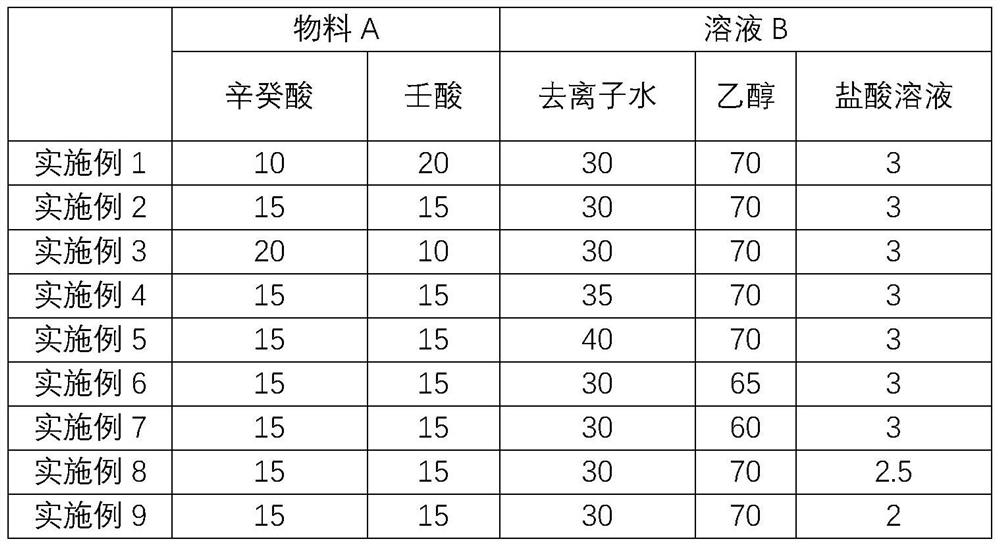

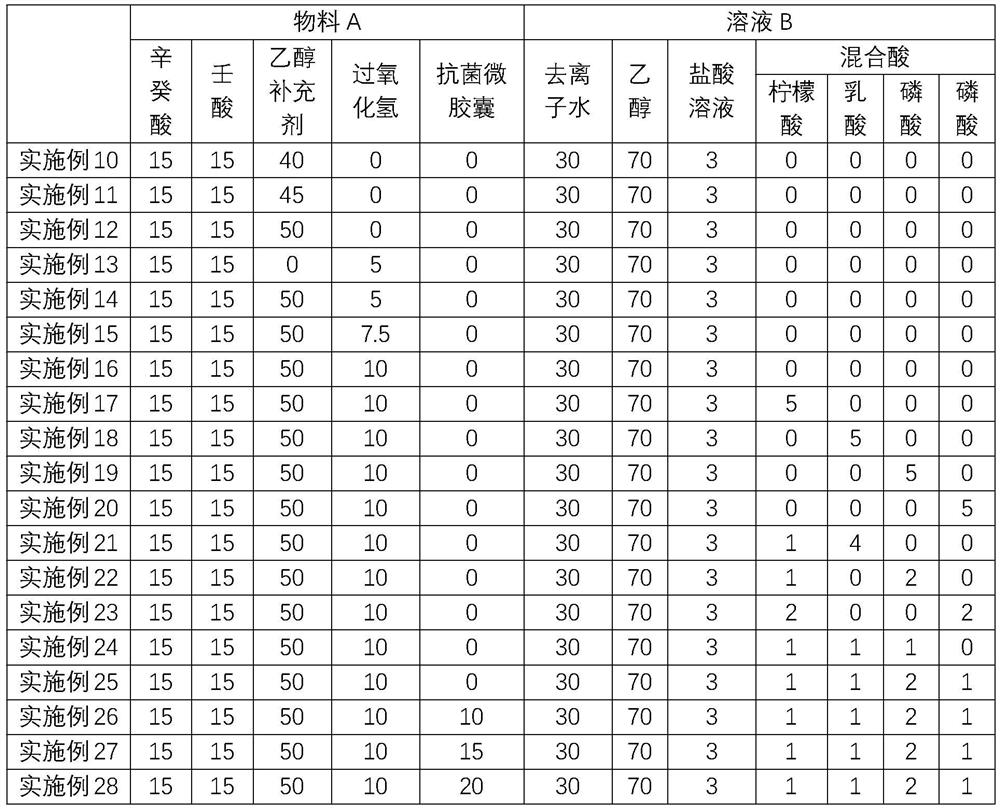

Ultralow-temperature-resistant disinfectant

ActiveCN113396940AReduced risk of icingImprove adaptabilityBiocideDisinfectantsNonanoic acidEnvironmental engineering

The invention discloses an ultralow-temperature-resistant disinfectant, and relates to the technical field of disinfectants. The ultralow-temperature-resistant disinfectant is obtained by mixing and stirring a material A and a solution B. The material A comprises the following components in parts by weight: 10-20 parts of octocapric acid and 10-20 parts of nonanoic acid. The solution B comprises the following components in parts by weight: 30-40 parts of deionized water, 60-70 parts of ethanol and 2-3 parts of a hydrochloric acid solution with the mass percent of 30%. The application has the effect of improving the applicability of the disinfectant in an ultralow-temperature environment.

