Closed crankcase ventilation systems for heavy-duty engine systems and heavy-duty engine systems

A technology for engine system and crankcase ventilation, which is applied in the direction of crankcase ventilation, engine components, machines/engines, etc. It can solve the problems affecting the efficiency of the supercharger, excessive oil carrying capacity, and pollution of the supercharger, so as to improve efficiency and The service life, the effect of improving the uneven air supply, and the effect of reducing the risk of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

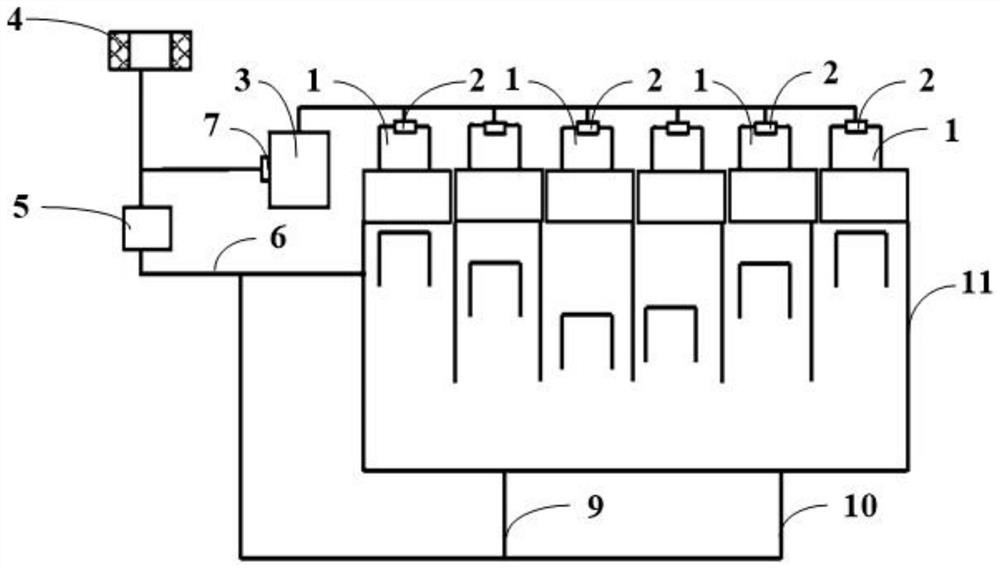

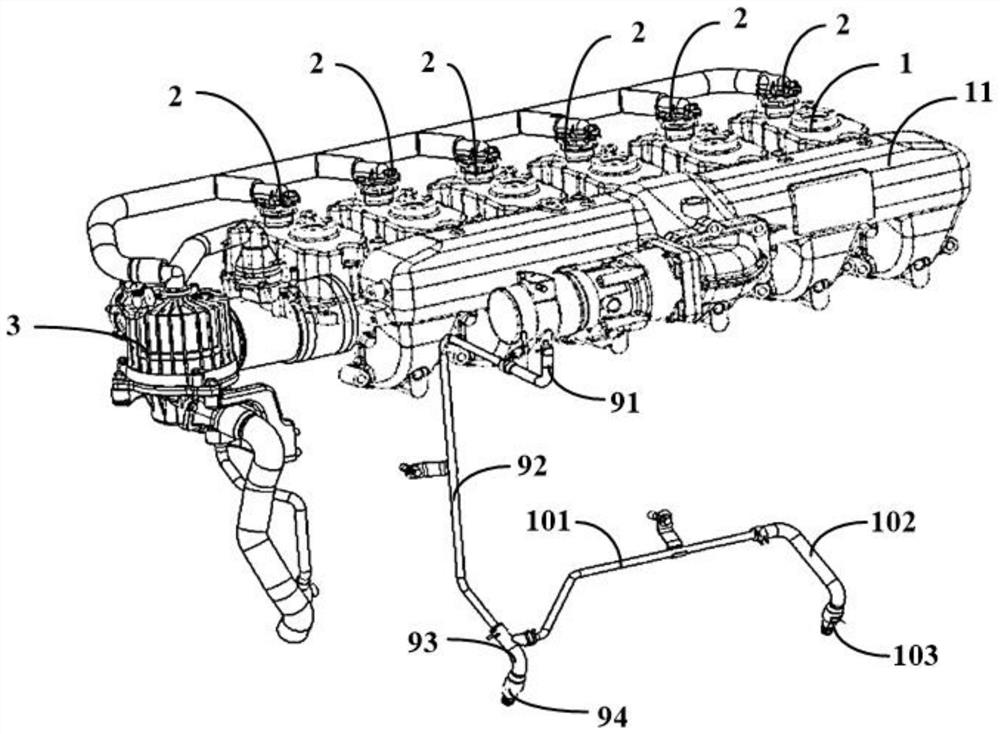

[0035] figure 1 A schematic schematic diagram of a closed crankcase ventilation system for a heavy duty engine system according to one embodiment of the invention is shown. figure 2 A schematic structural diagram of a closed crankcase ventilation system of a heavy-duty engine system according to an embodiment of the present invention is shown. The closed crankcase ventilation system is used on heavy duty diesel vehicles such as figure 1 and figure 2 As shown, the heavy duty diesel vehicle includes an air filter 4 , a traction control system 5 (TC), an intake manifold 6 and a PVC valve 7 . The closed crankcase ventilation system comprises at least one engine cylinder head cover 1 , at least one first oil-air separator 2 and a second oil-air separator 3 .

[0036] Each engine head cover 1 is arranged on an engine head of a heavy-duty engine system. Each first oil-air separator 2 is integrated inside an engine cylinder head cover 1, and is used for preliminary separation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com