Owner:杭州龙能科技有限公司

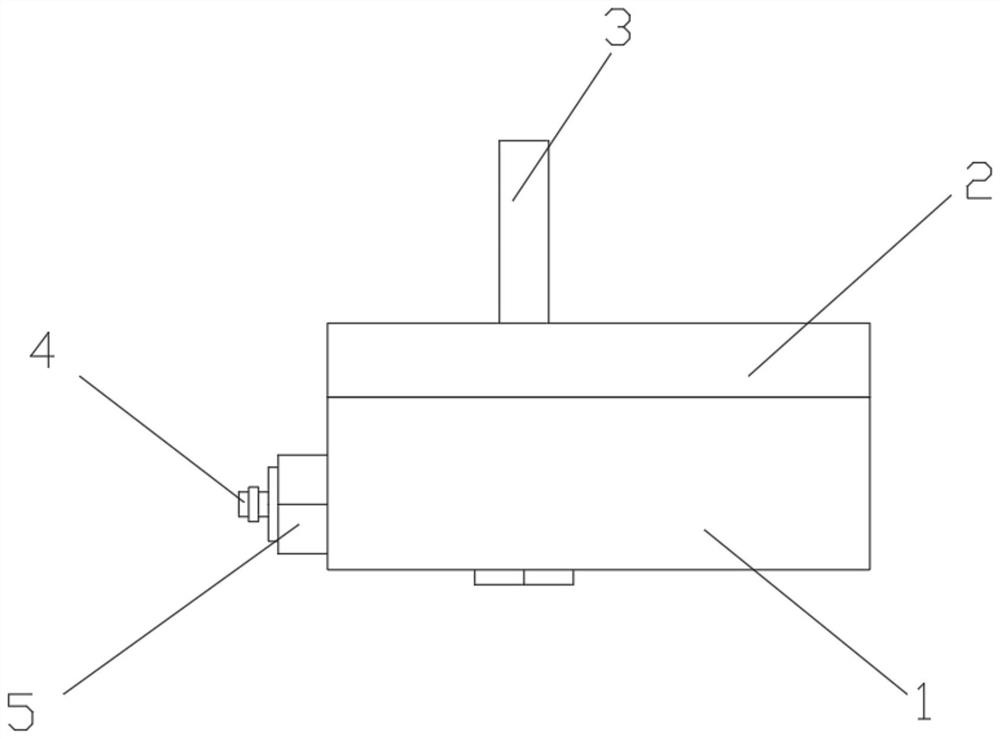

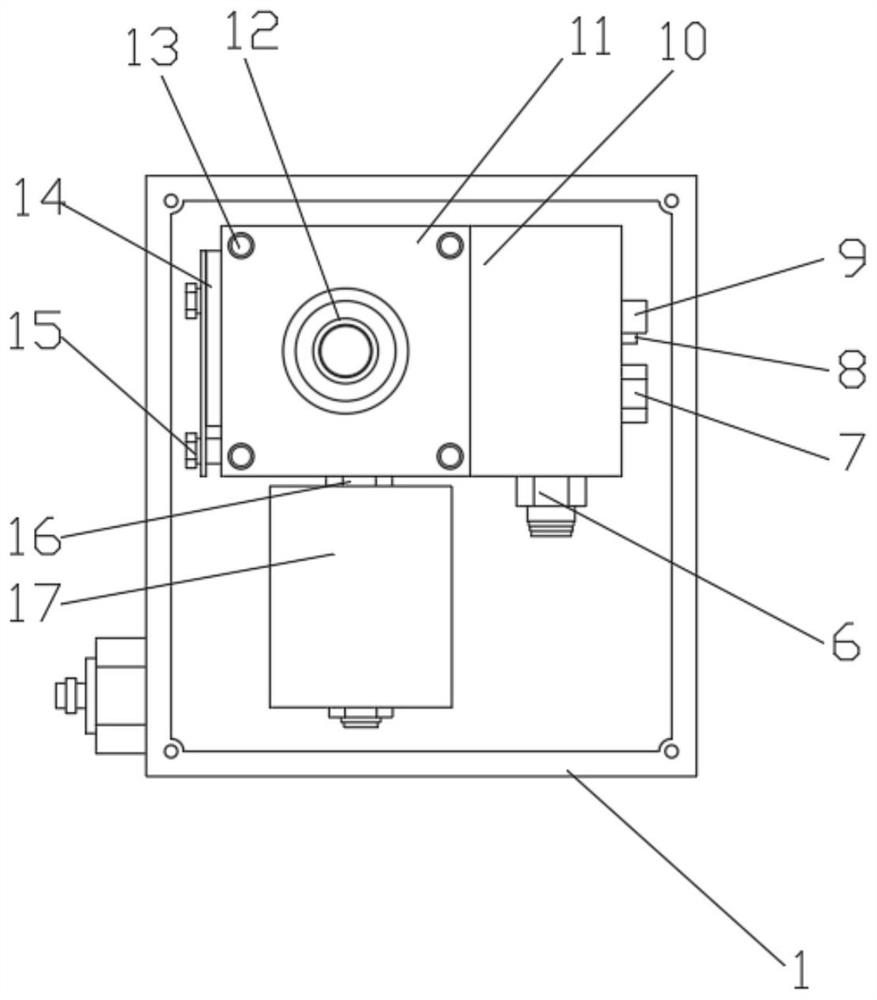

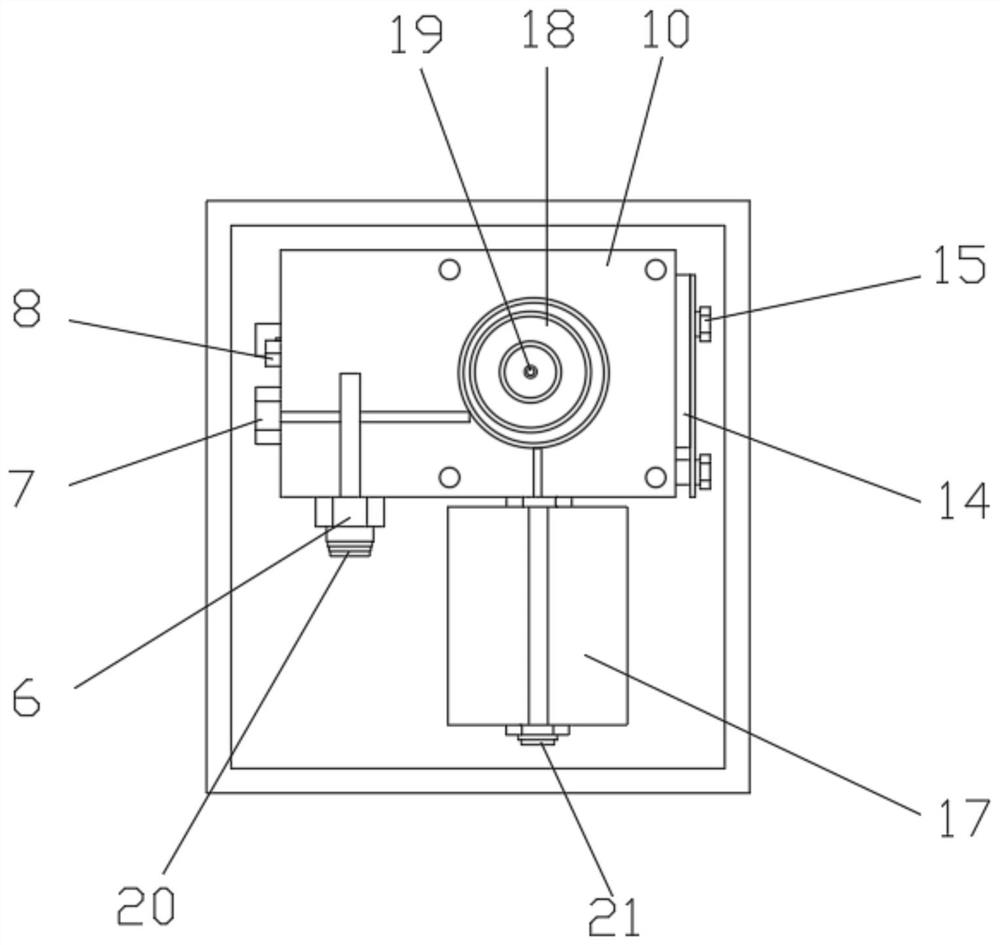

An intelligent sewage discharge system of an air storage tank and its control method

ActiveCN112066069BReduced risk of icingAvoid damageOperating means/releasing devices for valvesAir treatment devicesWater storageElectronic controller

The invention discloses an intelligent sewage discharge system for an air storage tank and a control method thereof, which comprises a control switch, an electronic controller and an intelligent drain valve. The intelligent drain valve includes a protective box and a protective cover, and the protective box is fixed inside There is a water storage box, one side of the water storage box is fixed with a heating sheet, the other side of the water storage box is fixed with a temperature sensor and a humidity sensor, and the side of the water storage box away from the protective box is provided with a connection plate and a pressure sensor, the side of the connecting plate away from the water storage box is fixedly connected with a solenoid valve, the upper side of the water storage box is fixedly connected with a water storage box cover, and the center of the water storage box cover is provided with a second Two connecting bolts; the present invention sets a temperature sensor and a heating plate in the intelligent drain valve to reduce the risk of freezing of the air path; the present invention is simple to install, easy to disassemble, and convenient for maintenance and slag discharge.

Owner:ANHUI ANKAI AUTOMOBILE

Wall diversion hedging Venturi integrated mixer

ActiveCN113417771BImprove mixing uniformityWell mixedInternal combustion piston enginesFlow mixersImpellerEngineering

The invention relates to a wall diversion hedging type Venturi integrated mixer, the integrated mixer includes a shell, an EGR core, a cross arm, a fixed pin, a natural gas beam and a natural gas impeller, the air enters the air channel from the inlet, and the EGR The exhaust gas passes through the round hole on the wall of the EGR core and the air hole in the center of the cross arm in turn, and then enters the air channel to mix with the air. The Venturi structure formed in the EGR core is used to increase the gas flow rate, and the mixing is promoted by the relationship between the flow rate and the pressure; the EGR core A wall deflector is added at the flaring of the Venturi structure inside to make the gas undergo primary rotation and mixing; the natural gas passes through the round hole on the wall surface of the natural gas beam and the central gas groove of the natural gas impeller in sequence, and then enters the gas channel to be mixed with the mixed gas for a second rotation. The rotation direction of the primary rotation mixing is opposite to that of the secondary rotation mixing. The mixed gas mixed in the primary rotation is reversely disturbed by the natural gas impeller, and the hedging is used to promote the mixing. At the same time, a rotating air flow is formed to improve the mixing uniformity.

Owner:DONGFENG COMML VEHICLE CO LTD

Closed crankcase ventilation systems for heavy-duty engine systems and heavy-duty engine systems

ActiveCN111636949BReduce the burden onReduce the risk of failureMachines/enginesCrankcase ventillationThermodynamicsFresh air

The invention provides a closed crankcase ventilation system of a heavy-duty engine system and the heavy-duty engine system. The closed crankcase ventilation system includes at least one engine head cover, each of said engine head covers being disposed on a respective engine head of a heavy-duty engine system, the interior of each said engine head cover being A first oil-gas separator is integrated, which is used for preliminary separation of the high-temperature oil gas entering the crankcase after combustion in the engine cylinder or the mixed oil-gas mixed with the high-temperature oil gas and fresh air; the second oil-gas separator, the The second oil-gas separator communicates with each of the first oil-gas separators, and is used to re-separate the oil and gas that has been initially separated by the first oil-gas separator, and the gas outlet of the second oil-gas separator is connected to the intake pipeline of the engine connected. The proposal of the invention can reduce the risk of failure of the second oil-gas separator, and improve the effect of uneven gas supply inside the large crankcase of the heavy-duty engine.

Owner:ZHEJIANG GEELY NEW ENERGY COMML VEHICLES CO LTD +3

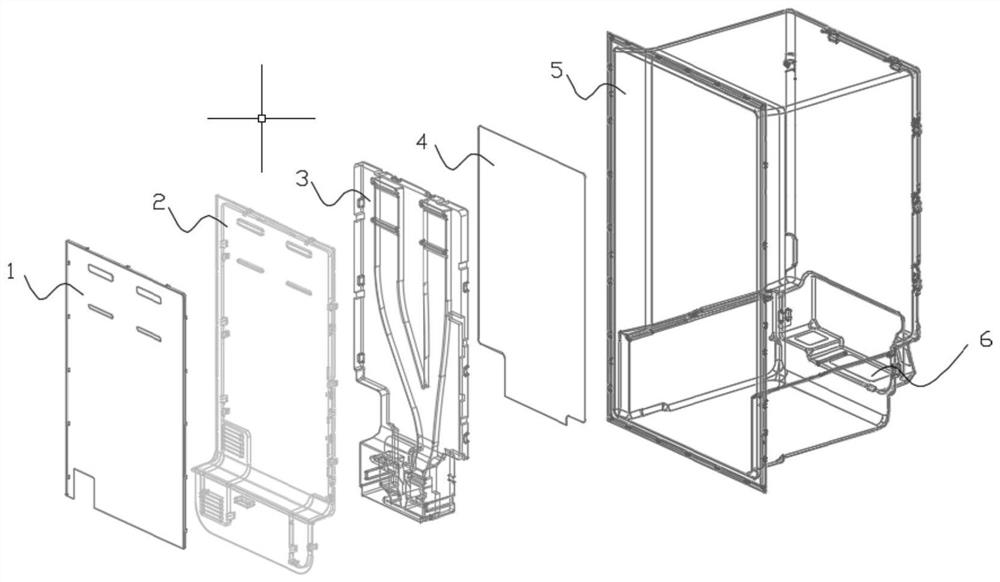

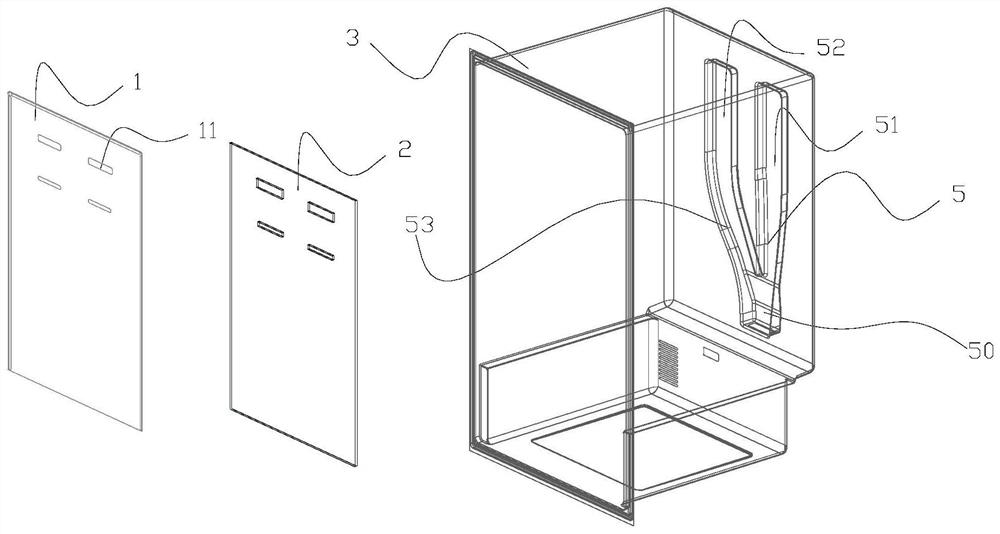

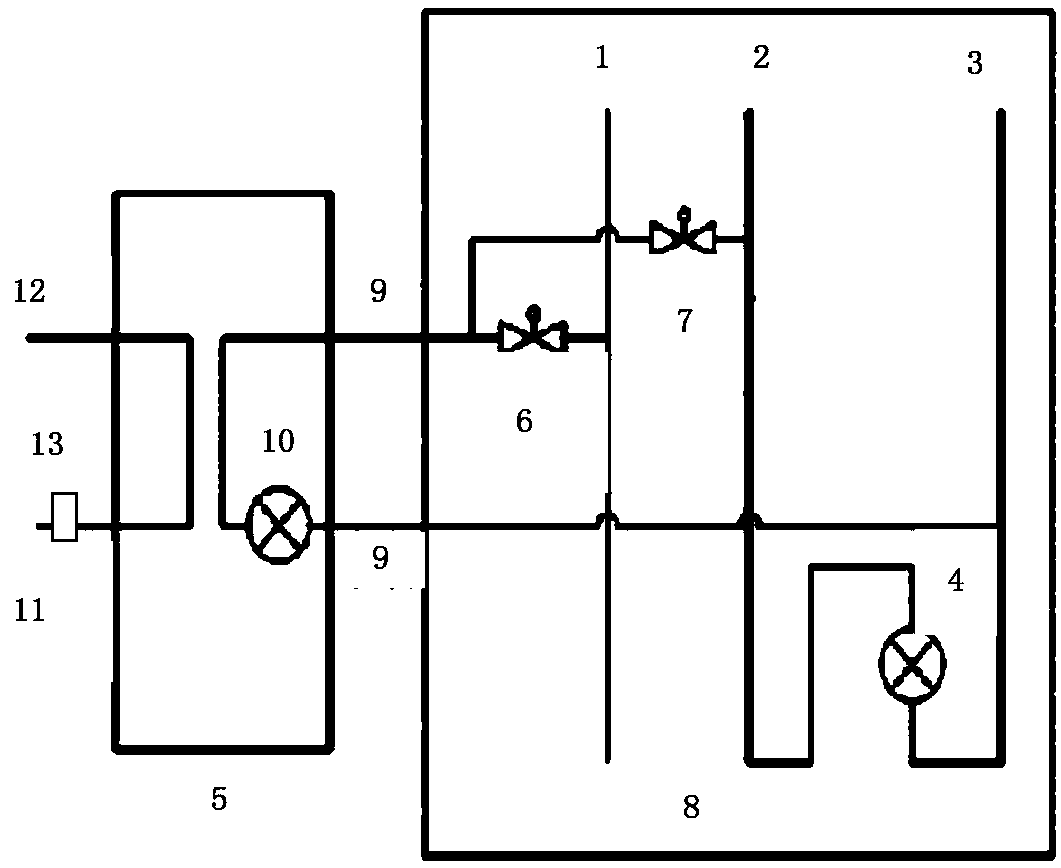

Refrigerator air duct structure, refrigerator refrigeration air duct, refrigerator freezing air duct and refrigerator

PendingCN113137817AEasy to operateReduced risk of icingLighting and heating apparatusDomestic refrigeratorsCold airIcebox

The invention relates to the technical field of refrigerators and manufacturing thereof, in particular to a refrigerator air duct structure, a refrigerator refrigeration air duct, a refrigerator freezing air duct and a refrigerator. The refrigerator air duct structure is enclosed by a groove integrally formed in a refrigerator liner and a cover plate covering the groove, wherein the groove is communicated with an air supply duct, the groove comprises a main groove and a plurality of branch grooves communicated with the main groove, and the branch grooves are formed in the refrigerator liner at intervals; and the cover plate is provided with a through hole for allowing cold air to flow into a refrigerator body of the refrigerator. The refrigerator air duct structure is naturally formed through the cover plate and a plastic uptake groove of the refrigerator liner, assembly components of the refrigeration air duct and the freezing air duct are reduced, the operation steps are simple during air duct assembly, the in-box splicing operation of a traditional air duct and an air outlet is omitted, cold leakage caused by poor sealing is reduced, and the risk of freezing of the bottom of a refrigerating chamber and a freezing chamber is reduced.

Owner:安徽蓝界智能家电有限公司

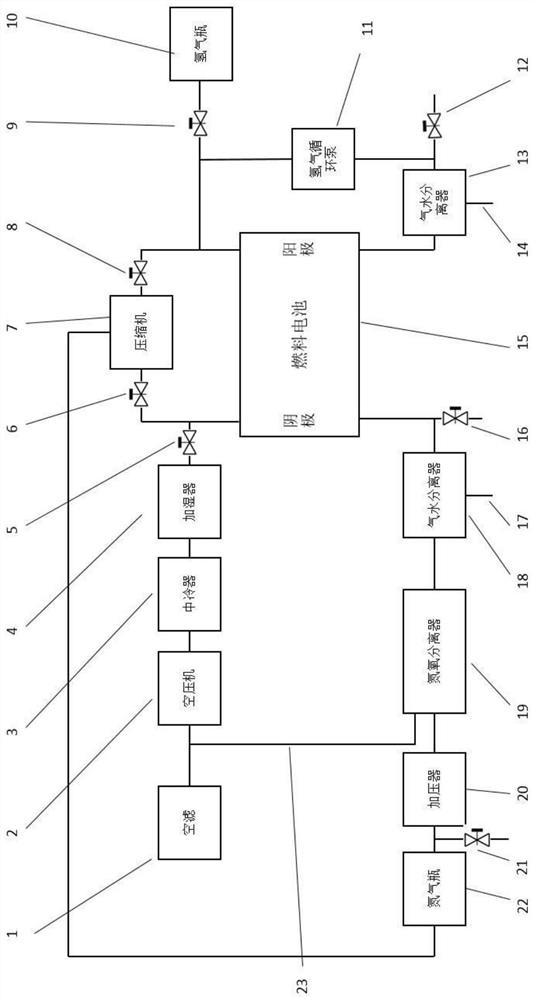

A vehicle fuel cell tail gas nitrogen production system and its purging method

ActiveCN112242545BImprove work performanceWork lessFinal product manufactureWater management in fuel cellsAir filterNew energy

Owner:BEIJING NEW ENERGY VEHICLE TECH INNOVATION CENT CO LTD

Optimized defrosting regulation of parallel arranged fresh air outlets of air conditioners

InactiveCN101522522BKeep the temperature constantStable temperatureAir-treatment apparatus arrangementsThin material handlingFresh airEngineering

The arrangement has pipelines (1, 2) connected to turbines (Ta, Tb), and arranged downstream from the turbines. An outlet of a heat exchanger (11) is connected to a pipeline (4), and feeds temperature-reduced fresh air to the pipeline (4). Pipe ends of valve-regulated pipelines (5, 6) are connected to each other. Temperature in a pipeline (3) is permanently kept above 0 degree Celsius. A pipe line (5) or a pipeline (6) is connected to the pipeline (1) or the pipeline (2) for transporting and fed valve regulating the temperature-reduced fresh air to the pipelines (1, 2). An independent claim is also included for a method for regulating a process air temperature of transported process air in pipeline connections of an aircraft.

Owner:AIRBUS OPERATIONS GMBH

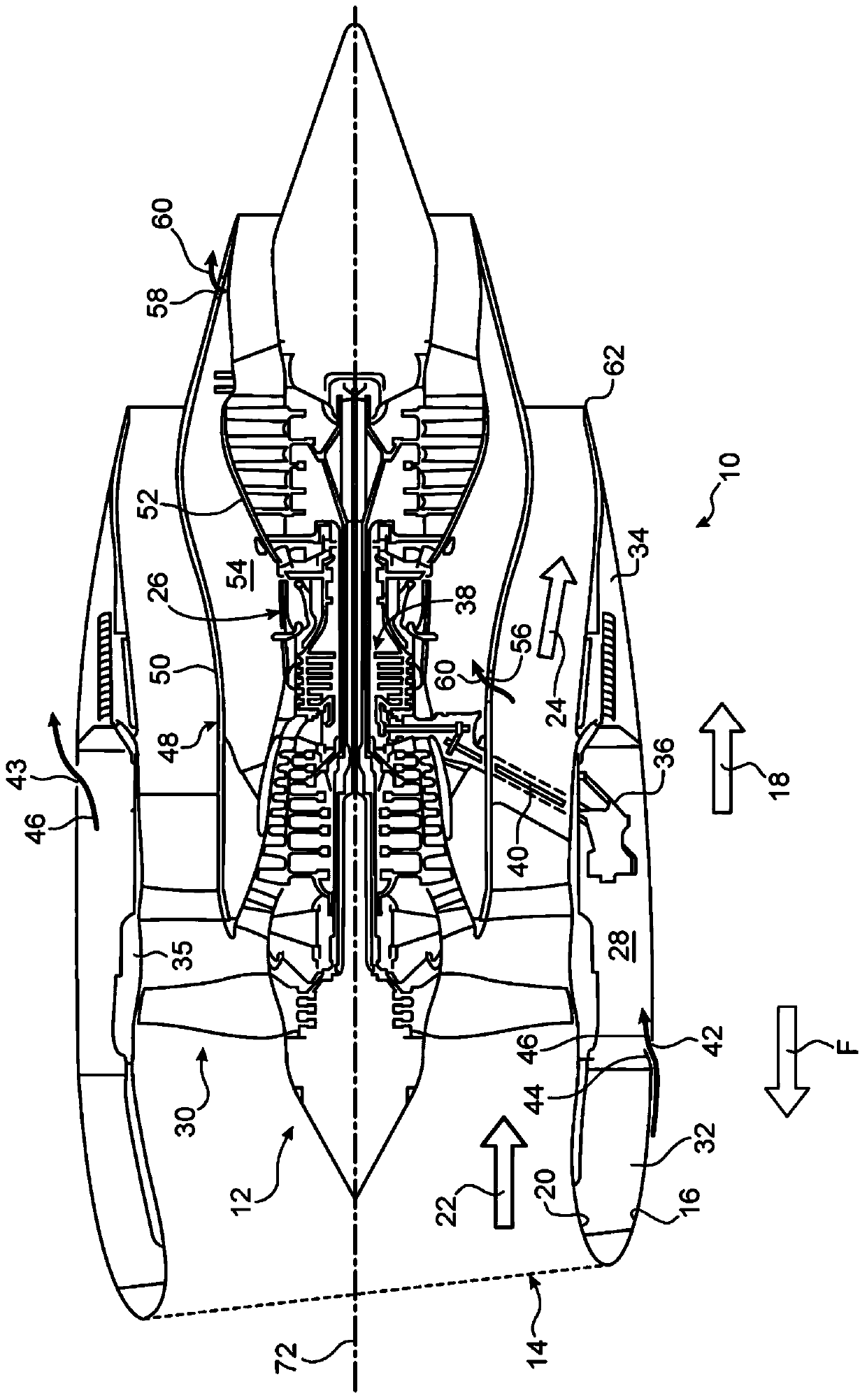

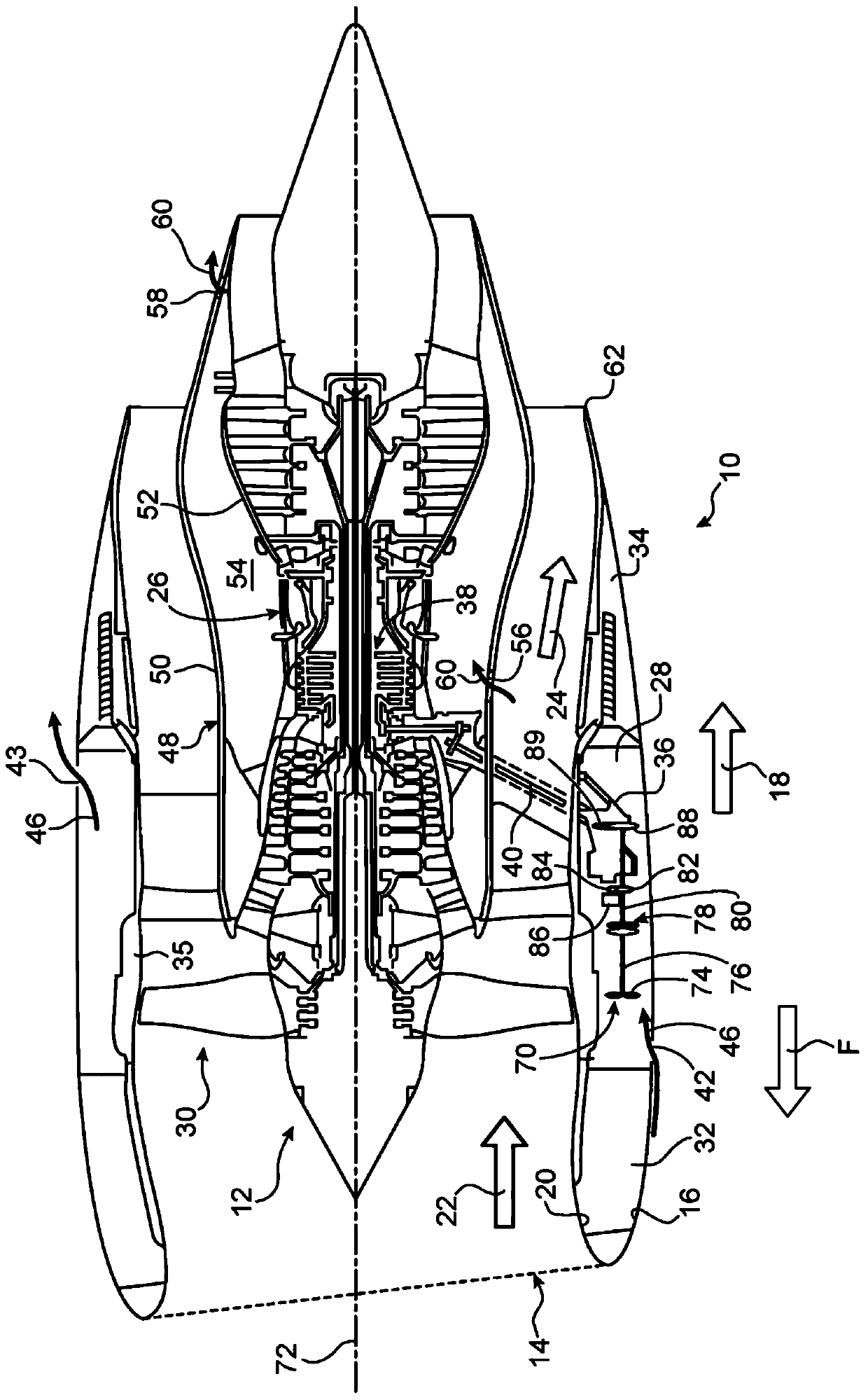

Propulsion assembly, aircraft including propulsion assembly and ventilation method thereof

ActiveCN104443405BReduce stamping resistanceReduced risk of icingPower plant cooling arrangmentsTurbine/propulsion engine coolingPropellerTurbine

Owner:AIRBUS OPERATIONS (SAS)

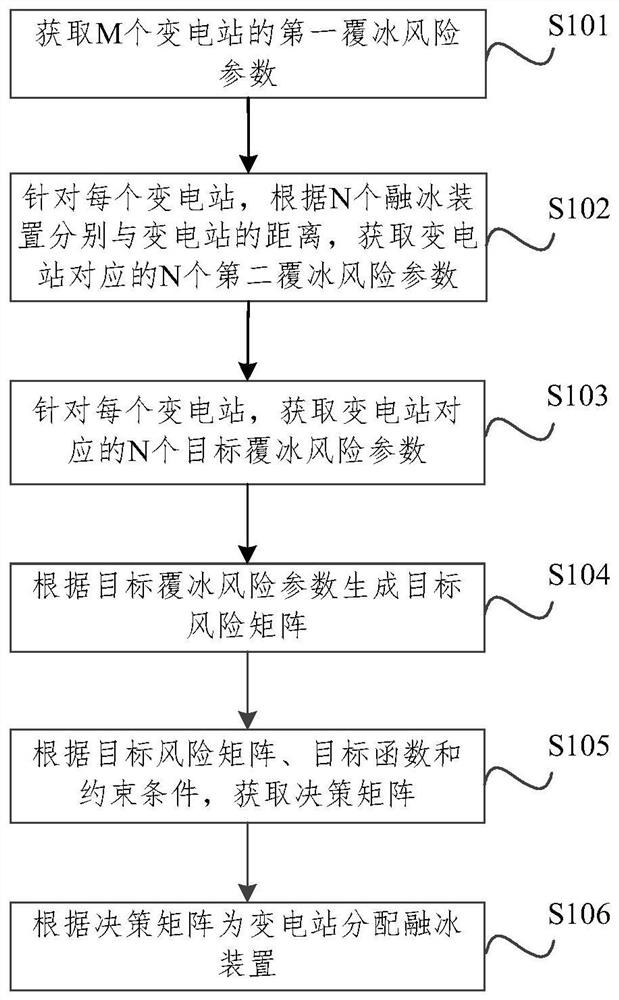

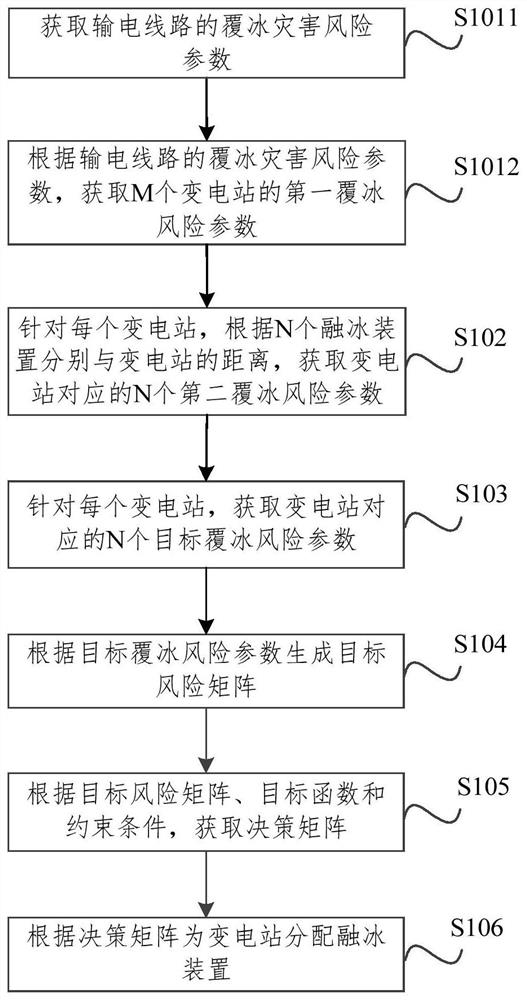

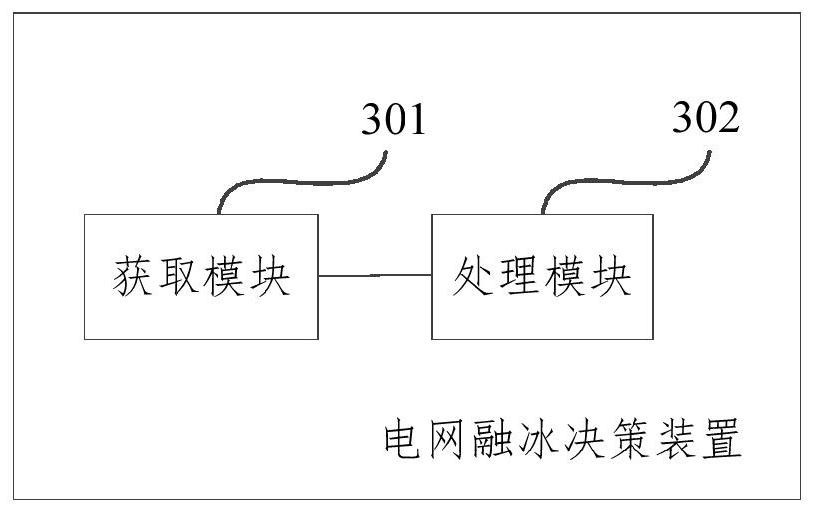

Power grid ice melting decision-making method and device, computer equipment and medium

ActiveCN112580237AReduce operational security risksReduced risk of icingDesign optimisation/simulationConstraint-based CADTransformerPower grid

The invention relates to a power grid ice melting decision-making method and device, computer equipment and a medium, and the method comprises the steps: obtaining first icing risk parameters of M substations, obtaining N second icing risk parameters and N target icing risk parameters corresponding to each substation, and generating a target risk matrix according to the target icing risk parameter, obtaining a decision-making matrix according to the target risk matrix, the target function and the constraint condition, and allocating an ice melting device to the transformer substation accordingto the decision-making matrix. Because the target icing risk parameter represents the icing risk which can be reduced when the ice melting device is distributed to the transformer substation, the target function indicates that the total ice melting income is maximum, and the decision-making matrix obtained according to the target risk matrix, the target function and the constraint condition is the optimal ice melting decision-making scheme. Therefore, the ice melting equipment is allocated according to the decision matrix to melt ice for the transformer substation, the ice melting efficiencyis improved, and the risk of safe operation of a power grid is reduced.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

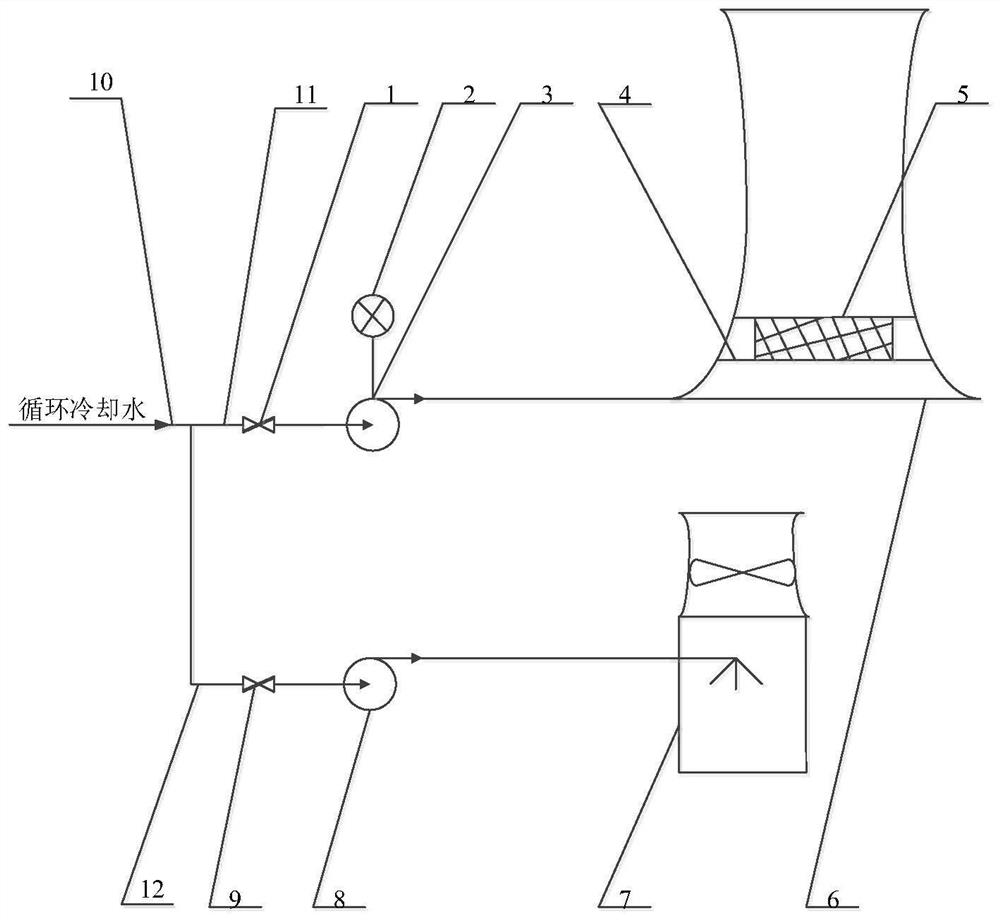

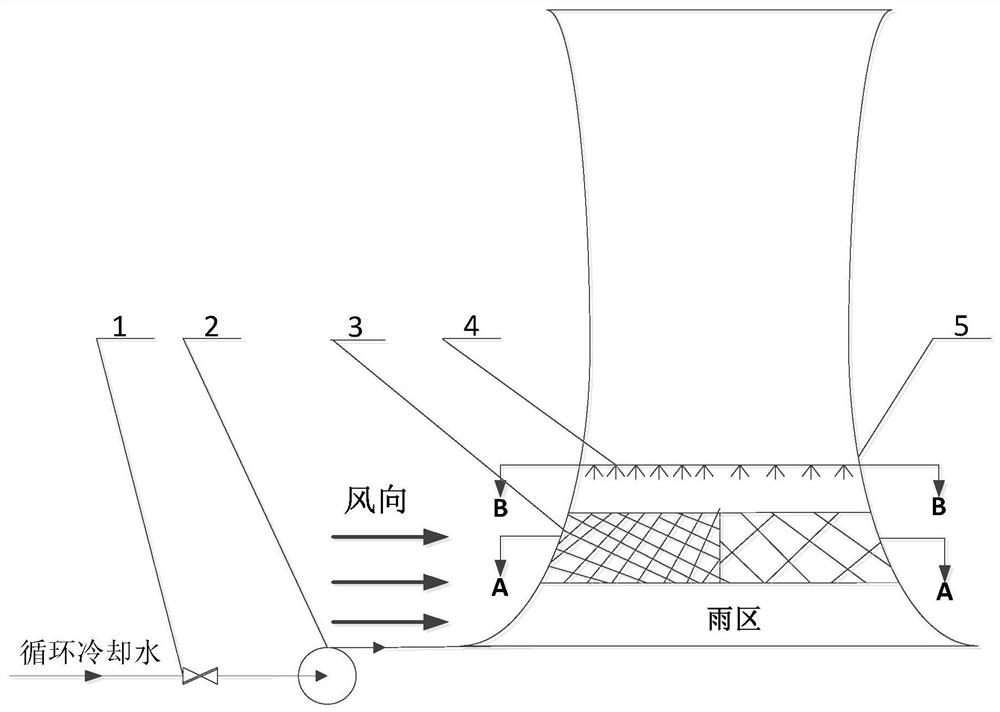

System and method for preventing freezing of coal-fired wet cooling unit in winter and reducing back pressure of coal-fired wet cooling unit in summer

PendingCN113028854AImprove economyReduce water densityHeat exchange apparatusTrickle coolersCooling towerWater flow

The invention discloses a system and a method for preventing freezing of a coal-fired wet cooling unit in winter and reducing back pressure of the coal-fired wet cooling unit in summer. The system is characterized in that a new cooling system is connected in parallel in an original cooling system, so that the cooling system of the cooling unit has multiple modes to choose. A new cooling circulation system is mainly added, and a low-power circulating water pump is adopted, so that the cooling water flow is reduced, the lift of the low-power circulating water pump is ensured to be consistent with the lift of an original circulating water pump, and the cooling water temperature is increased; and meanwhile, when the heat load entering a condenser rises, the tower feeding mode is changed, and a cooling tower is fed again. After the system is adopted, the freezing prevention problem can be solved, part of circulating cooling water can enter the mechanical draft cooling tower when the environment temperature and the unit load are high in summer, the water spraying density of an original natural draft cooling tower is reduced, the temperature of water flowing out of the tower is reduced, the back pressure of the unit is reduced, and the economical efficiency of the unit is improved.

Owner:XIAN THERMAL POWER RES INST CO LTD

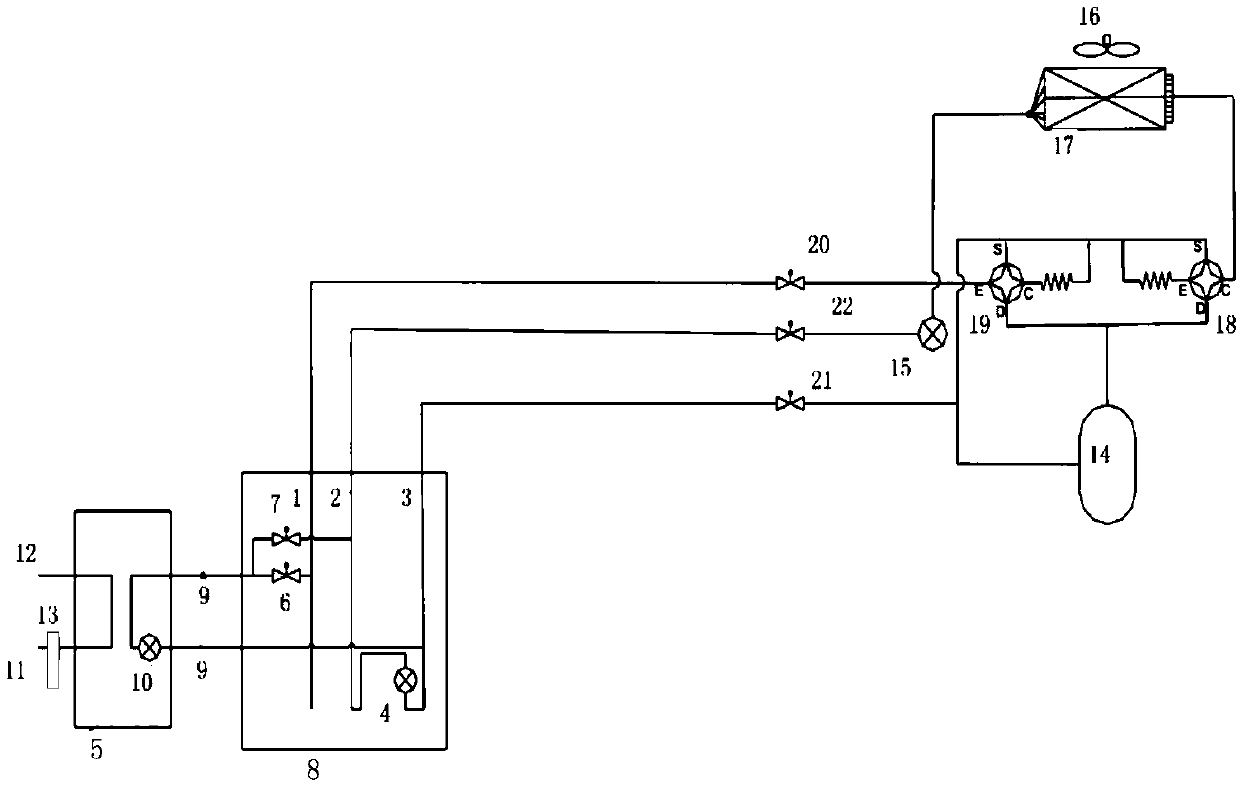

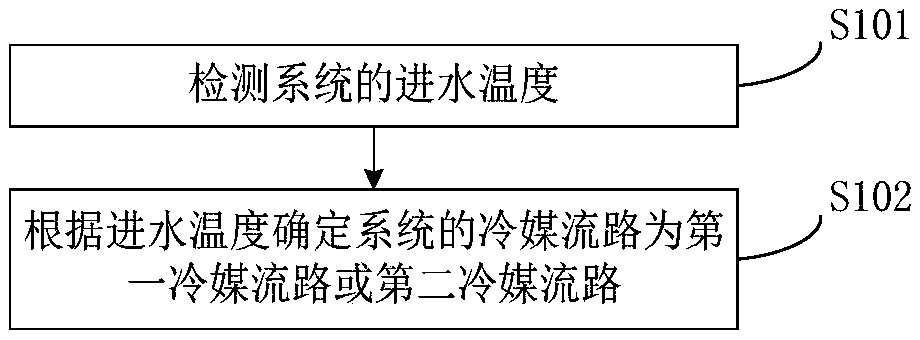

Heat recovery system and defrosting control method

ActiveCN109595856AReduced risk of icingEasy to useFluid heatersEnergy efficient heating/coolingCoolant flowProcess engineering

The invention discloses a heat recovery system and a defrosting control method. The heat recovery system comprises a first fluid pipe, a first gas pipe and a generator, wherein the generator comprisesa second pipeline; the first fluid pipe is connected with a first coolant flowing passage and a second coolant flowing passage; the first coolant flowing passage is used for enabling the first fluidpipe to communicate with the second pipeline and the first gas pipe through a first valve assembly; and the second coolant flowing passage is used for enabling the first fluid pipe to communicate withthe first gas pipe through a second valve assembly. Therefore, an appropriate defrosting manner can be selected; in the defrosting process, the risk that the pipeline in the machine unit is frozen caused by low-temperature coolants is reduced, so that the machine unit is protected, and the using performance of the machine unit is improved.

Owner:GREE ELECTRIC APPLIANCES INC

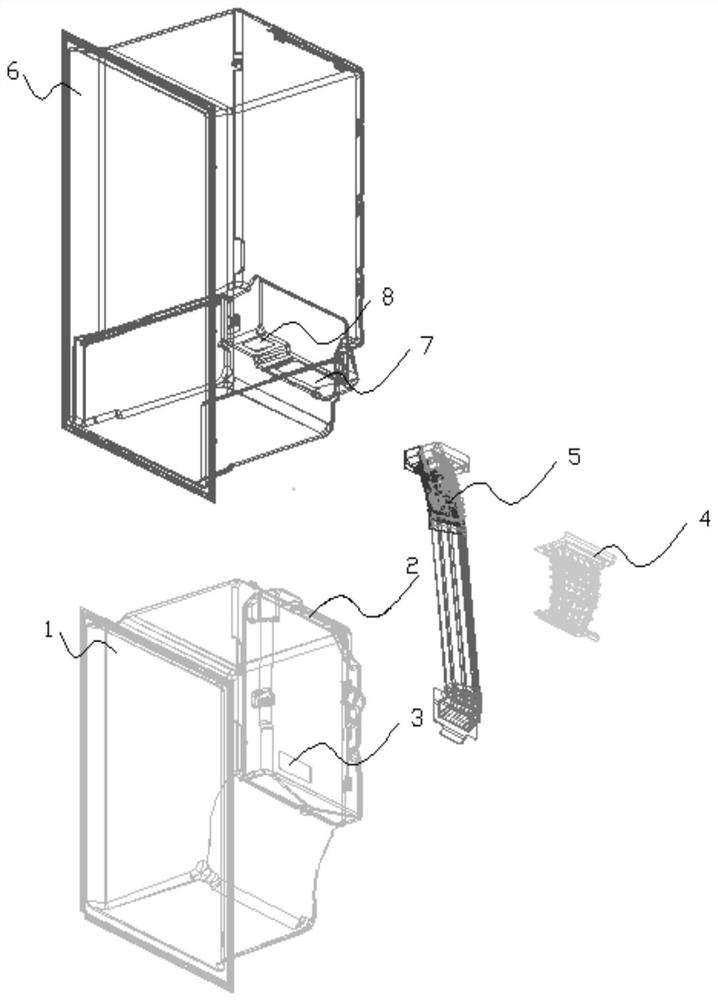

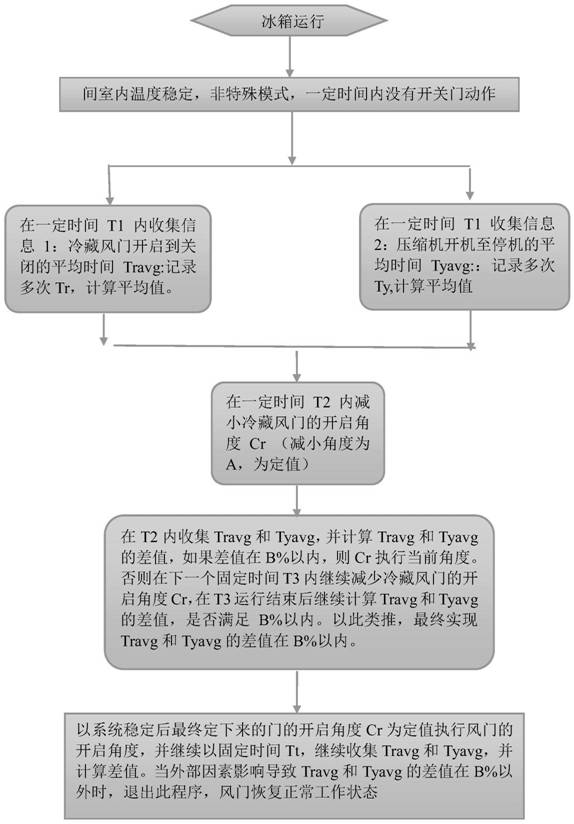

A control method to reduce the risk of icing at the air outlet of the refrigerator

ActiveCN110762935BReduced risk of icingReduce work timesLighting and heating apparatusCooling fluid circulationIceboxCool storage

The control method of the present invention for reducing the risk of icing at the air outlet of the refrigerating room is as follows: the refrigerator runs; Time Travg: Record the time Tr from opening to closing of the refrigeration damper multiple times, and calculate the average value; collect information within a certain period of time T1 2: The average time from compressor startup to shutdown Tyavg: Record the time Ty from multiple compressor startup to shutdown, Calculate the average value; reduce the opening angle of the refrigerating damper by 5 to 10° within 3 hours; collect Travg and Tyavg within T2, and calculate the difference between Travg and Tyavg, if the difference is within 20%, then Cr executes the current angle , otherwise continue to reduce the opening angle Cr of the refrigerating damper within the next 3 hours, and continue to calculate the difference between Travg and Tyavg after the end of T3 operation, whether it is within B%, and so on, and finally achieve the difference between Travg and Tyavg at 20 % within.

Owner:NANJING CHUANGWEI HOUSEHOLD ELECTRONICS APPLIANCES LTD

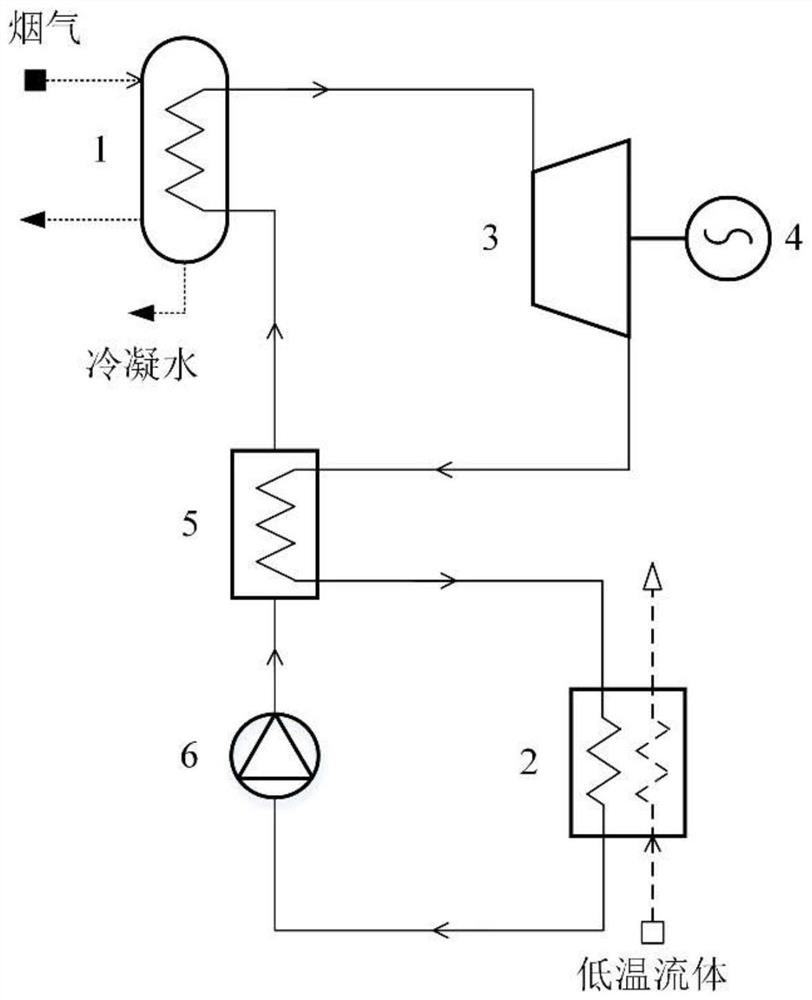

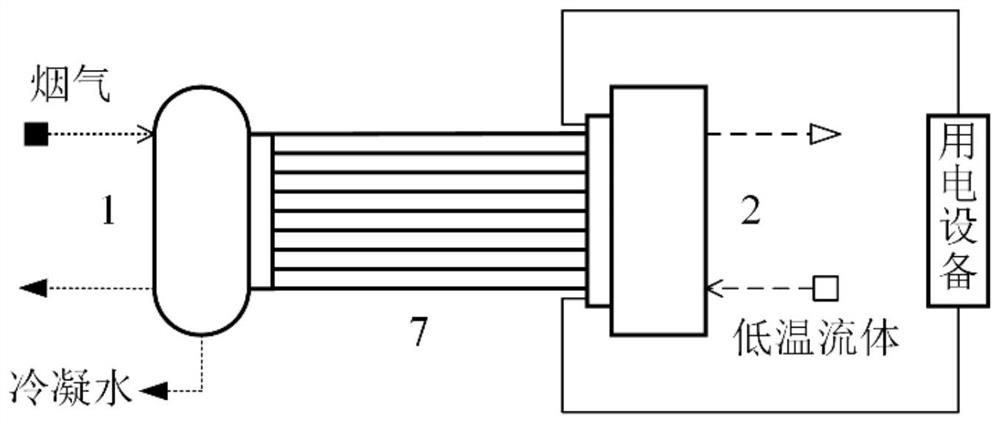

Novel flue gas white smoke removal system and method

PendingCN112901300AOff white to achieveGuaranteed freedomSteam useMechanical power devicesFlue gasProcess engineering

The invention discloses a novel flue gas white smoke removal system and method. The novel flue gas white smoke removal system is composed of three parts, namely a flue gas cooler, a low-temperature fluid gasifier and a heat-power / electricity conversion subsystem. The heat-power / electricity conversion subsystem is used for converting low-grade waste heat of flue gas and cold energy of low-temperature fluid into mechanical energy or electric energy by utilizing a thermodynamic cycle or thermoelectric power generation technology. The flue gas cooler realizes flue gas white smoke removal by reducing the flue gas temperature and the moisture content, and is used as a heater of a thermodynamic cycle or a hot end of thermoelectric power generation equipment. The low-temperature fluid gasifier is used for achieving gasification of low-temperature fluid and serves as a cooler of the thermodynamic cycle or a cold end of the thermoelectric power generation equipment. According to the novel flue gas white smoke removal system and method provided by the invention, the heat-power / electricity conversion subsystem is used for connecting flue gas condensation and white smoke removal with low-temperature fluid gasification, so that direct heat exchange between the flue gas and the low-temperature fluid is avoided, the freezing risk in a heat exchanger is reduced, and the operation safety, the energy utilization efficiency and the economic benefits are improved.

Owner:XI AN JIAOTONG UNIV

a car engine

ActiveCN103452697BAvoid overall overheatingReduce adverse effectsCasingsMachines/enginesEngineeringWater jacket

The invention discloses an automobile engine. The automobile engine comprises a cylinder cover, a cylinder cover hood, a temperature adjuster seat and an engine water inlet pipe, wherein the cylinder cover hood is provided with an oil filling port, a wavy oil collecting groove and a water jacket; the water jacket is positioned at one side of the oil collecting groove, is bent towards one end of the oil collecting groove and is L-shaped; the water jacket is provided with a cooling-liquid inlet, a cooling-liquid outlet and a cooling-liquid flowing channel; the cooling-liquid inlet is connected with the temperature adjuster seat by the water inlet pipe; the cooling-liquid outlet is connected with the engine water inlet pipe by a water outlet pipe; the cooling-liquid flowing channel is formed by a water jacket partition and a water jacket inner wall, and the water jacket partition is positioned in the water jacket and is L-shaped; the cooling-liquid inlet and the cooling-liquid outlet are respectively positioned at the two ends of the cooling-liquid flowing channel; the oil filling port is positioned at the outer end of the L-shaped bending position of the water jacket and is integrally connected with the water jacket. The automobile engine disclosed by the invention has the advantages that during cold starting, the cylinder cover hood can heat and rise the temperature quickly, white attachments on the cylinder cover hood and the oil filling port cover can be reduced, and simultaneously the icing risk of a crankcase ventilating system is reduced.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Wall-surface-flow-guide type Venturi integrated mixer

PendingCN113417773AImprove mixing uniformityWell mixedFlow mixersExhaust gas recirculationImpellerExhaust fumes

The invention relates to a Wall-surface-flow-guide type Venturi integrated mixer. The integrated mixer comprises an outer shell, an EGR core, a cross arm, a fixing pin, a natural gas cross beam, a natural gas impeller and a natural gas straight joint, wherein the EGR core, the natural gas cross beam and the natural gas impeller are sequentially and fixedly arranged in the outer shell in the direction of a gas channel; air enters the gas channel from an inlet, EGR waste gas sequentially passes through a wall-surface round hole of the EGR core and a central gas hole of the cross arm and then enters the gas channel to be mixed with the air, the flow speed of the gas is increased by means of a Venturi structure formed in the EGR core, and mixing is promoted by means of the relationship between the flow speed and pressure; a wall surface flow guide plate is additionally arranged at a flaring of the Venturi structure in the EGR core, so that the gas is rotationally mixed; and the natural gas sequentially passes through a wall-surface round hole of the natural gas cross beam and a central gas groove of the natural gas impeller and then enters the gas channel to be mixed with the mixed gas, then new mixed gas is disturbed through the natural gas impeller, and the rotating strength is enhanced, so that the mixing uniformity is further improved in a follow-up pipeline.

Owner:DONGFENG COMML VEHICLE CO LTD

A kind of ultra-low temperature resistant disinfectant

ActiveCN113396940BReduced risk of icingImprove adaptabilityBiocideDisinfectantsNonanoic acidDisinfectant

Owner:杭州龙能科技有限公司

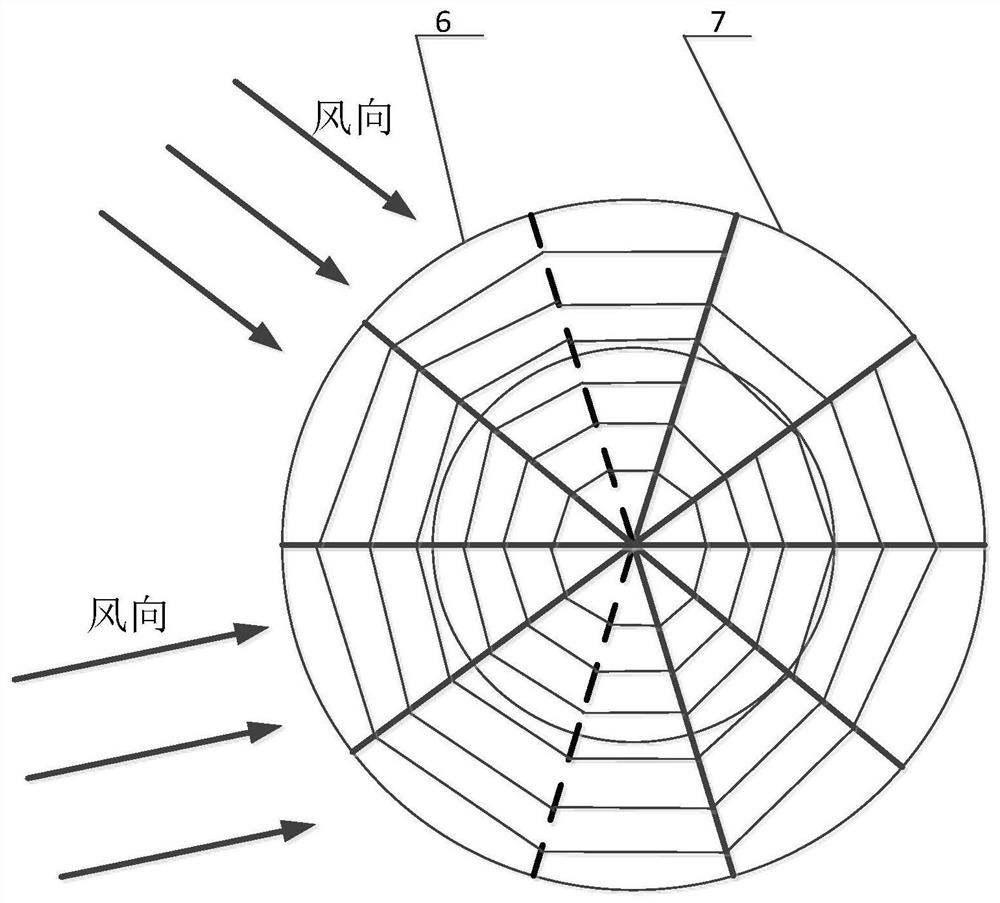

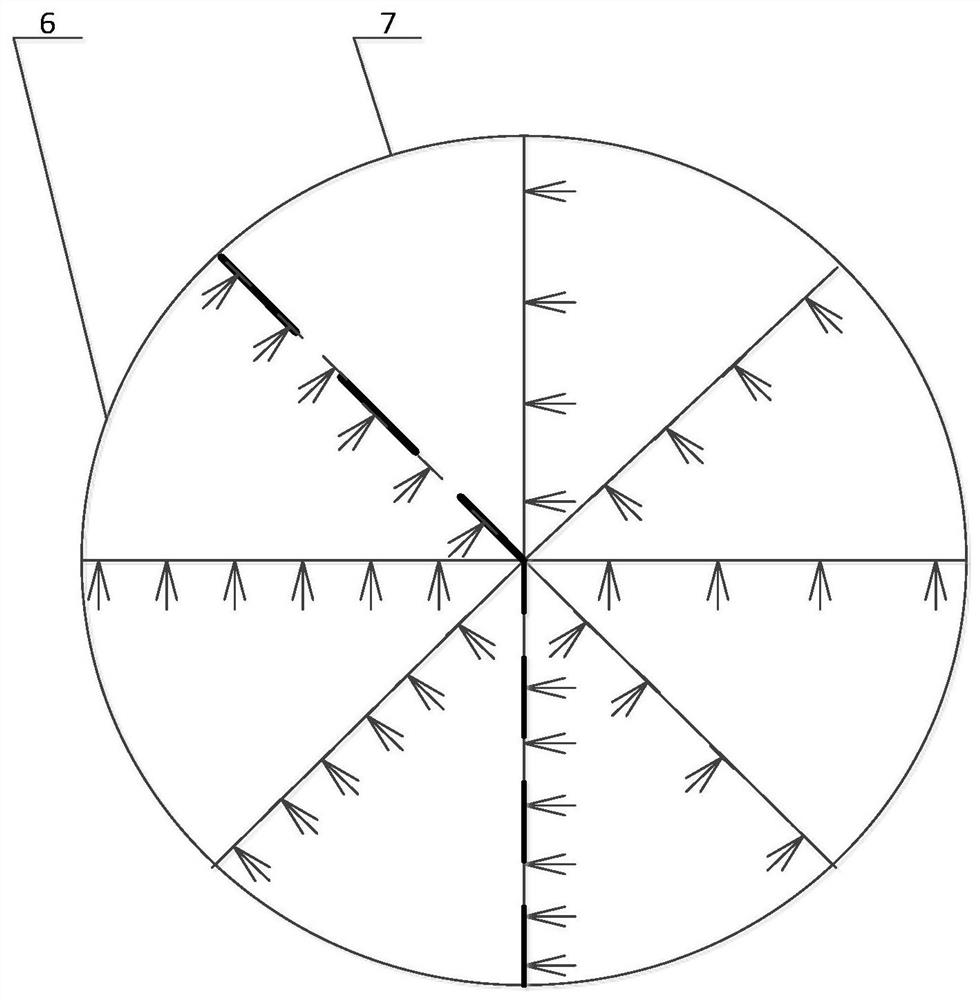

Wet cooling tower core component arrangement method for wind direction stable area

ActiveCN113375498AImprove cooling effectIncrease heat transfer volumeTrickle coolersCooling towerCooling effect

The invention discloses a wet cooling tower core component arrangement method for a wind direction stable area. The method comprises the steps that firstly, according to the local wind direction condition, a cooling tower is divided into a wind direction stable area and a windless area, grid encryption processing is conducted on the wind direction stable area so that the process of a key cooling area can be simulated more accurately, numerical simulation is conducted on multiple sets of parameters, and the parameters with the optimal solution are determined to arrange the cooling tower. According to the method, the arrangement mode and number of tower core components are guided and selected through numerical simulation and calculation results in the early stage, the situation that the heat exchange volume of filler is increased on the windward side is mainly considered, water distribution is enhanced, and the cooling effect of the windward side is enhanced.

Owner:XIAN THERMAL POWER RES INST CO LTD

Mixer assembly for an aircraft air conditioning system and method for operating the mixer assembly

ActiveCN102892674BReduced risk of icingIncreased risk of freezingAir-treatment apparatus arrangementsCold airEngineering

Owner:AIRBUS OPERATIONS GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com